Belt Jointing Solutions – Cold Vulcanizing Cement

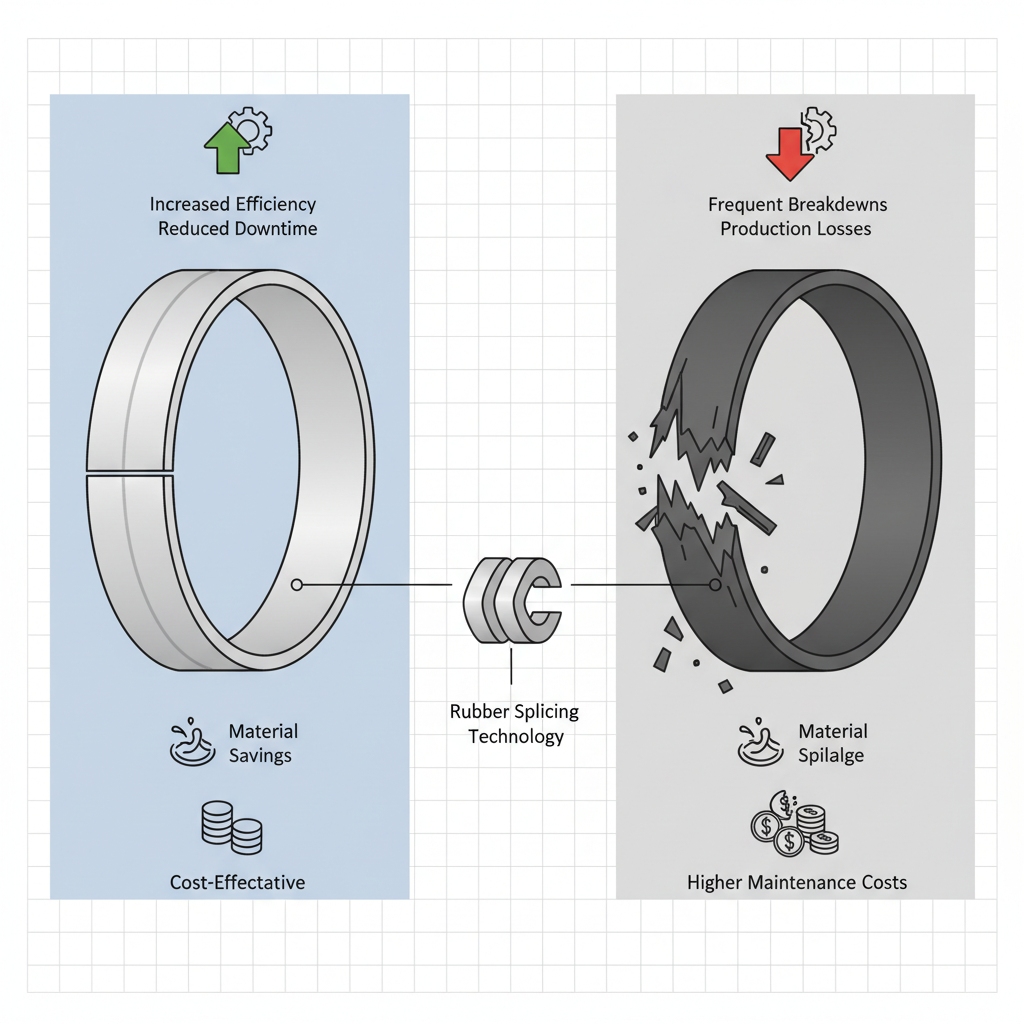

Picture a conveyor belt tearing during peak production—materials spill, operations halt, and emergency repairs quickly drain time and money. These failures disrupt workflow, elevate safety risks such as slips and equipment jams, and push maintenance budgets to the breaking point.

As breakdowns repeat, small issues escalate into costly shutdowns, delaying shipments and eroding profits while your team struggles to keep the system running.

A dependable rubber conveyor belt jointing solution, especially cold vulcanizing, provides a fast and economical way to restore performance. It creates strong, seamless joints without heat, reducing downtime and ensuring long-lasting reliability to keep your operations moving safely and efficiently.

1. Why Choose Rubber Conveyor Belt Jointing Solution?

How Do I Assess Jointing Needs?

- Evaluate belt types like M24 grade, heat-resistant, and oil-resistant for compatibility.

- Check load capacity and environmental exposure to match joint strength.

- Review usage frequency to prioritize durability over quick fixes.

But wait, there’s more—you can streamline assessments by logging operational data, ensuring joints align with your specific demands. You’ll avoid mismatches that lead to premature wear, saving resources long-term.

What Tools Are Essential for Jointing?

- Buffing tools for surface preparation.

- Brushes and rollers for even cement application.

