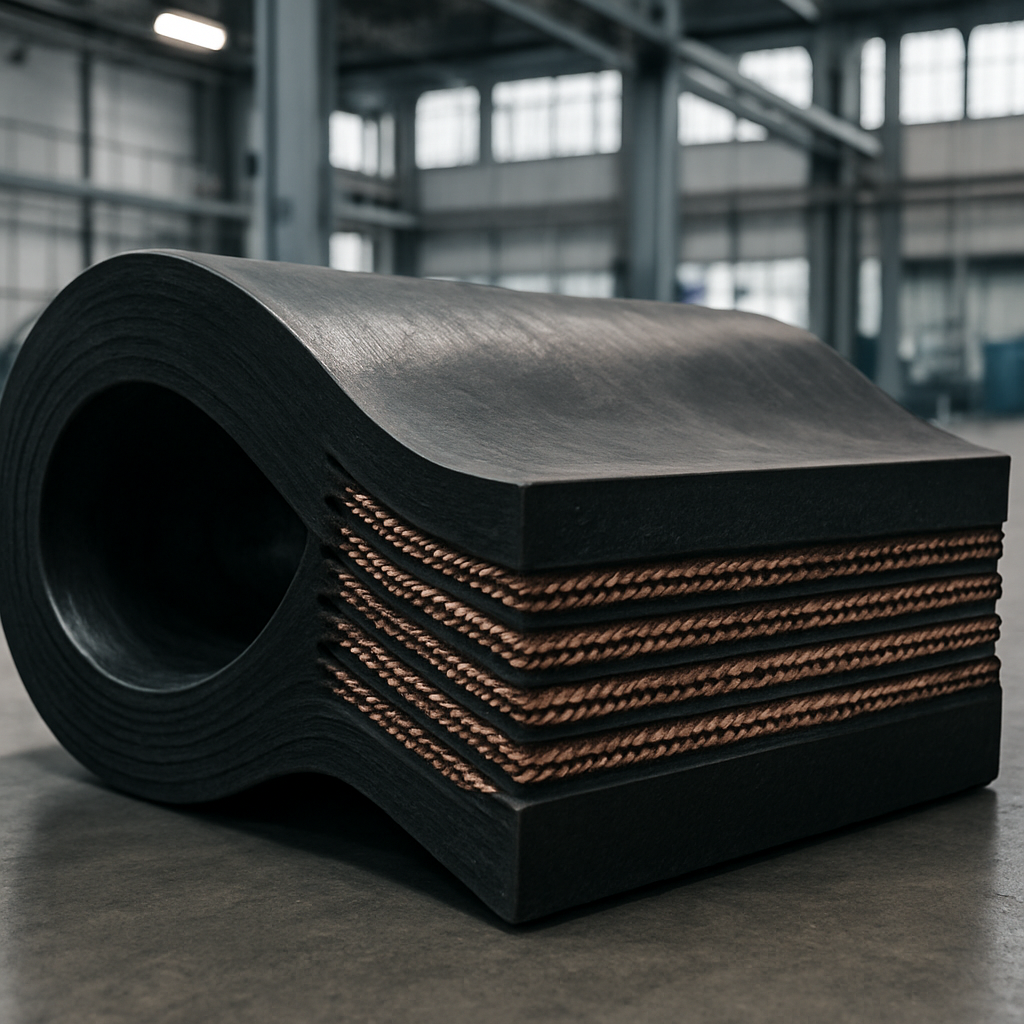

In any production environment, using the wrong belt or neglecting maintenance can cause breakdowns and costly downtime. The silence of halted machinery and rising losses is all too familiar. The key to uninterrupted operation lies in selecting the right heavy duty rubber conveyor belt — built with reinforced layers, superior abrasion resistance, and high tensile strength. Designed for the toughest conditions, it ensures reliable performance, longer service life, and continuous productivity in even the most demanding applications.

What defines a heavy duty rubber conveyor belt?

Here’s the deal: Its status is defined by a combination of a high-strength internal carcass and durable, application-specific outer rubber covers. These elements work together to withstand immense stress and abrasion.

The anatomy of a conveyor belt

A belt has three main parts. The carcass provides tensile strength, the top cover protects against material impact and wear, and the bottom cover protects the belt from the conveyor structure.

Understanding tensile strength

Tensile strength indicates the maximum load a belt can handle before it breaks. This is the most critical factor for determining a belt’s suitability for a heavy-duty application.

