Inefficient material handling creates bottlenecks that drain your productivity and increase costs. Relying on subpar equipment makes it worse, with frequent breakdowns and costly downtime halting your entire production line. High-performance rubber conveyor belts, engineered through a meticulous manufacturing process, are the solution to ensure your operations run smoothly and reliably.

Process Step 1: Material Sourcing

This initial stage involves carefully selecting all the raw components that will define the belt’s final properties. The process begins with sourcing high-quality natural or synthetic rubber, which forms the base of the conveyor belt. The specific grade of rubber is chosen based on the intended application’s demands for durability and resistance.

What raw materials are selected for the rubber?

The primary materials include natural rubber for flexibility and synthetic rubbers like SBR or Neoprene for resistance to oil and heat. Here’s the key: These are combined with reinforcing fillers to build a strong foundation. You must choose the right blend for your operational needs.

- Natural Rubber (NR)

- Styrene-Butadiene Rubber (SBR)

- Carbon Black

- Silica

Why is fabric carcass choice so important?

The fabric carcass provides the belt’s tensile strength and structural integrity, preventing it from stretching or breaking under load. The bottom line is your choice of fabric determines how much weight and stress the belt can handle. It acts as the skeleton of the entire belt.

- Polyester-Nylon (EP): Low stretch, high strength.

- Nylon-Nylon (NN): Excellent flexibility and troughability.

What is the purpose of sourcing additives?

Additives are sourced to give the rubber specific characteristics required for its operating environment. You might be wondering what they do; these chemicals can protect the belt from degradation due to heat, ozone, or abrasion. This customization is critical for longevity.

- Antioxidants: Protect against heat degradation.

- Antistatic agents: Prevent static buildup.

- Vulcanizing agents: Facilitate the curing process.

Key Takeaway: The quality of the final belt is determined before manufacturing even begins, through the precise selection of rubbers, fabrics, and chemical additives.

| Aspect | Description | Importance | |

|---|---|---|---|

| Rubber Base | Natural or synthetic rubber compounds. | Defines core flexibility and resistance. | |

| Fabric Carcass | Woven polyester or nylon layers. | Provides tensile strength and load support. | |

| Additives | Chemicals like antioxidants and fillers. | Customizes performance for specific environments. |

This meticulous material selection directly correlates with the belt’s future performance and lifespan.

Process Step 2: Compound Mixing

Compound mixing is where all the selected raw materials are homogenized into a consistent, unvulcanized rubber compound. This is typically done in a large, high-torque machine like a Banbury mixer, which generates heat and pressure to blend the components thoroughly. The resulting compound must have perfectly distributed ingredients to ensure uniform performance across the entire belt.

What happens inside the Banbury mixer?

Inside the mixer, rotors masticate the raw rubber while precisely measured amounts of fillers and additives are introduced. The process is intense: This mechanical shearing and heating action breaks down the rubber’s molecular structure, allowing it to uniformly blend with the other ingredients. The goal is to create a single, cohesive rubber mass.

- Raw rubber is softened.

- Additives are blended in.

- The mixture is heated through friction.

How do additives change belt properties?

Additives chemically and physically alter the rubber to enhance specific traits like fire resistance, oil resistance, or abrasion toughness. Think of it like this: you are programming the belt’s behavior by adding specific ingredients to the mix. Each additive has a distinct function.

- Carbon black increases tear strength.

- Plasticizers improve flexibility.

- Vulcanizing agents prepare the rubber for curing.

How is perfect rubber consistency achieved?

Achieving the perfect consistency requires precise control over mixing time, temperature, and the sequence in which ingredients are added. What’s the secret? Computer-controlled systems monitor the process, ensuring each batch meets exact specifications before it’s sheeted out for the next stage. This guarantees a uniform product.

- Monitored temperature and pressure.

- Timed ingredient addition.

- Batch-to-batch quality checks.

Key Takeaway: The mixing stage transforms individual raw materials into a single, high-potential rubber compound ready for shaping and curing.

| Element | Action | Outcome | |

|---|---|---|---|

| Banbury Mixer | Shears and blends materials. | Creates a hot, homogenous rubber mass. | |

| Additives | Integrate into the rubber matrix. | Impart specific performance properties. | |

| Process Control | Manages time, temp, and sequence. | Ensures consistent and uniform compound. |

This stage is foundational, as inconsistent mixing leads to weak spots and premature belt failure.

Process Step 3: Fabric Weaving

Fabric weaving creates the belt’s reinforcement layer, known as the carcass, which provides its tensile strength and dimensional stability. High-strength synthetic yarns like polyester and nylon are woven into dense fabrics on industrial looms. The weave pattern and yarn density are engineered to withstand the pulling forces experienced during operation.

How are EP and NN fabrics different?

EP (Polyester-Nylon) fabric uses polyester yarns for lengthwise strength and nylon for crosswise flexibility, offering excellent stability. On the other hand, NN (Nylon-Nylon) fabric uses nylon in both directions, providing superior flexibility and impact resistance. Your choice depends on the conveyor system’s design.

- EP Fabric: High modulus, low elongation.

- NN Fabric: High flexibility, good troughing ability.

How do you ensure tensile strength?

Tensile strength is ensured by using high-tenacity yarns and a tight, specific weave pattern during manufacturing. Here’s the deal: The number of fabric plies (layers) used in the final belt directly multiplies its overall strength. More plies equal a stronger belt for heavy-duty applications.

- Use of high-strength synthetic yarns.

- Tightly controlled weaving process.

