Are extreme temperatures damaging your equipment and halting production? Conventional belts harden, crack, and fail under heat, causing costly downtime and safety concerns. The solution is a heat resistant rubber conveyor belt — engineered with specialized compounds that endure intense temperatures, maintain flexibility, and deliver consistent performance. It safeguards your productivity, extends service life, and keeps operations running smoothly even in the toughest thermal conditions.

Basics of a heat resistant rubber conveyor belt

This belt is specifically engineered to transport hot materials without degrading. Its specialized rubber compounds and carcass construction allow it to maintain integrity at temperatures that would destroy standard belts. This ensures operational continuity in demanding industrial settings.

What defines this belt type?

A heat-resistant belt is defined by its ability to operate continuously at high temperatures, typically from 100°C to over 200°C. This capability comes from using special polymers like EPDM or SBR in the cover rubber. These materials resist the aging, hardening, and cracking caused by prolonged heat exposure.

Why are standard belts insufficient?

Standard belts, usually made from natural rubber or basic SBR, cannot handle high heat. They quickly become brittle, crack on the surface, and delaminate from the carcass. This leads to catastrophic failure, unplanned shutdowns, and significant replacement costs.

What are its primary benefits?

The main benefits are extended service life, reduced downtime, and enhanced operational safety. By resisting heat damage, these belts last longer and fail less often, which keeps your production lines running smoothly. This reliability is crucial in industries where stopping the line is extremely expensive.

Key Takeaway

Choosing a heat-resistant belt over a standard one is a strategic investment in reliability and long-term cost savings for any high-temperature application.

