Belt Conveyors: Types, Components and Applications

Inefficient material handling is a silent drain on productivity. This inefficiency quickly escalates into higher operational costs, frustrating downtime, and serious safety risks that can impact your team and your bottom line. The solution is an optimized belt conveyor system, a powerhouse of industrial automation designed to streamline your workflow, protect your products, and boost your overall efficiency.

1. Key Parts in Conveyor Belt Design

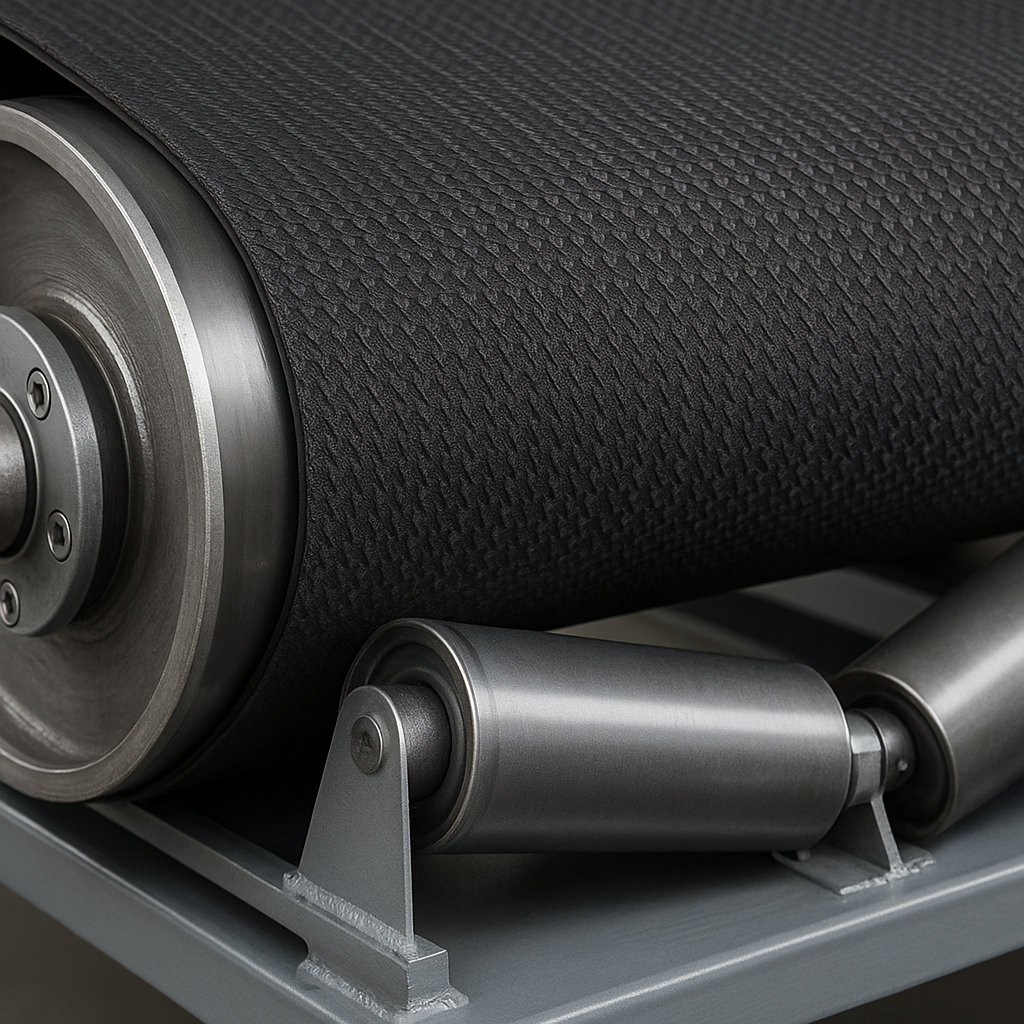

How do belts and carcasses work?

The belt provides the moving surface for your materials, while its internal carcass provides the tensile strength required to carry the load. Here’s the deal:

- The carcass is the core strength layer, often made of fabric or steel cord.

- The cover is the outer layer that protects the carcass from damage and abrasion.

What are head and tail pulleys?

