Heavy industries constantly face the challenge of moving large volumes of bulk materials efficiently, safely, and at lower cost. Dependence on truck fleets leads to rising fuel expenses, frequent maintenance, and environmental strain. The smarter solution is a rubber conveyor belt system — engineered to deliver continuous, automated, and energy-efficient material flow. It not only enhances productivity but also supports sustainable operations that align with modern industrial and environmental standards.

Key types of rubber conveyor belt

The main types of rubber conveyor belt are defined by their internal reinforcement, known as the carcass, which dictates their strength and application. You can choose between belts with textile fabrics or high-strength steel cords. This choice is fundamental to the conveyor system’s design.

What are EP (textile) belts?

EP belts use a carcass made of polyester and nylon fabric, offering excellent flexibility and durability for a wide range of uses. They are a common choice for general-purpose conveying over short to medium distances.

- Good for horizontal and vertical conveying.

- Cost-effective and versatile.

- Available in multiple layers (plies) for added strength.

What are steel cord belts?

Steel cord belts contain parallel steel cables embedded in the rubber, providing exceptionally high tensile strength and low elongation. You might be wondering if you need this much strength.

- Ideal for long-distance, high-tension systems.

- Resist stretching and elongation over many kilometers.

- Suitable for handling very heavy bulk materials.

When is special reinforcement needed?

Special reinforcement is needed when your application involves high impact, sharp materials, or a risk of ripping. In these cases, a belt with a transverse steel reinforcement in the top cover can prevent catastrophic failures. Key Takeaway: The right rubber conveyor belt type depends entirely on your application’s specific demands for strength, length, and durability.

| Belt Type | Carcass Material | Primary Advantage | |

|---|---|---|---|

| EP Belt | Polyester/Nylon Fabric | Flexibility and Versatility | |

| Steel Cord Belt | Steel Cables | High Tensile Strength | |

| Reinforced Belt | Fabric/Steel + Steel Mesh | Rip and Impact Resistance | |

| This comparison shows that belt selection is a critical first step in system design. |