| Feature | Standard Belt | Heat Resistant Rubber Conveyor Belt | |

|---|---|---|---|

| Max Temperature | < 80°C | 100°C to 200°C+ | |

| Rubber Compound | Natural Rubber / Standard SBR | EPDM / Special SBR | |

| Service Life | Short under heat | Significantly longer | |

| Failure Mode | Cracking, hardening, delamination | Gradual, predictable wear |

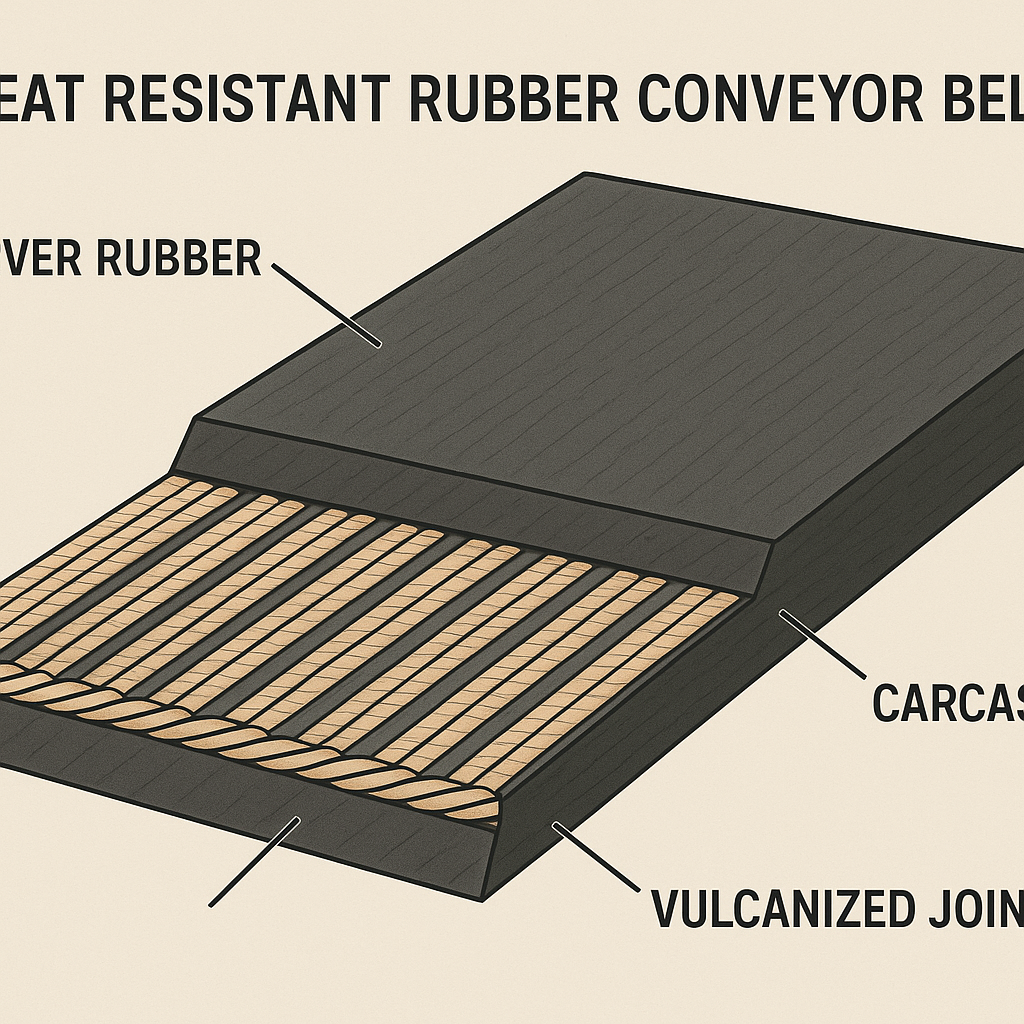

A heat resistant rubber conveyor belt build

The belt’s construction features a multi-layered design for maximum durability against heat and abrasion. It consists of specialized heat-resistant top and bottom rubber covers that protect a strong internal carcass. These components are bonded together through a high-pressure vulcanization process.

What are the cover rubber compounds?

The cover rubber is your belt’s first line of defense, typically made from EPDM or high-grade SBR. EPDM is superior for its excellent resistance to heat, ozone, and aging. The specific compound is chosen based on the operating temperature and the material being conveyed.

What are its structural layers?

Beneath the cover rubber lies the carcass, which provides tensile strength and structural integrity. This framework is usually made of multiple plies of EP (Polyester/Nylon) fabric, offering low elongation and high strength. For extreme heat, aramid fabrics or steel cords may be used.

How is it vulcanized for heat?

Vulcanization is a chemical process that uses heat and pressure to cure the rubber and bond the layers into a single, robust belt. For heat-resistant belts, this process is optimized to create strong cross-links within the rubber polymers. This ensures the belt remains stable and does not delaminate at peak operating temperatures.

Key Takeaway

The synergy between the specialized cover compound, strong carcass, and precise vulcanization process gives the belt its heat-resistant properties.

| Component | Material | Function | |

|---|---|---|---|

| Top/Bottom Cover | EPDM or SBR | Protects carcass from heat and abrasion | |

| Carcass | EP Canvas, Aramid | Provides tensile strength and structure | |

| Vulcanization | Heat and Pressure Curing | Bonds all layers into a solid unit |

A belt’s defense against heat

The belt protects itself by forming a non-conductive, porous carbonized layer on its surface upon contact with hot materials. This layer acts as a barrier, slowing the transfer of heat to the critical internal carcass. The result? The core of the belt stays cool enough to maintain its structural integrity.

What is a porous carbonized stratum?

When hot material touches the belt cover, the rubber chars slightly, creating a porous, insulating layer known as a carbonized stratum. This stratum does not easily flake off, providing a continuous shield against the intense heat. It effectively sacrifices a minuscule top layer to protect the entire belt structure.

Key Takeaway

The belt’s intelligent design creates a self-protective char layer, which is the secret to its long life in high-temperature conditions.

| Mechanism | Description | |

|---|---|---|

| Carbonized Stratum | A porous, insulating char layer forms on the surface. | |

| Heat Barrier | This layer slows heat transfer to the belt’s core. | |

| Carcass Protection | The internal carcass is shielded from damaging temperatures. |