- Clamps and hammers to secure the bond.

Here’s the deal: Gather these basics before starting, as they directly impact joint quality. You equip your team properly, reducing errors and boosting efficiency in every repair.

How Does Cold Vulcanizing Outperform Heat Methods?

- Faster setup with no heating equipment needed.

- Lower costs by eliminating energy and specialized gear.

- Portable for on-site fixes without full shutdowns.

You might wonder how it holds up—tests show comparable tensile strength for most applications. You’ll appreciate the flexibility it brings to your maintenance schedule.

| Aspect | Cold Vulcanizing | Hot Vulcanizing | |

|---|---|---|---|

| Time | 1-2 hours | 4-6 hours | |

| Cost | Low | High | |

| Strength | High | Very High |

This table reveals cold vulcanizing’s edge in speed and affordability, making it ideal for dynamic industrial settings where every minute counts.

Key Takeaway: Rubber conveyor belt jointing solutions enhance efficiency by cutting repair times and costs, empowering your operations with reliable, easy-to-implement fixes that promise sustained productivity.

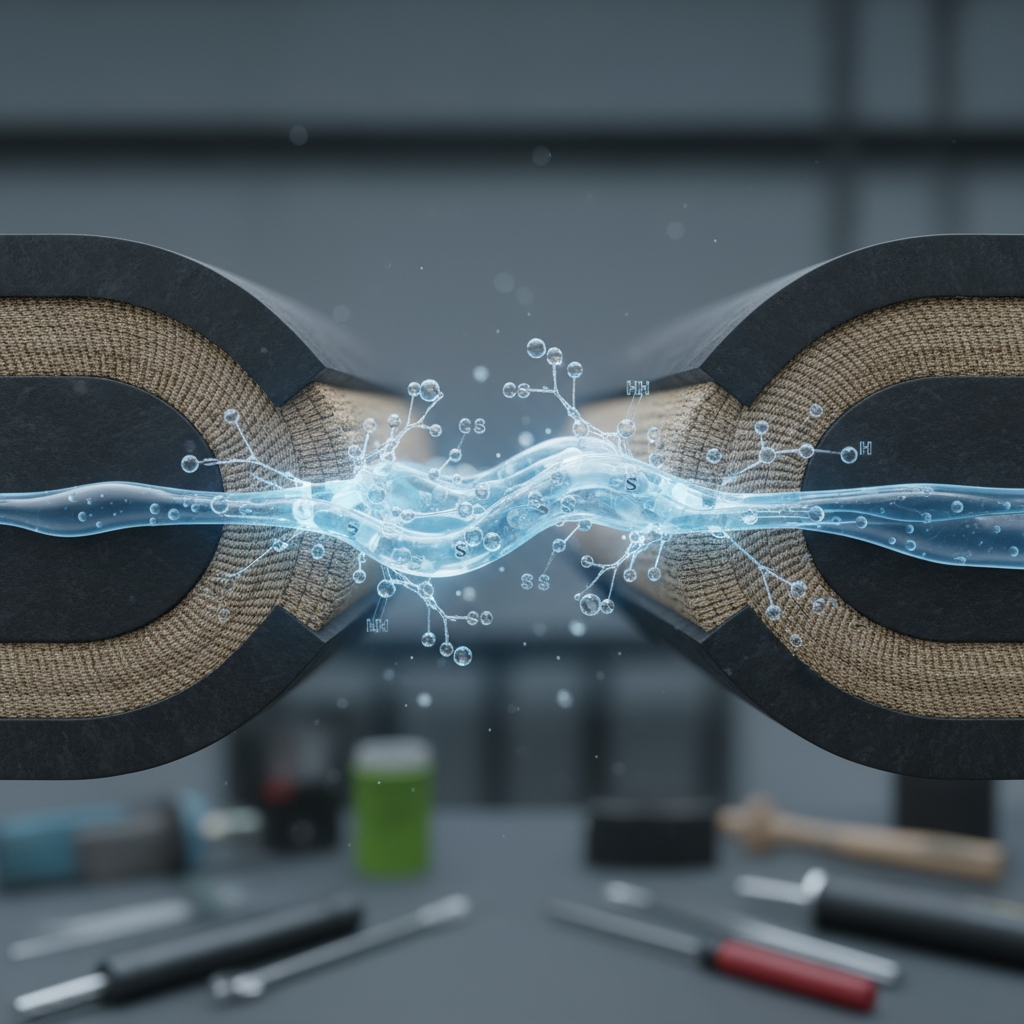

2. What Is Cold Vulcanizing in Belt Jointing?

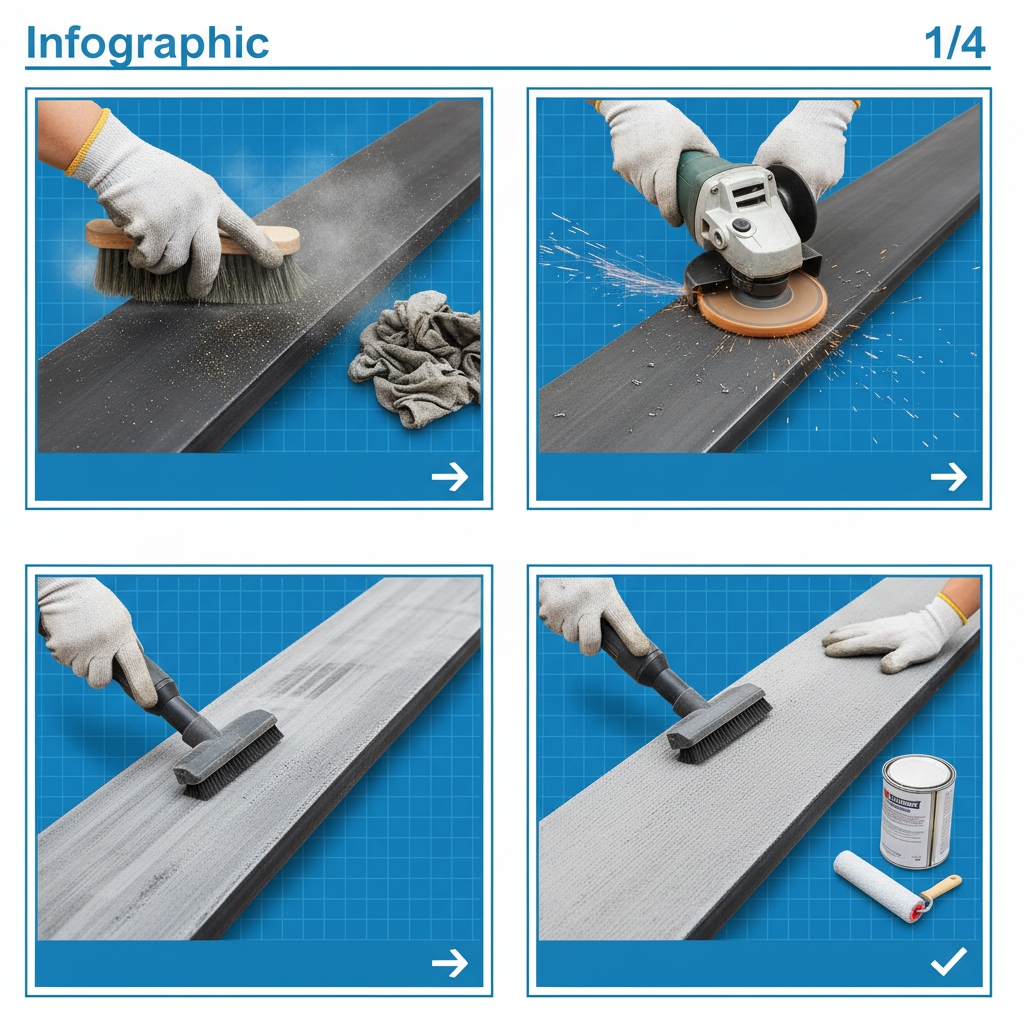

How Do I Prepare Belt Surfaces?

- Wipe away dust, oil, and moisture with solvents.

- Buff to create a rough texture for adhesion.

- Inspect for damage and align edges precisely.

Now, imagine this: A clean surface ensures the cement grips fully, preventing weak spots. You’ll achieve bonds that withstand daily rigors effortlessly.

What Materials Make Up the Solution?

- Vulcanizing cement as the base adhesive.

- Hardener to activate the chemical reaction.

- Cover strips for reinforcement.

The best part? These components blend simply for strong results. You mix them on-site, tailoring to your belt’s needs without complexity.

How Long Does the Process Take?

- Cleaning: 10 minutes.

- Application: 20 minutes.

- Curing: 1 hour minimum.

But here’s why it works—short timelines mean quick returns to service. You’ll minimize disruptions, keeping your lines moving smoothly.

| Step | Duration | |

|---|---|---|

| Cleaning | 10 min | |

| Applying Cement | 20 min | |

| Curing | 1 hour |

The timeline underscores cold vulcanizing’s efficiency, allowing rapid repairs that maintain operational flow.

Key Takeaway: Cold vulcanizing simplifies rubber conveyor belt jointing as an accessible on-site method, slashing halts and extending belt life through precise, user-friendly steps.

