Selecting the wrong Rubber Conveyor Belt material can result in expensive downtime, product damage, and safety hazards. The performance of your entire system depends on choosing the correct belt. Even a slight mismatch between the belt material and the application may cause premature wear, tearing, or unexpected breakdowns—leading to lost revenue and reduced reliability. This comprehensive guide helps you confidently choose the ideal Rubber Conveyor Belt material to match your specific operational needs, ensuring long-lasting durability and optimized performance.

What is rubber conveyor belt material?

A rubber conveyor belt material is a composite product primarily made from natural or synthetic rubber compounds reinforced with fabric or steel plies for strength. Its main purpose is to provide a durable, flexible surface for transporting goods across various industrial environments. The specific compound determines its resistance to heat, oil, and abrasion.

How is it made?

Production involves layering fabric plies, impregnating them with a rubber friction compound, and vulcanizing the assembly under heat and pressure. The real story is in the compound mixing, where additives are introduced to achieve specific properties. This process ensures a robust, unified belt structure.

- Compound Mixing

- Fabric Ply Layering

- Vulcanization

What are some common rubber types?

Common types include Styrene-Butadiene (SBR) for general use and Nitrile (NBR) for oil resistance. You might be wondering which one is best for you. The choice depends entirely on your operational conditions and the materials you handle.

- SBR: Ideal for general-purpose abrasion resistance.

- NBR: Best for applications with exposure to oils and solvents.

- EPDM: Excellent for resisting heat, weather, and ozone.

Key Takeaway: Understanding the fundamental composition of a rubber conveyor belt material is the first step toward making an informed purchasing decision.

| Compound | Primary Benefit | Common Use Case | |

|---|---|---|---|

| SBR | General-Purpose, Cost-Effective | Package Handling | |

| NBR (Nitrile) | Excellent Oil Resistance | Recycling Facilities | |

| EPDM | Weather & Heat Resistance | Outdoor Applications |

General rubber conveyor belt material uses.

General-purpose rubber conveyor belt material is used for a wide range of standard applications, such as moving boxes, bulk materials, and packaged goods. Its versatility and cost-effectiveness make it a foundational component in logistics, agriculture, and light manufacturing. You can find it in everything from airport baggage systems to grocery store checkouts.

What industries use it most?

Industries like distribution, agriculture, and general manufacturing heavily rely on this material for its reliability. Here’s the deal: these sectors need a workhorse belt that performs consistently without needing specialized features. It’s the go-to for moving non-abrasive products efficiently.

- Logistics and Distribution Centers

- Agriculture (Grain and Produce)

- Package Handling Systems

Key Takeaway: The widespread adoption of general-purpose rubber belting highlights its balance of performance and affordability for non-critical tasks.

