Your industrial operations deal with abrasive, heavy, or sharp materials that quickly wear down standard belts, leading to costly replacements and unplanned downtime. Each breakdown impacts productivity and profitability. The solution lies in a high-performance rubber conveyor belt, such as the M24 grade, specifically engineered for maximum durability, superior wear resistance, and long service life. It keeps your materials moving efficiently, even under the toughest working conditions.

What is an M24 rubber conveyor belt?

This belt is designed for moderate to heavy-duty applications where abrasion resistance is crucial. It conforms to specific quality standards, ensuring it can handle demanding materials without premature wear. The M24 designation signifies its toughness and suitability for challenging industrial environments.

What does the M24 grade mean?

The M24 grade is a classification indicating superior abrasion resistance. It means the belt cover can withstand significant scraping and cutting forces. Here’s the deal: it’s a step up from general-purpose belts.

- M: Signifies a moderate level of abrasion resistance.

- 24: Refers to its ultimate tensile strength in Megapascals (MPa).

What is the belt made of?

The belt combines a robust fabric core with durable rubber covers. This layered construction provides both strength and resilience. You see, this combination is key to its performance.

- Cover Rubber: A blend of synthetic and natural rubber for high durability.

- Carcass: Layers of EP (Polyester/Nylon) or NN (Nylon/Nylon) fabric for tensile strength.

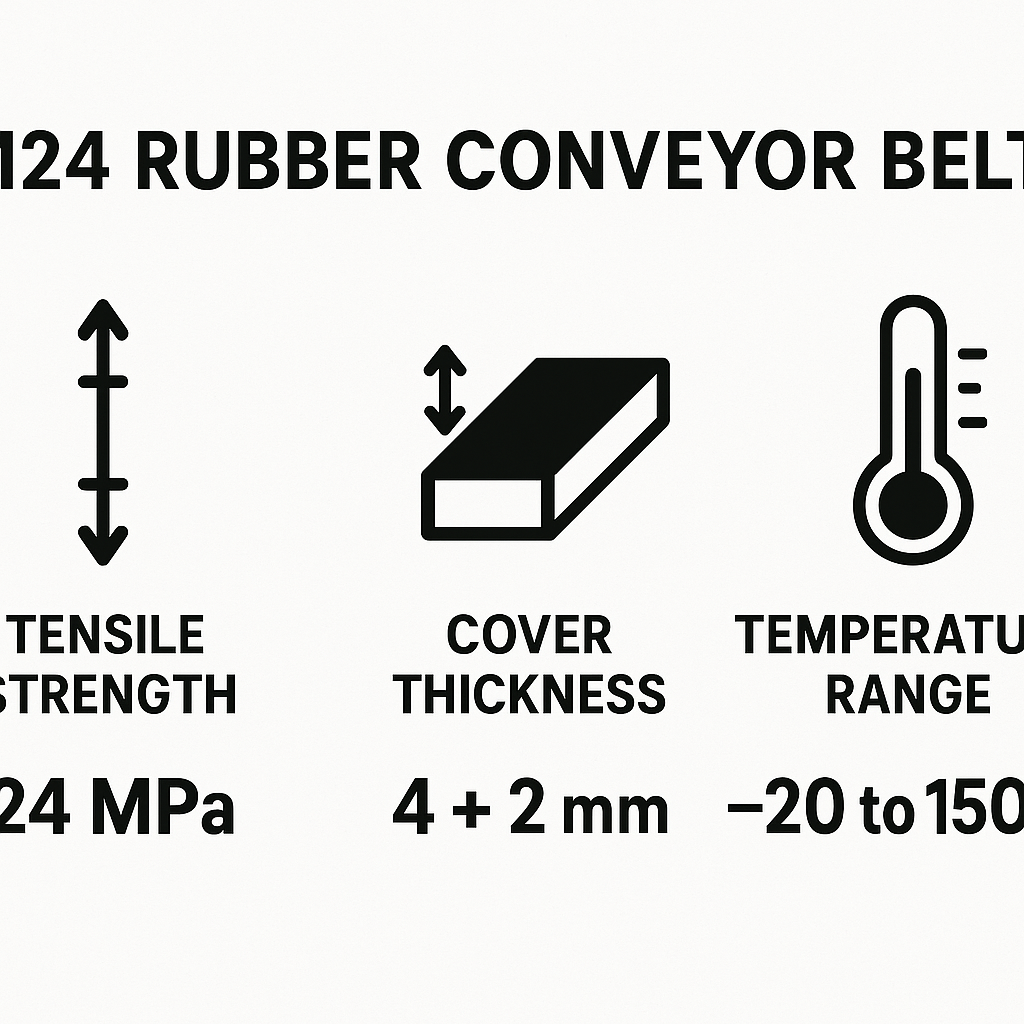

What are its key specifications?