These are the large drums at either end of the conveyor that move and guide the belt. You need to know that:

- The head pulley, or drive pulley, is powered by a motor and pulls the belt forward.

- The tail pulley idles at the opposite end, allowing the belt to loop back.

Why are idler rollers critical?

Idlers are small rollers positioned along the conveyor frame to support the belt and prevent it from sagging under load. What does this mean for you?

- They maintain proper belt alignment and reduce friction, which lowers energy consumption.

- They are essential for absorbing impact at loading points and supporting the belt’s path.

Key Takeaway: Your conveyor’s reliability is determined by how well these core components—the belt, pulleys, and idlers—are matched to your specific operational demands.

| Component | Primary Function | |

|---|---|---|

| Belt & Carcass | Move material and provide tensile strength | |

| Head & Tail Pulleys | Drive the belt and enable its return path | |

| Idler Rollers | Support the belt and its load to prevent sagging |

2. Frame Integrity in Conveyor Belt Design

What are conveyor frame basics?

The frame is the conveyor’s skeleton, providing structural support for all other components like rollers, pulleys, and the drive system.

- It is typically built from steel sections to ensure rigidity.

- The design must account for the total weight of the belt, components, and the maximum load.

How does frame impact alignment?

A weak or improperly assembled frame can flex or warp, causing the belt to drift to one side, a problem known as misalignment. The bottom line is:

- Misalignment leads to premature wear on the belt edges and structural components.

- A rigid, true frame is the first step to ensuring the belt runs straight.

How can you avoid structural failure?

To prevent failure, your frame must be engineered to exceed the stresses of its maximum load and operating conditions. But that’s not all.

- Use cross-bracing to increase rigidity, especially on long conveyors.

- Ensure all sections are securely bolted or welded according to design specifications.

Key Takeaway: A robust and precisely aligned frame is non-negotiable; it is the foundation that ensures the longevity and safe operation of your entire conveyor system.

| Frame Issue | Consequence | Prevention | |

|---|---|---|---|

| Flexing/Warping | Belt misalignment, premature wear | Proper engineering, sufficient bracing | |

| Poor Assembly | Structural instability, safety risk | Following design specs, quality checks | |

| Under-Engineering | Catastrophic failure, downtime | Calculating for maximum load stress |

3. Load Support in Conveyor Belt Design

What is a roller bed conveyor?

In this design, the belt rests on a series of rollers spaced closely together.

- This setup is ideal for transporting heavy items like boxes, totes, and pallets.

- The rollers minimize friction, reducing the power needed to move the load.

When should you use a flat belt system?

A flat belt system, where the belt slides over a solid, flat surface, is best for moving smaller, lighter, or irregularly shaped items. Here’s why:

- It provides complete support across the belt’s entire width.

- It is commonly used in assembly, inspection, and light-duty packaging tasks.

How do troughing idlers work?

Troughing idlers are sets of three rollers that angle the sides of the belt upward, creating a “trough” shape. What does this mean for you?

- This design is perfect for containing loose, bulk materials like gravel, sand, or grain.

- The trough shape increases the carrying capacity of the belt and prevents spillage.

Key Takeaway: The way you support the load—whether on rollers, a flat bed, or in a trough—directly impacts carrying capacity, efficiency, and the types of materials you can move.

| Support Type | Best For | Key Advantage | |

|---|---|---|---|

| Roller Bed | Heavy, flat-bottomed items | Low friction, high capacity | |

| Flat Belt | Small, light, or irregular items | Full surface support, simplicity | |

| Troughing Idlers | Bulk materials (gravel, grain) | High capacity, prevents spillage |

