Solid Woven PVC/PVG Conveyor Belt –

Request Your Safety Solution

→

PVG/PVC Solid Woven Flame Retardant Conveyor Belt

Industrial Grade Underground Mining Solution

sOLID wOVEN (PVC PVG) cONVEYOR BELT Overview

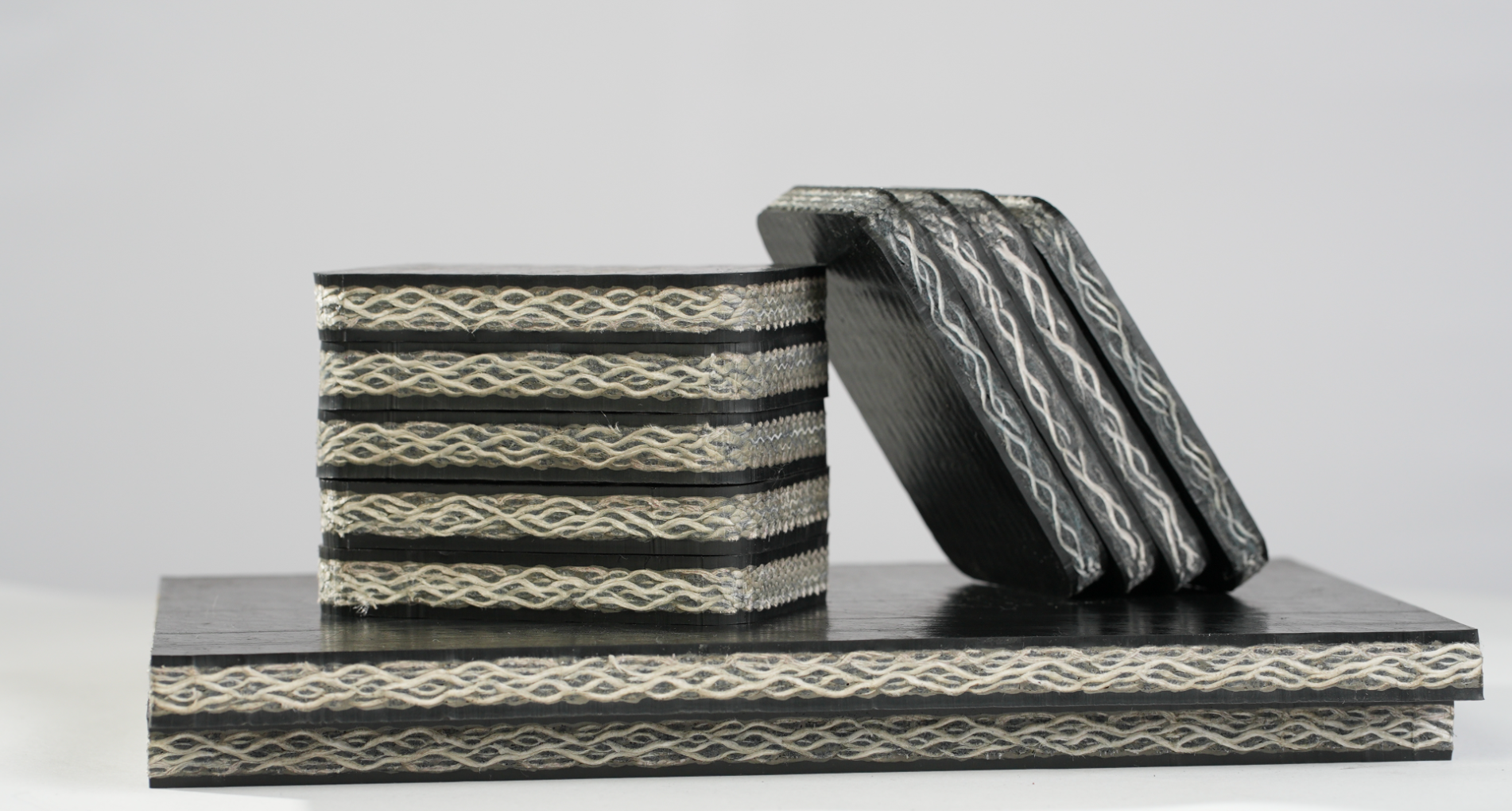

The company's PVG Solid woven core flame retardant conveyor belt is designed according to MT914-2019 standard. The product quality of enterprise that has passed ISO9001 quality system certification has reached the international advanced level. This product is made of solid woven carcass with chemical fiber and cotton as the skeleton, impregnated with paste, pasted with rubber covering and vulcanized.

Applications

Conveying materials under coal mine and other inflammable and explosive places. Flame retardant and antistatic properties make it ideal for underground mining operations.