How a rubber conveyor belt is made

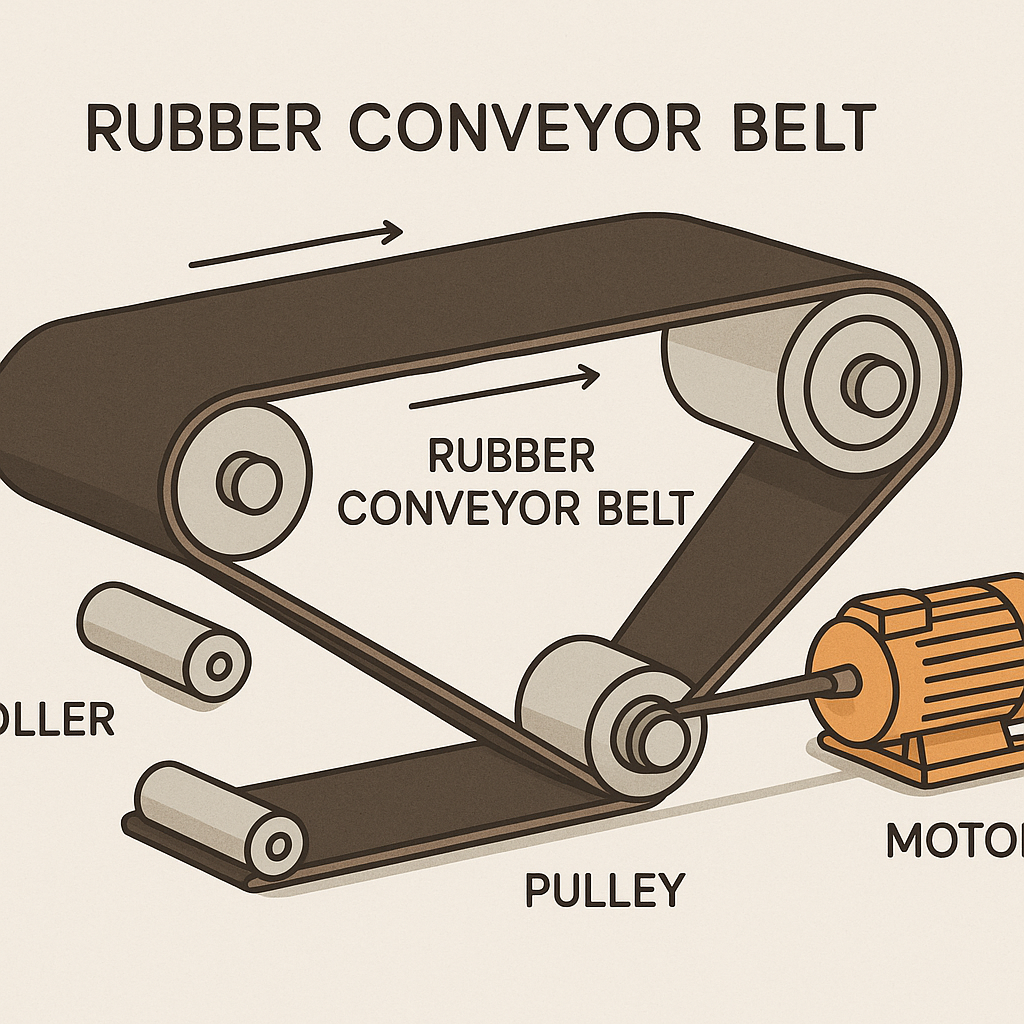

A rubber conveyor belt is manufactured through a precise two-stage process involving calendering and vulcanizing to create a durable, integrated product. This ensures the belt can withstand the intense demands of industrial use.

What is the calendering process?

Calendering is the first stage, where the belt’s carcass (either textile or steel) is coupled with the chosen uncured rubber compound. The components are pressed together through large rollers to create the raw, un-cured belt.

- Bonds the reinforcement layer to the rubber covers.

- Forms the belt to the correct width and thickness.

- Prepares the raw belt for the final curing stage.

What is the vulcanizing process?

What’s the real story? The raw belt then undergoes vulcanization, a chemical process that uses heat and pressure to cure the rubber. This transforms the soft, pliable rubber into a strong, elastic, and abrasion-resistant material.

- Creates permanent bonds between all components.

- Gives the belt its final strength and durability.

- Ensures the belt will perform reliably under stress.

Summary of manufacturing stages

From calendering to vulcanization, each step is critical to producing a high-quality rubber conveyor belt that meets specific operational requirements. The process ensures a seamless and robust construction. Key Takeaway: The manufacturing process is highly engineered to fuse the carcass and rubber covers into a single, resilient unit capable of handling extreme industrial stress.

| Stage | Process | Outcome | |

|---|---|---|---|

| 1. Calendering | Fusing carcass and raw rubber | An uncured, layered belt | |

| 2. Vulcanizing | Curing with heat and pressure | A strong, durable final product | |

| This streamlined process ensures every belt meets high performance standards. |

Uses for a rubber conveyor belt

The primary use for a rubber conveyor belt is the continuous handling and transport of bulk materials for heavy industries. It is the most technologically advanced and suitable method for conveying large quantities of goods without relying on wheeled vehicles.

What is bulk material handling?

