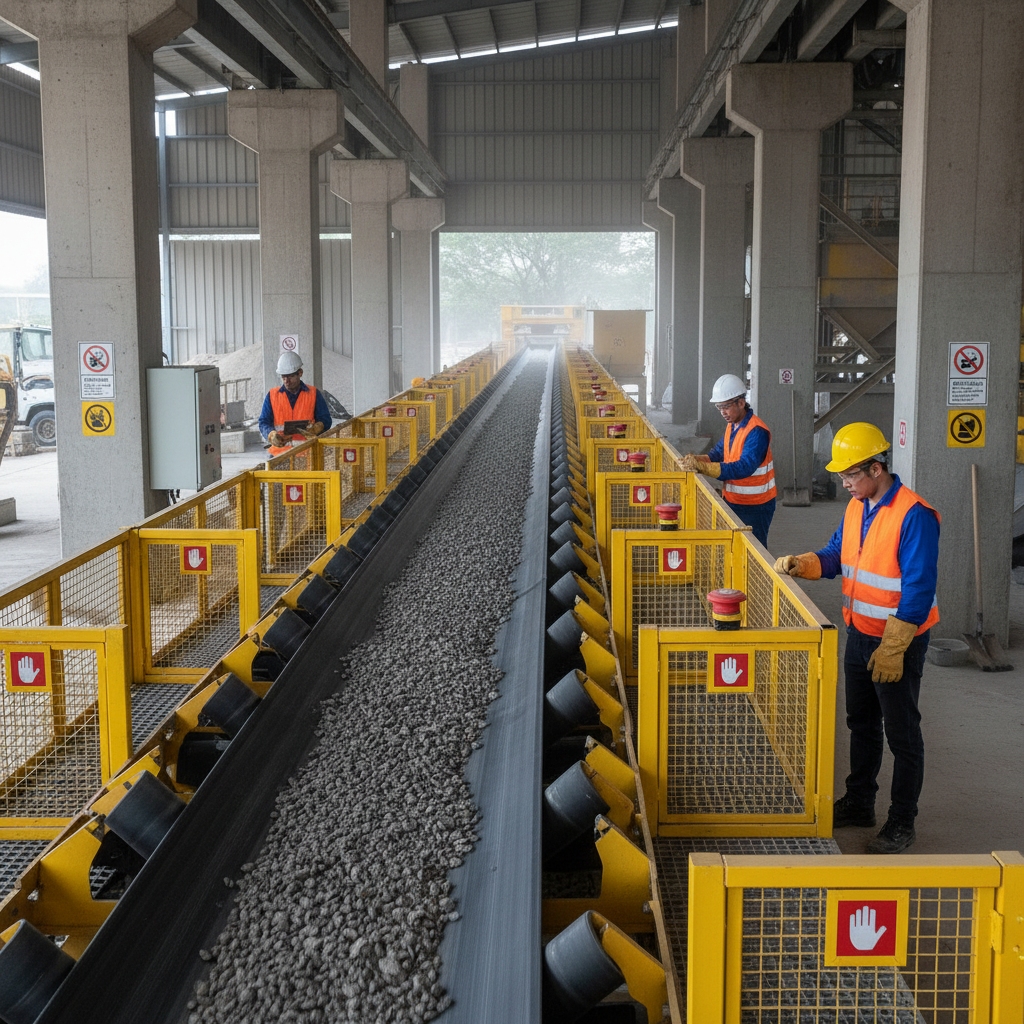

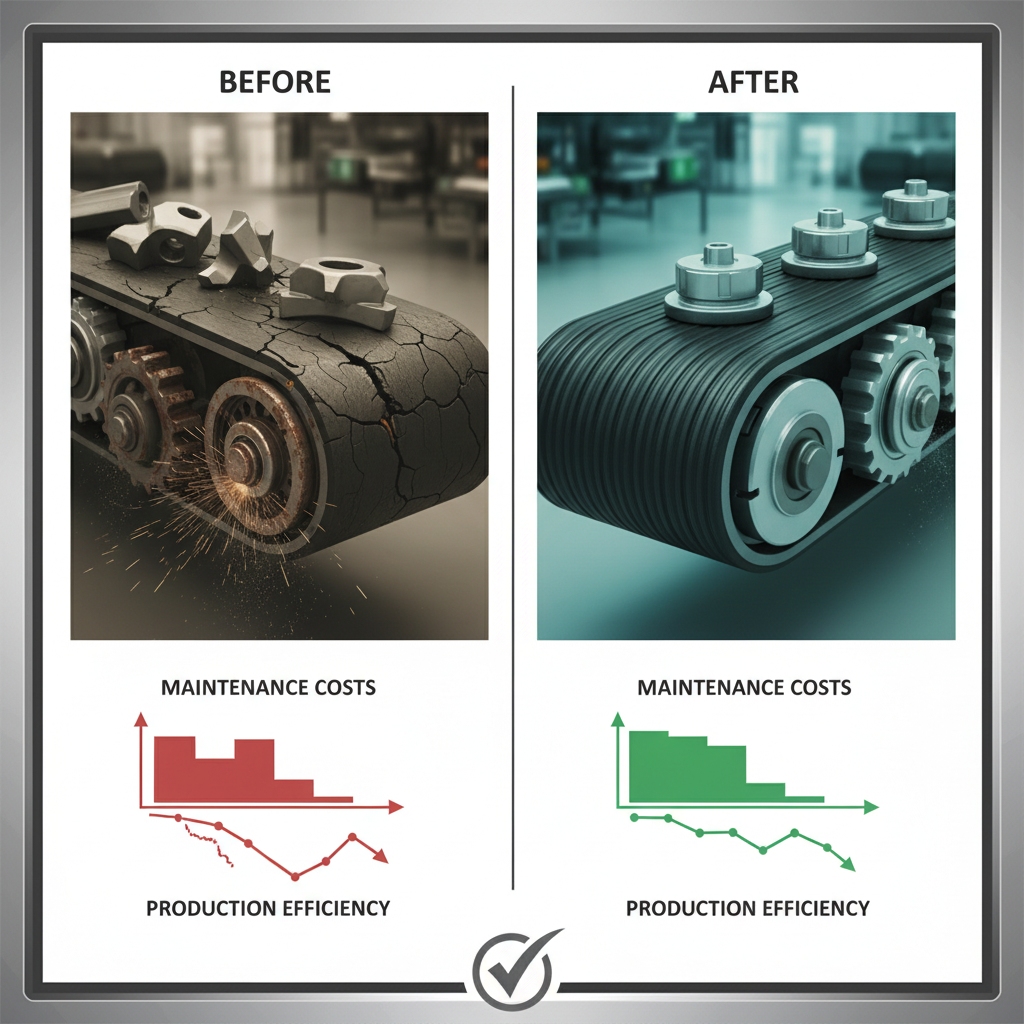

Quarry operations can face costly shutdowns when low-quality belting fails under the pressure of heavy stone. These interruptions derail production, compromise worker safety, and erode profitability with every passing minute. A high-performance black rubber conveyor belt delivers the strength, durability, and stability required to withstand aggressive aggregate environments—keeping your operation running smoothly and efficiently.

Selecting a Black Rubber Conveyor Belt

You must evaluate load weight and impact zones to choose the right black rubber conveyor belt. Matching tensile strength to your specific application prevents premature snapping. Incorrect specifications ruin efficiency.

Key Factors Impacting Performance

- Material weight: Heavier loads require higher tensile strength.

- Drop impact zones: High drops necessitate specialized carcasses.