4. Specialty Conveyor Belt Design Types

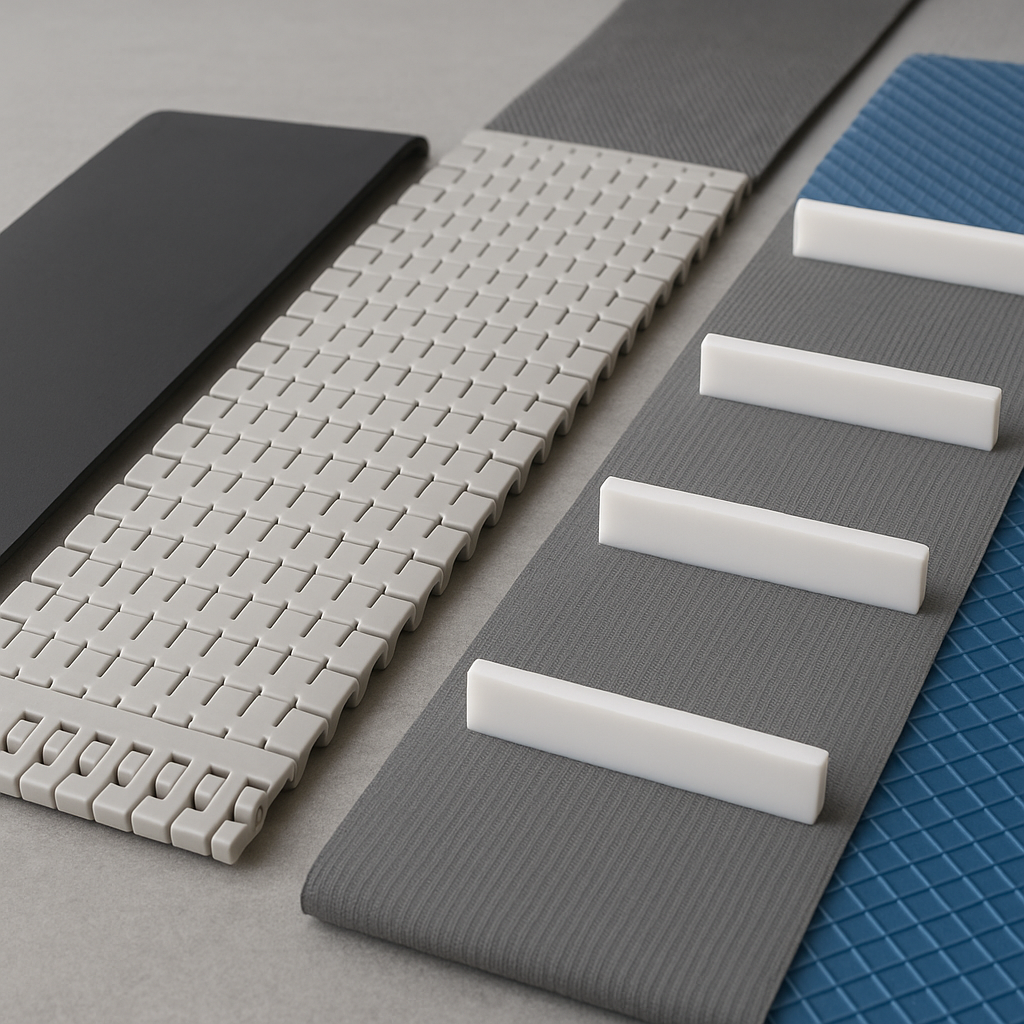

What makes modular belts unique?

Modular belts are made of interconnected plastic segments, creating a hard, durable surface similar to a chain.

- They are easy to repair, as you can replace individual damaged segments.

- They can be designed to travel in straight lines, around curves, and up inclines.

Why use a cleated belt system?

Cleated belts have vertical barriers or partitions (cleats) attached to the belt’s surface at regular intervals. Here’s the deal:

- They are essential for moving products up steep inclines or declines.

- The cleats prevent loose or round items from rolling back or sliding off.

When is a curved belt needed?

A curved belt conveyor allows you to transport items around corners, saving floor space and connecting different processing lines. The bottom line is:

- They are crucial in complex layouts found in airports, warehouses, and food processing plants.

- They require a specialized tapered belt and frame design to operate without slipping.