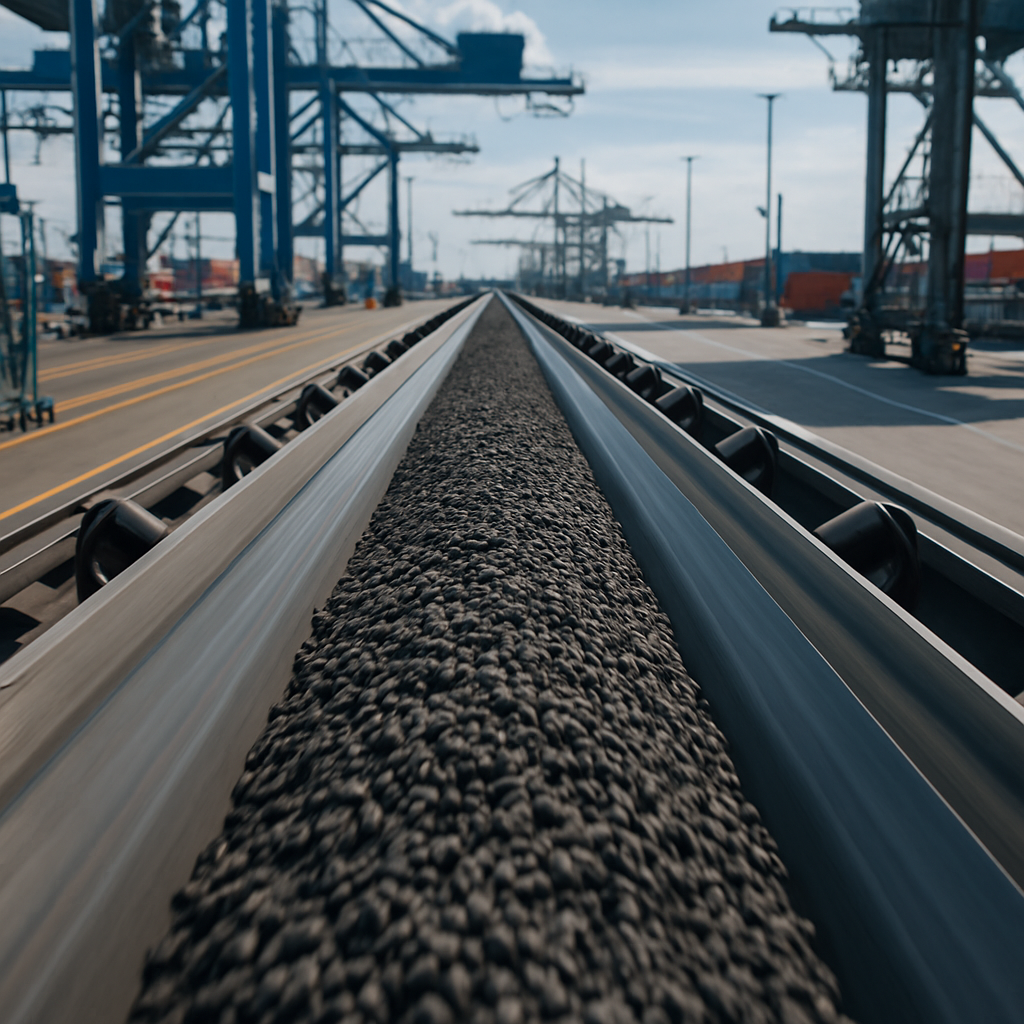

Bulk material handling refers to the transportation of loose, unpackaged items in large quantities. Here’s the deal: a rubber conveyor belt moves materials like ore, coal, grain, sand, and stone efficiently over a set path.

- Automates the movement of raw and processed goods.

- Connects different stages of an industrial process.

- Reduces manual labor and vehicle dependency.

Which industries use them most?

You will find rubber conveyor belt systems in a variety of sectors where moving large volumes is essential. These industries form the backbone of the global economy.

- Mining: Transporting extracted ore and minerals.

- Ports and Terminals: Loading and unloading ships.

- Cement and Steel Plants: Moving raw materials and finished products.

Summary of key applications

From extracting resources deep underground to loading them onto ships for global trade, the rubber conveyor belt is indispensable. Its applications are defined by the material being moved and the operational needs of the industry. Key Takeaway: Rubber conveyor belts are a fundamental component of logistics and production in nearly every heavy industry sector.

| Industry | Common Materials Handled | |

|---|---|---|

| Mining | Coal, Bauxite, Gold Ore, Iron Ore | |

| Agriculture | Grain, Sugar, Fertilizers | |

| Shipping | Bulk Cargo, Containers (in some systems) | |

| Construction | Sand, Gravel, Cement | |

| This table illustrates the wide-ranging utility of conveyor systems. |

Why use a rubber conveyor belt?