Key Characteristics

- ● Good anti-tear and excellent climbing performance

- ● Good elasticity and impact resistance

- ● Good flexibility and easy maintenance

- ● Low temperature resistance

- ● Small constant load elongation, suitable for long-distance transportation

- ● Long service life

Main Safety Characteristics

- A. Surface resistance value: ≤ 3 × 10⁸Ω

- B. Drum friction performance: The surface temperature of the drum is ≤ 325℃, and there is no fume combustion or flameless combustion

- C. Combustion performance of alcohol blowtorch:

- Average combustion speed: ≤ 250mm

- Time of burning flame: average value ≤ 5.0 S, single value ≤ 15.0 S

- D. Tear propagation combustion performance: Retention length of undamaged length ≥ 500mm

Covering Characteristics (MT/T914-2019)

| Tensile Strength (MPa) |

Elongation at Break (%) |

Abrasion Loss (mm³) |

|---|---|---|

| ≥ 10.0 | ≥ 50% | ≤ 200 |

Note: At normal temp. (After 168hr), the change rate of tensile strength and elongation of PVC covering shall not be greater than 25% of the measured value before aging.

Adhesive Strength

| Between Covering & Core Layers |

Between Core Layers | Full Thickness Longitudinal Reference Value |

|

|---|---|---|---|

| Average | Minimum | ||

| ≥ 4.00 | — | — | ≥ 3.50 |

| ≥ 3.25 | ≥ 6.5 | ≥ 6.5 | ≥ 3.25 |

Main Physical Properties

| Tensile Strength | Minimum Warp Strength (N/mm) |

Minimum Weft Strength (N/mm) |

Minimum Tear Force (N) |

Minimum Elongation at Break in Warp Direction (%) |

Min Elongation at Break in Weft Direction at Break (%) |

|---|---|---|---|---|---|

| 680/Grade 4 | 680 | 265 | 1090 | 15 | 18 |

| 800/Grade 5 | 800 | 280 | 1180 | 15 | 18 |

| 1000/Grade 6 | 1000 | 300 | 1180 | 15 | 18 |

| 1250/Grade 7 | 1250 | 350 | 1540 | 15 | 18 |

| 1400/Grade 8 | 1400 | 350 | 1540 | 15 | 18 |

| 1600/Grade 9 | 1600 | 400 | — | 15 | 18 |

| 2000/Grade 10 | 680 | 400 | — | 15 | 18 |

| 2500/Grade 11 | 680 | 400 | — | 15 | 18 |

PVC PVG Conveyor Belt

Solid Woven

Characteristics

Mine-use flame-retardant conveyor belts are mainly designed for underground coal transportation, and can also be used for material handling in metallurgy and chemical industries. Solid-woven flame-retardant conveyor belts are classified into PVC type and PVG type. The PVC type uses PVC as both the top and bottom cover rubber, with a single-side cover thickness ≥ 0.8 mm. The PVG type uses a blended cover of nitrile rubber and PVC, with a single-side thickness of 1.5 mm–4.5 mm. PVC belts are suitable for conveying angles below 16°, while PVG belts can handle angles below 20°. Both types can be used for material transportation in coal mines, both underground and above ground.

Technical Specifications

| Strength Grade | Tensile Strength (Min.) | Carcass Thickness |

Carcass Weight |

Cover Grade and Recommended Thickness (mm) |

Belt Width | ||

|---|---|---|---|---|---|---|---|

| Warp | Weft | mm | Kg/m2 | PVC | PVG | (mm) | |

| 680s/Grade4 | 680 | 265 | 6 | 8 | 1.0+1.0 | 1.5+1.5 | 500~1600 |

| 800s/Grade5 | 800 | 280 | 6.5 | 8.5 | 1.0+1.0 | 1.5+1.5 | |

| 1000s/Grade6 | 1000 | 300 | 7.5 | 10 | 1.0+1.0 | 1.5+1.5 | |

| 1250s/Grade7 | 1250 | 350 | 9 | 12 | 1.5+1.5 | 2.0+1.5 | |

| 1400s/Grade8 | 1400 | 350 | 9.5 | 12.5 | 2.0+1.5 | 2.5+1.5 | |

| 1600s/Grade9 | 1600 | 400 | 10.5 | 14 | 2.0+2.0 | 2.5+1.5 | |

| 1800s/Grade10 | 1800 | 400 | 11.5 | 15 | 2.0+2.0 | 3.0+2.0 | |

| 2000s/Grade11 | 2000 | 400 | 12.5 | 16.5 | 2.0+2.0 | 3.0+2.0 | |

| 2240s/Grade12 | 2240 | 450 | 13.5 | 18 | 3.0+2.0 | 3.0+2.0 | |

| 2500s/Grade13 | 2500 | 450 | 14.5 | 19.5 | 3.0+2.0 | 3.0+3.0 | |

| 2800s/Grade14 | 2800 | 450 | 16.5 | 21.5 | 3.0+3.0 | 5.0+3.0 | |

| 3100s/Grade15 | 3100 | 450 | 18.0 | 24.0 | Selection based on conveyor systems | ||

