Rough Top Conveyor Belt for

Inclined Transport up to 35°

Non-slip. Shock-absorbing. Stable conveying for light materials.

Rough Top Conveyor Belts

Engineered with superior friction technology and multi-ply construction to deliver exceptional grip on inclined surfaces, ensuring your materials stay secure during transport while maximizing operational efficiency.

Advanced Construction

Our rough top belts feature 2-3 ply NN/EP carcass construction with wear-resistant rough rubber top cover that provides exceptional grip. The synthetic fabric carcass ensures high tensile strength and durability, while the textured surface prevents material rollback on inclines.

✓ 3.2mm thick top cover for maximum friction

✓ Synthetic EP fabric reinforcement

✓ Bare back option for slider bed applications

Versatile Applications

Designed for medium to long-distance transport of light to medium materials on inclines up to 35°. The unique rough texture provides superior grip compared to standard smooth belts, reducing slippage and improving throughput in your operation.

✓ Compatible with roller and slider bed systems

✓ Reduces material return and spillage

✓ Shock-absorbing properties protect delicate goods

Perfect for Multiple Industries

Express Sorting Centers

Handle packages and parcels smoothly on inclined sorters, preventing slippage and damage during high-speed sorting operations.

Waste & Solid Waste Processing

Efficiently handle waste materials on sorting lines and inclined discharge systems, ensuring stable transport of mixed solid waste with reduced slippage and improved operational safety.

Airport Baggage Systems

Move luggage safely on inclined sections of baggage handling systems, ensuring gentle treatment and reliable transport of passenger belongings.

Carton Conveying Lines

Perfect for moving cardboard boxes and packaged goods on assembly lines and packaging operations with varying elevations.

Light Manufacturing

Ideal for food processing, electronics assembly, and other light industrial applications requiring gentle yet secure material handling.

E-commerce Fulfillment

Support rapid order processing in fulfillment centers with reliable inclined transport between picking, packing, and shipping zones.

Friction Performance & Incline Capability

Scientific data demonstrates superior grip performance across various operating angles, ensuring reliable material transport even on steep inclines

Safe Operating Angles by Belt Type

Performance by Application

Manufacturing Excellence & Quality Assurance

State-of-the-art production facilities and rigorous quality control ensure every belt meets international standards

Advanced Mixing

Precision-controlled rubber compound mixing ensures consistent material properties and optimal friction characteristics in every batch.