You should use a rubber conveyor belt to gain significant financial savings, a safer work environment, and a more efficient, continuous workflow. It is a strategic investment that modernizes your material handling operations.

How do they save money?

They dramatically lower operational costs by replacing expensive truck fleets. But here’s the kicker: you eliminate expenses related to fuel, driver salaries, and frequent vehicle maintenance, leading to substantial long-term savings.

- Lower energy consumption per ton compared to trucks.

- Fewer moving parts result in less maintenance.

- Reduced labor requirements for operation.

How do they improve workflow?

A rubber conveyor belt improves your workflow by providing an uninterrupted, 24/7 flow of materials. This eliminates the bottlenecks and delays common with vehicle-based transport, ensuring your production lines run smoothly.

- Enables fully automated and continuous operation.

- Eliminates truck queuing and loading/unloading times.

- Guarantees a consistent and predictable material supply.

Summary of business advantages

The advantages of a rubber conveyor belt are both financial and operational, creating a more streamlined and profitable business. This technology is a direct investment in your company’s productivity. Key Takeaway: Investing in a rubber conveyor belt system boosts your bottom line by cutting costs and simultaneously increasing operational efficiency.

| Feature | Conveyor System | Truck Transport | |

|---|---|---|---|

| Operating Cost | Low (Electricity, Low Maintenance) | High (Fuel, Labor, High Maintenance) | |

| Workflow | Continuous, 24/7 | Intermittent, Prone to Delays | |

| Environmental | Low Emissions, Minimal Footprint | High Emissions, Requires Roads | |

| This clear comparison highlights the superior efficiency of conveyor systems. |

The rubber conveyor belt in mining

A rubber conveyor belt is an ideal solution for the mining industry, where operators must overcome difficult terrain and logistical hurdles. It provides a reliable way to move vast quantities of material from remote extraction sites.

Why are they vital for mines?