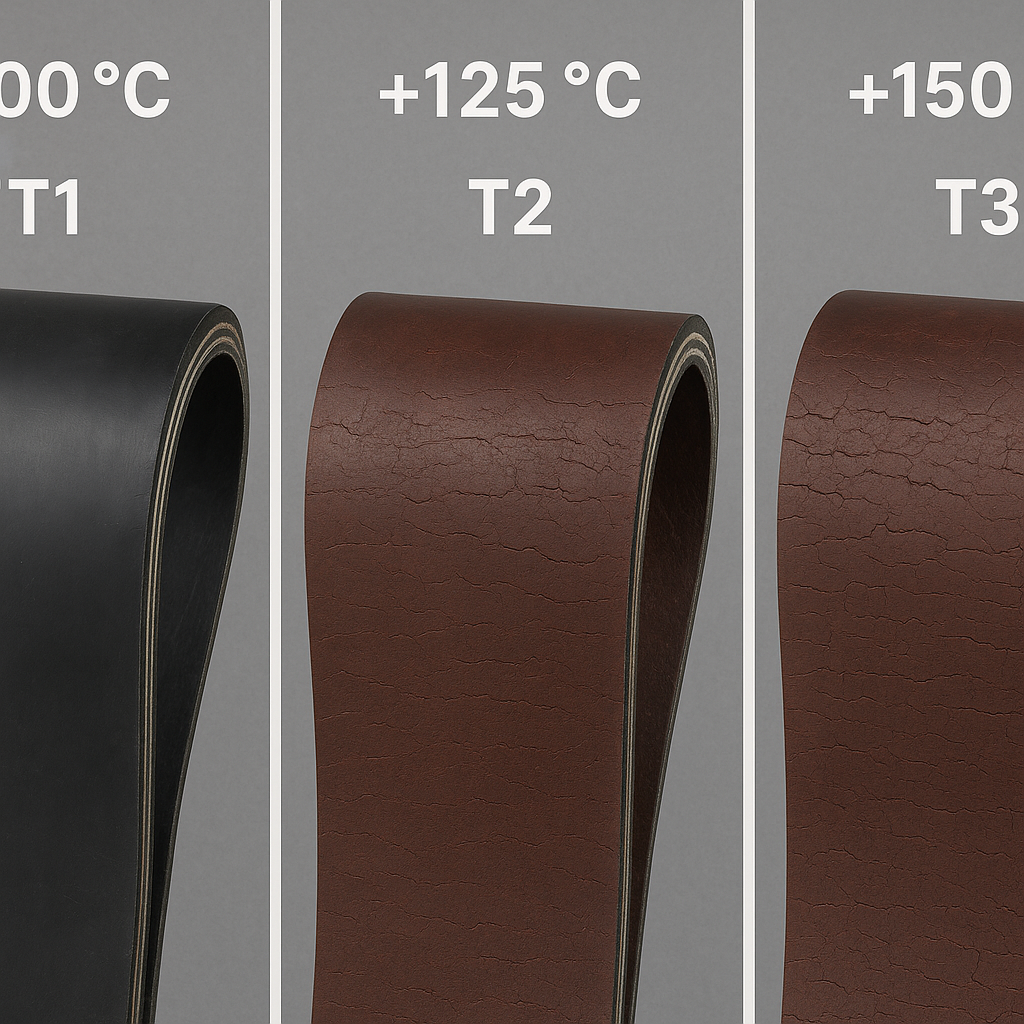

Heat resistant rubber conveyor belt grades

Yes, heat-resistant belts are categorized into grades, most commonly T1, T2, and T3, based on the maximum continuous material temperature they can handle. These grades, often aligned with standards like DIN 22102, help you select the correct belt for your specific application. Choosing the right grade prevents premature failure and optimizes cost.

What do T1, T2, and T3 grades mean?

These grades represent different levels of heat resistance.

- T1 is for moderate heat applications.

- T2 is for medium-high heat.

- T3 is designed for very high-temperature materials.

What temperatures can each grade handle?

T1 belts are typically rated for material temperatures up to 100-125°C. T2 belts can handle up to 150°C, while T3 belts are engineered for extreme conditions, handling materials up to 175°C or even 200°C continuously. Always verify the exact rating, as it can vary slightly.