| 3400s/Grade16 | 3400 | 450 | 20.0 | 26.0 | |||

Safety Performance

| Items | Indexes | |

|---|---|---|

| Anti-static property | Average electrical resistance of both surfaces (Ω) | 3.0*10⁸ |

| Surface temperature of drum (°C) | ≤325 | |

| Drum friction | Any test piece shall not show any sign of flame or glow | |

| Burning on spirit burner (flame or glow) |

Burning with cover rubber | |

| Average duration of flame for six test pieces (S) | ≤3 | |

| Duration of flame for any individual test piece (S) | ≤10 | |

| Burning without cover rubber | ||

| Average duration of flame for six test piece (S) | ≤5 | |

| Duration of flame for any individual test piece (S) | ≤15 | |

| Burning on propane burner | The undamaged length of each sample | ≥600 mm |

| The undamaged length shall not be less than 50 mm; the maximum average temperature rise shall not be greater than 140°C and the loss band length shall not be greater than 1250 mm. | ||

SAFETY CERTIFICATE OF APPROVAL

FOR MINING PRODUCTS

PVG Conveyor Belt

Both top and bottom covers are Nitrile rubber. Advantage of steep gradient (<20 lift angle), For use at environmental temperature above -10°C.

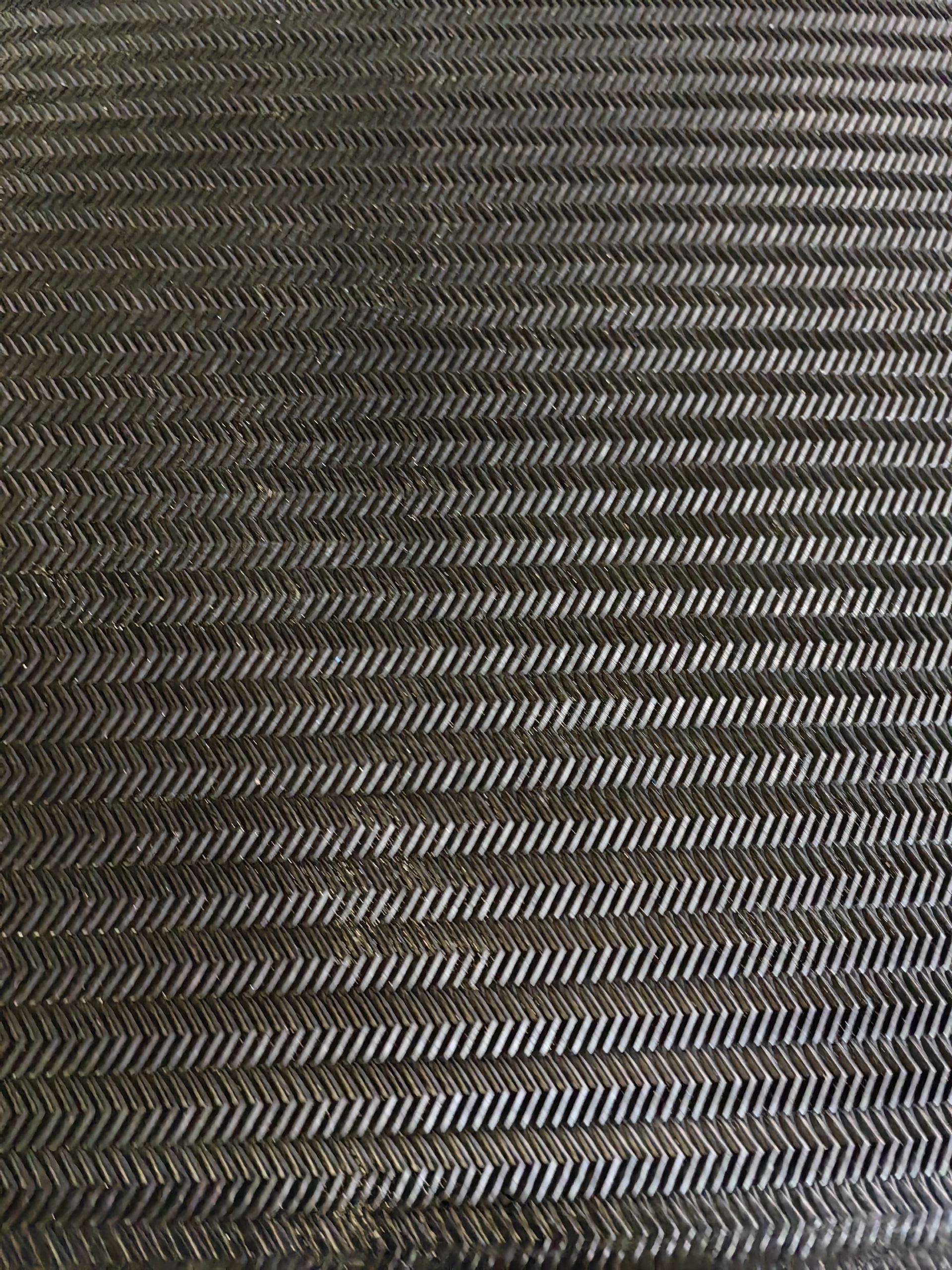

Patterned Solid Woven Conveyor Belt

PVG Solid Woven conveyor belt can be patterned.

