Inefficient material handling slows productivity and drives up costs. Outdated equipment adds to the problem, causing frequent breakdowns and downtime. The key lies in a precise rubber conveyor belt manufacturing process — one that engineers each layer for superior strength, flexibility, and longevity, ensuring your production line runs smoothly and efficiently from start to finish.

Process Step 1: Material Sourcing

This initial stage involves carefully selecting all the raw components that will define the belt’s final properties. The process begins with sourcing high-quality natural or synthetic rubber, which forms the base of the conveyor belt. The specific grade of rubber is chosen based on the intended application’s demands for durability and resistance.

What raw materials are selected for the rubber?

The primary materials include natural rubber for flexibility and synthetic rubbers like SBR or Neoprene for resistance to oil and heat. Here’s the key: These are combined with reinforcing fillers to build a strong foundation. You must choose the right blend for your operational needs.

- Natural Rubber (NR)

- Styrene-Butadiene Rubber (SBR)

- Carbon Black

- Silica

Why is fabric carcass choice so important?

The fabric carcass provides the belt’s tensile strength and structural integrity, preventing it from stretching or breaking under load. The bottom line is your choice of fabric determines how much weight and stress the belt can handle. It acts as the skeleton of the entire belt.

- Polyester-Nylon (EP): Low stretch, high strength.

- Nylon-Nylon (NN): Excellent flexibility and troughability.

What is the purpose of sourcing additives?

Additives are sourced to give the rubber specific characteristics required for its operating environment. You might be wondering what they do; these chemicals can protect the belt from degradation due to heat, ozone, or abrasion. This customization is critical for longevity.

- Antioxidants: Protect against heat degradation.

- Antistatic agents: Prevent static buildup.

- Vulcanizing agents: Facilitate the curing process.

Key Takeaway: The quality of the final belt is determined before manufacturing even begins, through the precise selection of rubbers, fabrics, and chemical additives.

| Aspect | Description | Importance | |

|---|---|---|---|

| Rubber Base | Natural or synthetic rubber compounds. | Defines core flexibility and resistance. | |

| Fabric Carcass | Woven polyester or nylon layers. | Provides tensile strength and load support. | |

| Additives | Chemicals like antioxidants and fillers. | Customizes performance for specific environments. |

This meticulous material selection directly correlates with the belt’s future performance and lifespan.

Process Step 2: Compound Mixing

Compound mixing is where all the selected raw materials are homogenized into a consistent, unvulcanized rubber compound. This is typically done in a large, high-torque machine like a Banbury mixer, which generates heat and pressure to blend the components thoroughly. The resulting compound must have perfectly distributed ingredients to ensure uniform performance across the entire belt.

What happens inside the Banbury mixer?

Inside the mixer, rotors masticate the raw rubber while precisely measured amounts of fillers and additives are introduced. The process is intense: This mechanical shearing and heating action breaks down the rubber’s molecular structure, allowing it to uniformly blend with the other ingredients. The goal is to create a single, cohesive rubber mass.

- Raw rubber is softened.

- Additives are blended in.

- The mixture is heated through friction.

How do additives change belt properties?

Additives chemically and physically alter the rubber to enhance specific traits like fire resistance, oil resistance, or abrasion toughness. Think of it like this: you are programming the belt’s behavior by adding specific ingredients to the mix. Each additive has a distinct function.

- Carbon black increases tear strength.

- Plasticizers improve flexibility.

- Vulcanizing agents prepare the rubber for curing.

How is perfect rubber consistency achieved?

Achieving the perfect consistency requires precise control over mixing time, temperature, and the sequence in which ingredients are added. What’s the secret? Computer-controlled systems monitor the process, ensuring each batch meets exact specifications before it’s sheeted out for the next stage. This guarantees a uniform product.

- Monitored temperature and pressure.

- Timed ingredient addition.

- Batch-to-batch quality checks.

Key Takeaway: The mixing stage transforms individual raw materials into a single, high-potential rubber compound ready for shaping and curing.

| Element | Action | Outcome | |

|---|---|---|---|

| Banbury Mixer | Shears and blends materials. | Creates a hot, homogenous rubber mass. | |

| Additives | Integrate into the rubber matrix. | Impart specific performance properties. | |

| Process Control | Manages time, temp, and sequence. | Ensures consistent and uniform compound. |

This stage is foundational, as inconsistent mixing leads to weak spots and premature belt failure.