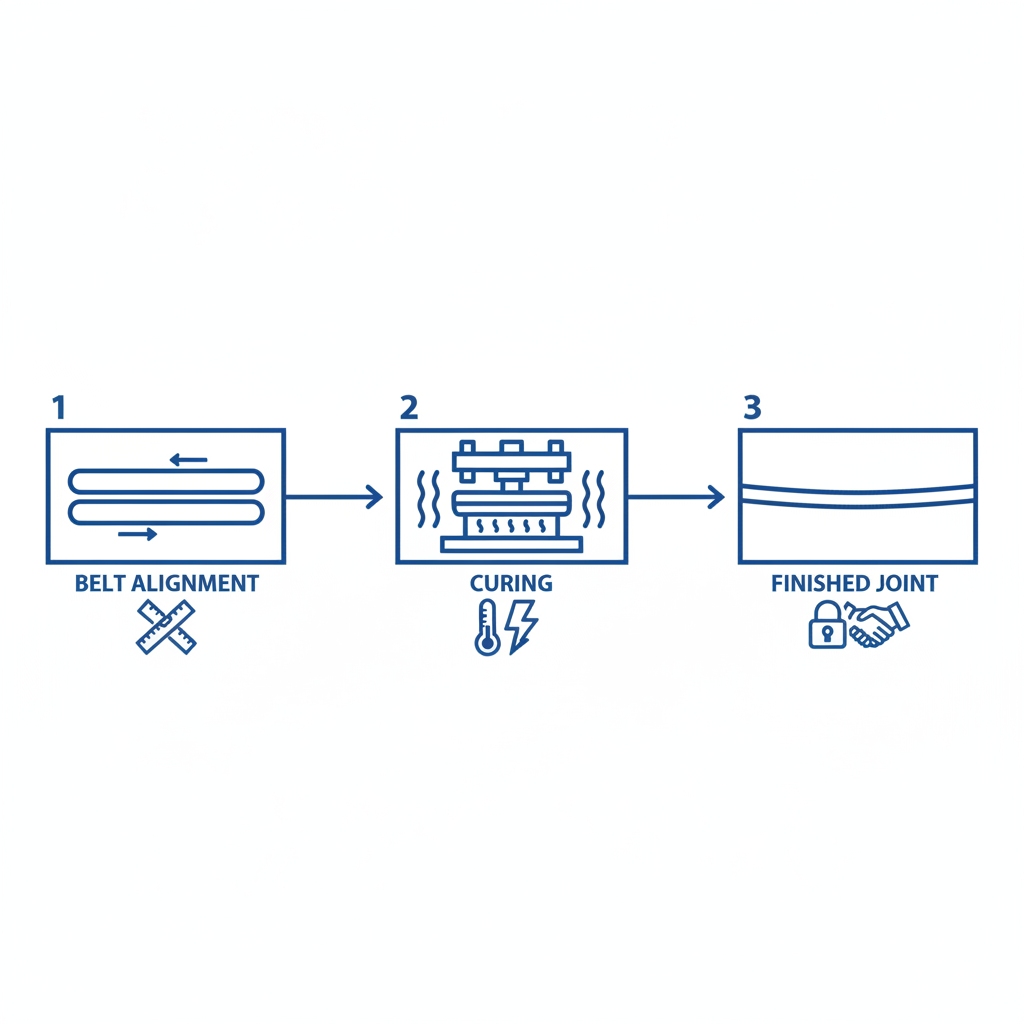

3. How to Apply Rubber Conveyor Belt Jointing Solution?

How Do I Mix the Vulcanizing Cement?

- Ratio: 100 parts cement to 6 parts hardener.

- Stir vigorously for uniform consistency.

- Let settle briefly before use.

Ready to try? Proper mixing activates the bond fully. You’ll ensure even application, avoiding lumps that compromise strength.

What Steps Follow Mixing?

- Apply first coat and dry completely.

- Add second thin layer after 15 minutes.

- Press surfaces together firmly.

This changes everything—sequential layers build a robust seal. You control the process, achieving professional-grade results independently.

How Do I Ensure a Strong Bond?

- Hammer to expel air bubbles.

- Clamp under pressure for 1 hour.

- Allow full cure before loading.

What if I told you technique matters most? You’ll prevent delamination, extending joint reliability in tough conditions.

| Technique | Benefit | |

|---|---|---|

| Hammering | Removes Air | |

| Clamping | Increases Pressure | |

| Resting | Allows Curing |

These methods highlight hands-on control, optimizing bond integrity for demanding use.

Key Takeaway: Applying rubber conveyor belt jointing solution proves straightforward yet powerful, giving you quality oversight—consider team training to maximize outcomes.