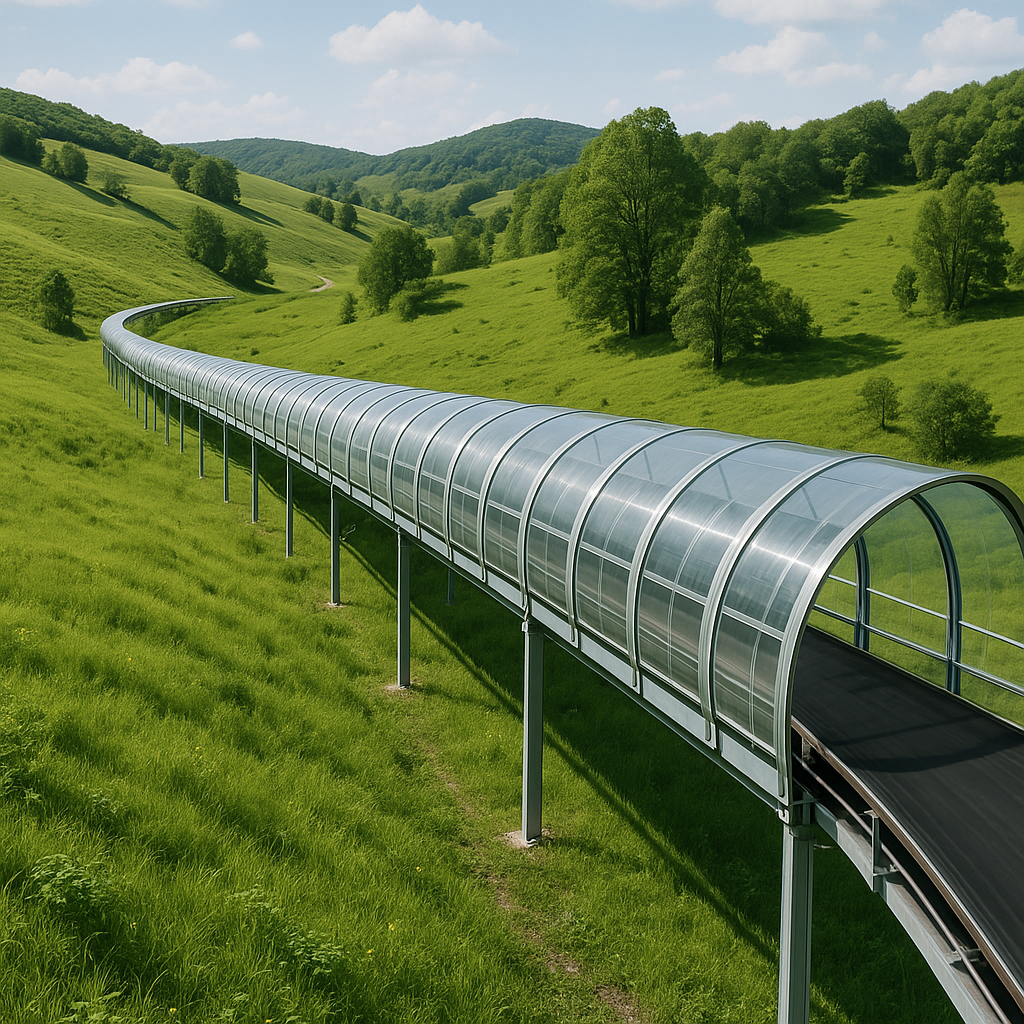

Mines are frequently located in deserts, canyons, or mountainous regions where building and maintaining roads for trucks is impractical or impossible. This is where it gets interesting: a rubber conveyor belt can be installed almost anywhere.

- Can traverse steep inclines and declines.

- Can be routed through tunnels or over obstacles.

- Requires minimal ground preparation compared to roads.

How do they handle tough terrain?

A rubber conveyor belt handles tough terrain by closely following the land’s natural contour, which minimizes environmental impact. This adaptability makes it the most suitable solution for connecting remote mining pits with processing facilities.

- Overcomes physical barriers like rivers and valleys.

- Reduces the need for extensive earthworks.

- Maintains operational efficiency regardless of topography.

Summary of mining suitability

The suitability of a rubber conveyor belt for mining operations is unmatched by any other material transport method. Its ability to conquer challenging environments makes modern mining possible in many locations. Key Takeaway: In the mining world, a rubber conveyor belt isn’t just an option; it’s often the only feasible technology for efficient material handling.

| Terrain Challenge | Conveyor Belt Solution | |

|---|---|---|

| Steep Mountains | High-angle conveyor systems | |

| Canyons or Rivers | Elevated or suspended belt structures | |

| Environmentally Sensitive Areas | Enclosed belts with minimal footprint | |

| Long, Flat Deserts | High-strength, long-distance overland conveyors | |

| This demonstrates how conveyors are engineered to solve specific geographical problems. |

Mining tasks for a rubber conveyor belt

Within a mining operation, a rubber conveyor belt executes several critical tasks that form a continuous chain from material extraction to final shipment. It seamlessly integrates the entire mine-to-port workflow.

What is material extraction handling?

Immediately after ore is blasted and extracted from the earth, a rubber conveyor belt is used to move it out of the mining pit. This first step is crucial for getting the raw material to the next stage of processing.

- Handles heavy, abrasive, and large-lump materials.

- Operates continuously to clear the extraction area.

- Often requires high-impact resistant belts.

Transporting to processing plants?

Once out of the pit, the ore is transported via a network of conveyor belts to various industrial plants for processes like washing, crushing, or refining. Think about it: this creates an automated factory-style flow across vast distances.

- Connects multiple processing stages without interruption.

- Ensures a steady supply of material to each plant.

- Can be routed to different destinations as needed.

How they aid in ship loading?