Process Step 3: Fabric Weaving

Fabric weaving creates the belt’s reinforcement layer, known as the carcass, which provides its tensile strength and dimensional stability. High-strength synthetic yarns like polyester and nylon are woven into dense fabrics on industrial looms. The weave pattern and yarn density are engineered to withstand the pulling forces experienced during operation.

How are EP and NN fabrics different?

EP (Polyester-Nylon) fabric uses polyester yarns for lengthwise strength and nylon for crosswise flexibility, offering excellent stability. On the other hand, NN (Nylon-Nylon) fabric uses nylon in both directions, providing superior flexibility and impact resistance. Your choice depends on the conveyor system’s design.

- EP Fabric: High modulus, low elongation.

- NN Fabric: High flexibility, good troughing ability.

How do you ensure tensile strength?

Tensile strength is ensured by using high-tenacity yarns and a tight, specific weave pattern during manufacturing. Here’s the deal: The number of fabric plies (layers) used in the final belt directly multiplies its overall strength. More plies equal a stronger belt for heavy-duty applications.

- Use of high-strength synthetic yarns.

- Tightly controlled weaving process.

- Layering multiple plies for added strength.

Why is treating the fabric so vital?

The woven fabric must be treated with a special solution to promote adhesion between the fabric and the rubber layers. Without this step, the rubber could peel away from the carcass under stress, a failure known as delamination. This treatment ensures all components bond into a single, durable unit.

- Improves bond strength.

- Prevents delamination.

- Creates a unified belt structure.

Key Takeaway: The fabric carcass acts as the belt’s skeleton, providing all the necessary tensile strength to handle operational loads without stretching or snapping.

| Fabric Type | Primary Benefit | Best Use Case | |

|---|---|---|---|

| EP (Polyester-Nylon) | Dimensional stability, low stretch. | Long, high-tension conveyors. | |

| NN (Nylon-Nylon) | Superior flexibility, impact resistance. | Troughing and short-distance conveyors. | |

| Adhesion Treatment | Strong rubber-to-fabric bond. | Essential for all belt types to prevent delamination. |

The quality of the fabric weave is a direct predictor of the belt’s load-bearing capacity.