Key Takeaway: Specialty belts like modular, cleated, and curved designs solve specific material handling challenges that standard flat belts cannot address.

| Belt Type | Primary Use Case | Main Benefit | |

|---|---|---|---|

| Modular | Complex paths, food-grade needs | Durability, easy repair | |

| Cleated | Steep inclines and declines | Prevents product rollback | |

| Curved | Transporting items around corners | Saves floor space, connects lines |

5. Drive Systems in Conveyor Belt Design

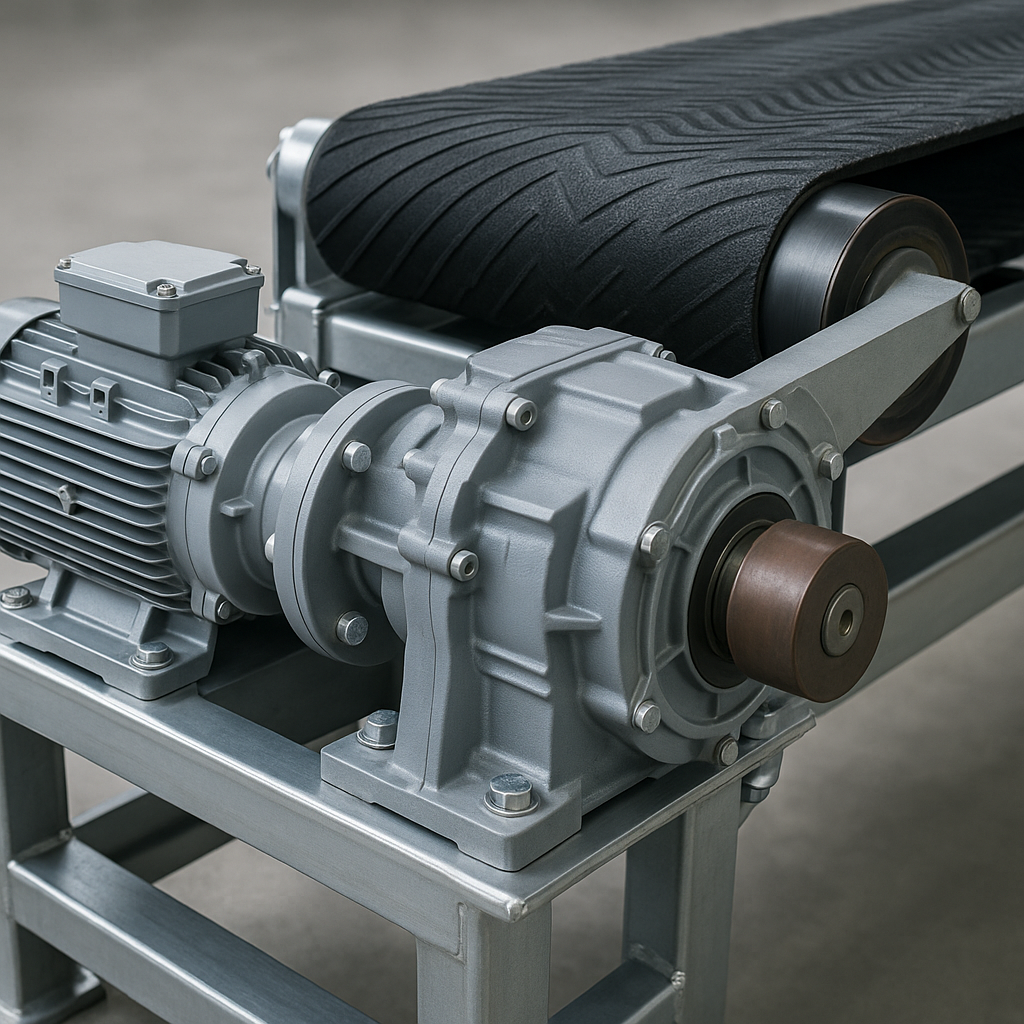

How to select motors and gearboxes?

You must choose a motor and gearbox combination that provides enough torque to start the conveyor under a full load and run it at the desired speed.

- The motor provides the power.

- The gearbox reduces the motor’s high speed to a slower, more powerful output speed.

How is pulling force calculated?

The required pulling force, or effective tension, depends on factors like the load weight, belt weight, incline angle, and friction from all components. But there’s more.

- This calculation is critical for sizing the motor and gearbox correctly.

- Under-sizing the drive will lead to stalls and motor burnout.

What is the optimal conveyor speed?

The ideal speed depends entirely on your application, balancing the need for throughput with the risk of product damage.

- High speeds increase throughput but can cause unstable items to fall.

- Slower speeds are better for delicate items, manual assembly tasks, or steep inclines.

