Kevlar® Aramid Conveyor Belt

• High Strength • Low Elongation •

Join 500+ companies trusting our industrial solutions worldwide

Why Choose Aramid Technology?

Experience the next generation of conveyor belt performance with advanced aramid fiber reinforcement

Superior Strength & High Modulus

Aramid fibers deliver 5x the tensile strength of steel at just 20% of the weight, ensuring maximum load capacity with minimal belt thickness

Ultra-Low Elongation Rate

Experience less than 0.5% elongation under full load, eliminating frequent re-tensioning and reducing maintenance downtime by up to 60%

Exceptional Impact & Wear Resistance

Withstand harsh operating conditions with superior cut resistance and impact absorption, extending belt life by 2-3x in demanding environments

Energy-Efficient Design

Lighter weight than steel cord belts with equal strength reduces power consumption by 15-25%, lowering your operational costs significantly

Ready to upgrade your conveyor system efficiency?

Advanced Construction Features

Engineered with precision to deliver unmatched performance in the most demanding industrial environments

-

Multi-Layer Aramid Reinforcement

Strategically positioned aramid fiber layers provide exceptional tensile strength up to 3200 N/mm, ensuring reliable performance under extreme loads while maintaining flexibility for smaller pulley diameters

-

Heat-Resistant Compound

Special rubber compounds withstand temperatures from -25°C to +80°C continuously, with short-term resistance up to 150°C, perfect for hot material handling in cement, steel, and power plants

-

Advanced Adhesion System

Proprietary bonding technology ensures superior adhesion between layers with 15 N/mm ply adhesion strength, preventing delamination and extending service life even in moisture-rich environments

Need customized belt specifications for your application?

Technical Parameters for Aramid Conveyor Belts

Comprehensive specifications to help you select the perfect belt for your operational requirements

| Classification | Belt Tensile Strength N/mm |

Elongation at Break% |

Rated elongation of 10% |

Fabric Gauge mm |

Cover Gauge mm |

|||

|---|---|---|---|---|---|---|---|---|

| Warp ≥ | Weft ≥ | Warp ≥ | ≤ | mm | ||||

| DPP315 | 315 | 120 | 5 | 0.5 | 1.8 | Top cover Bottom cover |

Belt width Cover grade 6-25 5-15 500-3200 Abrasion resistant, Impact resistant, Heat resistant, Chemical resistant, Fire resistant, Cold resistant |

|

| DPP500 | 500 | 120 | 5 | 0.5 | 1.8 | |||

| DPP630 | 630 | 120 | 5 | 0.5 | 2.1 | |||

| DPP800 | 800 | 150 | 5 | 0.5 | 2.2 | |||

| DPP1000 | 1000 | 150 | 5 | 0.5 | 2.4 | |||

| DPP1250 | 1250 | 150 | 5 | 0.5 | 2.7 | |||

| DPP1400 | 1400 | 150 | 5 | 0.5 | 2.8 | |||

| DPP1600 | 1600 | 150 | 5 | 0.5 | 2.9 | |||

| DPP1800 | 1800 | 150 | 5 | 0.5 | 3.2 | |||

| DPP2000 | 2000 | 150 | 5 | 0.5 | 3.6 | |||

| DPP2500 | 2500 | 150 | 5 | 0.5 | 4 | |||

| DPP3150 | 3150 | 150 | 5 | 0.5 | 4.3 | |||

Can't find your specifications? We offer custom solutions!

Kevlar® Aramid Conveyor Belt

Revolutionary aramid fiber technology replacing traditional steel cord - delivering superior strength, reduced weight, and exceptional energy efficiency for modern conveyor systems

Superior Alternative to Steel Cord Belts

Kevlar aramid fiber conveyor belts represent a breakthrough in material handling technology, offering unmatched strength-to-weight ratio and operational efficiency

Performance Comparison Analysis

See how Kevlar® aramid outperforms traditional steel cord and NN/EP conveyor belts across critical performance metrics