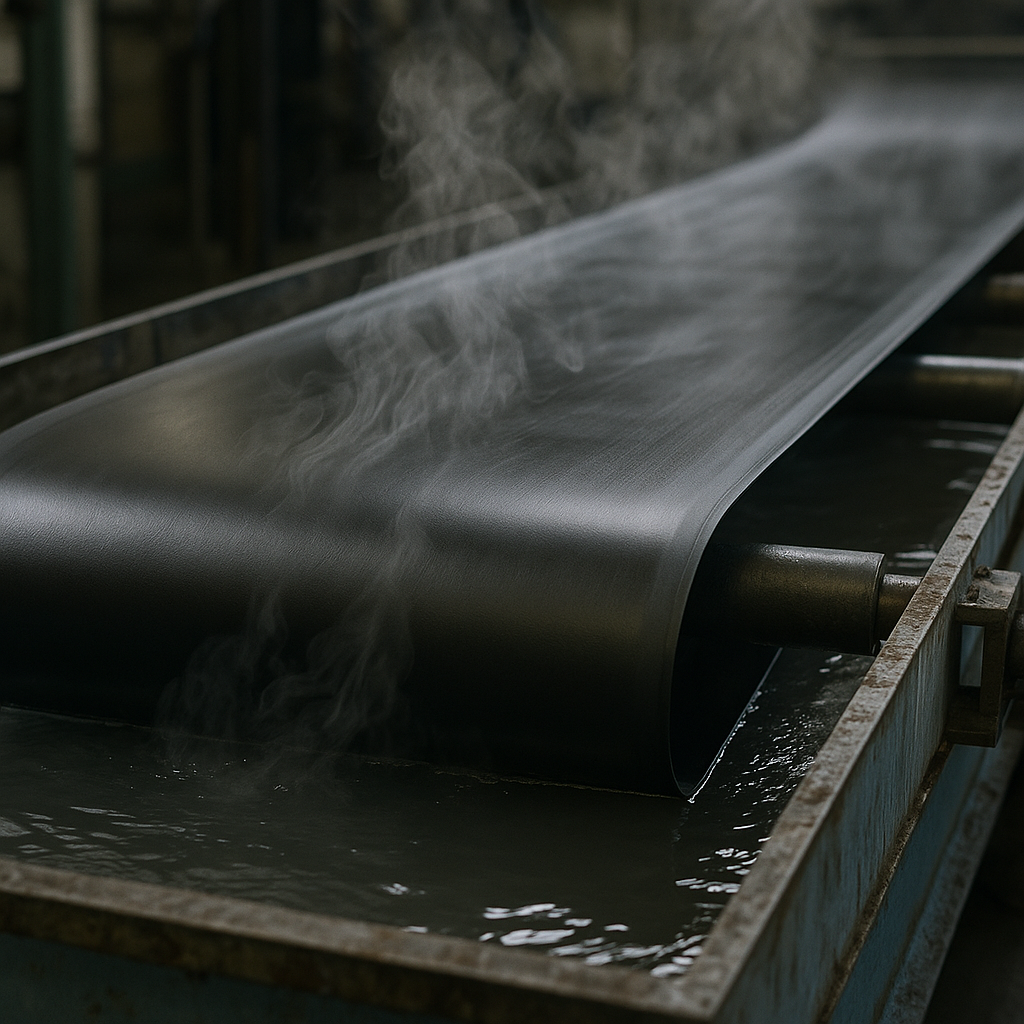

Process Step 4: Calendaring

Calendaring is the process where the mixed rubber compound is pressed into smooth, uniform sheets of a specific thickness. The warm, pliable rubber is fed through a series of large, heated rollers that squeeze it into a continuous sheet. This step is also used to apply the first layers of rubber directly onto the treated fabric carcass.

What is the calendaring machine’s role?

The calendering machine’s primary role is to transform the lumpy, mixed rubber compound into a thin, uniform sheet. It’s a critical step for ensuring the final belt has a consistent thickness from edge to edge. It functions like a giant, industrial-grade rolling pin.

- Flattens rubber compound.

- Controls sheet thickness.

- Prepares rubber for layering.

How is uniform thickness achieved?

Uniform thickness is achieved by maintaining a precise, computer-controlled gap between the massive steel rollers. The secret is precision: Sensors continuously measure the rubber sheet as it exits the rollers and make micro-adjustments to the gap. This ensures every inch of the sheet meets specification.

- Computer-controlled roller gaps.

- Laser or optical thickness sensors.

- Constant feedback and adjustment.

Applying the first rubber layer to fabric.

During calendaring, the treated fabric carcass can be fed through the rollers along with the rubber. Look at it this way: The pressure from the rollers forces the rubber to permeate and bond with the fabric surface. This creates a single, integrated ply of rubber-coated fabric.

Fabric and rubber are fed simultaneously.

Pressure embeds rubber into the fabric.

Creates the first bonded layer.

Key Takeaway: Calendaring creates perfectly uniform rubber sheets and applies the initial rubber coating to the fabric, preparing the components for final assembly.

Process

Function

Result

Sheeting

Squeezing rubber through rollers.

A uniform, continuous rubber sheet.

Frictioning

Forcing rubber into fabric weave.

A strong mechanical bond.

Coating

Applying a rubber layer onto fabric.

A smooth, rubberized fabric ply.

This process ensures that every layer of the belt is perfectly consistent before being assembled.

Process Step 5: Belt Laminating

Multiple layers of woven fabric carcass being fed into rollers for lamination.

Belt laminating is the assembly stage where individual plies of rubber-coated fabric and rubber sheets are layered together to build the belt to its final thickness. A building machine carefully stacks the calendered layers in the correct sequence, including the bottom cover, fabric plies, and top cover. This unvulcanized, multi-layered structure is then ready for the final curing process.

How are multiple layers bonded together?

The layers are bonded together through pressure as they are assembled on the building machine. The key is tackiness: The unvulcanized rubber has a natural stickiness that holds the layers together temporarily before they are permanently fused during vulcanization. Rollers press the layers firmly to remove any trapped air.

Layers are stacked in sequence.

Pressure rollers ensure contact.

Natural tack of the rubber creates a temporary bond.

Is a special adhesive used for lamination?

Generally, a separate adhesive is not needed because the unvulcanized rubber itself acts as the bonding agent. However, in some cases, a thin layer of highly tacky rubber, known as a tie-gum, is used between plies. This enhances the bond strength, especially in heavy-duty belts.

Unvulcanized rubber provides natural adhesion.

Tie-gum layers can be added for extra bond strength.