In the final step, a rubber conveyor belt transports the processed goods to a port terminal and loads them directly onto ships for export. This high-capacity loading is far more efficient than using trucks or cranes alone. Key Takeaway: The rubber conveyor belt acts as the logistical artery of a modern mining operation, connecting every stage of production into one highly efficient system.

| Mining Task | Conveyor Belt Role | Required Belt Feature | |

|---|---|---|---|

| Extraction | Move raw ore from pit | High impact & abrasion resistance | |

| Processing | Connect washing/refining plants | Versatility and reliability | |

| Shipment | Load bulk materials onto vessels | High capacity and speed | |

| This workflow illustrates the belt’s central role from start to finish. |

Select the right rubber conveyor belt

Selecting the right rubber conveyor belt requires a careful analysis of your conveyor system’s design and the specific characteristics of the material you will be handling. This decision directly impacts the system’s efficiency and lifespan.

How does conveyor length affect choice?

Conveyor length is a primary factor in belt selection. What does this all mean? For long-distance systems (over 500 meters), you typically need a steel cord belt to handle the high tension and prevent excessive stretching.

- Long distances (>500m): Steel cord belts are essential.

- Short-to-medium distances: EP textile belts are often suitable.

- Elongation must be minimized to ensure proper function.

What material characteristics matter?

You must analyze the material’s properties, including its abrasiveness, weight, lump size, and temperature. This information determines the most suitable top and bottom cover thicknesses and the specific rubber compound to use.

- Abrasiveness: Requires thicker, more durable covers.

- Lump Size: Influences impact resistance needs.

- Temperature: May require special heat-resistant rubber.

Summary of selection factors

A systematic review of all mechanical and material factors is essential for choosing a belt. A proper analysis ensures you select a product that provides optimal performance and a long service life. Key Takeaway: Don’t guess—base your rubber conveyor belt selection on hard data about your system and material to maximize your return on investment.

| Selection Factor | Key Question to Ask | |

|---|---|---|

| Conveyor Length | Will the belt stretch under tension? | |

| Material Abrasiveness | How quickly will the cover wear down? | |

| Material Weight/Size | Is high impact resistance needed? | |

| Special Conditions | Is the material hot, oily, or sharp? | |

| This checklist guides you toward making an informed decision. |

Rubber conveyor belt carcass choice

The carcass is the heart of a rubber conveyor belt, providing its tensile strength and structural integrity. Choosing between a textile or steel carcass is one of the most critical decisions in belt specification.

When is a textile carcass best?

A textile carcass, typically made of EP (Polyester/Nylon) fabric, is the universal solution for a wide range of applications. It is best for short to medium-length conveyors where extreme tension is not a factor.

- Offers good flexibility and impact resistance.

- A cost-effective choice for general-purpose conveying.

- Can be layered (plies) to increase strength.

When is a steel carcass needed?

Here’s a simple way to think about it: a steel carcass is the only option for long overland conveyors or high-tension applications. The steel cords inside provide immense strength and prevent elongation problems that would plague a textile belt over long distances.

- Essential for conveyor lengths exceeding 500 meters.

- Provides excellent longitudinal flexibility for troughing.

- Maintains its length under extreme tension.

Summary of carcass comparison

Your choice between textile and steel depends almost entirely on the length and tension requirements of your conveyor system. Both are excellent when applied in the correct context. Key Takeaway: Match the carcass to the job: textile for versatility and shorter distances, steel for strength and long-haul applications.

| Carcass Type | Best Use Case | Key Property | |

|---|---|---|---|

| Textile (EP) | General purpose, short/medium conveyors | Flexibility and cost-effectiveness | |

| Steel Cord | Long-distance, high-tension conveyors | Superior strength, low elongation | |

| This direct comparison simplifies the primary difference between the two core types. |

A rubber conveyor belt’s covers

The top and bottom covers of a rubber conveyor belt protect the internal carcass from damage and wear. The thickness and rubber compound of these covers are crucial for the belt’s performance and longevity.

Why are cover thicknesses important?

Cover thickness must be sufficient to protect the carcass from the material being conveyed. The top cover is typically thicker to withstand impact and abrasion, while the bottom cover protects against wear from rollers and idlers.