| Performance Metrics | Kevlar® (R) | Steel | NN/EP |

|---|---|---|---|

| Impact Resistance | ●●● | ●● | ● |

| Adhesion | ●●● | ●● | ● |

| Toughness | ●●● | ●● | ● |

| Slit Resistance | ●●● | ●● | ● |

| Low Elongation | ● | ●●● | ●● |

| Flame Resistance | ● | ●●● | ●● |

| Static Electricity Proof | ●●● | ●● | ● |

| Corrosion Resistance | ●●● | ●● | ● |

| No Warp Cord Pop-out | ●●● | ●● | ● |

| Flexibility | ●●● | ●● | ● |

| Light Weight | ●●● | ●● | ● |

| Fatigue Resistance | ●●● | ● | ●● |

| Fast Splicing Time | ● | ●● | ●●● |

| Belt Life | ●●● | ● | ●● |

| Flexibility When Overload | ●●● | ●● | ● |

| Minimum Power Consumption | ●●● | ●● | ● |

| Smaller Diameter Pulley | ●●● | ●● | ● |

| Long Splicing Life | ●●● | ● | ●● |

| Minimum Facility Cost | ●●● | ●● | ● |

| Minimum Splicing for Long Distance | ●●● | ●● | ● |

| Heat Resistance | ●●● | ●● | ● |

Kevlar® outperforms in 18 out of 21 critical performance metrics

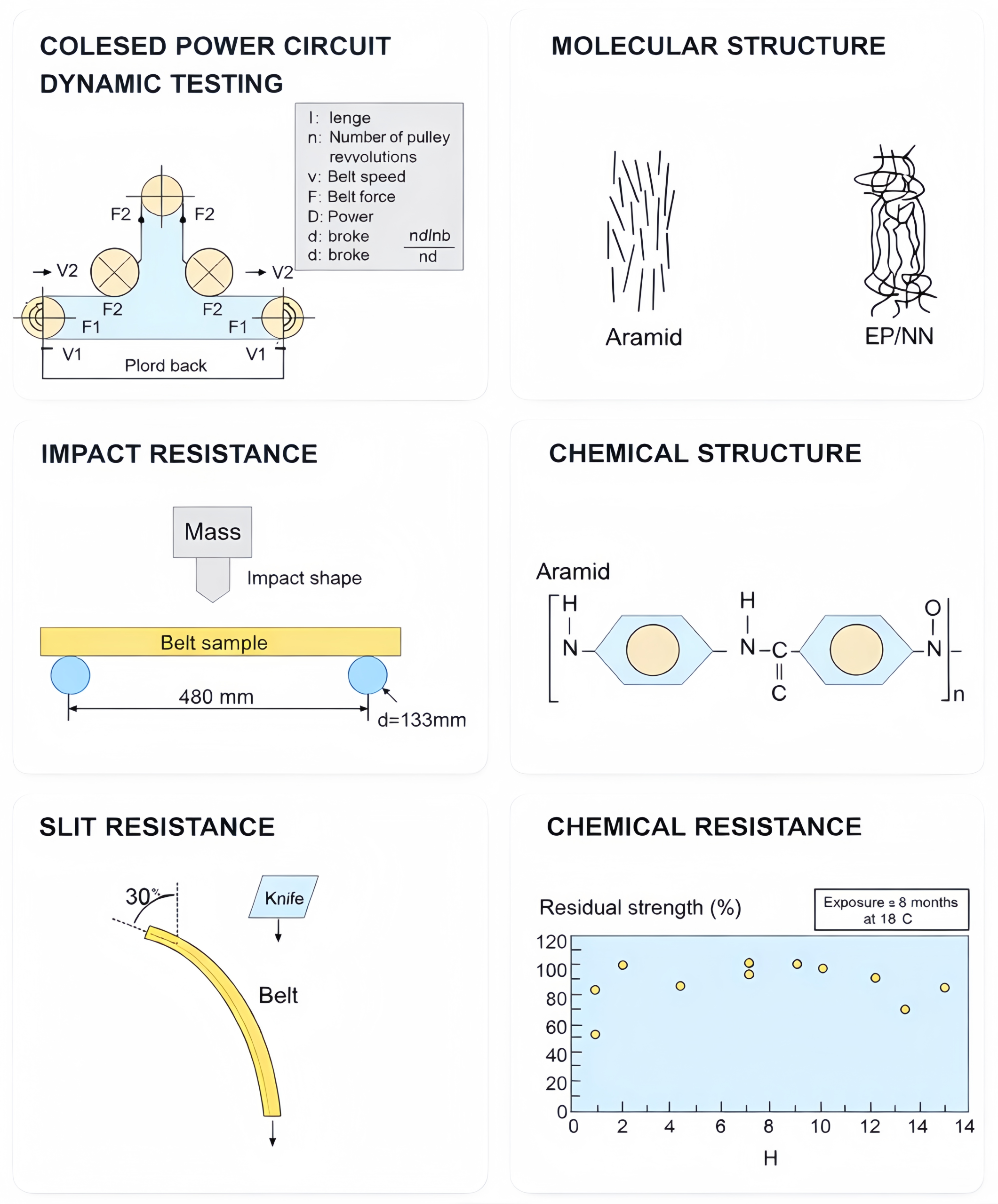

Advanced Fiber Properties & Testing

Scientific testing and molecular structure analysis demonstrating superior mechanical properties of Kevlar® aramid fibers