How is layer alignment maintained?

Precise alignment is maintained using automated guides and sensors on the belt building machine. You might be wondering how it stays straight; these systems ensure each ply is perfectly centered as it is added to the stack. Misalignment can create weak spots and cause the belt to track incorrectly during operation.

Automated optical or laser guides.

Tension control systems on feeding racks.

Manual checks by skilled operators.

Key Takeaway: Lamination is the careful, precise assembly of all belt components into a single, multi-layered structure before it undergoes permanent curing.

Step

Purpose

Method

Stacking

Assembling layers in order.

Automated belt building machine.

Bonding

Adhering layers together.

Pressure and the natural tack of rubber.

Aligning

Ensuring all layers are centered.

Laser guides and tension control.

Proper lamination is crucial for preventing air pockets and ensuring a uniform belt structure.

Process Step 6: Vulcanizing

A massive press uses intense heat and pressure to vulcanize a rubber conveyor belt.

Vulcanization is the chemical process that cures the rubber, transforming it from a soft, pliable material into a strong, durable, and elastic product. The laminated belt is placed into a large hydraulic press where it is subjected to intense heat and pressure for a specific amount of time. This step permanently cross-links the rubber molecules, locking the belt’s shape and properties.

What happens during vulcanization?

During vulcanization, the sulfur and other curing agents mixed into the rubber form chemical bridges between long-chain polymer molecules. Here’s the transformation: This creates a stable, three-dimensional molecular network. The process permanently fuses all the layers of rubber and fabric into a single, solid slab.

Rubber molecules form cross-links.

Layers of rubber and fabric are fused.

The belt’s final properties are set.

How does this process create strength?

The cross-linked molecular structure prevents the polymer chains from moving independently, which is why vulcanized rubber is much stronger and more elastic than raw rubber. It’s like this: a bowl of uncooked spaghetti (raw rubber) becomes a solid, unified mass when cooked (vulcanized). This network structure resists tearing and abrasion.

Prevents polymer chain slippage.

Increases tensile strength and elasticity.

Improves resistance to abrasion and heat.

Why is pressure as vital as heat?

Pressure is vital to ensure that all layers are in intimate contact, eliminating any trapped air or potential voids between them. You can’t have one without the other: It also ensures the belt maintains a uniform thickness and density during the curing process. The combination of heat and pressure guarantees a solid, flawless belt.

Removes trapped air and voids.

Ensures uniform density and thickness.

Forces layers into a single monolithic structure.

Key Takeaway: Vulcanization is the irreversible chemical reaction that gives the conveyor belt its final strength, elasticity, and durability.

Factor

Role in Vulcanization

Impact on Belt

Heat

Activates the chemical cross-linking reaction.

Cures the rubber, making it strong.

Pressure

Compresses layers and removes air.

Creates a solid, dense, void-free product.

Time

Controls the extent of the reaction.

Determines the final cure level and properties.

This step is the most critical in defining the belt’s ultimate physical performance characteristics.

Process Step 7: Surface Finishing

A sharp trimming tool cuts the edge of a thick black rubber conveyor belt for a clean finish.

Surface finishing involves the final steps to prepare the belt’s surface and edges after it has been vulcanized and cooled. This can include creating textured patterns for specific applications or trimming the belt’s edges to ensure it is perfectly straight and meets precise width specifications. This stage ensures the belt is ready for installation and use.

How are smooth vs. textured surfaces made?

Smooth surfaces are the default result of using smooth plates in the vulcanizing press. To create texture, patterned plates, like those for a chevron or rough top design, are used during the vulcanization process. The rubber flows into the pattern under heat and pressure, permanently molding the texture into the belt’s top cover.

Smooth press plates create a smooth finish.

Engraved plates mold textured patterns.

The pattern is set during vulcanization.

What is the purpose of a rough top belt?

A rough top belt provides extra grip for transporting items up or down an incline, preventing them from sliding back. Think of it as tread on a tire: This texture is essential in applications like package handling, airport baggage systems, and food processing. It increases the coefficient of friction.

Prevents slippage on inclines.

Ideal for package and baggage handling.

Increases grip for lightweight goods.

Why is precise edge trimming necessary?

Precise edge trimming ensures the belt has a uniform width along its entire length, which is critical for proper tracking on the conveyor system. The bottom line is uneven edges can cause the belt to wander from side to side, leading to damage and operational failure. Trimming creates a clean, straight, and durable edge.