This belt is defined by its strength, hardness, and low abrasion loss. So, what does this mean for you? It means less downtime and a longer service life for your conveyor system.

- Tensile Strength: Minimum 24 MPa.

- Hardness: Typically 60±5 Shore A.

- Abrasion Loss: Maximum 150 mm³.

Key Takeaway: The M24 grade signifies a tough, durable belt with a minimum tensile strength of 24 MPa and excellent abrasion resistance, making it ideal for moving abrasive materials.

| Specification | Value | |

|---|---|---|

| Tensile Strength | 24 MPa (min) | |

| Abrasion Loss | 150 mm³ (max) | |

| Hardness (Shore A) | 60 ± 5 |

Why choose this rubber conveyor belt?

You should choose this belt for its exceptional durability in handling tough materials. Its design minimizes wear and tear, leading to fewer replacements and more consistent operations. This reliability makes it a cost-effective choice for demanding industrial settings.

How does it resist abrasion?

The secret lies in its specially formulated rubber cover. This compound is designed to resist the grinding and scraping action of materials like gravel, crushed stone, and ores. In other words, it’s built to last.

- Reduces surface wear from coarse materials.

- Maintains integrity even with constant friction.

How does it resist cuts?

The belt’s robust carcass and thick rubber cover work together to absorb impacts and resist punctures. This makes it perfect for handling sharp-edged materials that would shred lesser belts. Here’s the bottom line: sharp rocks and metal shards are no match for it.

- Handles sharp rocks and ores.

- Prevents deep gouges and tears.

What are its top benefits?

Choosing this belt means investing in operational efficiency and lower long-term costs. The primary benefits are extended service life and reduced maintenance needs. What does this mean for your output? Less downtime and more productivity.

- Durability: Lasts longer under harsh conditions.

- Low Maintenance: Requires fewer repairs and replacements.

- Cost-Effective: Lower total cost of ownership over time.

Key Takeaway: Its superior resistance to abrasion and cuts translates directly into longer belt life, less maintenance, and greater operational reliability.

| Feature | Benefit | |

|---|---|---|

| Abrasion Resistance | Longer service life | |

| Cut & Impact Resistance | Reduced downtime from damage | |

| Overall Durability | Lower long-term maintenance costs |

What’s the rubber conveyor belt tensile strength?

The tensile strength is a critical measure of how much pulling force the belt can withstand before breaking. For the M24 grade, this is a defining feature that ensures it can carry heavy loads over long distances. This strength is fundamental to its performance in demanding applications.

What does the ’24’ in M24 mean?

The ’24’ directly refers to the belt’s minimum ultimate tensile strength, measured in Megapascals (MPa). This number guarantees a high level of strength for the rubber cover itself. Simply put, it’s a promise of toughness.

- Indicates a tensile strength of at least 24 MPa.

- Ensures the cover won’t easily crack under tension.

How does strength affect load capacity?

Higher tensile strength allows the belt to handle heavier materials without stretching or failing. It directly correlates to the belt’s ability to support significant weight across the conveyor’s length. Look at it this way: a stronger belt can carry more, faster.

- Enables transport of heavy bulk materials.

- Reduces the risk of belt sag and stress.

What about strength vs. flexibility?

While incredibly strong, the belt remains flexible enough for effective troughing and wrapping around pulleys. But what about troughing? The EP or NN fabric carcass provides the perfect balance.

- Strength: Provided by the multi-ply fabric carcass.

- Flexibility: Allows the belt to form a trough to contain material.

- Balance: Ensures smooth operation around pulleys.

Key Takeaway: The 24 MPa tensile strength ensures the belt can handle heavy loads reliably, while its carcass construction provides the necessary flexibility for smooth conveyor operation.

| Strength Aspect | Implication for Use | |

|---|---|---|

| 24 MPa Cover | Resists cracking and surface damage | |

| Carcass Strength | Supports heavy loads over long spans | |

| Flexibility | Allows for efficient troughing and pulley wrap |

What is the rubber conveyor belt construction?

The belt is built in layers to maximize durability and performance. It consists of a top cover, a fabric core, and a bottom cover, all bonded together. This multi-layer design is what gives it both its strength and its resilience.