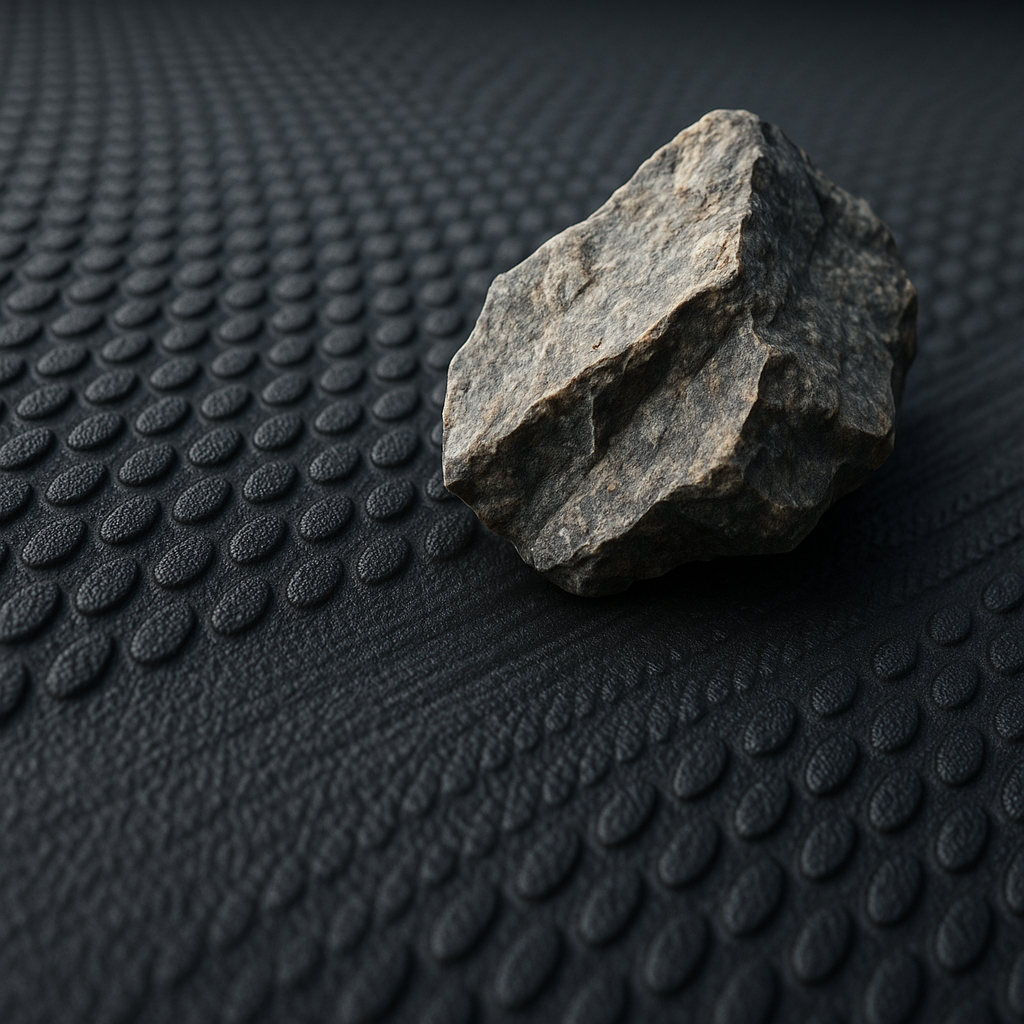

The role of protective rubber covers

Protective covers are your belt’s shield against damage.

- Abrasion-Resistant: For sharp materials like rock or gravel.

- Heat-Resistant: For conveying hot materials like clinker or slag.

- Oil-Resistant: For applications with grease, oils, or fats.

Key Takeaway: A belt’s “heavy duty” status comes from the synergy between its internal strength (carcass) and its external shield (cover).

| Cover Type | Best For | Avoids | |

|---|---|---|---|

| Abrasion-Resistant | Sharp, abrasive materials | Cuts and gouges | |

| Heat-Resistant | High-temperature products | Cracking and hardening | |

| Oil-Resistant | Oily or greasy materials | Swelling and degradation |

Reinforcing a heavy duty rubber conveyor belt

But what’s the real story? Reinforcement provides the tensile strength, or backbone, that allows the belt to carry heavy loads over long distances without stretching or snapping.