Ensures uniform belt width.

Critical for proper belt tracking.

Prevents edge fraying and damage.

Key Takeaway: Finishing perfects the belt’s dimensions and surface characteristics, tailoring it for its specific application and ensuring reliable operation.

Finishing Step

Purpose

Application

Surface Molding

Create smooth or textured surfaces.

Incline conveying, general use.

Edge Trimming

Ensure uniform width.

All conveyor belts for proper tracking.

Cooling

Stabilize the rubber post-vulcanization.

All belts to prevent deformation.

This final touch-up ensures the belt is not only functional but also perfectly manufactured to specification.

Process Step 8: Quality Testing

A quality control inspector uses a micrometer to measure the thickness of a rubber conveyor belt.

Quality testing is a continuous process of rigorous checks and inspections performed at multiple stages to ensure the final product meets all performance and safety standards. Samples are taken from production runs and subjected to a battery of destructive and non-destructive tests. This guarantees that every belt leaving the factory is free from defects and performs as expected.

How is tensile strength tested?

Tensile strength is tested by cutting a sample piece from the belt and pulling it apart in a machine called a tensometer. This is a crucial test: The machine measures the force required to break the belt and how much it elongates before failing. This data verifies that the belt meets its specified strength rating.

A sample is cut from the belt.

A tensometer pulls the sample until it breaks.

Measures breaking force and elongation.

How do you check for hidden defects?

Hidden defects like air bubbles, voids, or delamination are checked using non-destructive methods like X-ray or ultrasonic scanning. You can’t just rely on visual checks: These technologies allow inspectors to see inside the belt’s structure without damaging it. Any belt with internal flaws is immediately rejected.

X-ray inspection for internal voids.

Ultrasonic scanning for delamination.

Visual inspection for surface cracks and blisters.

What certifications should a quality belt have?

A quality belt should have certifications that comply with international standards, such as ISO (International Organization for Standardization) or DIN (German Institute for Standardization). Look for these marks of quality: Specific certifications for fire resistance (ISO 340) or abrasion resistance (ISO 4649) also validate the belt’s suitability for hazardous environments.

ISO 9001 for quality management.

DIN 22102 for general belt standards.

Application-specific certs (e.g., fire, oil resistance).

Key Takeaway: Relentless quality testing at every stage is the only way to guarantee a conveyor belt is safe, reliable, and will perform under pressure.

Test Type

Purpose

Method

Tensile Test

Verify breaking strength and elongation.

Tensometer machine.

Abrasion Test

Measure resistance to wear and tear.

Rotating drum abrader.

Adhesion Test

Check bond strength between layers.

Pulling plies apart with a force gauge.

These tests provide quantifiable proof of the belt’s manufacturing quality and performance capabilities.

Process Step 9: Belt Cutting

A large industrial saw cuts a long, rolled-up rubber conveyor belt to a specific length.

Belt cutting is the final manufacturing step where the long, continuous slab of conveyor belting is cut to the specific lengths ordered by the customer. This process must be done with high precision to ensure the belt fits the customer’s conveyor system perfectly. The ends are also prepared for splicing, which is the process of joining them to form a continuous loop.

How are belts cut to customer lengths?

Belts are rolled out onto a long cutting table and cut to precise lengths using large, automated cutting machines. Accuracy is everything: These machines use powerful rotary blades or water jets to make a clean, perfectly square cut. This ensures the belt ends will align perfectly for splicing.

Automated cutting tables with measuring systems.

High-speed rotary blades or water jet cutters.

Cuts are made at a perfect 90-degree angle.

What is done to prepare ends for splicing?

To prepare the ends for splicing, the rubber layers are carefully stripped back in a stepped pattern to expose the fabric plies. This preparation is critical: This allows the plies of the two ends to be overlapped and bonded together, creating a splice that is nearly as strong as the belt itself. The surface is also buffed to promote adhesion.

Rubber covers are removed.

Fabric plies are exposed in steps.

Surfaces are cleaned and buffed.

Can belts be made endless at the factory?

Yes, belts can be made “endless” at the factory by performing the splice before the belt is shipped. This offers a huge advantage: A factory-made endless belt is spliced in a controlled environment using a press, resulting in a stronger and more reliable join than one made on-site. This is ideal for ensuring maximum belt life.

Ends are joined using a vulcanizing press.

Creates a strong, seamless loop.