| Industry | Suitability | Reason | |

|---|---|---|---|

| Logistics/Distribution | High | Moving packaged goods | |

| Agriculture | High | Transporting grains, produce | |

| Heavy Mining | Low | Lacks high abrasion resistance |

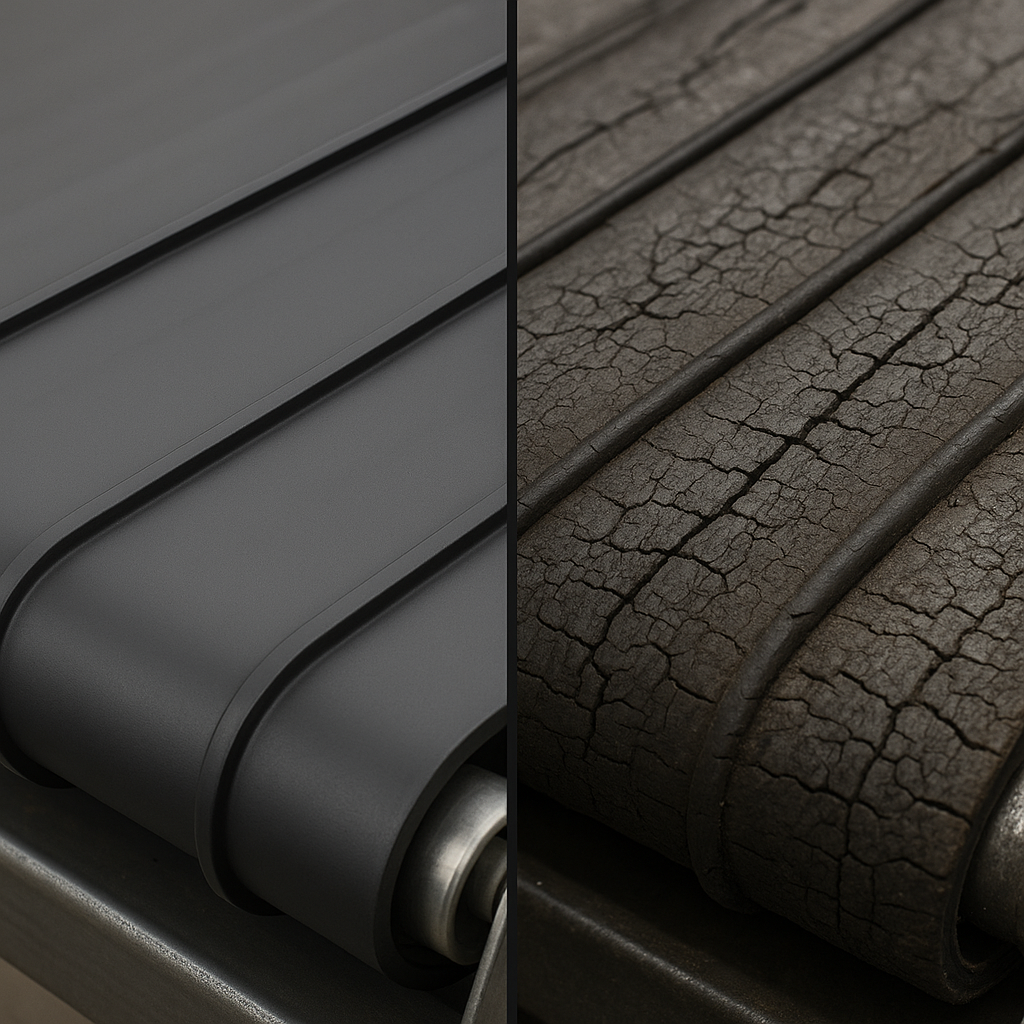

Abrasion-resistant rubber conveyor belt material.

Abrasion-resistant rubber conveyor belt material is specifically engineered to withstand scraping, rubbing, and friction from sharp or rough materials. It uses tough rubber compounds that prevent premature wear and extend the belt’s service life. This is critical for handling items like gravel, sand, or crushed rock.

What makes rubber abrasion-resistant?

High-quality polymers and specific carbon black fillers are added to the rubber compound to increase its toughness and tear strength. But here’s the kicker: the vulcanization process creates strong cross-links between polymer chains. This makes the surface less likely to chip or wear away under stress.

- High-Quality Polymer Base

- Specialized Carbon Black Fillers

- Strong Vulcanization Cross-links

Key Takeaway: The value of abrasion-resistant belting comes from its ability to reduce replacement frequency in harsh conditions.

| Grade | Description | Ideal For | |

|---|---|---|---|

| Grade I | Premium Resistance | Sharp, heavy materials (ore, glass) | |

| Grade II | General Resistance | Moderate materials (gravel, coal) |

Impact-resistant rubber conveyor belt material.

Impact-resistant rubber conveyor belt material is designed to absorb the energy from heavy, falling objects without puncturing or tearing. It features a durable top cover and often includes special breaker fabric layers beneath the surface. This construction protects the belt’s core from damage at loading points.

How does it handle heavy impact?

The belt’s resilience comes from a thick, elastic top rubber cover that deforms upon impact and then returns to its original shape. This is where it gets interesting: special fabric layers, known as breakers, are woven into the carcass to distribute the impact force over a wider area. This prevents localized damage.

- Thick, elastic top cover

- Energy-absorbing breaker plies

- Flexible carcass construction

Key Takeaway: Investing in impact resistance is non-negotiable for primary loading zones in heavy industry.

| Feature | Function | Benefit | |

|---|---|---|---|

| Thick Rubber Cover | Absorbs and dampens impact energy | Prevents cuts and gouges | |

| Breaker Plies | Distributes force across the carcass | Protects internal fabric layers |

Heat-resistant rubber conveyor belt material.