- Thicker top covers are used for heavy, sharp materials.

- Cover thickness is a key factor in the belt’s lifespan.

- It must be matched to the application’s severity.

What are specific rubber compounds?

The bottom line is this: standard rubber is not always enough. Specific rubber compounds are engineered to resist unique challenges, ensuring the belt survives in harsh conditions.

- Heat-resistant compounds: For handling hot materials like clinker.

- Oil-resistant compounds: For applications with oily materials like grain.

- Abrasion-resistant compounds: For sharp, abrasive materials like ore.

Summary of cover properties

Choosing the correct cover thickness and compound is just as important as selecting the right carcass. This decision directly determines how long your belt will last in its operating environment. Key Takeaway: The covers are the belt’s first line of defense; specifying them correctly is essential for protecting your investment.

| Rubber Compound | Designed to Resist | Common Application | |

|---|---|---|---|

| Abrasion-Resistant | Wear from sharp, hard materials | Mining and quarries | |

| Heat-Resistant | High temperatures | Cement plants, foundries | |

| Oil-Resistant | Swelling and degradation from oils | Agriculture, recycling | |

| This table helps you match the right protective cover to your specific challenge. |

Rubber conveyor belt eco-advantages

A major benefit of choosing a rubber conveyor belt system is its significantly smaller environmental impact compared to using a fleet of trucks. This makes it a more sustainable choice for modern industrial operations.

How do they reduce CO2 emissions?

Powered by electricity, a rubber conveyor belt eliminates the direct CO2 emissions produced by diesel-burning trucks. The best part? This move significantly lowers your operation’s carbon footprint and helps meet environmental regulations.

- No fossil fuel combustion on-site.

- Higher energy efficiency per ton-kilometer moved.

- Can be powered by renewable energy sources.

How do they limit infrastructure impact?

A conveyor system requires only a narrow, dedicated path, which avoids the need to build wide, permanent roads that scar the landscape. This minimizes habitat destruction and long-term disruption to the local ecosystem.

- Reduces earthmoving and deforestation.

- Follows the natural contour of the land.

- Can be removed with less permanent impact after use.

Summary of environmental benefits

From reducing air pollution to preserving natural landscapes, the environmental advantages of a rubber conveyor belt are clear and substantial. It is a technology that aligns with corporate responsibility goals. Key Takeaway: Opting for a rubber conveyor belt is a powerful, strategic move toward building a more sustainable and environmentally responsible industrial operation.

| Environmental Factor | Conveyor System Impact | Truck Transport Impact | |

|---|---|---|---|

| CO2 Emissions | Very Low (Indirect from electricity) | High (Direct from diesel fuel) | |

| Land Use | Minimal (Narrow corridor) | High (Requires wide, permanent roads) | |

| Noise Pollution | Low and consistent | High and intermittent | |

| This highlights the stark contrast in environmental performance. |

Conclusion

Rubber conveyor belts are a highly engineered, efficient, and versatile solution for modern bulk material handling. Choosing the correct rubber conveyor belt is a strategic investment that pays dividends in operational excellence, cost savings, and sustainable practice. Our vision is to empower industries with transport solutions that are not only productive but also responsible.

Ready to optimize your material handling? Contact an industrial solutions expert today to analyze your needs and design a conveyor system that delivers results.

FAQ Section

Q1: What’s the best rubber conveyor belt for long distances?A: For long distances (typically over 500 meters), a steel cord rubber conveyor belt is the best choice. Its steel carcass prevents stretching and handles the high tension required for such applications.

Q2: Can a rubber conveyor belt operate 24/7?A: Yes, rubber conveyor belt systems are designed for continuous, 24/7 operation. This allows for a constant, uninterrupted workflow, which is one of their main advantages over vehicle-based transport.

Q3: How does a rubber conveyor belt reduce pollution?A: A rubber conveyor belt reduces pollution primarily by eliminating the direct CO2 emissions from diesel trucks. Since they run on electricity, their environmental footprint is much smaller, especially if powered by renewable energy.