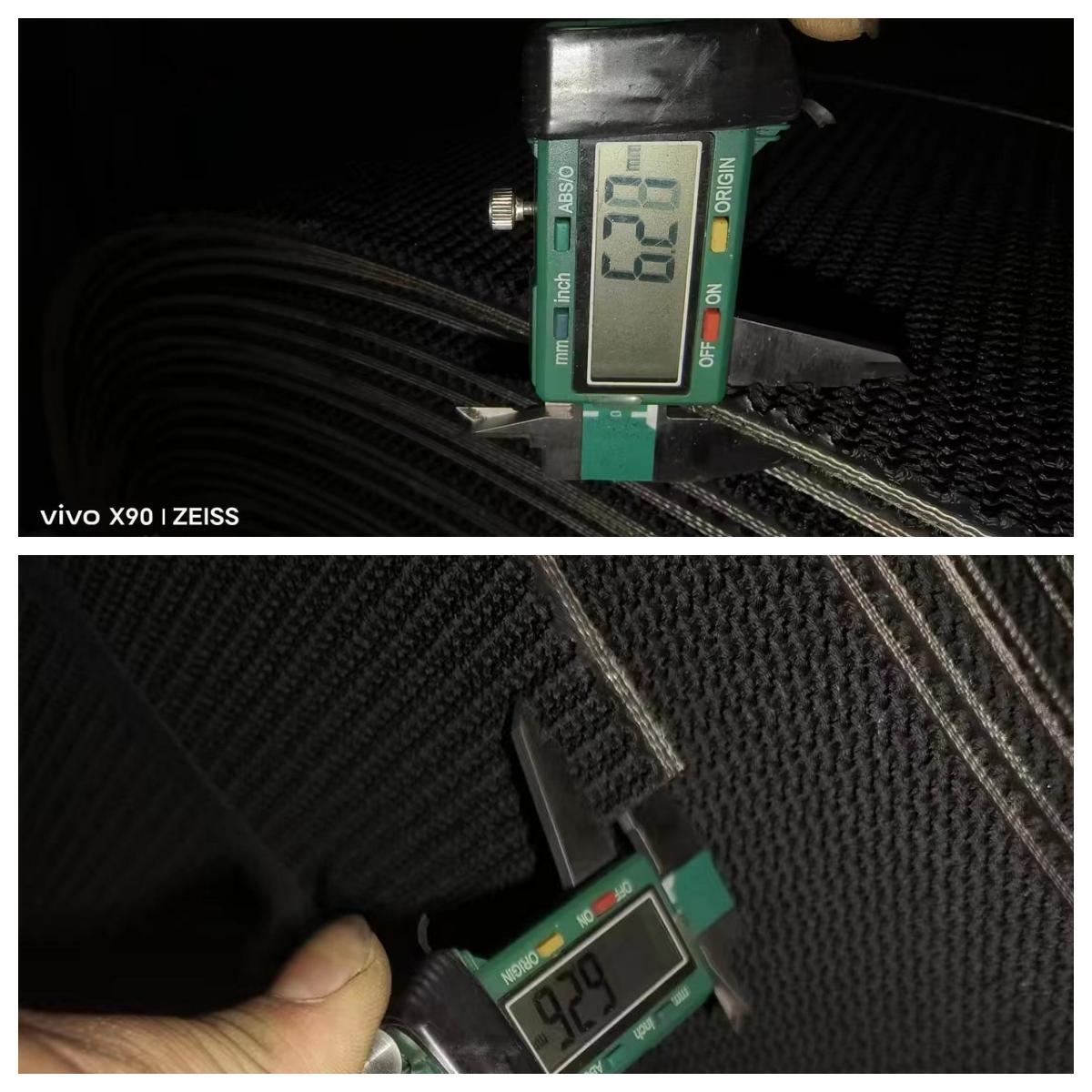

Precision Calendering

Computer-controlled calendering process creates uniform thickness and textured surface patterns with tolerance within ±0.1mm.

Vulcanization

Multi-zone heating vulcanization chambers ensure complete rubber curing and optimal bonding between fabric layers and rubber covers.

Online Inspection

Automated vision systems detect surface defects, while tensile testers verify strength parameters during production for zero-defect delivery.

Traceability System

Every belt receives unique identification enabling full traceability from raw materials through production to final installation.