Key Takeaway

Matching the belt’s T-grade to your material’s maximum temperature is critical for ensuring safety, performance, and longevity.

| Grade | Continuous Material Temperature | Common Application | |

|---|---|---|---|

| T1 | up to 125°C (257°F) | Dried materials, ash | |

| T2 | up to 150°C (302°F) | Clinker, cokes | |

| T3 | up to 175°C (347°F) | Sintered ore, hot cement |

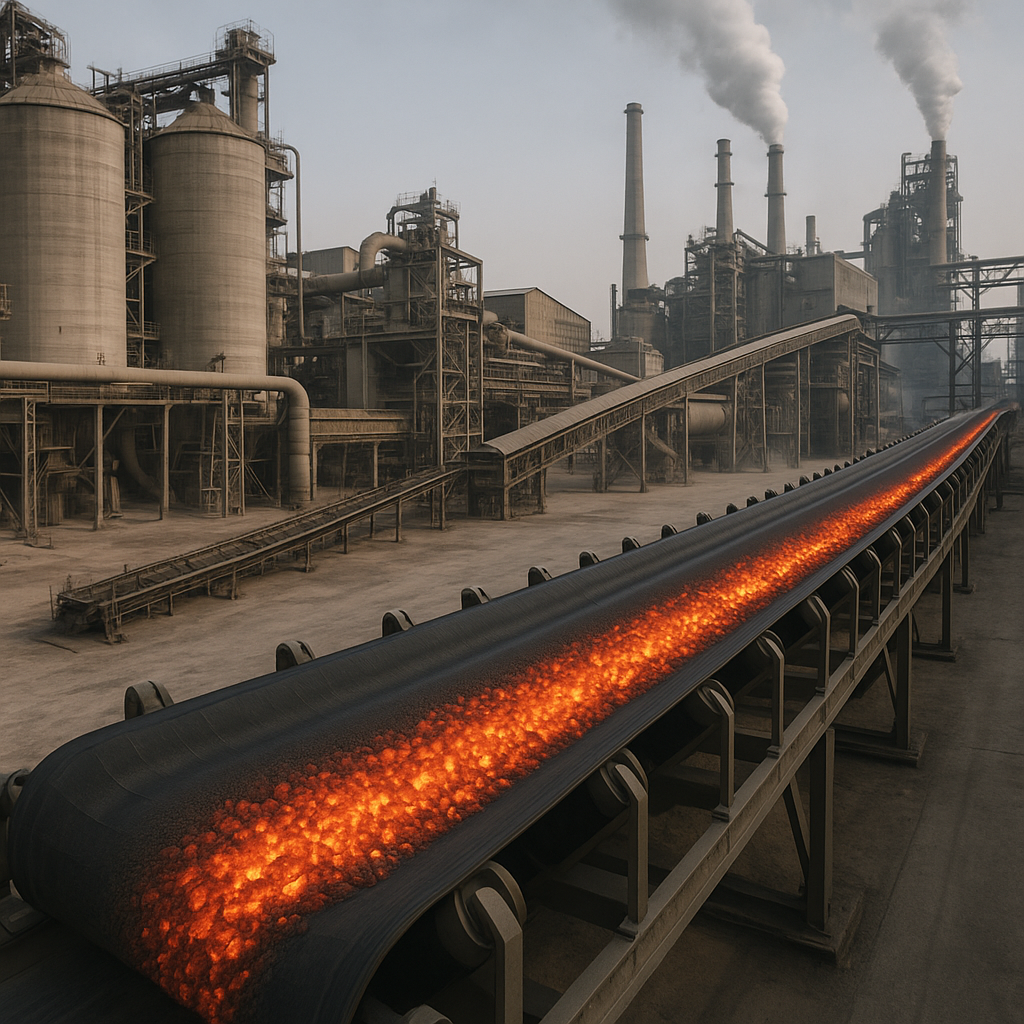

Heat resistant rubber conveyor belt uses

Yes, these belts are essential in heavy industries where materials are processed at high temperatures. You will find them in cement plants, steel mills, foundries, and chemical processing facilities. They are the backbone of material transport systems in these harsh environments.

Which industries depend on these belts?

Key industries include cement, steel, metallurgy, and chemical manufacturing. Anywhere hot, bulk materials like clinker, coke, sinter, or ash need to be moved efficiently, a heat-resistant belt is required. They are also used in recycling plants for handling hot processed materials.

Why is it vital for cement and steel?

In cement plants, they transport hot clinker from the kiln, which can exceed 150°C. In steel mills, they move hot sinter, pellets, and coke. Failure in these applications would halt the entire production process, making belt reliability a top priority.