- Operating tension: Essential for maintaining belt integrity.

| Key Takeaway | Metric | Impact | |

|---|---|---|---|

| Proper assessment prevents costly downtime | Tensile Strength | Prevents snapping |

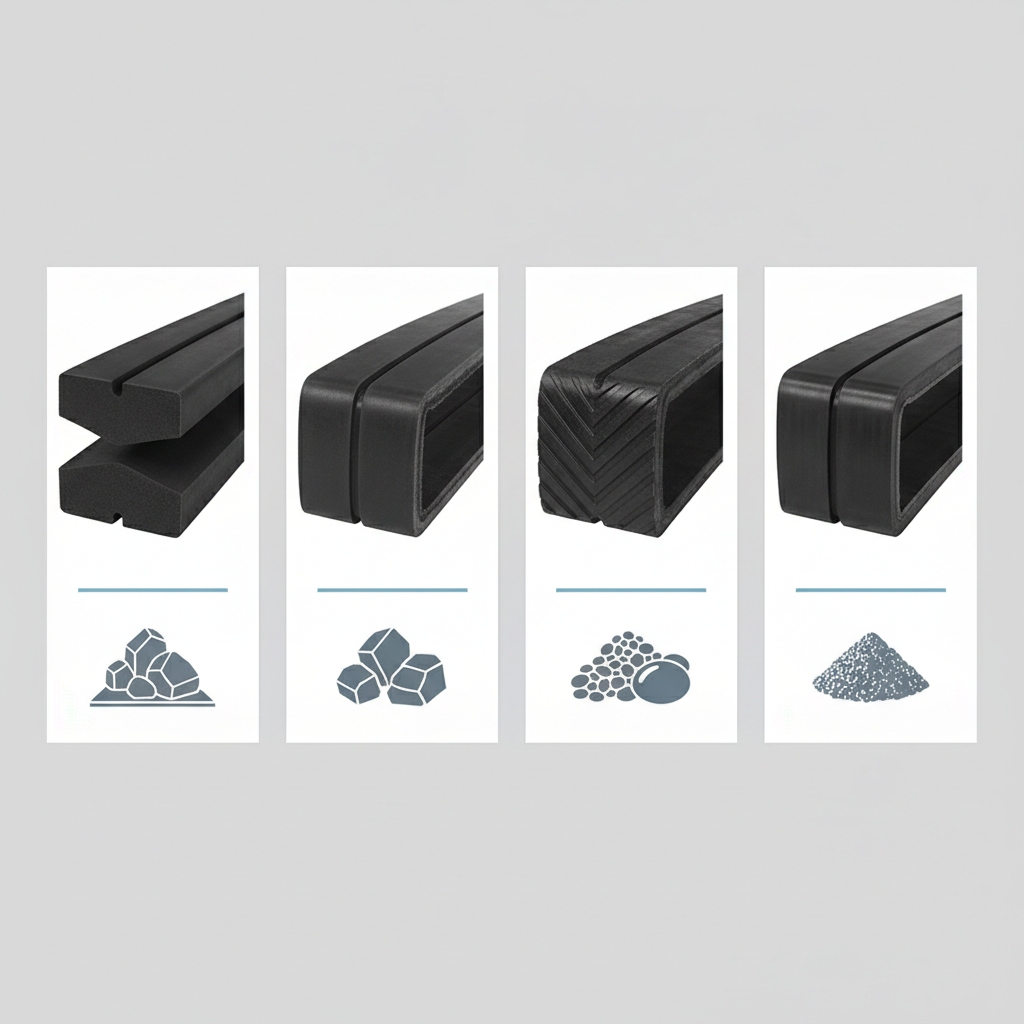

Two-Ply Black Rubber Conveyor Belt Basics

You can rely on this versatile black rubber conveyor belt for lighter aggregate transport applications. It works perfectly for sand or small gravel transport.

Ideal Applications

- Sand processing

- Light gravel

- Portable stackers

| Key Takeaway | Belt Type | Best Use | |

|---|---|---|---|

| Cost-effective solution for light duty | Two-Ply | Sand and Fines |

Three-Ply Black Rubber Conveyor Belt Power

You gain necessary carcass stability for heavy stone with this black rubber conveyor belt. Upgrade to this tier when moving heavy crushed stone volumes because weight demands strength.