Recommended for critical applications.

Key Takeaway: The cutting and end-preparation stage customizes the belt for a specific conveyor system and is the first step in creating a strong, reliable endless loop.

Action

Purpose

Benefit

Length Cutting

Cut belt to customer’s required size.

Ensures a perfect fit for the conveyor.

End Preparation

Prepare belt ends for joining.

Enables a strong and durable splice.

Factory Splicing

Create an endless loop before shipping.

Provides a superior, more reliable join.

This final customization step ensures the belt arrives ready for seamless integration into your system.

Process Step 10: Packing & Shipping

A large, heavy-duty rubber conveyor belt is rolled up and wrapped for shipping in a warehouse.

The final stage of the manufacturing process is packing and shipping, where the finished conveyor belt is prepared for safe transport to the customer’s location. The belt is carefully rolled onto a core, wrapped in protective materials, and securely strapped to prevent damage during handling and transit. Proper packing ensures the belt arrives in perfect condition, ready for installation.

How are belts rolled for safe transport?

Belts are typically rolled with the top cover facing inwards to protect the carrying surface from scratches and impacts. Here’s the standard practice: They are wound onto a sturdy core to prevent the roll from collapsing and are often secured with a “belly band” to keep the roll tight. The direction of the roll is clearly marked to simplify unrolling on-site.

Rolled with the carrying surface inside.

Wound onto a strong central core.

Clearly marked for easy installation.

How is the belt protected from damage?

The entire roll is wrapped in durable, waterproof material, such as polypropylene or reinforced plastic sheeting. This is essential protection: This wrapping shields the belt from moisture, UV radiation, and dirt during storage and shipping. For heavy-duty belts, wooden or steel cradles may be used for added structural support.

Wrapped in waterproof, tear-resistant material.

Protects against UV, moisture, and contamination.

Cradles or pallets are used for heavy rolls.

What documentation accompanies the belt?

Each shipment is accompanied by critical documentation that identifies the product and its specifications. Don’t lose this paperwork: This typically includes a packing list, the belt’s technical data sheet, quality control and testing certificates, and installation instructions. This ensures you have all the necessary information for receiving and installing the belt correctly.

Packing list with roll details.

Technical data sheet and specifications.

Quality certificates and installation guides.

Key Takeaway: Careful packing and complete documentation are the final steps to ensure the high-quality, factory-made belt reaches you safely and is ready for a long service life.

Packing Element

Function

Importance

Rolling Method

Protects the belt’s carrying surface.

Prevents damage and simplifies installation.

Protective Wrap

Shields from environmental factors.

Keeps the belt clean and dry until use.

Documentation

Provides technical and logistical info.

Ensures proper identification and handling.

This final step bridges the gap between the factory floor and your operational success.

Your Partner in Material Handling

By understanding the intricate process behind rubber conveyor belt manufacturing, you can better appreciate the quality and durability engineered into every roll. We are committed to a vision of seamless industrial flow, where high-quality components eliminate operational bottlenecks and drive productivity. For a conveyor belt solution that is built to last and designed for your specific needs, let’s connect.

Frequently Asked Questions (FAQ)

1. Can I order a conveyor belt with a specific thickness or width?Absolutely. Conveyor belts are manufactured to custom specifications, allowing you to order the exact width, length, and thickness required for your unique application and conveyor system.

2. What’s the best type of rubber belt for high-temperature environments?For high-temperature environments like foundries or cement plants, you should use a heat-resistant belt made from special rubber compounds like EPDM (Ethylene Propylene Diene Monomer), which can withstand temperatures well above standard belts.

3. On average, how long can I expect a high-quality rubber conveyor belt to last?The lifespan of a high-quality belt varies greatly based on the application, material being conveyed, and maintenance schedule, but with proper care, many belts can last for several years in demanding industrial environments.

4. Is it more cost-effective to repair a damaged belt section or replace the entire belt?For small punctures or localized damage, a professional repair is often more cost-effective. However, if the belt has extensive edge wear, long rips, or carcass damage, replacing the entire belt is usually the safer and more economical long-term solution.

5. What is the functional difference between an EP and NN fabric carcass?EP (Polyester-Nylon) fabric offers excellent dimensional stability and low stretch, making it ideal for long, high-tension conveyors. NN (Nylon-Nylon) fabric provides superior flexibility and impact resistance, which is better for troughing conveyors or systems with smaller pulley diameters.