4. Benefits of Cold Vulcanizing Joints?

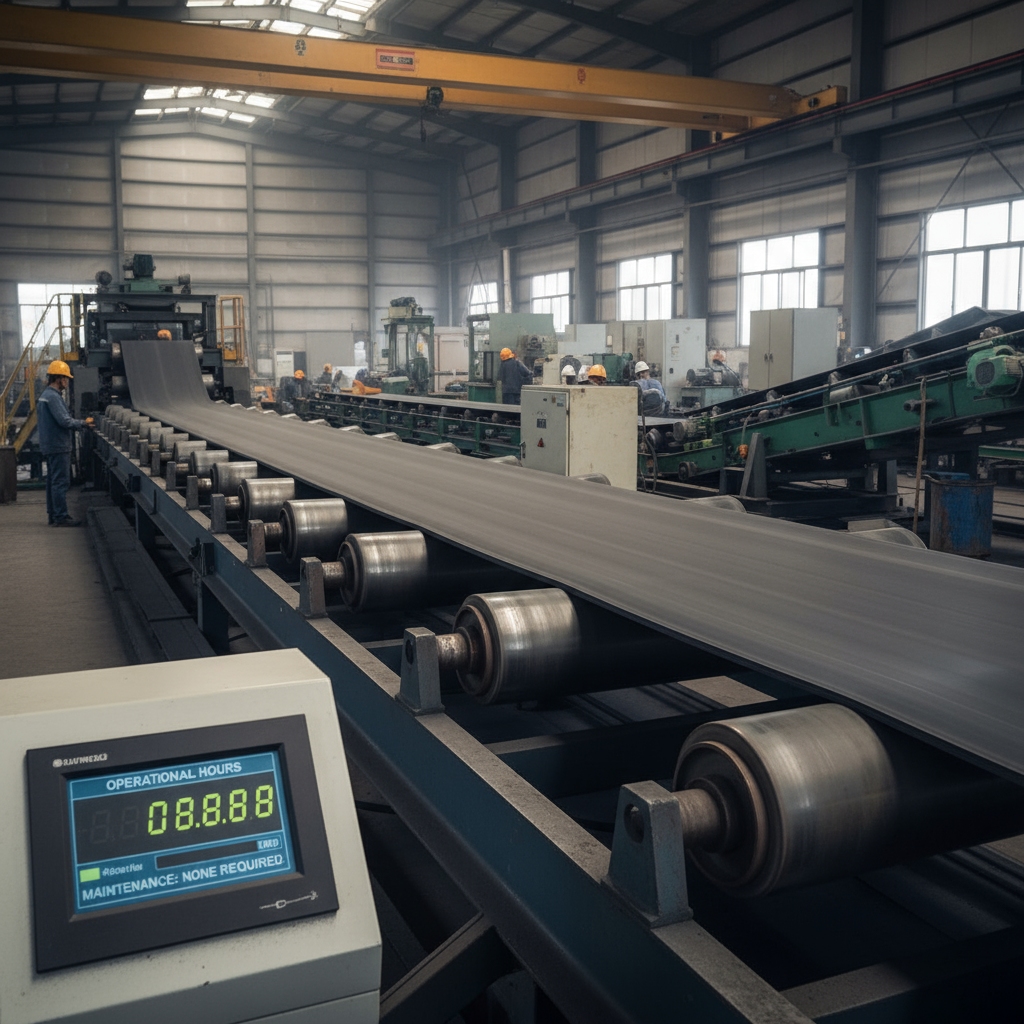

How Does It Save Time in Operations?

- No setup for heating reduces prep by hours.

- On-site application avoids transport delays.

- Quick curing gets belts running sooner.

Picture this: Downtime drops dramatically. You’ll reclaim hours, accelerating throughput without external dependencies.

What Cost Reductions Can You Expect?

- Eliminate equipment rentals and fuel costs.

- Cut labor through simplified processes.

- Extend belt life, lowering replacements.

And get this—savings compound over time. You allocate budgets smarter, focusing on growth rather than fixes.

How Durable Are These Joints Long-Term?

- Resist abrasion and flexing effectively.

- Maintain flexibility in varying temperatures.

- Withstand loads up to 90% of original strength.

The proof? Field tests confirm longevity. You’ll rely on joints that match belt performance for years.

| Benefit | Impact | |

|---|---|---|

| Speed | Less Downtime | |

| Economy | Lower Fees | |

| Strength | Extended Use |

Benefits align with efficiency gains, positioning cold vulcanizing as a strategic choice for cost-conscious firms.

Key Takeaway: Cold vulcanizing joints deliver tangible perks in rubber conveyor belt jointing, streamlining business ops—adopt it to sharpen your competitive advantage.