Key Takeaway

These belts are indispensable for the continuous operation of the world’s most critical heavy industries, moving materials at temperatures that would instantly destroy standard belts.

| Industry | Materials Handled | |

|---|---|---|

| Cement | Hot Clinker, Hot Cement, Ash | |

| Steel & Metallurgy | Sinter, Coke, Pellets, Casting Sand | |

| Foundries | Hot Castings, Foundry Sand | |

| Chemical Plants | Hot Fertilizers, Processed Chemicals |

Carcass: heat resistant rubber conveyor belt

The carcass is the belt’s skeleton, providing the tensile strength needed to move heavy loads over long distances. It must resist stretching and maintain its integrity even as heat is transferred from the cover. For heat-resistant belts, the carcass material is as crucial as the rubber compound.

Why is EP canvas commonly used?

EP (Polyester warp and Nylon weft) canvas is the most common carcass material due to its excellent properties. It has high tensile strength, low elongation to prevent sagging, and superior resistance to heat degradation compared to other fabrics like nylon (NN). This stability ensures the belt tracks correctly and lasts longer.

Are other carcass materials available?

Yes, for the most extreme applications, other materials are used. Aramid fabric offers even higher strength and heat resistance than EP. For the ultimate in strength and heat durability, a carcass made of steel cords is the top choice, especially for long, high-tension conveyor systems.

Key Takeaway

A strong, heat-stable carcass made from EP canvas, aramid, or steel is essential to support the belt and prevent stretching or failure under load.

| Carcass Material | Key Properties | Best Use Case | |

|---|---|---|---|

| EP Canvas | Good strength, low stretch, heat stable | General purpose heat-resistant belts | |

| Aramid Fabric | Very high strength, excellent heat resistance | Extreme heat, high-tension systems | |

| Steel Cord | Highest tensile strength, max durability | Long, heavy-duty overland conveyors |

Choose a heat resistant rubber conveyor belt

Yes, selecting the correct belt requires a careful analysis of your specific operating conditions. You must consider the material temperature, the size of the lumps being carried, and the ambient environment. A mismatched belt will fail quickly, so a thorough evaluation is essential.

How do material temps affect choice?

The maximum temperature of the material is the most critical factor, dictating the required T-grade (T1, T2, or T3). Consider both the continuous operating temperature and any intermittent peaks. A belt that is under-spec’d for the temperature will rapidly degrade.

How does lump size impact selection?

Large, sharp lumps can cause physical damage and gouging, which requires a thicker, more durable cover rubber. The heat from large lumps also dissipates more slowly, increasing the thermal load on the belt. Your belt cover must be thick enough to handle both the physical impact and the prolonged heat contact.

Key Takeaway

A systematic evaluation of temperature, material properties, and physical demands is necessary to select a belt that delivers both performance and value.

| Factor | Consideration | Why It Matters | |

|---|---|---|---|

| Material Temp. | Continuous & peak temps | Determines the required T-grade (T1, T2, T3) | |

| Lump Size | Abrasiveness and physical impact | Dictates necessary cover rubber thickness | |

| Belt Speed | Contact time between material and belt | Slower speeds increase heat transfer | |

| Ambient Temp. | Overall operating environment | Affects belt cooling and overall lifespan |

Heat resistant rubber conveyor belt vs fire

No, heat resistance and fire resistance are two different properties designed for different hazards. A heat-resistant belt is made to handle hot materials without degrading. A fire-resistant belt is designed to self-extinguish and not propagate a flame if exposed to an external fire source.

What is the key functional difference?

The key difference is the hazard they protect against. Heat-resistant belts protect against damage from transported hot materials. Fire-resistant belts protect against an external fire, such as in an underground coal mine, preventing the belt itself from becoming a fuel source.

When is one type preferred over another?

Use a heat-resistant belt when your primary task is moving hot materials like clinker or sinter. Choose a fire-resistant belt when the operating environment has a high risk of fire, even if the material being conveyed is not hot. In some cases, a belt can be both heat and fire-resistant.

Key Takeaway

Understand your primary hazard: is it the material on the belt or the environment around it? Answering this question determines which belt type you need.

| Belt Type | Primary Function | Typical Environment | |

|---|---|---|---|

| Heat-Resistant | Withstand heat from hot materials | Steel mills, cement plants | |

| Fire-Resistant | Self-extinguish when exposed to flame | Underground mines, power plants |

Install a heat resistant rubber conveyor belt

Yes, proper installation is absolutely critical to the performance and lifespan of your belt. Before you even begin, you must ensure the conveyor structure is clean, aligned, and free of any sharp edges that could damage the new belt. A rushed or improper installation can cause failure just as quickly as using the wrong belt.