Key Takeaway: The drive system is the heart of your conveyor; it must be precisely calculated and specified to provide reliable power without being overworked or oversized.

| Drive System Aspect | Key Consideration | Impact of Miscalculation | |

|---|---|---|---|

| Motor & Gearbox | Required torque and output speed | Stalling or excessive energy use | |

| Pulling Force | Load, incline, friction | Undersized drive, motor failure | |

| Conveyor Speed | Throughput vs. product stability | Product damage or low productivity |

6. Application-Based Conveyor Belt Design

How are sanitary conveyors built?

Sanitary conveyors, used in food and pharmaceutical industries, are designed for easy and thorough cleaning.

- They often use stainless steel frames and modular plastic belts.

- The design minimizes crevices where bacteria could grow.

What defines an incline system?

An incline conveyor moves products between different elevations. Here’s what you should know:

- It requires a high-friction belt surface or cleats to prevent items from sliding back.

- The drive system must have sufficient power to lift the load against gravity.

How do magnetic belts operate?

Magnetic conveyors use a bed of permanent magnets located beneath the belt to hold and transport ferrous (iron-containing) parts. What does this mean for you?

- They are excellent for moving small metal parts, even on steep inclines or upside down.

- They are also used to separate ferrous contaminants from other materials.

Key Takeaway: Designing for a specific application—whether for sanitation, elevation change, or material handling—requires specialized components and construction principles.

| Application | Key Design Feature | Common Industry | |

|---|---|---|---|

| Sanitary | Stainless steel, easy-to-clean design | Food, Pharmaceutical | |

| Incline/Decline | High-friction or cleated belt | Warehousing, Manufacturing | |

| Magnetic | Magnet bed under the belt | Metalworking, Recycling |

7. Tension in Your Conveyor Belt Design

Why is belt tension so important?

Proper tension ensures the drive pulley has enough grip on the belt to move it without slipping.

- Too little tension causes slippage and loss of power.

- Too much tension stresses the belt, splices, and bearings, leading to premature failure.

What is a screw take-up system?

This is a manual tensioning system where bolts are used to move the tail pulley, tightening or loosening the belt. The bottom line is:

- It is a simple and cost-effective solution for shorter conveyors.

- It requires manual readjustment as the belt stretches over time.

When is gravity take-up better?

A gravity take-up system uses a weighted pulley in a loop of belting to automatically maintain constant tension. But that’s not all.

- It is ideal for long or heavily loaded conveyors where significant belt stretch is expected.

- It automatically adjusts for changes in load and temperature, reducing maintenance needs.

Key Takeaway: Managing belt tension is a critical balancing act; a proper take-up system is essential for maintaining drive traction and maximizing component life.

| Take-Up System | Mechanism | Best For | |

|---|---|---|---|

| Screw Take-Up | Manual adjustment with bolts | Short, simple conveyors | |

| Gravity Take-Up | Weighted pulley maintains tension | Long, heavy-duty conveyors |

8. Pulley Selection in Conveyor Belt Design

What are motorized vs. drive pulleys?

A standard drive pulley is connected to an external motor and gearbox. A motorized pulley contains the motor and gearing inside the pulley shell itself.

- Drive Pulley: Traditional, with external motor.

- Motorized Pulley: Compact, integrated design with improved safety.

What do snub and bend pulleys do?

These pulleys are used to change the direction of the belt or increase its wrap angle around a drive pulley. Here’s why that matters:

- Snub Pulleys: Increase belt wrap on the drive pulley to improve traction.

- Bend Pulleys: Redirect the belt’s path along the conveyor frame.

How do wing and magnetic pulleys work?

These are specialty pulleys used for specific functions at the discharge point.

- Wing Pulleys: Have fins that eject lumps and debris, preventing them from getting caught between the belt and pulley.

- Magnetic Pulleys: Used as the head pulley to separate ferrous metal objects from the main product stream.

Key Takeaway: Beyond the main head and tail pulleys, a variety of specialized pulleys are used to guide the belt, improve traction, and perform sorting tasks.

| Pulley Type | Main Function | Application | |

|---|---|---|---|

| Motorized Pulley | Drives the belt with an internal motor | Compact, sanitary, or high-safety areas | |

| Snub/Bend Pulley | Increase wrap angle or change belt direction | Improving drive grip, complex belt paths | |

| Wing/Magnetic Pulley | Self-cleaning or material separation | Bulk handling, recycling |

9. Benefits of Smart Conveyor Belt Design

How does it boost efficiency?