Performance Benefits

- Higher impact rating

- Reduced stretch

- Better fastener holding

| Key Takeaway | Metric | Advantage | |

|---|---|---|---|

| Stronger carcass equals less maintenance | Load Support | 50% heavier loads |

Straight Warp Black Rubber Conveyor Belt

You achieve immense strength without bulk using this specialized black rubber conveyor belt. Straight polyester yarns locked by binders eliminate crimp, providing strength without unnecessary thickness.

Resistance Features

- 3x higher rip resistance

- High impact tolerance

- Excellent flexibility

| Key Takeaway | Construction | Benefit | |

|---|---|---|---|

| Solves impact zone failures effectively | Uncrimped yarns | Max tensile strength |

CFW Black Rubber Conveyor Belt Advantages

You prevent rip propagation in high-abuse zones with a Crows Foot Weave black rubber conveyor belt. This unique weave pattern locks yarns to prevent unraveling and locks tears in place.

Rip Prevention

- High fastener strength

- Superior adhesion

- Rip isolation

| Key Takeaway | Property | Performance | |

|---|---|---|---|

| Best option for sharp, jagged material | Tear Resistance | Isolates punctures |

Heavy-Duty Black Rubber Conveyor Belt Specs

You extend operational life by choosing the correct cover grade for your black rubber conveyor belt. Grade 1 covers offer the highest resistance to cutting.

Cover Considerations

- 0.25 inch top cover

- 0.18 inch standard cover

- 0.06 inch bottom cover

| Key Takeaway | Spec | Recommendation | |

|---|---|---|---|

| Thicker covers last significantly longer | Cover Grade | Grade 1 for primary rock |

Primary Crushing Black Rubber Conveyor Belt

You need maximum impact resistance to survive the drop onto a black rubber conveyor belt here. Only premium belts withstand the drop from a primary jaw crusher.

Preventing Issues

- Proper tension rating

- Correct idler spacing

- Stiff carcass design

| Key Takeaway | Zone | Requirement | |

|---|---|---|---|

| Stiffness prevents dangerous load spillage | Primary Crusher | Max impact resistance |

Sourcing a Black Rubber Conveyor Belt

You minimize costly delays by finding a supplier with local black rubber conveyor belt inventory. When belts break, speed saves money.

Supply Chain Essentials

- Same-day shipping options

- Nationwide warehousing

- Emergency service

| Key Takeaway | Service | Value | |

|---|---|---|---|

| Local stock reduces downtime to hours | Stock Availability | Reduces downtime |