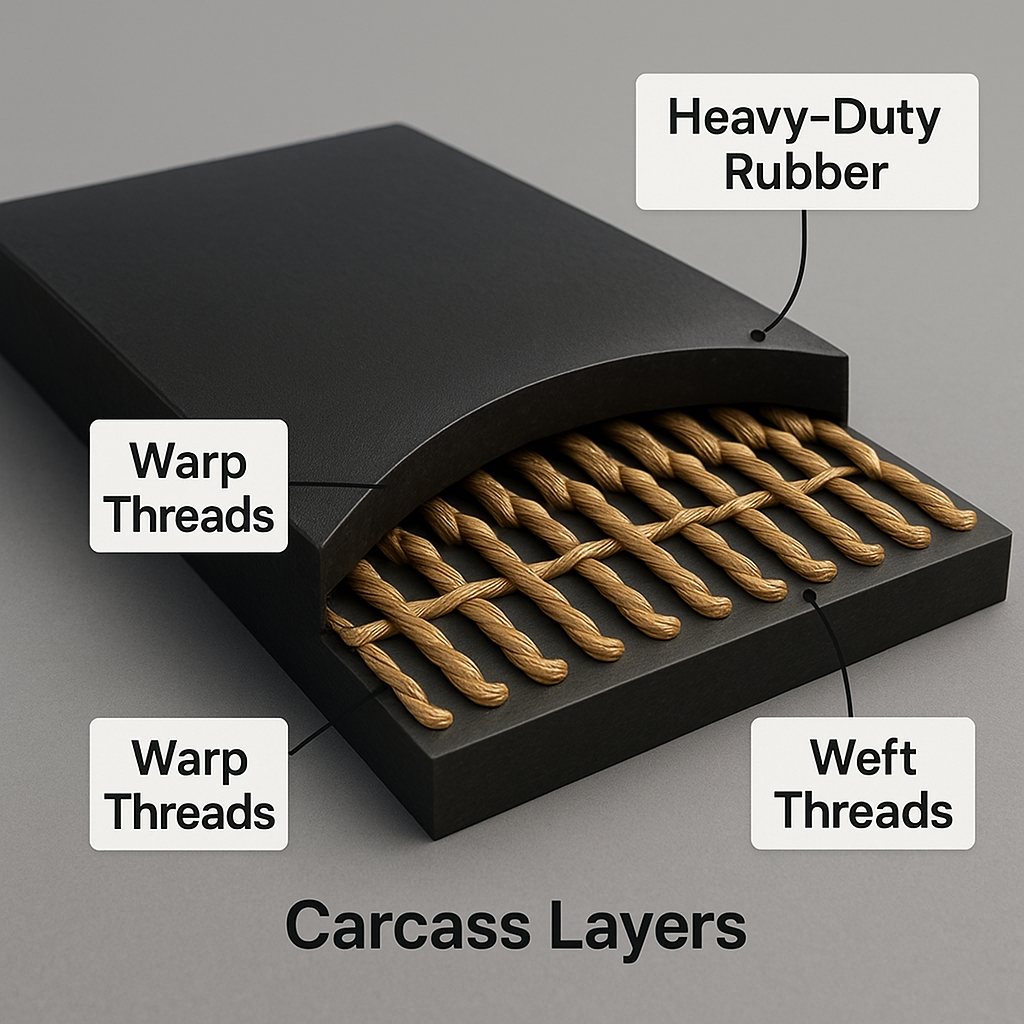

What is fabric reinforcement?

Multiple layers of synthetic fabric, like a polyester-nylon blend (EP), create a strong, flexible carcass. This is ideal for most small to medium-length conveyor systems.

What is steel cord reinforcement?

For the most demanding applications, steel cords are embedded in the rubber. They provide the highest tensile strength and lowest stretch, perfect for long-distance and high-tension systems.

When should you choose steel over fabric?

You need steel reinforcement for specific conditions.

- Conveyor systems over a kilometer long.

- Extremely heavy or high-tension loads.

- Applications where belt stretch must be minimal.

Key Takeaway: The reinforcement is the belt’s backbone; choosing the wrong one guarantees failure under load.

| Reinforcement | Pros | Cons | |

|---|---|---|---|

| Fabric (EP) | Flexible, cost-effective | Higher stretch, lower strength | |

| Steel Cord | Very high strength, low stretch | More rigid, higher cost |

Selecting the right heavy duty rubber conveyor belt

You might be wondering how to pick the perfect belt for your needs. A correct selection is based on a thorough analysis of the material you are conveying, the system’s operational demands, and the surrounding environment.

How do you analyze your material?