A well-designed conveyor system automates material flow, moving goods faster and more consistently than manual labor ever could.

- It reduces bottlenecks and ensures a steady pace for downstream processes.

- It allows you to reallocate labor to more value-added tasks.

How does it reduce product damage?

Automated conveyance provides a smooth, controlled journey for your products, minimizing the drops, impacts, and mishandling common in manual processes. The bottom line is:

- It is crucial for handling fragile items, electronics, or food products.

- It leads to less waste and higher customer satisfaction.

How does it lower maintenance costs?

Designing a system with high-quality components matched to the application reduces premature wear and tear. What does this mean for you?

- It results in less frequent breakdowns and fewer emergency repairs.

- Features like automatic tensioning and proper guarding reduce the overall maintenance burden.

Key Takeaway: Investing in smart conveyor design isn’t just an operational upgrade; it’s a strategic business decision that pays dividends in efficiency, product quality, and long-term cost savings.

| Benefit | How It’s Achieved | Business Impact | |

|---|---|---|---|

| Higher Efficiency | Automated, consistent material flow | Increased throughput, better labor use | |

| Less Product Damage | Smooth, controlled handling | Reduced waste, higher quality output | |

| Lower Maintenance | Quality components, smart design | Less downtime, lower repair costs |

10. Fixing Common Conveyor Belt Design Flaws

What causes belt misalignment?

Misalignment, or belt tracking issues, is often caused by an unlevel frame, improperly installed pulleys, or uneven loading.

- Check that all rollers and pulleys are perfectly square to the frame.

- Ensure material is loaded onto the center of the belt.

Why does a conveyor belt slip?

Slippage, especially at the drive pulley, is almost always due to insufficient belt tension. Here’s what to do:

- Adjust the take-up unit to increase tension until the slipping stops.

- If the problem persists, the drive may be undersized for the load.

How do you prevent belt overstretching?

While all belts stretch over time, excessive stretching is a sign of overpowering or over-tensioning the system. But there’s more.

- Ensure the tension is set to the lowest level required to prevent slippage, and no higher.

- Verify that the belt’s tensile rating is appropriate for the forces being applied by the drive and load.

Key Takeaway: Most common conveyor problems—misalignment, slipping, and stretching—are design or setup issues that can be prevented or fixed with careful attention to tension, alignment, and loading.

| Flaw | Primary Cause | Solution | |

|---|---|---|---|

| Misalignment | Un-square components, off-center loading | Align components, center the load | |

| Belt Slippage | Insufficient tension | Adjust the take-up unit | |

| Overstretching | Excessive tension or undersized belt | Reduce tension, verify belt rating |

Conclusion

Stop letting inefficient material handling dictate your operational success. By moving beyond stop-gap fixes and embracing intelligent conveyor belt design, you can eliminate costly downtime, protect your products, and create a safer, more productive environment. We are committed to engineering forward-thinking solutions that power the future of automation.

Ready to build a conveyor system that works as hard as you do? Contact our design experts today to create a custom solution that drives your business forward.

FAQ

Q1: Can I use the same belt for hot and cold items?No, you need a belt specifically rated for the temperature range you’re handling. High-temperature belts use materials like silicone, while low-temperature belts use special compounds to prevent cracking.

Q2: What’s the best conveyor for ensuring food safety?For food safety, you should use a sanitary conveyor with a stainless steel frame and a modular plastic or solid thermoplastic belt. These are designed for easy washdown and have minimal crevices for bacteria to hide.

Q3: How do I know if my belt tension is set correctly?The belt is correctly tensioned when it is just tight enough to prevent slippage at the drive pulley under a full load. Over-tensioning will cause premature wear on bearings and the belt splice.

Q4: What are the main causes of wear on belt edges?Edge wear is almost always caused by belt misalignment. When the belt drifts to one side, it rubs against the conveyor frame or other structural components, causing fraying and damage.

Q5: How much stretch should I expect from a new belt?A new belt will undergo an initial “break-in” stretch, typically around 0.5% to 1% of its total length, after which it should stabilize. Continuous stretching indicates a problem with tensioning or specification.