Why Bucket Elevator Belts Require Professional Engineering?

Suitable Materials

Key Performance Values

- Vertical Transport Efficiency: Lift materials up to 60+ meters while maintaining consistent capacity and speed without spillage.

- Space-Saving Design: Compact footprint compared to inclined conveyors, maximizing floor space utilization in your facility.

- High Capacity Handling: Proven to transport 50-500 tons per hour depending on configuration and material characteristics.

Ready to optimize your vertical material handling system?

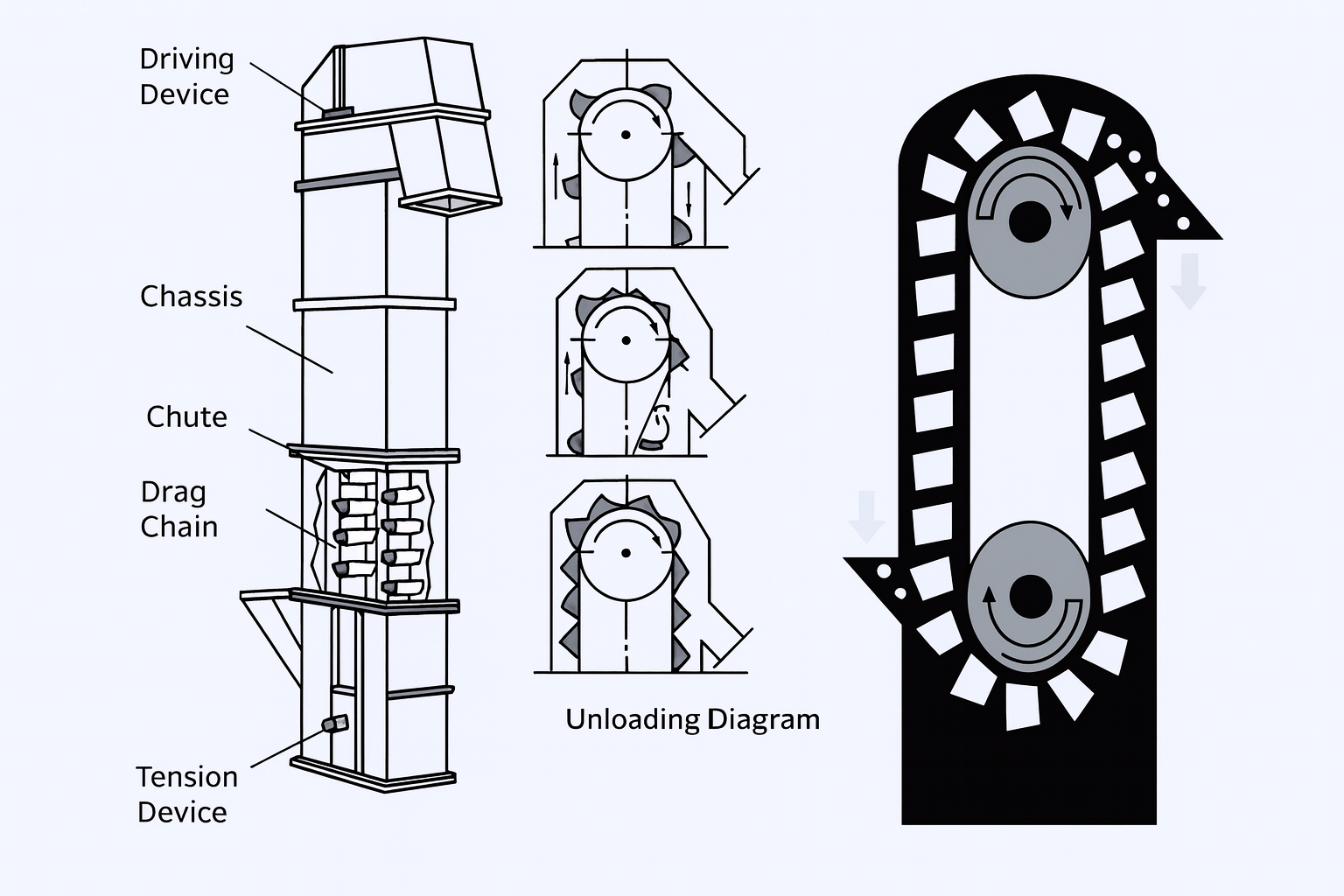

Product Structure Analysis: Engineering That Performs

Bucket Bolt Holes

EP Polyester Construction

Steel Cord Option

Why EP Fabric is the Optimal Choice for Most Applications

EP (Polyester-Nylon) Advantages

- Best Cost-Performance Ratio: Delivers industrial-grade strength at lower cost than steel cord for lifts up to 50m.

