-

Tensile Strength TestingPrecision measurement of rubber and fabric tensile properties using computerized testing equipment

-

Adhesion Force AnalysisComprehensive testing of cover-to-ply and ply-to-ply bonding strength to ensure durability

-

Abrasion Resistance EvaluationAccelerated wear testing to predict service life under various operational conditions

-

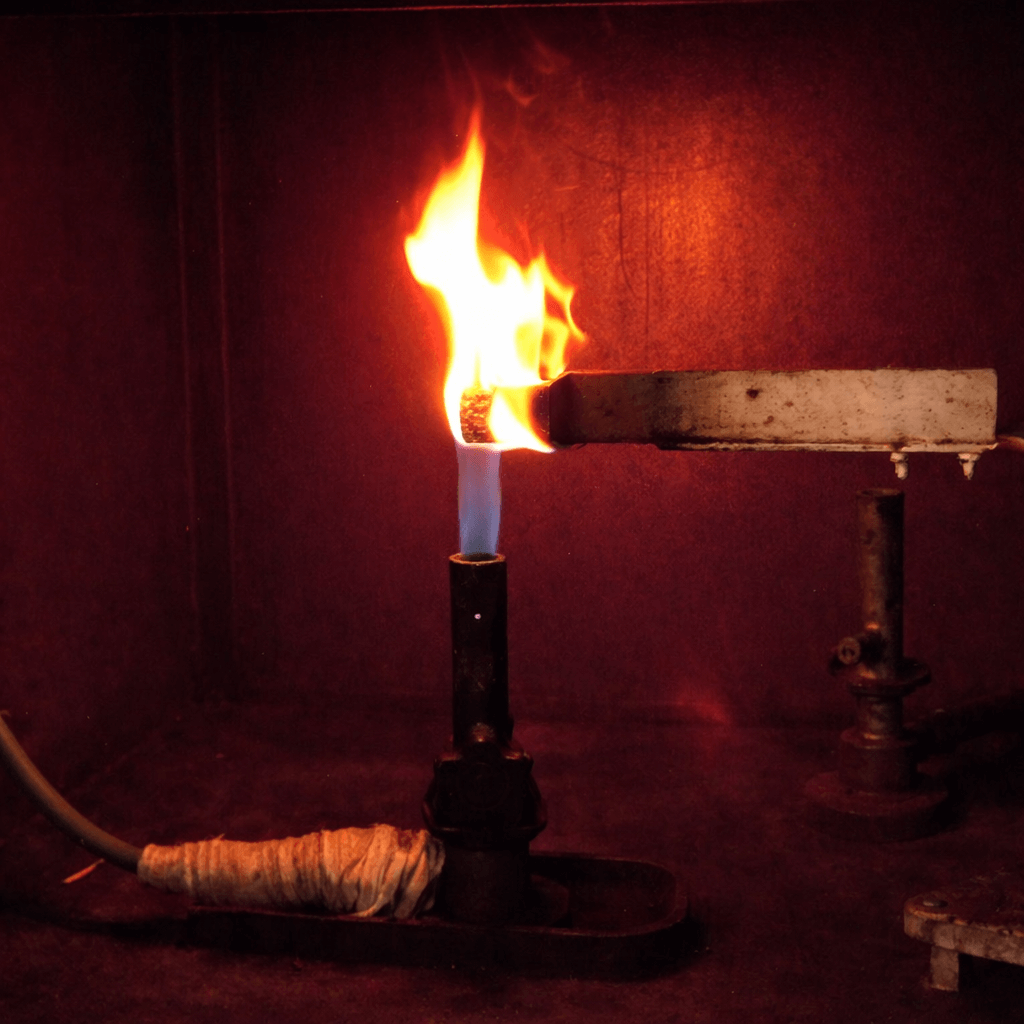

Flame & Heat Resistance TestingCertification testing for fire-resistant belts including drum friction and flame propagation tests

Fabric (Textile) Conveyor Belt

6 Production Line for EP EE NN Fabric (Textile Conveyor Belt) Double-plate vulcanization with a maximum width of 2400 mm, vulcanized in 10-meter lengths.

Comprehensive Fabric (Textile) Conveyor Belt Solutions

Explore our full range of specialized fabric conveyor belts, engineered to deliver exceptional performance across diverse industrial applications and challenging operating environments.