Chevron Pattern

Herringbone Pattern

Diamond Pattern

Custom Pattern

EN14973 C1-PVG600-2800S

Customize LOGO

according to your requirements

ZHENXING Data

better than that of the EN14973 standard.

Certificate EN14973

C1 Class

Why Underground Mining Demands Solid Woven Flame-Resistant Belts

Conventional belts create serious safety risks and operational costs in underground environments. Discover the superior alternative engineered specifically for hazardous mining conditions.

Underground Challenges

- Flammable and explosive underground atmosphere demands rigorous fire prevention measures to protect miners and equipment from catastrophic incidents

- Standard conveyor belts lack adequate flame resistance and anti-static properties, creating severe fire hazards in coal dust environments that can trigger devastating explosions

- Unexpected belt failures cause production shutdowns costing thousands per hour, while emergency repairs in confined underground spaces expose workers to dangerous conditions and extend downtime

Solid Woven PVC/PVG Solution

- Integrated solid woven structure delivers exceptional tear resistance and impact absorption, maintaining belt integrity even under heavy coal loads and preventing dangerous longitudinal ripping

- Superior flame retardant and anti-static performance exceeds MT914 and EN14973 international standards, self-extinguishing within 3 seconds to eliminate fire propagation risks in underground mining operations

- Extended service life reduces replacement frequency by 40% compared to conventional belts, minimizing costly downtime while enhanced safety features protect your workforce and comply with stringent mining regulations

Two Series, Complete Underground Conveying Coverage

Choose the optimal solid woven belt configuration for your specific underground application. Both series deliver certified safety performance with distinct advantages for different conveying challenges.

PVC Solid Woven

PVG Solid Woven

Need help selecting the right series for your mine?

Consult Our Mining Experts →Technical Parameters & Standard Specifications

Comprehensive specifications demonstrating compliance with international mining safety standards while delivering the strength and durability required for demanding underground conveying applications.

| Strength Grade | Thickness (mm) | Weight (kg/m²) | Max Incline | Compliance Standards |

|---|---|---|---|---|

| 680S | 7-9 | 10-12 | PVC <16° / PVG <20° | EN14973, MT914 |

| 1000S | 8-10 | 11-13 | PVC <16° / PVG <20° | EN14973, MT914 |

| 1250S | 9-11 | 12-14 | PVC <16° / PVG <20° | EN14973, MT914 |

| 1600S | 10-12 | 13-15 | PVC <16° / PVG <20° | EN14973, MT914 |

| 2000S | 10-12 | 14-16 | PVC <16° / PVG <20° | EN14973, MT914 |

| 2500S | 11-12 | 15-17 | PVC <16° / PVG <20° | EN14973, MT914 |

| 3150S | 11-12 | 16-18 | PVC <16° / PVG <20° | EN14973, MT914 |

| 3400S | 12 | 17-18 | PVC <16° / PVG <20° | EN14973, MT914 |

Need custom specifications for your application? Our engineers can optimize belt parameters for your exact requirements

Request Custom Specification →Flame Resistance & Anti-Static Performance Meets International Standards

Comprehensive safety testing validates superior flame retardant and anti-static properties that exceed MT914 and EN14973 requirements, ensuring maximum protection in hazardous underground coal mining environments.

Certified Safety Test Results

- Drum Friction Temperature: ≤325℃

- Self-Extinguishing Time: ≤3 seconds

- Propane Burn Length: ≤600mm

- Average Surface Resistance: ≤3.0×10⁸ Ω

- Oxygen Index (OI): ≥28%

- Tensile Strength Retention: ≥90%

Compliance Certifications

Coal Mine Safety (MA)

EN14973 European Standard

ISO 9001:2015

MT914 Chinese Standard

Download complete certification documents and test reports for your project approval

Request Certification Package →Frequently Asked Questions

Expert answers to common questions about solid woven flame-resistant conveyor belts for underground mining applications, helping you make informed procurement and operational decisions.

Have additional questions about specifications, certifications, or applications?

Contact Our Technical Team →Share Your Conveying Requirements, Get Your Custom Solution

✓ Engineering team responds within 24 hours