How can improper installation cause failure?

Misalignment is a primary cause of failure, leading to uneven wear, edge damage, and belt mistracking. Incorrect splicing can create a weak point that fails under tension. Over-tensioning the belt puts excessive stress on the carcass and splices, leading to premature failure.

What are best practices for tensioning?

The best practice is to apply only the minimum tension required to prevent slippage at the drive pulley under full load. Use a tensioning device to measure and apply the correct force as specified by the manufacturer. Never guess or over-tighten, as this will drastically reduce the belt’s life.

Key Takeaway

Meticulous installation—focusing on alignment, proper splicing, and correct tensioning—is a non-negotiable step for maximizing your belt’s service life.

| Installation Step | Best Practice | |

|---|---|---|

| Pre-Installation | Clean and inspect the conveyor frame for damage/sharp edges. | |

| Alignment | Ensure all idlers, pulleys, and structures are perfectly aligned. | |

| Splicing | Use the correct splicing method (hot vulcanization is best). | |

| Tensioning | Apply the manufacturer-recommended tension; do not overtighten. |

Care for a heat resistant rubber conveyor belt

Yes, you can significantly extend your belt’s service life through a program of regular inspection and proactive maintenance. Consistent care helps you catch minor issues before they become major failures. It involves keeping the system clean and monitoring the belt for signs of wear and tear.

What are common signs of wear to monitor?

Look for hardening and cracking on the belt surface, which indicates the rubber is losing its heat-resistant properties. Also, watch for delamination (layers separating), cuts or gouges, and any damage to the belt edges. These are early warnings that the belt is nearing the end of its life.

What are key maintenance procedures?

Key procedures include ensuring the belt is tracking correctly to prevent edge wear and cleaning up material spills that can get under the belt and damage it. Regularly inspect splices, as they are often the first point of failure. Proper loading is also crucial; ensure material is loaded onto the center of the belt to prevent spillage and uneven wear.

Key Takeaway

A routine of inspection, cleaning, and tracking adjustment is the most effective way to protect your investment and get the maximum possible lifespan from your belt.

| Maintenance Task | Frequency | Purpose | |

|---|---|---|---|

| Visual Inspection | Daily/Weekly | Check for cracks, damage, and wear. | |

| Tracking Check | Weekly | Ensure the belt is running true to prevent edge damage. | |

| Splice Inspection | Monthly | Check for signs of separation or weakness. | |

| System Cleaning | As Needed | Remove spillage and debris that can cause damage. |

By eliminating downtime and failures from high temperatures, these belts are the workhorses of critical industries. We are dedicated to providing durable, reliable, and customized conveyor solutions that power the world’s most demanding operations. We analyze your unique challenges to engineer the perfect belt, ensuring maximum performance and longevity.

Facing production halts from belt failure? Contact our experts today for a complimentary consultation and find your permanent solution.

Frequently Asked Questions (FAQ)

1. Can I use a T2 belt for temperatures slightly above its 150°C rating?It’s not recommended. Exceeding the continuous temperature rating, even slightly, will drastically shorten the belt’s lifespan and can lead to sudden, catastrophic failure.

2. How do I know if I need a heat-resistant or fire-resistant belt?Use a heat-resistant belt for transporting hot materials. Use a fire-resistant belt in environments with a risk of external fire, like underground mining, to prevent the belt from igniting and propagating a flame.

3. Is it possible to repair a damaged section of my heat-resistant belt?Yes, specialized repair materials and hot vulcanization techniques can be used. However, you should consult a professional to ensure the repair matches the belt’s original heat-resistant properties and integrity.

4. Does the speed of the belt affect its heat resistance?Yes, it does. A slower belt speed increases the contact time between the hot material and the belt surface, which can raise the belt’s core temperature and accelerate degradation. This should be a factor in your selection process.

5. How can I tell when my heat-resistant belt needs to be replaced?Look for deep cracks, hardening or brittleness of the cover rubber, loss of overall flexibility, and visible damage or exposure of the internal carcass. These signs indicate that the heat-resistant properties have degraded and failure is imminent.