- Layering multiple plies for added strength.

Why is treating the fabric so vital?

The woven fabric must be treated with a special solution to promote adhesion between the fabric and the rubber layers. Without this step, the rubber could peel away from the carcass under stress, a failure known as delamination. This treatment ensures all components bond into a single, durable unit.

- Improves bond strength.

- Prevents delamination.

- Creates a unified belt structure.

Key Takeaway: The fabric carcass acts as the belt’s skeleton, providing all the necessary tensile strength to handle operational loads without stretching or snapping.

| Fabric Type | Primary Benefit | Best Use Case | |

|---|---|---|---|

| EP (Polyester-Nylon) | Dimensional stability, low stretch. | Long, high-tension conveyors. | |

| NN (Nylon-Nylon) | Superior flexibility, impact resistance. | Troughing and short-distance conveyors. | |

| Adhesion Treatment | Strong rubber-to-fabric bond. | Essential for all belt types to prevent delamination. |

The quality of the fabric weave is a direct predictor of the belt’s load-bearing capacity.

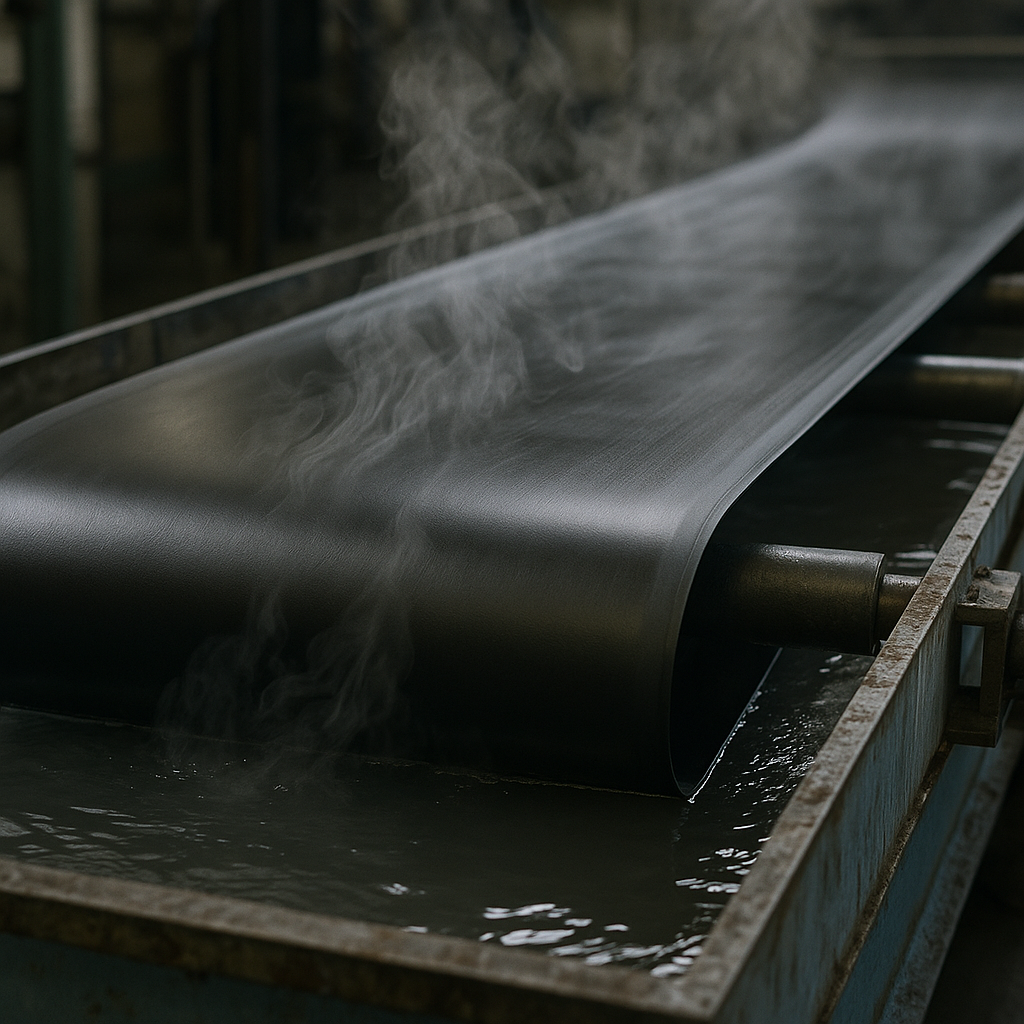

Process Step 4: Calendaring

Calendaring is the process where the mixed rubber compound is pressed into smooth, uniform sheets of a specific thickness. The warm, pliable rubber is fed through a series of large, heated rollers that squeeze it into a continuous sheet. This step is also used to apply the first layers of rubber directly onto the treated fabric carcass.

What is the calendaring machine’s role?

The calendering machine’s primary role is to transform the lumpy, mixed rubber compound into a thin, uniform sheet. It’s a critical step for ensuring the final belt has a consistent thickness from edge to edge. It functions like a giant, industrial-grade rolling pin.

- Flattens rubber compound.

- Controls sheet thickness.

- Prepares rubber for layering.

How is uniform thickness achieved?

Uniform thickness is achieved by maintaining a precise, computer-controlled gap between the massive steel rollers. The secret is precision: Sensors continuously measure the rubber sheet as it exits the rollers and make micro-adjustments to the gap. This ensures every inch of the sheet meets specification.

- Computer-controlled roller gaps.

- Laser or optical thickness sensors.

- Constant feedback and