- Superior Flexibility: Easily wraps around smaller diameter pulleys (300-850mm), reducing equipment costs.

- Excellent Adhesion: Stronger bond between fabric and rubber layers prevents delamination and extends belt life.

- Damage Containment: Fabric damage remains localized, preventing catastrophic belt failure during operation.

- Moisture Resistance: Synthetic fibers don't absorb water, maintaining consistent performance in humid environments.

When to Choose Steel Cord

- Extreme Lifting Heights: Required for vertical transport exceeding 60 meters where EP would need excessive plies.

- Maximum Load Capacity: Handles 500+ tons per hour with minimal elongation under continuous heavy loading.

- Lowest Elongation: Steel cords provide near-zero stretch, eliminating tracking issues on ultra-tall elevators.

- Long-Term Investment: Higher upfront cost justified by extended service life in mission-critical, high-capacity installations.

- Harsh Conditions: Superior resistance to impact and abrasion in cement plants, mining operations, and power stations.

Not sure which construction is right for your application?

Product Advantages: Performance You Can Measure

Our bucket elevator belts integrate proven technologies and precision manufacturing to deliver measurable improvements in uptime, maintenance costs, and operational efficiency across diverse industrial applications.

Multiple Cover Rubber Options

Available in heat-resistant (up to 150°C), oil-resistant, and flame-retardant specifications. Performs reliably in grain silos, power plants, chemical facilities, and outdoor installations without deterioration.

Flexible Splicing Solutions

Multiple splicing options (hot vulcanization, cold bonding, mechanical fasteners) allow quick installation and repairs. Lower energy consumption due to reduced friction and excellent tracking stability.

Discover how our elevator belts can reduce your operational costs

EP Textile vs. Steel Cord: Complete Comparison

Selecting the right carcass type determines your bucket elevator's performance, maintenance requirements, and total cost of ownership. Compare key characteristics to make an informed decision based on your specific operational parameters.

EP Textile Belts

Polyester-nylon fabric construction offers excellent strength-to-weight ratio and flexibility. The standard choice for 90% of bucket elevator applications worldwide, combining proven reliability with cost-effectiveness.

- Ideal for lifting heights: 10-50 meters

- Capacity range: 50-300 tons/hour

- Polyester warp: High tensile strength, low stretch

- Nylon weft: Transverse strength, bolt holding

- Available: EP315 to EP1500 (3-7 plies)

Steel Cord Belts

Steel cable reinforcement provides maximum breaking strength with controlled elasticity. Engineered for extreme-duty applications where EP fabric limitations are exceeded, ensuring reliability in mission-critical installations.

- Ideal for lifting heights: 50-100+ meters

- Capacity range: 300-1000+ tons/hour

- Steel cord warp: Maximum strength, minimal elongation

- Optimized modulus: Balance of strength & flexibility

- Lower diameter pulleys possible vs. traditional steel

| Comparison Factor | EP Textile Belts | Steel Cord Belts |

|---|---|---|

| Breaking Strength | 315-1500 N/mm (per ply) | 2000-5000 N/mm |

| Elongation at Rated Load | 1.0-1.5% | 0.2-0.4% |

| Min. Pulley Diameter | 300-1400mm (depending on ply) | 800-1600mm |

| Belt Weight | Lighter (4-15 kg/m²) | Heavier (15-30 kg/m²) |

| Flexibility | Excellent | Good (improved vs. traditional steel) |

| Transverse Tear Resistance | Excellent (nylon weft) | Moderate |

| Splicing Methods | Hot vulcanization, cold bonding, mechanical | Hot vulcanization (specialized) |

| Repair & Maintenance | Easier, less specialized | Requires expert technicians |

| Service Life | 3-5 years (typical) | 5-8 years (optimal conditions) |

| Initial Cost | Lower | Higher (2-3x EP equivalent) |

| Best Applications | General industrial, cement, grain, mining (standard height) | Ultra-tall elevators, heavy-duty mining, power plants, extreme capacity |

| Installation Complexity | Standard | Requires specialized equipment |

Need help selecting the right belt type for your elevator?