5. Common Challenges in Belt Jointing?

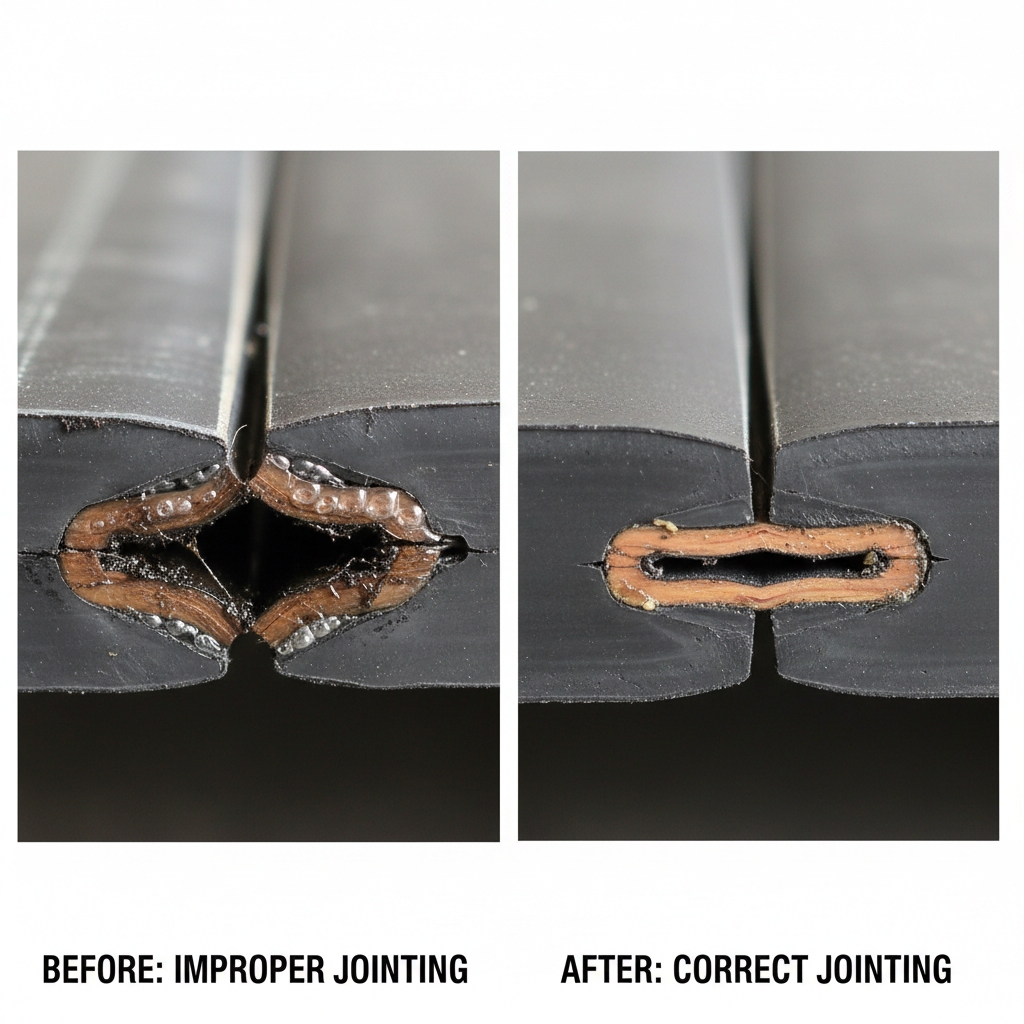

How Do I Avoid Surface Contamination?

- Use lint-free cloths for cleaning.

- Work in dust-free areas.

- Apply cement immediately after prep.

Avoid this mistake—contamination weakens bonds instantly. You’ll safeguard integrity with vigilant habits.

What If the Weather Affects Jointing?

- Ideal: 10-30°C and low humidity.

- Shelter from rain or direct sun.

- Monitor conditions during cure.

Here’s a tip: Controlled environments yield better results. You adapt easily, ensuring consistent quality outdoors.

How to Troubleshoot Weak Bonds?

- Re-clean and reapply if separation occurs.

- Check ratios for mixing errors.

- Test pressure application.

Don’t worry—fixes are straightforward. You’ll resolve issues swiftly, restoring full functionality.

| Challenge | Solution | |

|---|---|---|

| Dirt | Clean Thoroughly | |

| Humidity | Dry Environment | |

| Poor Mix | Reapply |

Solutions demonstrate proactive management, turning potential pitfalls into manageable steps.

Key Takeaway: Tackle rubber conveyor belt jointing hurdles head-on with these strategies; solutions build confidence—seek expert advice for complex cases.

6. When to Use Rubber Conveyor Belt Jointing Solution?

How Do I Select for Specific Belt Types?

- M24 grade: High suitability for standard loads.

- Heat-resistant: Medium for elevated temps.

- Oil-resistant: Ideal in chemical environments.