Multi-ply (Textile) Conveyor Belt

Our multi-ply fabric conveyor belts are designed for medium to long-distance, heavy-load, and high-speed transportation of materials. Widely utilized across mining, metallurgy, architecture, ports, electricity, and chemical industries, these belts deliver reliable performance through advanced multi-layer textile reinforcement technology.

| Standards | Cover Rubber Tensile Strength | Elongation at break | Abrasion | Cover to Ply Adhesion | Ply to Ply Adhesion | |

|---|---|---|---|---|---|---|

| DIN 22102 | Mpa | % | mm³ | N/mm (≤1.5mm) | N/mm (≥1.5mm) | N/mm |

| DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

| DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

| DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

| DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

| Standards | Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply |

|---|---|---|---|---|---|---|

| AS 1332 | Mpa | % | mm³ | N/mm (≤1.5mm) | N/mm (≥1.5mm) | N/mm |

| AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

| AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

| Standards | Tensile Strength | Elongation at break | Cover to Ply | Cover to Ply | Ply to Ply |

|---|---|---|---|---|---|

| RMA | Mpa | % | N/mm (≤1.6mm) | N/mm (≥1.6mm) | N/mm |

| RMA-I | 17 | 400 | 3 | 4.4 | 4 |

| RMA-II | 14 | 400 | 3 | 4.4 | 4 |

| Standards | Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Ply to Ply |

|---|---|---|---|---|---|

| SANS 1173 | Mpa | % | mm³ | N/mm | N/mm |

| A | 18 | 400 | 70 | 5 | 7 |

| C | 20 | 400 | 150 | 5 | 7 |

| M | 25 | 450 | 120 | 5 | 7 |

| N | 17 | 400 | 150 | 5 | 7 |

Heat Resistant, High Temperature Resistant Fabric Conveyor Belt

Specifically engineered for high-temperature solid material transportation including sintering ore, coke, cement clinker, and other heated materials. Deployed extensively in metallurgical, cement, chemical, and related industries requiring thermal resistance. Our advanced cover rubber formulation utilizes superior ethylene-propylene rubber or halogenate rubber to significantly enhance heat resistance and prevent premature aging.

Key Applications:

Ideal for conveying high-temperature materials in metallurgical plants, cement factories, chemical processing facilities, and power generation stations where thermal stability is paramount.

| Item | GB20021 Standard | ZHENXING Standard | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | DAHR150 | DAHR180 | |

| Test temperature | ||||||

| Hardness | ≤100°C | ≤125°C | ≤150°C | ≤175°C | ≤150°C | ≤180°C |

| Permitted change range - Difference before and after aging | ||||||

| Hardness - Change before and after aging | 20 | 20 | ±20 | ±20 | ±10 | ±10 |

| Hardness - Maximum value after aging | 85 | 85 | 85 | 85 | 75 | 75 |

| Tensile strength - Change rate of property % | 25 | 30 | 40 | 40 | ±15 | ±25 |

| Tensile strength - Min value after aging | 12 | 10 | 5 | 5 | 10 | 8 |

| Elongation at break - Change rate after aging % | 50 | 50 | 55 | 55 | ±15 | ±15 |

| Elongation at break - Minimum value after aging | 200 | 200 | 180 | 180 | 400 | 350 |

Customized Temperature Solutions:

We offer customized super high temperature resistant and burn resistant conveyor belts rated for HR200°C - HR250°C - HR300°C - HR450°C through patented technology. Our engineering team can develop bespoke thermal solutions for your specific operating conditions.

Oil Resistant Fabric Conveyor Belt

Premium oil-resistant conveyor belts featuring NBR (nitrile rubber) covers with exceptional oil resistance properties. The carefully selected reinforced materials ensure compatibility with oil-exposed environments while maintaining structural integrity. Ideal for conveying oily materials in diverse working conditions with sustained strength retention and dimensional stability.

Typical Applications:

Perfect for transporting pine wood, food processing materials, and items with oily or greasy surfaces. Widely used in food industry, woodworking, chemical processing, and any environment where oil exposure is inevitable.

| Type | Rubber material | Permissible temperature °C | Application areas |

|---|---|---|---|

| COR | NBR/BR or T rubber | 35-70 | Conveying products containing animal and vegetable oil and fat in cold areas |

| MOR | NBR/SBR or T rubber | -20-70 | Most products containing animal and vegetable oil and fat |

| OR | NBR T rubber | 20-70 | Products containing mineral oil |

| HOR | NBR T rubber | 20-120 | Hot asphalt |

| Item | Tensile strength/MPa | Elongation at break/% | Abrasion/mm³ |

|---|---|---|---|

| LO | ≥14.0 | ≥350 | ≤200 |

| DO | ≥16.0 | ≥350 | ≤160 |

Cold Resistant Fabric Conveyor Belt

Engineered for sub-zero temperature environments, our cold-resistant conveyor belts maintain flexibility and mechanical properties in freezing conditions. Designed for conveying low-temperature materials or operating in cold and freezing regions where standard belts would become brittle and fail.