The properties of the material dictate the belt’s cover compound. Consider its abrasiveness, temperature, chemical composition, and lump size to prevent premature wear.

How do you calculate system demands?

You must calculate the required capacity, belt speed, and incline angle. These factors determine the necessary tensile strength and surface type (smooth or cleated) of the belt.

What are environmental considerations?

The surrounding environment is a critical factor.

- Is the belt exposed to sunlight or ozone?

- Will it operate in extreme cold or heat?

- Is it a dusty or moist environment?

Key Takeaway: There is no one-size-fits-all solution; a detailed application analysis is the first step to a reliable system.

| Factor | Questions to Ask | |

|---|---|---|

| Material | Is it hot, oily, sharp, or abrasive? | |

| Load | What is the weight and volume per hour? | |

| Environment | Is it indoors, outdoors, hot, or cold? |

Specialized heavy duty rubber conveyor belts

Now, this is where it gets interesting. Standard belts are not suitable for all jobs; many industries require specialized belts that meet strict safety and handling regulations.

What are food-grade approved belts?

These belts use compounds that are compliant with food safety standards (e.g., FDA). They are designed to prevent contamination when conveying products like grains, sugar, or salt.

What are flame-resistant belts?

In environments with combustible dust, such as grain elevators or sugar refineries, flame-resistant belts are mandatory. They are designed to self-extinguish and prevent the spread of fire.

Do you need a custom-made solution?

Sometimes, a standard belt won’t work.

- Unique product shapes

- Complex conveyor paths

- Extreme environmental challenges

Key Takeaway: Standard belts fail in specialized environments; industry-specific compliance is non-negotiable for safety and quality.

| Belt Type | Key Feature | Common Industry | |

|---|---|---|---|

| Food-Grade | Non-toxic materials | Food Processing | |

| Flame-Resistant | Self-extinguishing | Mining, Grain | |

| Custom Profile | Special cleats or shapes | Packaging, Manufacturing |

Managing heat with a heavy duty rubber belt

Think about it for a second: High heat is a primary enemy of rubber, causing it to age rapidly, crack, and lose strength, leading to unexpected belt failure.

How does high temperature degrade rubber?

Heat accelerates the aging process, making the rubber hard and brittle. This leads to surface cracks and can cause the belt layers (plies) to separate, a process called delamination.

What are features of heat-resistant belts?

These belts use special rubber compounds.

- They maintain flexibility at high temperatures.

- They resist cracking and hardening.

- They ensure strong adhesion between layers.

Which industries need heat resistance?

Many industries handle hot materials and require heat-resistant belts. These include cement plants (clinker), steel mills (slag, coke), and chemical processing facilities.

Key Takeaway: Investing in a proper heat-resistant belt prevents premature failure and enhances safety in high-temperature operations.

| Industry | Hot Material | Temperature Range | |

|---|---|---|---|

| Cement | Clinker | Up to 200°C (400°F) | |

| Steel | Sinter, Coke | Up to 180°C (356°F) | |

| Chemical | Fertilizer, Ash | Varies by process |

Conquering inclines with a heavy duty conveyor belt

So, what’s the bottom line? Moving materials up an incline requires more than just a flat belt; you need the right surface profile to prevent product rollback and maintain efficiency.

Can smooth belts handle inclines?

Smooth belts work well for gentle inclines, typically under 20 degrees. Any steeper, and most bulk materials will begin to slide back down the belt.

What are chevron belts for steeper transport?

For angles between 20 and 45 degrees, you need a chevron belt. These belts have vulcanized cleats in a ‘V’ pattern that grip the material and carry it up the incline.

What are sidewall belts for vertical conveying?

For angles above 45 degrees or even vertical transport, sidewall belts are the solution. They feature corrugated sidewalls and large cleats that form pockets to securely elevate material.

Key Takeaway: The angle of conveyance is a primary factor that dictates the belt’s surface profile.

| Belt Type | Maximum Incline Angle | Best For | |

|---|---|---|---|

| Smooth | < 20° | Bulk bags, boxes | |

| Chevron | 20-45° | Loose bulk materials | |

| Sidewall | 45-90° | Vertical transport |

Handling oil on a heavy duty rubber conveyor belt

Here’s a question for you: What happens when a standard rubber belt meets oil or fat? The rubber swells, softens, and quickly deteriorates, leading to costly failures.

How do oil and fat destroy rubber?

Oils and fats penetrate standard rubber compounds, causing them to swell and lose their physical properties. This results in a soft, weak belt that can no longer perform its function.