Technical Specifications: Precision Engineering Data

Select the exact belt configuration for your bucket elevator based on lifting height, load capacity, and pulley diameter. Our comprehensive specification range ensures optimal performance for any application requirement.

EP Multi-Ply Belt Specifications with Rubber Cover (2.0 x 2.0mm)

| Specification | 4 Ply | 5 Ply | 6 Ply | 7 Ply |

|---|---|---|---|---|

| EP 315 | 500mm | - | - | - |

| EP 400 | 650mm | 600mm | - | - |

| EP 500 | 650mm | 750mm | 850mm | - |

| EP 630 | 700mm | 800mm | 950mm | 1000mm |

| EP 800 | 800mm | 850mm | 1000mm | 1150mm |

| EP 1000 | 850mm | 1000mm | 1000mm | 1200mm |

| EP 1250 | 900mm | 1050mm | 1200mm | 1400mm |

| EP 1500 | 1050mm | 1100mm | 1300mm | 1400mm |

Need help selecting the right specification for your application?

| Belt Tension Rating | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. Breaking Load (N/mm) | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Max. Cord Dia (mm) | 4.1 | 4.9 | 5.6 | 5.6 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Supplied Cord Dia (mm) | 3.6 | 4.4 | 5.2 | 5.2 | 6.8 | 7.7 | 8.1 | 8.6 | 9.5 | 10.3 | 10.8 |

| Cord pitch (mm±1.5) | 12 | 14 | 15 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 |

| Min. Cover Gauge (mm) | 4.0 | 4.0 | 4.0 | 4.0 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 |

| Belt width | Number Of Cords | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width (mm) | Width Tolerance | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 |

| 500 | ±5 | 39 | 34 | - | - | - | - | - | - | - | - | - |

| 650 | ±7 | 51 | 44 | - | - | - | - | - | - | - | - | - |

| 800 | ±8 | 64 | 55 | 50 | 64 | - | - | - | - | - | - | - |

| 1000 | ±10 | 81 | 69 | 64 | 81 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | ±10 | 97 | 84 | 77 | 97 | 77 | 77 | 77 | 77 | 71 | 66 | 66 |

| 1400 | ±12 | 114 | 98 | 90 | 114 | 90 | 90 | 90 | 90 | 84 | 78 | 78 |

| 1600 | ±12 | 131 | 112 | 104 | 131 | 104 | 104 | 104 | 104 | 96 | 90 | 90 |

| 1800 | ±14 | 147 | 127 | 117 | 147 | 117 | 117 | 117 | 117 | 109 | 102 | 102 |

| 2000 | ±14 | 164 | 141 | 130 | 164 | 130 | 130 | 130 | 130 | 121 | 113 | 113 |

| 2200 | ±15 | 181 | 155 | 144 | 181 | 144 | 144 | 144 | 144 | 134 | 125 | 125 |

| 2400 | ±15 | 197 | 169 | 157 | 197 | 157 | 157 | 157 | 157 | 146 | 137 | 137 |

Experience the quality difference from a trusted manufacturer

Schedule Factory TourManufacturing Excellence You Can Trust

With state-of-the-art production facilities, advanced quality control systems, and decades of expertise, we deliver bucket elevator belts that exceed international standards. Our factory capabilities ensure consistent quality and on-time delivery for projects of any scale.

Production Capabilities

Automated Water Jet Punching Technology

Equipped with automated water jet punching systems, ensuring precise hole diameter and spacing. This guarantees consistent accuracy, improved installation efficiency, and stable belt performance during operation..

300mm-2600mm Textile (Fabric) Conveyor Belt

ST500-ST10000 Steel Cord Belt Strength Range

Let's Build Reliable Conveyor Solutions Together

Send us your specifications or project details — our engineers will analyze your requirements in 24h

Why Choose ZHENXING?

Contact Information

zhenxinglisa@hotmail.com

+86 18661664598

1. EP NN CC ST,SIDEWALL FR MOR HR EPDM -DONGYING

2. Solid Woven PVC PVG Conveyor Belt -JINING, Shandong

3. Sidewall Conveyor Belt -Weifang, Shandong

Get Your Custom Solution in 24 Hours

Share your requirements and receive expert guidance with a tailored quote