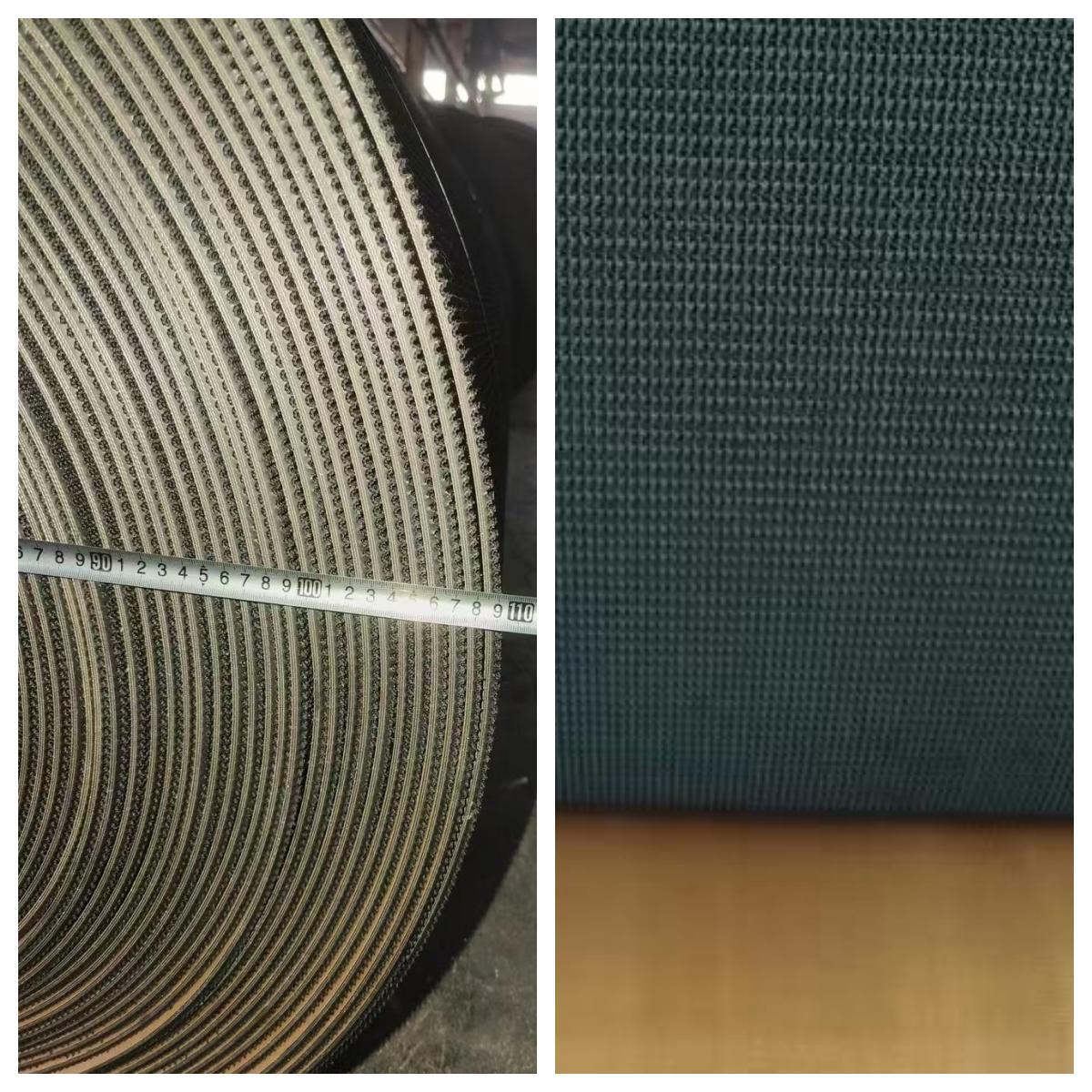

Production Status Showcase

Real-time glimpse into our manufacturing operations showing various Rough Top Conveyor Belts at different production stages, demonstrating our commitment to quality and precision.