What is the all-important cover rubber?

The top and bottom covers are the belt’s first line of defense against abrasion, impact, and the environment. The M24 grade cover is specially compounded for high wear resistance. Essentially, it’s the belt’s protective shield.

- Top Cover: Thicker to handle direct contact with material.

- Bottom Cover: Protects the carcass from the conveyor frame.

What’s inside the EP/NN carcass core?

The carcass is the belt’s powerhouse, providing the tensile strength to handle the load. It’s made of multiple layers (plies) of either EP or NN fabric. So what’s the difference?

- EP (Polyester/Nylon): Offers low stretch and good dimensional stability.

- NN (Nylon/Nylon): Provides excellent flexibility and impact resistance.

What do plies and thickness mean?

The number of plies and the cover thickness determine the belt’s overall duty rating. More plies mean greater strength, while thicker covers offer more protection. Think of it this way: you customize it based on the job’s demands.

- Plies: More plies for heavier loads and longer distances.

- Cover Thickness: Thicker covers for larger, sharper materials.

Key Takeaway: The belt’s construction—combining tough rubber covers with a strong EP or NN fabric carcass—can be customized by ply count and thickness to match specific operational demands.

| Component | Function | |

|---|---|---|

| Top Rubber Cover | Resists abrasion and impact from material | |

| Fabric Carcass | Provides tensile strength and load support | |

| Bottom Rubber Cover | Protects the carcass from rollers and friction |

Where is this rubber conveyor belt used?

This heavy-duty belt is the workhorse of industries that move abrasive and heavy materials. You’ll find it in quarries, processing plants, and any operation where belt durability is non-negotiable. Its robust nature makes it indispensable for tough jobs.

Where is it used in heavy industries?

In mining and cement industries, the M24 grade is essential for moving raw, abrasive materials. It reliably transports everything from jagged rocks to clinker. The bottom line is: these industries depend on its toughness.

- Mining: Transporting ores, coal, and rock.

- Cement: Moving limestone, clay, and clinker.

What about power and steel plants?

Power, steel, and crushing plants use these belts to handle bulk materials efficiently. They are crucial for feeding boilers, moving coke, and transporting crushed stone. You might be surprised where else it’s used.

- Power Plants: Conveying coal and ash.

- Steel Plants: Handling coke and iron ore.

- Crushing Plants: Moving gravel and granite.

Is it right for my industry?

If your application involves conveying sharp, heavy, or abrasive materials, this belt is likely an excellent fit. It provides a reliable solution for industries beyond the ones listed. Think about it: any place where standard belts fail is a place for an M24.

- Recycling: Transporting glass and scrap metal.

- Quarries: Moving sand and gravel.

- Agriculture: Handling bulk grains and fertilizers.

Key Takeaway: The M24 rubber conveyor belt is a versatile solution for any industry that needs to reliably convey abrasive materials, from mining and cement to recycling and agriculture.

| Industry | Typical Application | |

|---|---|---|

| Mining | Ore, coal, and rock transport | |

| Cement | Limestone, clinker, and gypsum conveying | |

| Power & Steel | Coal, coke, and aggregate handling | |

| Recycling | Glass, metal, and plastic transport |

How durable is the rubber conveyor belt?

The durability of an M24 rubber conveyor belt is its defining characteristic. It is engineered to withstand extreme conditions, offering a significantly longer service life than lower-grade belts. This toughness translates directly into better performance and lower operational costs.

How does it resist wear and tear?

Its high-quality rubber compound and robust fabric carcass are key to resisting daily abuse. The belt is designed to handle gouges, abrasion, and heavy impacts without failing. What’s the secret? A superior material composition.

- Abrasion Resistance: The cover won’t easily wear away.

- Impact Resistance: The carcass absorbs shock from falling material.

What is the expected service life?

While service life varies, this belt consistently outlasts conventional belts in the same application. Longevity depends on several factors. The better you manage them, the longer your belt will last.

- Material Conveyed: Harsher materials may reduce lifespan.

- Operating Conditions: Load, speed, and tension play a role.

- Maintenance: Proper care is crucial for maximizing life.

How can I maximize my belt’s lifespan?

Proactive maintenance and correct operational practices are the best ways to get the most out of your belt. Get this right, and you’ll see the difference. Simple checks can prevent major problems down the line.

- Ensure proper belt alignment and tension.

- Regularly inspect for and repair minor damage.

- Keep the conveyor system clean of debris.