Heat-resistant rubber conveyor belt material is formulated to operate reliably at elevated temperatures without cracking, hardening, or degrading. It uses compounds like EPDM or SBR blended with special additives. This allows it to transport hot materials found in foundries, cement plants, and bakeries.

What are its temperature limits?

Different grades can handle a range of temperatures, typically from 100°C (212°F) up to 200°C (400°F) for short periods. What’s the real story? The belt’s true limit depends on both the material temperature and the duration of contact. Continuous exposure requires a higher-grade belt.

- Tier 1: Up to 100°C (212°F)

- Tier 2: Up to 150°C (300°F)

- Tier 3: Up to 200°C (400°F)

Key Takeaway: Choosing the right heat-resistant grade prevents belt delamination and ensures operational safety.

| Rating | Max Material Temperature | Example Application | |

|---|---|---|---|

| T1 | 100°C (212°F) | Hot pellets, dried foods | |

| T2 | 150°C (300°F) | Cement clinker, sintered ore | |

| T3 | 200°C (400°F) | Foundry sand, coke |

Oil-resistant rubber conveyor belt material.

Oil-resistant rubber conveyor belt material uses nitrile (NBR) or other synthetic compounds that do not swell, weaken, or degrade when exposed to petroleum-based or vegetable oils. Standard rubber absorbs oil, which causes it to soften and lose strength. This specialized material is essential for recycling, food processing, and metal stamping.

Which rubber type resists oil best?

Nitrile (NBR) is the most common and effective choice for oil resistance due to its chemical structure. But what does that mean for you? It means you can transport oily parts or handle oil-soaked materials without the belt swelling up and failing. This ensures consistent performance and a longer lifespan.

- MOR (Moderately Oil Resistant): For light exposure.

- OR (Oil Resistant): For consistent exposure.

Key Takeaway: For any application involving oils or fats, oil-resistant belting is a mandatory safety and operational requirement.

| Material | Oil Resistance | Main Benefit | |

|---|---|---|---|

| Nitrile (NBR) | Excellent | Prevents swelling and degradation | |

| Standard SBR | Poor | Swells, softens, and fails quickly |

Chemical-proof rubber conveyor belt material.

Chemical-proof rubber conveyor belt material is made from compounds like EPDM or Viton that can withstand acids, alkalis, and other corrosive substances. These materials are engineered to maintain their integrity and not leach chemicals. They are vital in fertilizer plants, chemical processing, and pharmaceutical manufacturing.

What chemicals can it withstand?

The specific resistance depends on the compound, with EPDM being excellent for acids and alkalis, while more expensive options handle aggressive solvents. You might be wondering if there’s a one-size-fits-all solution. There isn’t; you must match the belt material to the specific chemicals in your environment.

- EPDM: Resists acids, alkalis, and ketones.

- Nitrile: Resists oils and solvents but not strong acids.

- Viton: Offers broad resistance but at a higher cost.

Key Takeaway: Proper selection of a chemical-resistant belt is crucial for preventing dangerous failures and ensuring product purity.

| Compound | Resists | Not Recommended For | |

|---|---|---|---|

| EPDM | Acids, Alkalis, Ketones | Petroleum Oils, Solvents | |

| Nitrile | Oils, Solvents | Strong Oxidizing Acids |

Food-grade rubber conveyor belt material.

Food-grade rubber conveyor belt material is made from compounds that comply with strict regulatory standards (like the FDA) for direct contact with food. These belts are non-toxic, non-staining, and easy to clean. They also resist the buildup of bacteria and are often made with oil- and fat-resistant compounds.

What makes a rubber belt food-safe?

A belt is food-safe if its components are on an approved list of materials that will not transfer harmful substances to food. The bottom line is that every ingredient, from the rubber itself to the colorants and fabrics, must be certified. This ensures the safety and purity of the food product.

- Must use FDA-approved compounds.

- Resistant to oils and fats.

- Non-marking and non-toxic surface.

Key Takeaway: In food processing, using a certified food-grade belt is not optional—it is a legal and ethical requirement.

| Feature | Importance | Compliance Standard | |

|---|---|---|---|

| Non-Toxic Compounds | Prevents food contamination | FDA, EU Regulations | |

| Fat & Oil Resistance | Prevents belt degradation | Ensures belt longevity | |

| Easy-to-Clean Surface | Inhibits bacterial growth | HACCP Principles |

Choosing a rubber conveyor belt material.