Raw Material Preparation

High-grade rubber compounds being prepared for mixing process

Fabric Layering

EP fabric layers being precisely positioned for reinforcement

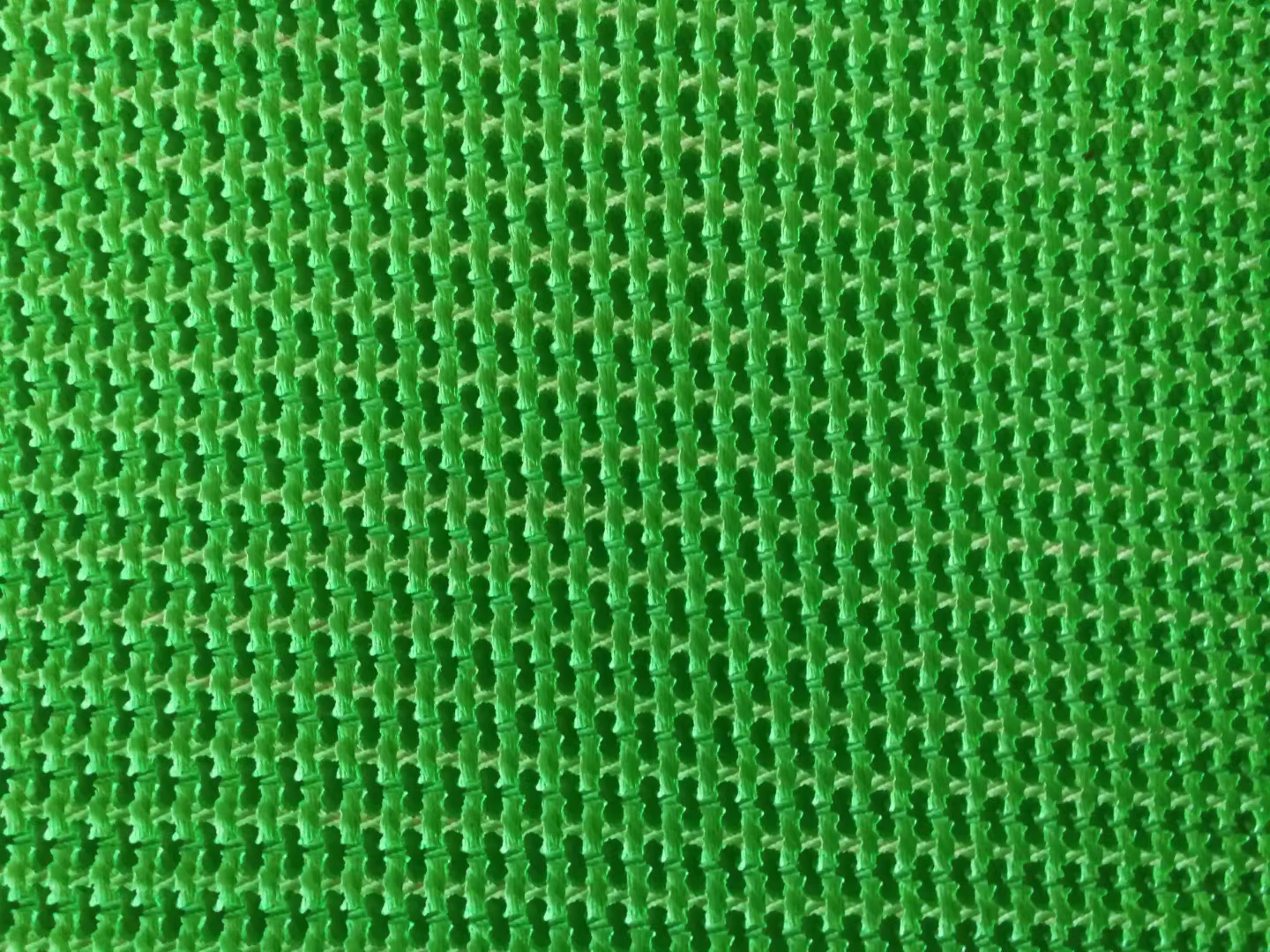

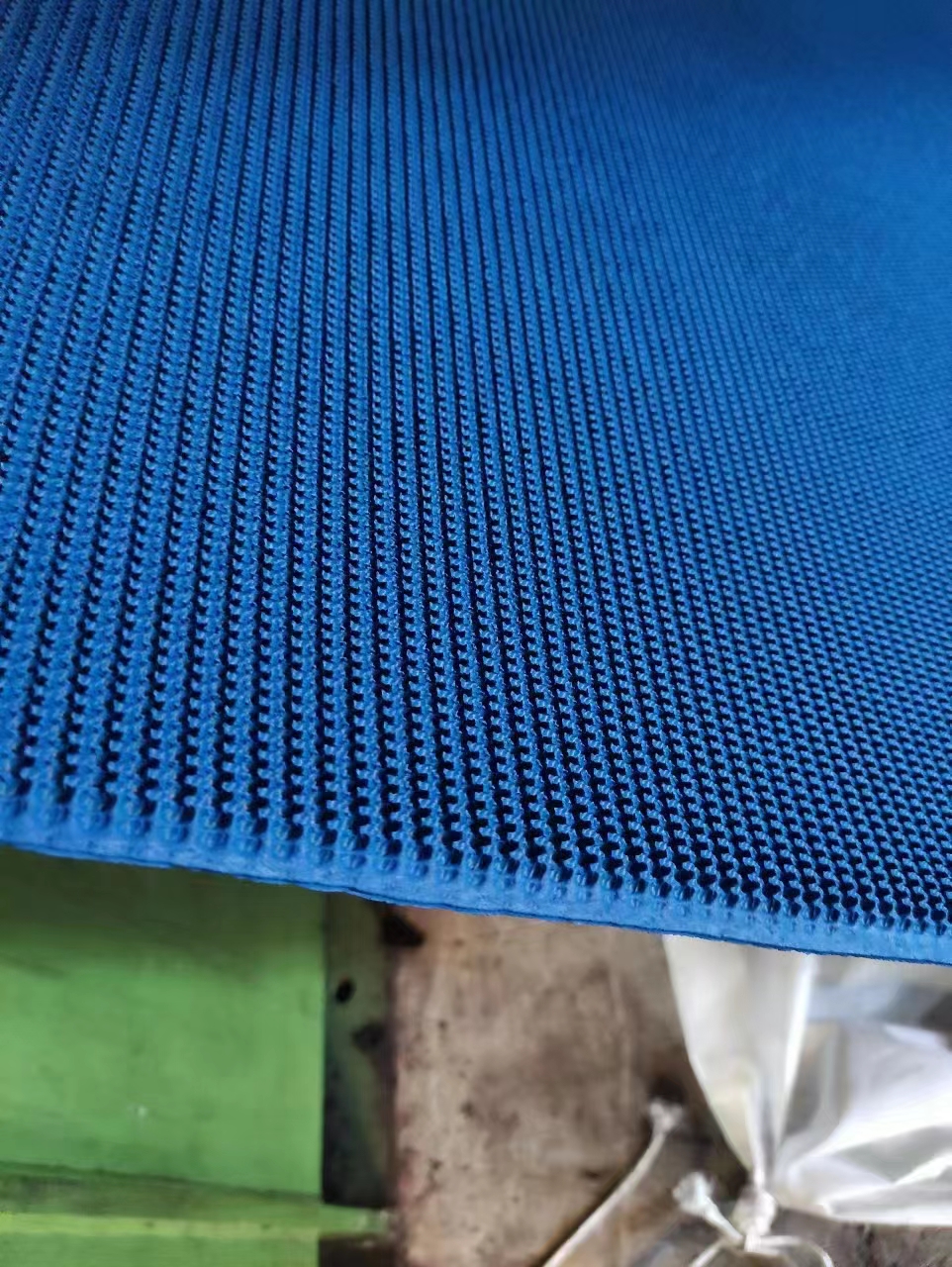

Texture Application

Creating the signature rough top surface pattern for maximum friction

Vulcanization Process

Belts undergoing heat treatment in controlled-temperature chambers

Quality Inspection

Comprehensive testing of tensile strength and surface quality

Final Packaging

Finished belts being prepared for shipment to customers worldwide

Complete Service From Design to Installation

End-to-end support ensuring your conveyor system operates at peak efficiency from day one

Consultation

Our engineers analyze your specific requirements, material types, and conveyor parameters

Design

Custom specifications developed including width, thickness, material grade, and splicing method

Sampling

Free samples provided for on-site testing and approval before full production begins

Production

Manufacturing with real-time quality monitoring and progress updates throughout the process

Installation

On-site installation support and training, plus ongoing technical assistance

Available in Multiple Colors

Our advanced manufacturing capabilities enable us to produce Rough Top Conveyor Belts in a wide range of colors to meet specific industry requirements, enhance safety, and maintain brand consistency across your operations.

Why Color Matters in Conveyor Systems

Different industries require specific belt colors for hygiene standards, visibility requirements, temperature management, and regulatory compliance. Our color customization capability ensures your conveyor belts meet all operational and safety standards.

Black

Black

Black Belts

Industry standard color offering excellent durability and dirt concealment for heavy-duty industrial applications.

- ✓ General manufacturing

- ✓ Warehouse operations

- ✓ Mining & aggregates

Green

Green

Green Belts

Popular for recycling and environmental applications, providing high visibility and eco-friendly appearance.