Key Takeaway: The inherent durability of the M24 belt, combined with proper maintenance, ensures a long and reliable service life even in the most demanding environments.

| Durability Factor | Impact on Belt Life | |

|---|---|---|

| Abrasion Resistance | Extends the life of the cover rubber | |

| Impact Absorption | Prevents carcass damage from heavy loads | |

| Proper Maintenance | Maximizes overall service lifespan |

What are the rubber conveyor belt temp limits?

A standard M24 rubber conveyor belt is designed to perform reliably within a typical range of ambient temperatures. While it is exceptionally tough, extreme heat requires special consideration. Understanding its thermal limits is key to selecting the right belt for your specific environment.

What are its standard operating temps?

This belt is generally suitable for conveying materials with temperatures up to 60°C (140°F). It performs excellently in most mining, quarrying, and industrial applications. You see, this range covers the vast majority of bulk material handling needs.

- Ideal for ambient to moderately warm conditions.

- Maintains flexibility and strength within this range.

How does it handle moisture and heat?

The M24 grade’s rubber compound offers good resistance to moisture and moderate heat. It won’t degrade or become brittle under normal operating temperatures. Here’s a quick rule of thumb: if the material is too hot to touch for long, you might need a specialized belt.

- Moisture: Resists water absorption, preventing carcass rot.

- Heat: Stable up to approximately 60-70°C.

When should I use a heat-resistant version?

For applications involving materials like hot clinker, ash, or foundry sand, you must use a specialized heat-resistant (HR) belt. A standard M24 belt will degrade quickly when exposed to continuous high temperatures. Don’t take the risk: always match the belt to the material’s temperature.

- Use HR belts for materials above 80°C (176°F).

- Specialized belts are available for temperatures up to 200°C (392°F).

Key Takeaway: While a standard M24 belt is perfect for temperatures up to 60°C, always choose a specialized heat-resistant (HR) or super-heat-resistant (SHR) belt for high-temperature applications.

| Belt Type | Max. Material Temperature | |

|---|---|---|

| Standard M24 | ~60°C (140°F) | |

| Heat-Resistant (HR) | ~120°C (250°F) | |

| Super-Heat-Resistant (SHR) | ~200°C (392°F) |

How to select a rubber conveyor belt?

Selecting the right conveyor belt involves matching the belt’s specifications to your unique operational needs. Factors like the material you’re moving, the conveyor design, and load requirements are crucial. Getting this choice right is the first step toward a reliable and efficient system.

How do I assess my conveyed material?

Analyze the characteristics of the material you need to move. Consider its lump size, abrasiveness, and sharpness. You see, a fine powder requires a different belt than large, jagged rocks.

- Abrasiveness: Determines the required cover grade (e.g., M24 for high abrasion).

- Lump Size: Influences the necessary cover thickness and impact resistance.

How do I choose plies and thickness?

The number of fabric plies and the rubber cover thickness depend on your conveyor’s tension and the impact from the material. Heavier loads over longer distances require more plies. Think of it this way: the tougher the job, the thicker the protection.

- Plies: Select based on belt tension and load support needs.

- Cover Thickness: Increase for larger lump sizes and higher drop heights.

Is M24 the right grade for you?

The M24 grade is ideal for moderate-to-heavy abrasion, but it might be overkill for less demanding applications. So, is M24 always the answer? No, for lighter materials like grain or wood chips, a general-purpose N17 grade may be more cost-effective.

- M24 Grade: For rock, ore, clinker, and other highly abrasive materials.

- N17 Grade: For sand, wood chips, and general-purpose use.

Key Takeaway: Choose the M24 grade for its superior abrasion resistance when handling harsh materials; for lighter duty, a lower grade like N17 may be more economical.

| Grade | Primary Use Case | |

|---|---|---|

| M24 | Heavy abrasion (rock, ore, glass) | |

| N17 | General purpose (sand, gravel, coal) | |

| General Duty | Light-duty (wood chips, grain) |

What is your rubber conveyor belt ROI?

The return on investment (ROI) for an M24 rubber conveyor belt goes beyond its initial purchase price. Its superior durability and reliability generate long-term value by reducing operational costs and maximizing uptime. It’s an investment in uninterrupted productivity.

How do you calculate the long-term value?

Calculate ROI by comparing the total cost of ownership of an M24 belt against a cheaper, lower-grade alternative. Factor in the costs of replacement belts, labor for installation, and lost production during downtime. The truth is, the upfront cost is only part of the story.

- Longer lifespan means fewer replacements.

- Reduced downtime leads to higher production output.