Choosing the right rubber conveyor belt material requires a careful analysis of your specific operational needs. You must consider the product being moved, the environment, and performance requirements like speed and load. A systematic evaluation prevents costly mistakes and maximizes system efficiency.

How does product type affect choice?

The product’s characteristics—such as weight, temperature, sharpness, and oiliness—are the most important factors. Think about it this way: you wouldn’t use a general-purpose belt for hot asphalt. Matching the belt to the product is rule number one.

- Sharp/Abrasive: Requires an abrasion-resistant belt.

- Oily/Greasy: Requires a nitrile (NBR) belt.

- Hot Materials: Requires a heat-resistant (EPDM) belt.

What about load, speed, and incline?

Heavier loads and higher speeds require a belt with more reinforcing plies and greater tensile strength. Here’s something to consider: for incline applications, you’ll need a belt with a textured or cleated surface. These features prevent material rollback.

- Load: Determines required tensile strength.

- Speed: Affects cover wear and heat buildup.

- Incline: May require a profiled surface.

Key Takeaway: A checklist-based approach is the most reliable method for selecting the correct belt specification.

| Factor | Question to Ask | Why It Matters | |

|---|---|---|---|

| Product | Is it hot, oily, or sharp? | Determines compound type | |

| Load | What is the max weight per foot? | Determines tensile strength | |

| Environment | Is it exposed to chemicals/UV? | Determines cover compound |

Maintaining rubber conveyor belt material.

Maintaining your rubber conveyor belt material involves regular inspection, proper cleaning, and ensuring correct alignment and tension. Proactive maintenance is the key to preventing catastrophic failures and getting the maximum possible life from your investment. It is far cheaper to maintain a belt than to replace it unexpectedly.

How do you inspect for wear?

You should regularly look for signs of cracking, fraying at the edges, and uneven wear on the top cover. The trick is to catch these issues early before they compromise the belt’s structural integrity. A visual inspection schedule is your best defense.

- Check for cover cracks or gouges.

- Inspect edges for fraying or damage.

- Look for splice separation.

What actions extend belt lifespan?

Simple actions like keeping the belt properly tensioned, ensuring rollers are clean and functioning, and preventing material buildup can dramatically extend its life. Let’s be real: most premature failures come from neglect. Proper tracking and cleaning are simple but highly effective.

- Correct Belt Tracking/Alignment

- Proper Tensioning

- Regular Cleaning

Key Takeaway: A consistent maintenance program is the most effective way to protect your conveyor system and reduce long-term costs.

| Frequency | Task | Goal | |

|---|---|---|---|

| Daily | Visual check for mistracking | Prevent edge damage | |

| Weekly | Check for material buildup | Reduce wear and tension issues | |

| Monthly | Inspect splices and fasteners | Prevent catastrophic failure |

You now have the framework to choose the right rubber conveyor belt material, moving beyond guesswork to make informed decisions that prevent downtime and protect your products. Our vision is to empower every operation with durable, efficient, and perfectly matched conveyor solutions. For a personalized assessment of your needs, contact our specialists today to ensure your system performs at its peak.

Frequently Asked Questions (FAQ)

Q1: Can I use one rubber belt for both hot and cold items?It’s not recommended. A heat-resistant belt may become brittle at very low temperatures, while a standard belt will degrade with heat. It’s best to use a belt rated for the specific temperature range.

Q2: What’s the best rubber conveyor belt material for sharp rocks?You should choose a heavy-duty, abrasion-resistant belt with a high tear strength, often designated as Grade I. It should also have impact-resistant features like breaker plies if the rocks are loaded from a height.

Q3: How often should I replace my rubber conveyor belt?There is no fixed schedule; replacement depends on wear and tear. A proactive maintenance and inspection program will help you identify when a belt is nearing the end of its service life, preventing unexpected failures.

Q4: Can I repair a small tear in a rubber conveyor belt?Yes, small punctures and tears can often be repaired using special patches or vulcanizing kits. However, any damage that compromises the belt’s structural integrity, especially near the edges, may require a full replacement.

Q5: What’s the main difference between a PVC and a rubber conveyor belt?The primary difference is flexibility and durability. Rubber is generally more flexible and far more resistant to impact and abrasion, making it suitable for heavy-duty applications. PVC is less expensive and common for light-duty, general-purpose package handling.