What are moderate vs. high-resistance belts?

Moderately resistant belts have an oil-resistant cover, which is sufficient for light contamination. For heavy exposure, you need a belt where the entire carcass is also oil-resistant.

What are common applications?

Industries requiring oil resistance are diverse.

- Food processing (vegetable oils, animal fats)

- Recycling centers (residual oils)

- Fertilizer plants and agriculture

Key Takeaway: Using a standard belt in an oily environment is a recipe for rapid deterioration and failure.

| Resistance Level | Application | Belt Construction | |

|---|---|---|---|

| Moderate | Light oil mist | Resistant covers only | |

| High | Direct contact | Resistant covers & carcass |

Proper installation of your heavy duty rubber conveyor belt

But wait, there’s more. Even the highest quality belt will fail prematurely if it is not installed correctly. Proper installation, splicing, and tracking are vital for performance.

What are critical pre-installation checks?

Before installing, inspect the conveyor structure. Ensure all rollers are clean and turning freely, and check that the frame is square and aligned.

What are splicing methods?

Mechanical fasteners are quick but create a weak point. A hot vulcanized splice creates a seamless, strong, and durable joint that is nearly as strong as the belt itself.

What is tracking and alignment?

Tracking is the process of aligning the belt so it runs true on the idlers.

- A belt running off-center will suffer edge damage.

- Proper alignment prevents premature wear and failure.

Key Takeaway: Professional installation is just as important as belt selection for maximizing service life and performance.

| Problem | Likely Cause | |

|---|---|---|

| Belt runs to one side | Misaligned idler or pulley | |

| Edge fraying/damage | Belt rubbing against structure | |

| Belt slips | Incorrect tension or worn pulley |

Extending your heavy duty conveyor belt’s life

What if I told you there’s a better way than just running your belt to failure? A proactive strategy of routine maintenance and smart repairs can dramatically extend its service life.

The power of routine maintenance

Regularly inspect your belt for damage. A simple maintenance checklist helps you catch problems early before they become catastrophic failures.

How do smart repair systems work?

For localized gouges and tears, modern repair systems can be used. These allow you to fix damage quickly on-site, minimizing downtime without requiring a full belt replacement.

What is proactive conveyor belt monitoring?

Implement a proactive monitoring schedule.

- Check for cover wear and cracks.

- Inspect splices for signs of separation.

- Ensure scrapers and rollers are clean and functional.

Key Takeaway: A proactive maintenance and monitoring strategy is far cheaper than reactive replacement and downtime.