How does M24 reduce maintenance costs?

This belt’s resistance to wear, cuts, and gouges means it requires fewer patch-ups and repairs. This translates directly into lower labor costs and less spending on repair materials. Here’s the deal: a tougher belt simply breaks down less often.

- Fewer instances of belt tearing and damage.

- Less need for emergency splicing and repairs.

How does it boost operational efficiency?

A reliable conveyor belt ensures a smooth, continuous flow of materials through your facility. What does this mean for your output? It means predictable, consistent production without the costly interruptions caused by belt failures.

- Minimizes unscheduled production stoppages.

- Maintains a consistent throughput of materials.

- Allows maintenance teams to focus on other priorities.

Key Takeaway: The M24 rubber conveyor belt delivers a strong ROI by significantly lowering long-term costs associated with maintenance, replacements, and production downtime.

| ROI Factor | Contribution to Value | |

|---|---|---|

| Longer Lifespan | Reduces frequency and cost of belt replacement | |

| Reduced Maintenance | Lowers labor and material costs for repairs | |

| Increased Uptime | Maximizes production output and revenue |

How do you maintain the rubber conveyor belt?

Proper maintenance is key to unlocking the full service life and performance of your M24 rubber conveyor belt. Regular inspections and proactive care can prevent minor issues from becoming major, costly problems. This ensures your investment continues to pay off.

What’s in a simple inspection checklist?

Routinely walk the line and look for signs of trouble. Early detection is the best form of prevention. You can catch issues like misalignment or damage before they cause a shutdown.

- Check for proper belt tracking and alignment.

- Inspect for cuts, gouges, or edge wear.

- Listen for unusual noises from rollers or pulleys.

What are the proper repair methods?

For repairing tears or joining belt ends, you have a few options. The best method depends on the damage and your operational needs. Get this right, and your repair will be as strong as the belt itself.

- Hot Vulcanizing: Strongest, most durable bond.

- Cold Splicing: Good for quick, reliable field repairs.

- Mechanical Fasteners: Fastest method for emergency repairs.

What are some pro tips for a longer life?

Beyond basic inspections, a few best practices can dramatically extend your belt’s life. These simple habits protect the belt from unnecessary stress and wear. And the best part? They are easy to implement.

- Ensure loading points are designed to minimize impact.

- Use high-quality belt scrapers to keep the surface clean.

- Maintain correct belt tension—not too tight, not too loose.

Key Takeaway: A proactive maintenance schedule that includes regular inspections, proper repair techniques, and smart operational habits is essential for maximizing the lifespan of your belt.

| Maintenance Task | Frequency | |

|---|---|---|

| Visual Inspection | Daily / Weekly | |

| Tension & Tracking Check | Monthly | |

| Scraper & Cleaner Check | Weekly | |

| Splice Inspection | Monthly |

Conclusion

Ready to upgrade to a conveyor belt that can withstand your toughest challenges? By choosing the M24 grade, you solve the persistent problems of rapid wear and operational interruptions, ensuring a more reliable workflow. Contact our experts today for a personalized consultation and discover how the right belt can strengthen your entire operation.

Frequently Asked Questions (FAQ)

1. Can I use a standard M24 belt for high-heat materials like hot clinker?No, a standard M24 belt is rated for materials up to about 60°C (140°F). For high-heat materials, you must use a specialized Heat-Resistant (HR) or Super-Heat-Resistant (SHR) belt to prevent rapid degradation.

2. What’s the best way to clean an M24 rubber conveyor belt safely?The best way is to use properly installed belt scrapers and brushes. For manual cleaning, use water, mild detergents, and soft brushes, ensuring the system is locked out and tagged out for safety. Avoid harsh solvents that can damage the rubber.

3. How do I know if my rubber conveyor belt’s tension needs adjustment?Signs of incorrect tension include belt slippage on the drive pulley (too loose) or excessive stress on splices and pulleys (too tight). A properly tensioned belt will have a slight sag between the idlers on the return side.

4. Can I repair a significant tear or gouge in an M24 rubber conveyor belt?Yes. Minor cuts can be fixed with repair kits. For significant tears, a section of the belt may need to be cut out and a new piece installed using a vulcanized splice or mechanical fasteners for a durable repair.

5. How do I know if M24 grade is overkill for my specific application?If you are conveying non-abrasive or very light materials like sawdust, grain, or packaged goods, the M24 grade’s high abrasion resistance may be unnecessary. In such cases, a more economical general-purpose grade like N17 would be a more suitable choice.