Ideal Operating Conditions:

Essential for cold storage facilities, frozen food processing, outdoor winter operations, arctic mining, and any application requiring reliable belt performance in freezing environments.

| Grade | Tensile strength min. (ISO37) Mpa | Elongation at break min. (ISO37) % | Abrasion resistance max. (ISO4649) mm |

|---|---|---|---|

| H | 24 | 450 | 120 |

| D | 18 | 400 | 100 |

| L | 15 | 350 | 200 |

Temperature Ratings:

Tensile cold resistance coefficient: C1: 45°C (suitable environmental temperature: -45°C~-50°C±3), C2: 60°C (suitable environmental temperature: -60°C~-60°C±5°C±3.2)

Ozone Resistant Conveyor Belt

Specifically designed for outdoor applications with strong UV exposure, our ozone-resistant conveyor belts utilize NN or EP fabric carcass with specialized ozone-resistant cover compounds. The product structure incorporates compound mixing technology, belt vulcanization, inspection, and rigorous packing protocols to ensure maximum UV and ozone protection.

Primary Applications:

Ideal for transporting various sized materials or packages in outdoor environments with strong UV exposure. Perfect for ports, open-pit mining, construction sites, agriculture, and any conveyor system exposed to direct sunlight and atmospheric ozone.

| Item | Type | |||

|---|---|---|---|---|

| NN・EP | ||||

| Cover thickness > 1.5mm | 4.5 N/mm | |||

| Adhesion - Cover rubber and ply | Cover thickness > 1.5mm | 4.5 N/mm | ||

| Cover thickness < 1.5mm | 3 N/mm | |||

| Ply to Ply Adhesion | ≥ N/mm | |||

| Cover rubber physical property | Tensile strength/Mpa ≥ | 20 | 18 | 25 |

| Elongation at break/% ≥ | 400 | 400 | 450 | |

| Abrasion loss/mm3 ≤ | 150 | 90 | 120 | |

| Aging test (70±CX168h) | Not change by more than 25% from the original value | |||

| Ozone aging test results no crack | Test condition: ozone concentration (50+/-5)×10-8 (volume fraction), temperature(40+/-2)℃, (elongation(20±2) %,time 15h,70h,ozone aging test results no crack | |||

Ready to find the perfect fabric conveyor belt solution for your application?

Contact Our Engineering Team →Acid-Alkaline Resistant Fabric Conveyor Belt

Engineered for chemical resistance in harsh industrial environments

| Project | Tensile strength /Mpa |

Elongation at break % |

Abrasion/mm³ | Hardness/Ao | Ozone aging | |

|---|---|---|---|---|---|---|

| physical property | Before aging | ≥14.0 | ≥400 | ≥250 | 55-70 | No crack |

| After aging | ≥12.0 | ≥340 | -- | 60-75 |

| Category | Soaking solution | Concentration | Soaking condition |

Performance change rate before and after soaking |

|

|---|---|---|---|---|---|

| Volume Expansion Rate |

Tensile Strength Change Rate |

||||

| Acid and alkali resistance |

A1 hydrochloric acid |

18% | 50°C × 96h | +10% Following +10% below |

-10% within -10% below |

| A2 sulphuric acid |

50% | +10% Following +10% below |

-10% within -10% below |

||

| A3 sodium hydroxide |

48% | +10% Following +10% below |

-10% within -10% below |

||

Test conditions:

Ozone concentration (50±5)*10 (volume fraction), temperature (40±2)°C, elongation (20±2)%, time 15h

Need custom acid-alkaline resistant specifications?

Request Technical Consultation →Fire Resistant Conveyor Belt

Textile Fire-Resistant Conveyor Belting for Coal Mine - Meeting K2/K3 Standards

Technical Specification Tables

| Item | Standard Name |

Standard No. & Type | Formula No. |

Tensile Strength MPa ≥ |

Elogation at break % ≥ |

Abrasion mm³ ≤ |

Heat Aging | Burning on spirit burner | Surface resistance / Drum Friction |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Change rate of Tensile Strength |