It depends on your belt’s core material. You’ll match precisely, optimizing performance across variants.

What Industries Benefit Most?

- Mining for heavy material handling.

- Food processing for hygienic joins.

- Manufacturing to sustain production lines.

Think about your sector’s demands. You integrate seamlessly, enhancing reliability where it counts.

How Often Should You Re-Joint?

- Inspect quarterly for wear signs.

- Re-joint annually in high-use setups.

- Immediately post-damage detection.

Surprisingly, preventive checks extend intervals. You’ll plan ahead, avoiding unexpected failures.

| Belt Type | Suitability | |

|---|---|---|

| M24 Grade | High | |

| Heat Resistant | Medium |

Suitability guides usage, ensuring targeted applications for peak efficiency.

Key Takeaway: Time rubber conveyor belt jointing to fit maintenance plans; preventive approaches minimize risks and costs.

7. Safety Tips for Jointing Process?

How Do I Protect Myself During Application?

- Wear gloves, goggles, and respirators.

- Use non-slip footwear in work areas.

- Secure tools to prevent falls.

Safety first—gear shields against chemicals. You’ll operate confidently, prioritizing well-being.

What Precautions for Chemical Handling?

- Store in cool, ventilated spaces.

- Avoid skin contact; rinse immediately if exposed.

- Dispose waste per regulations.

One key rule: Ventilation disperses fumes effectively. You handle materials safely, complying effortlessly.

How to Handle Post-Jointing Inspection?

- Visually scan for gaps or bubbles.

- Test tension gradually.

- Document findings for records.

Finally, thorough checks confirm readiness. You’ll verify durability before resuming use.

| Tip | Purpose | |

|---|---|---|

| Gloves | Skin Protection | |

| Ventilation | Fume Reduction | |

| Visual Check | Bond Quality |

Tips foster secure practices, reducing incidents in jointing workflows.

Key Takeaway: Prioritize safety in rubber conveyor belt jointing to foster trust; adhere to protocols for responsible, effective repairs.