Molecular Structure & Testing

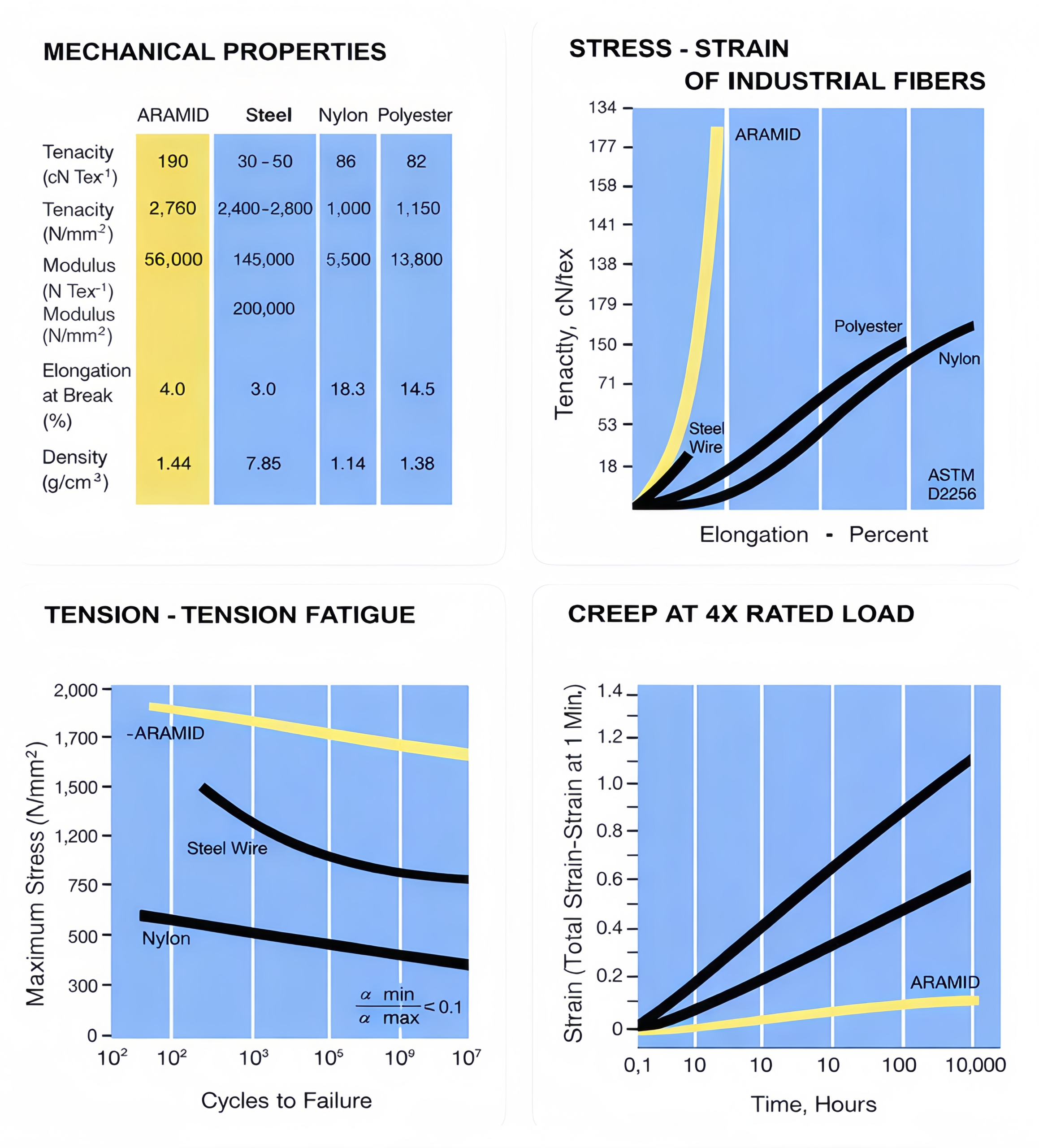

Superior Mechanical Performance

Aramid fibers demonstrate 190 cN/tex tenacity compared to steel's 30-50 cN/tex, with exceptional fatigue resistance maintaining performance over millions of cycles. The stress-strain curve shows minimal creep under sustained loads