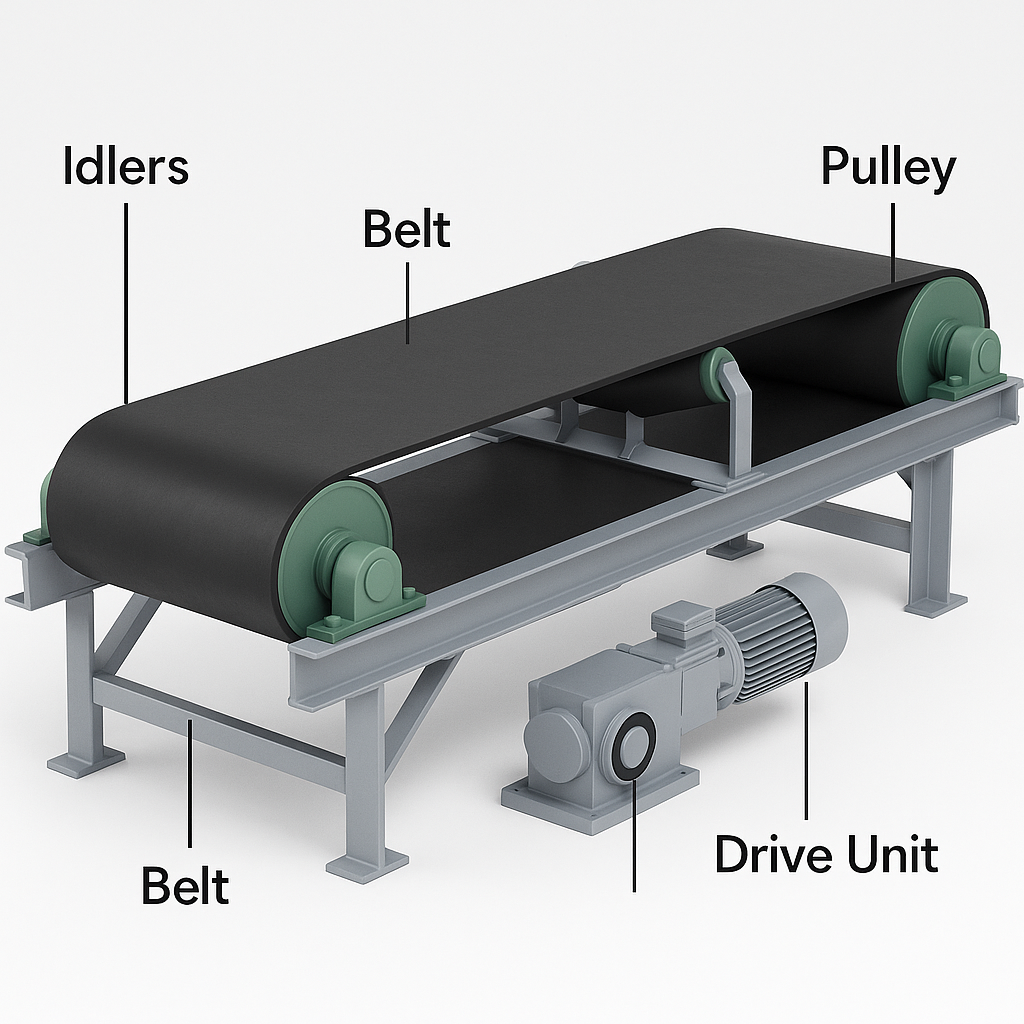

Q4: What are the main parts of a rubber conveyor belt?A: The two main parts are the internal carcass and the external rubber covers. The carcass (made of textile or steel) provides the belt’s tensile strength, while the rubber covers protect the carcass from abrasion, impact, and other environmental factors.

Q5: Can I use a rubber conveyor belt for abrasive material?A: Absolutely. You can use a rubber conveyor belt for abrasive materials by selecting one with a special abrasion-resistant rubber compound for its covers. These compounds are engineered to withstand wear from sharp and hard materials like ore and rock.