| Task | Frequency | Purpose | |

|---|---|---|---|

| Visual Inspection | Daily/Weekly | Catch obvious damage | |

| Splice Check | Monthly | Ensure splice integrity | |

| Tension/Tracking | As needed | Optimize performance |

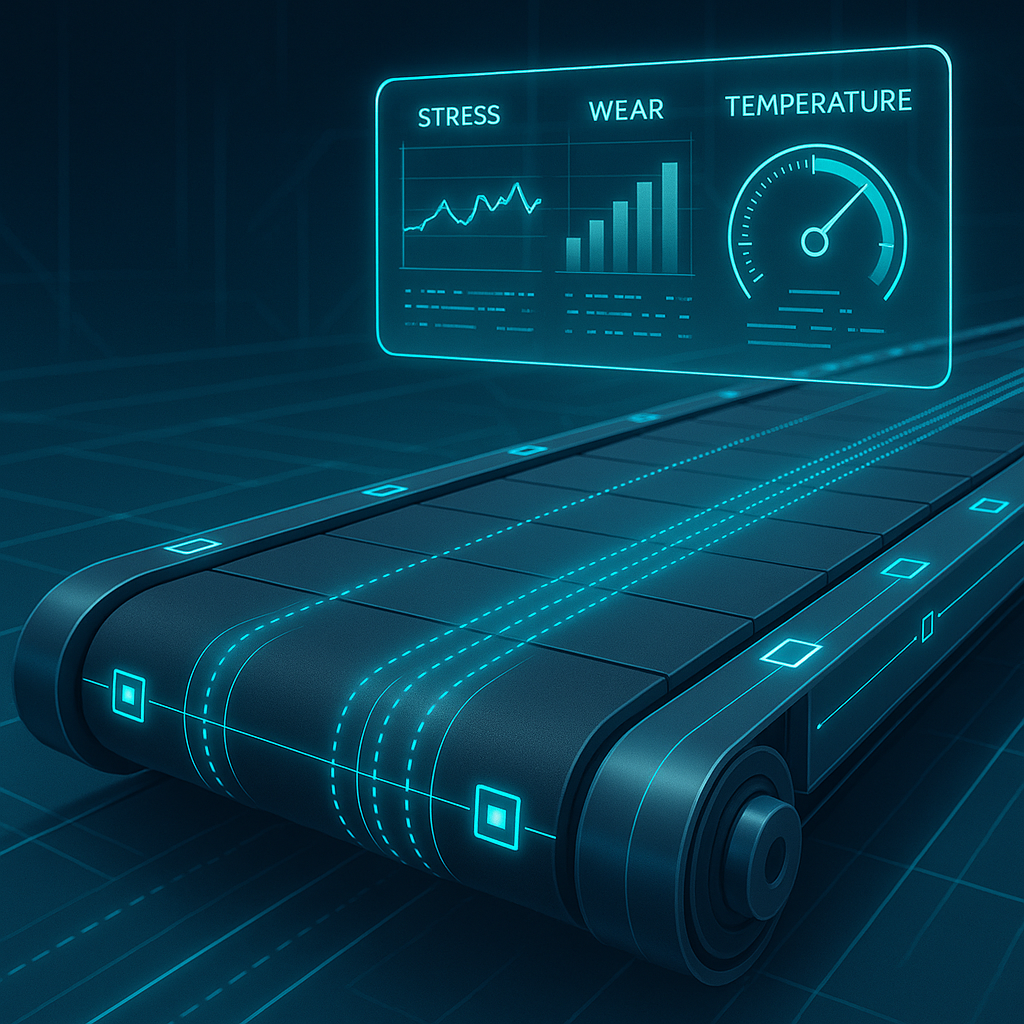

Innovations in heavy duty rubber conveyor belts

Ready for the good part? Conveyor belt technology is constantly advancing, with innovations focused on creating smarter, more efficient, and more sustainable material handling systems.

What is smart sensor integration?

New belts can be embedded with sensors. These sensors monitor wear, tension, and temperature in real-time, allowing you to predict failures before they happen.

What are advanced eco-friendly compounds?

Manufacturers are developing new rubber compounds that offer superior performance and a longer lifespan. Many of these are also designed to be more environmentally friendly.

What are energy-efficient designs?

Belt designs are evolving to reduce operational costs.

- Lighter-weight belts require less energy to run.

- Low-rolling-resistance compounds minimize friction.

Key Takeaway: The future of conveyor technology is smarter, more efficient, and more sustainable.

| Innovation | Benefit | |

|---|---|---|

| IoT Sensors | Predictive maintenance, less downtime | |

| Eco-Compounds | Better performance, sustainability | |

| Efficient Designs | Lower energy consumption |

Conclusion

Selecting the correct heavy duty rubber conveyor belt is a critical operational decision that hinges on understanding reinforcement, rubber quality, and application demands. Don’t let your conveyor belt be an afterthought; treat it as the critical asset it is. Feeling overwhelmed by the options? Contact us today for a no-obligation assessment of your application and ensure your production never stops.

Frequently Asked Questions (FAQ)

Q1: Can I repair a heavy duty rubber conveyor belt myself?A: Minor surface repairs can sometimes be handled with repair kits. However, for damage affecting the belt’s carcass or for creating splices, professional service is highly recommended to ensure the belt’s structural integrity and safety.

Q2: What’s the best belt for highly abrasive materials like sand or gravel?A: You should look for a belt with a high abrasion resistance rating, often designated as “W” grade. These belts use a special rubber compound designed to withstand the cutting and gouging action of sharp, abrasive materials.

Q3: How do I know if my conveyor belt needs replacing?A: Key signs include deep cracks in the cover, exposed fabric or steel cords, significant edge damage, and difficulty in keeping the belt tracked. Any sign of delamination (layers separating) means immediate replacement is necessary.

Q4: What does the “EP” designation mean in a belt’s specification?A: “EP” refers to the carcass construction. “E” stands for Polyester for the warp (longitudinal threads), and “P” stands for Polyamide (Nylon) for the weft (transverse threads). An EP belt has low elongation and high strength.

Q5: How can I find the right chevron pattern for my inclined conveyor?A: The right pattern depends on the material being conveyed and the angle of inclination. Open ‘V’ patterns are good for most bulk materials, while other special cleats may be needed for finer materials or steeper angles. Consulting a specialist is the best approach.