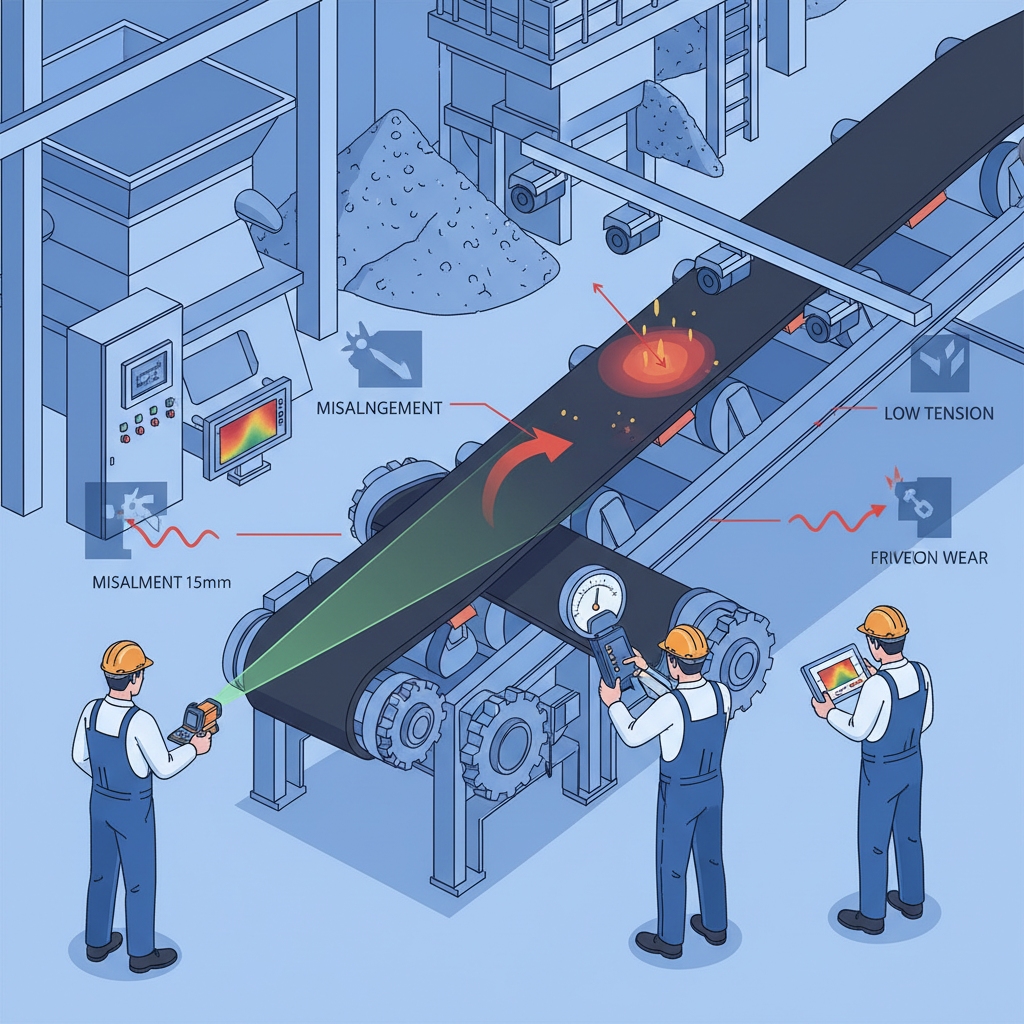

Installing Your Black Rubber Conveyor Belt

You must align the structure to ensure your black rubber conveyor belt tracks correctly. Verify structure alignment before applying tension.

Splicing Options

- Vulcanized: Maximum strength.

- Mechanical: Speed and ease.

- Cold bond: Alternative bonding method.

| Key Takeaway | Method | Note | |

|---|---|---|---|

| Square structure ensures straight tracking | Vulcanization | 90% strength retention |

Custom Black Rubber Conveyor Belt Solutions

You get perfect fitment with a custom-fabricated black rubber conveyor belt. We slit belts to your exact frame specifications, removing standard size limits.

Available Modifications

- Chevron patterns

- Sidewalls

- V-guides

| Key Takeaway | Modification | Use Case | |

|---|---|---|---|

| Modifications enable incline conveying | Cleats | Prevents rollback |

Conclusion

From cost-effective two-ply options to rugged Crows Foot Weaves, selecting the right black rubber conveyor belt is critical for aggregate efficiency. Empower seamless operations for a stronger future. Contact us to optimize your setup.

FAQ

Q1: What is the best black rubber conveyor belt for sharp granite?A Straight Warp or Crows Foot Weave belt is best. These reinforced weaves resist cutting and tearing better than standard multi-ply belts.

Q2: Can I use a two-ply belt for a primary crusher?No, it is generally not recommended. The high impact will likely puncture a two-ply belt; you need the stability of a 3-ply or straight warp belt.

Q3: How do I know if my belt needs replacing?Look for visible carcass exposure or edge fraying. If white fabric layers show through the top rubber cover, failure is imminent.

Q4: What is the difference between Grade 1 and Grade 2 covers?Grade 1 is designed for high-impact, sharp materials like trap rock. Grade 2 is a general-purpose cover for less abrasive materials like sand.

Q5: Can I repair a rip in a black rubber conveyor belt?Yes, use mechanical fasteners for small tears. However, for extensive longitudinal rips, replacing the section is safer to prevent failure.