Change rate of Elogation at break |

|||||||||

| 1 | General purpose fabric flame retardant conveyor belt |

GB/T 10822-D-K₂ | Z20、TZ | 18.0 | 450 | 200 | 70℃×168h ±25 | 70℃×168h ±25 | Average value of duration of flame of 6 full thickness test pieces does not exceed 45s and there is no reappearance of flame for any individual test result. | Anti-Static property shall not exceed 3×10⁸Ω |

| GB/T 10822-L-K₂ | Z15、TZ | 14.0 | 400 | 250 | ||||||

| GB/T 10822-D-K₃ | Z20、TZ | 18.0 | 450 | 200 | Average value of duration of flame of three full thickness test pieces does not exceed 60s and there is no reappearance of flame for any individual test result. | |||||

| GB/T 10822-L-K₃ | Z15、TZ | 14.0 | 400 | 250 | ||||||

| Tensile Strength (MPa) | > 14 MPa |

| Elongation at Break (%) | > 350% |

| Abrasion Loss (mm³) | < 200 mm³ |

| Aging Variation – Tensile Strength | -25% ~ +25% |

| Aging Variation – Elongation at Break | -25% ~ +25% |

| Surface Electrical Resistance (Top & Bottom Cover – Arithmetic Mean) |

≤ 3.0 × 10⁸ Ω |

| Flaming Combustion | Not allowed |

| Flameless Combustion | Not allowed |

| Maximum Drum Surface Temperature | ≤ 325°C |

| Test Condition | Flaming Time (Average) |

Flameless Time (Average) |

Single Specimen Limit |

|---|---|---|---|

| Intact Cover Specimen | ≤ 3.0 s | ≤ 3.0 s | Flaming and flameless time ≤ 10.0 s |

| Cover Removed Specimen |

≤ 5.0 s | ≤ 5.0 s | Flaming and flameless time ≤ 15.0 s |

| Requirement Option | Specification |

|---|---|

| Option A | Undamaged length ≥ 600 mm |

| Option B | Undamaged length ≥ 50 mm AND Average temperature rise ≤ 140°C AND Damage length ≤ 1250 mm |

Note:

The belt is considered qualified when it meets either requirement above. If the test is terminated early due to danger to personnel or equipment, the belt is regarded as failed.

Require fire-resistant belts certified for coal mine operations?

Get K2/K3 and EN 14973 C1 Certified Solutions →Our Manufacturing Capabilities

Industry-leading production capacity and technical specifications

Belt Width Range

Comprehensive width range covering all standard and custom applications, from light-duty conveying to heavy industrial transport systems.

Rubber Strength Grade

Multiple tensile strength grades available to match specific load requirements and operational conditions across diverse industries.

Heat Resistance Temperature

Extreme temperature capability for high-heat applications including cement clinker, sintering ore, and other heated material transportation.

Flame Retardant Standards

Complete fire-resistant formulations including specialized underground coal mine textile core conveyor belts with full certification compliance.

Custom Solutions Available

We offer specialized customization including MOR+FRAS (Moderately Oil Resistant + Flame Resistant Anti-Static) combinations and other application-specific formulations tailored to your unique operational requirements.

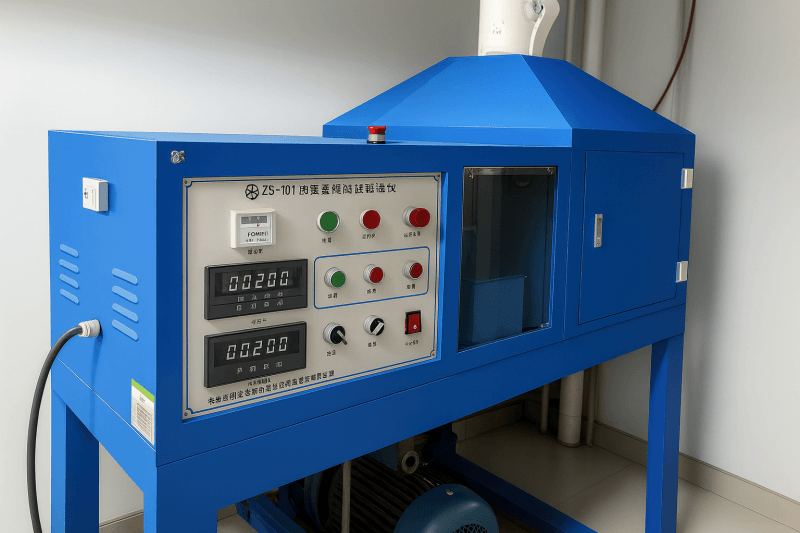

Quality Control & Testing Laboratory

State-of-the-art testing facilities ensuring consistent product excellence

Daily Shipping & Logistics

Efficient global delivery ensuring your operations never stop

Let's Build Reliable Conveyor Solutions Together

Send us your specifications or project details — our engineers will analyze your requirements in 24h

Why Choose ZHENXING?

Contact Information

zhenxinglisa@hotmail.com

+86 18661664598

1. EP NN CC ST,SIDEWALL FR MOR HR EPDM -DONGYING

2. Solid Woven PVC PVG Conveyor Belt -JINING, Shandong

3. Sidewall Conveyor Belt -Weifang, Shandong

Get Your Custom Solution in 24 Hours

Share your requirements and receive expert guidance with a tailored quote