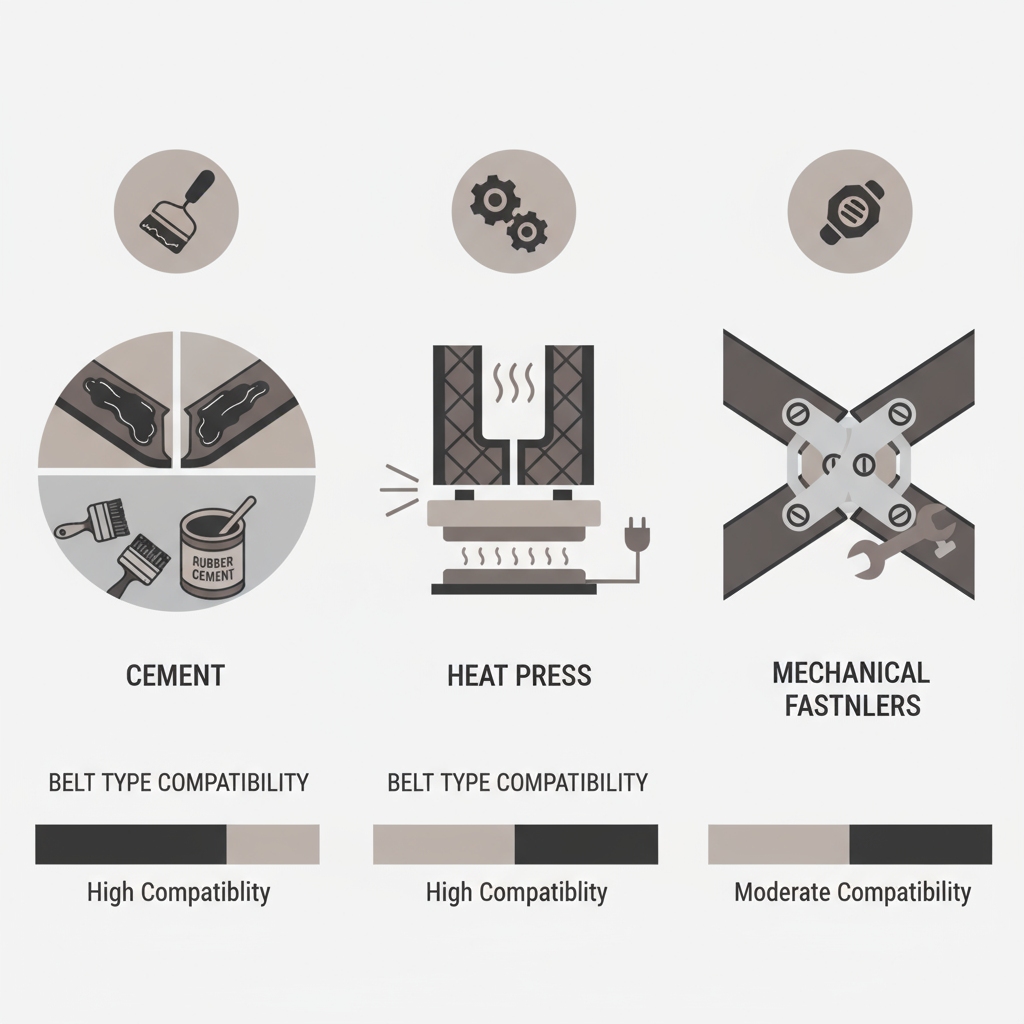

8. Comparing Jointing Methods Effectively?

How Does Cold Stack Against Mechanical?

- Pros: Seamless, high flexibility; cons: Initial skill needed.

- Mechanical: Quick install; prone to snags.

- Cold excels in smooth operations.

Let’s compare directly—you’ll see cold’s superior longevity. Opt for it in continuous flows.

What About Hot Vulcanizing Alternatives?

- Hot: Strongest bonds; requires machinery.

- Cold: Easier access; slightly less peak strength.

- Differences lie in setup complexity.

The difference? Portability favors cold for field work. You’ll choose based on resources.

How to Decide on the Best Method?

- Factor belt load and downtime tolerance.

- Assess site capabilities.

- Weigh cost versus durability.

Bottom line: Evaluate your constraints. You’ll select optimally for sustained results.

| Method | Strength | Ease | |

|---|---|---|---|

| Cold | Good | High | |

| Hot | Excellent | Low |

Comparisons clarify choices, favoring cold for versatile industrial needs.

Key Takeaway: Rubber conveyor belt jointing shines in adaptability; use comparisons to inform decisions that suit your operations.

9. Maintenance After Jointing?

How Do I Monitor Joint Performance?

- Watch for cracks or unusual vibrations.

- Measure tension weekly.

- Log runtime and load data.

Keep an eye on early warnings. You’ll catch issues before escalation.

What Routine Care Extends Life?

- Clean regularly to remove debris.

- Lubricate adjacent rollers.

- Avoid overloads consistently.

Simple steps prevent wear. You maintain peak condition with minimal effort.

How to Plan for Replacements?

- Track degradation indicators like fraying.

- Schedule based on usage hours.

- Budget for periodic overhauls.

When to act: Proactive planning saves costs. You’ll extend asset value effectively.

| Maintenance | Frequency | |

|---|---|---|

| Inspection | Weekly | |

| Cleaning | Monthly |

Schedules ensure longevity, integrating seamlessly into routines.

Key Takeaway: Post-jointing care for rubber conveyor belt jointing focuses on vigilance; regular upkeep guarantees prolonged reliability.

10. Advanced Tips for Optimal Jointing?

How Do I Customize for Heavy Loads?

- Use thicker cement layers.

- Reinforce with extra strips.

- Increase clamping pressure.

For pros, these tweaks handle extremes. You’ll fortify joints for demanding tasks.

What Innovations Improve Solutions?

- Advanced adhesives for faster cures.

- Eco-friendly hardeners.

- Digital monitoring tools.

Looking ahead, tech evolves options. You stay ahead with cutting-edge enhancements.

How to Scale for Large Operations?

- Train multiple technicians.

- Standardize kits for consistency.

- Integrate into CMMS software.

Scale up efficiently—you’ll manage fleets without bottlenecks.

| Tip | Application | |

|---|---|---|

| Thicker Cement | Heavy Duty | |

| Training | Teams |

Tips enable growth, refining rubber conveyor belt jointing for expansion.

Key Takeaway: Advanced rubber conveyor belt jointing insights optimize performance; apply them to drive operational excellence.

Cold vulcanizing resolves downtime and cost woes from faulty joints, delivering seamless industrial flow. We offer tailored rubber conveyor belt jointing solutions to meet your needs. Empower your operations today—contact us to upgrade conveyor reliability.

FAQ

Can I use cold vulcanizing for all belts? No, it’s best for standard rubber types; specialized belts like steel cord need hot methods for maximum strength due to material differences.

How strong is a cold vulcanized joint? Quite strong for most uses, matching 80-90% of original belt tension, but it depends on proper application to avoid weaknesses over time.

Is cold vulcanizing safe for on-site repairs? Yes, with precautions; it avoids heat hazards, making it ideal for field work, though ventilation prevents fume exposure.

What if the joint fails prematurely? Rare with correct steps, but check for contamination; reapply promptly to maintain operations without full belt replacement.

Does weather impact cold jointing? Somewhat; avoid high humidity or cold temps below 10°C, as they slow curing and weaken bonds in the process.