- ✓ Recycling facilities

- ✓ Agricultural processing

- ✓ Packaging lines

Orange

Orange

Orange Belts

High-visibility safety color ideal for environments requiring maximum operator awareness and hazard zone identification.

- ✓ Construction materials

- ✓ Chemical processing

- ✓ High-traffic areas

Blue

Blue

Blue Belts

Detectable by metal detectors and x-ray systems, ideal for food safety applications requiring contamination prevention.

- ✓ Meat & poultry processing

- ✓ Bakery operations

- ✓ Beverage production

Advantages of Custom Color Options

Brand Consistency

Match your company's brand colors for a cohesive visual identity across all facility equipment and operations.

Enhanced Safety

High-visibility colors like yellow or orange improve operator awareness and reduce workplace accidents.

Easy Inspection

Light-colored belts make contamination, wear, and damage immediately visible for proactive maintenance.

Regulatory Compliance

Meet industry-specific color requirements for food safety, pharmaceuticals, and other regulated environments.

Process Organization

Color-code different production lines or material types for improved workflow management and traceability.

Temperature Management

Lighter colors reflect heat better in high-temperature environments, extending belt service life.

Need a Custom Color for Your Application?

We can produce belts in virtually any color to meet your specific requirements - contact us to discuss your color needs

Request Color SamplesFrequently Asked Questions

Everything you need to know about rough top conveyor belts

Let's Build Reliable Conveyor Solutions Together

Send us your specifications or project details — our engineers will analyze your requirements in 24h

Why Choose ZHENXING?

Contact Information

zhenxinglisa@hotmail.com

+86 18661664598

1. EP NN CC ST,SIDEWALL FR MOR HR EPDM -DONGYING

2. Solid Woven PVC PVG Conveyor Belt -JINING, Shandong

3. Sidewall Conveyor Belt -Weifang, Shandong

Get Your Custom Solution in 24 Hours

Share your requirements and receive expert guidance with a tailored quote