Engineering excellence backed by comprehensive testing data

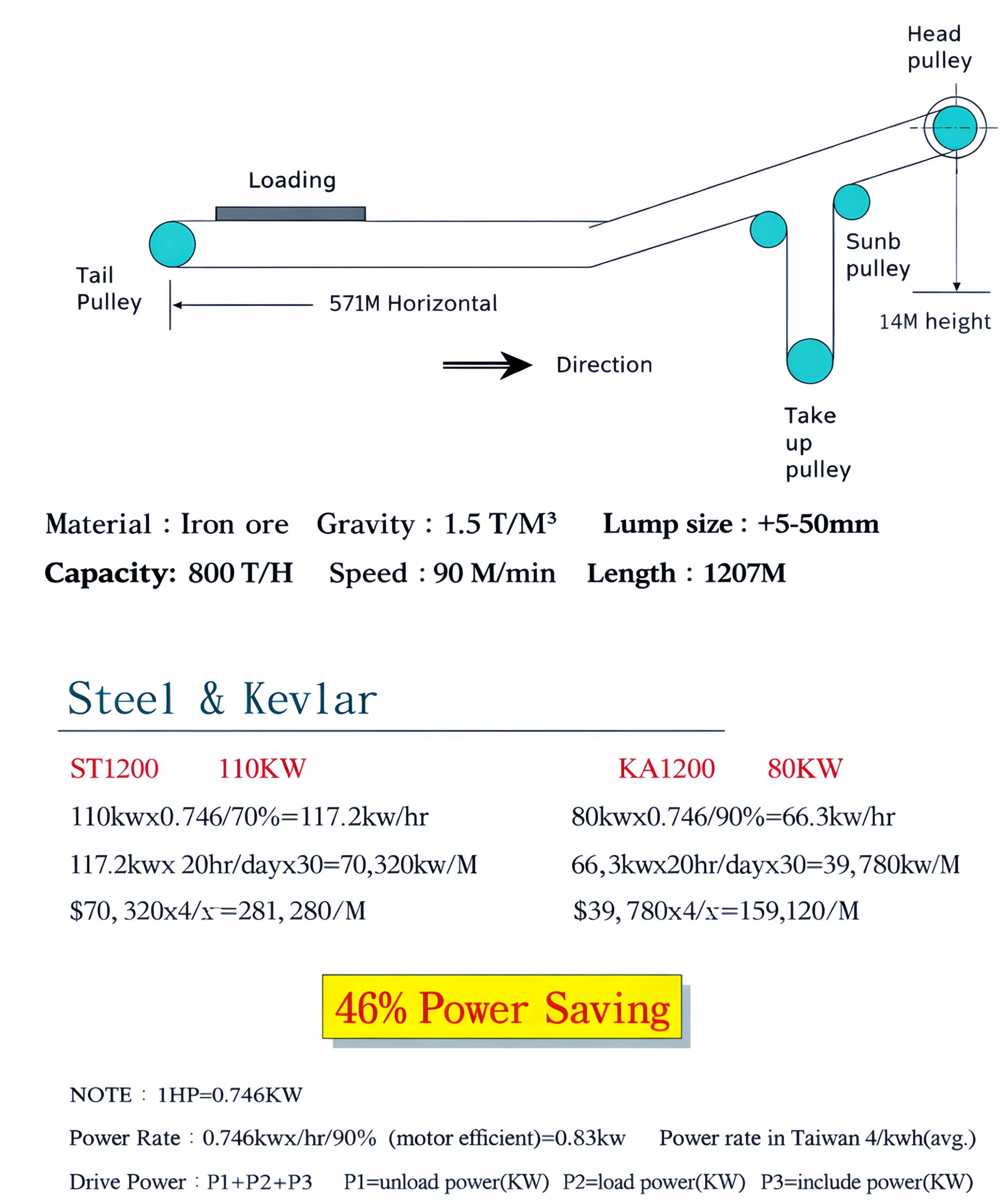

Dramatic Energy Savings & ROI

Real-world case study demonstrates significant power consumption reduction and operational cost savings

Steel Cord ST1200

Annual Cost: $70,320

Kevlar® KA1200

Annual Cost: $39,780

Let's Build Reliable Conveyor Solutions Together

Send us your specifications or project details — our engineers will analyze your requirements in 24h

Why Choose ZHENXING?

Contact Information

zhenxinglisa@hotmail.com

+86 18661664598

1. EP NN CC ST,SIDEWALL FR MOR HR EPDM -DONGYING

2. Solid Woven PVC PVG Conveyor Belt -JINING, Shandong

3. Sidewall Conveyor Belt -Weifang, Shandong

Get Your Custom Solution in 24 Hours

Share your requirements and receive expert guidance with a tailored quote