Inefficient material handling can slow production, increase labor costs, and create operational bottlenecks in industries such as mining, logistics, and manufacturing. Manual systems often struggle to deliver consistency, resulting in unreliable throughput and wasted resources. The solution lies in understanding the rubber conveyor belt manufacturing process, which reveals how advanced mixing, calendaring, curing, and quality-control steps contribute to producing durable, high-performance belts. By leveraging insights from the rubber conveyor belt manufacturing process, factories can choose belts engineered for stability, long service life, and improved overall efficiency.

Table of Contents

Rubber Belt Raw Mixing Basics

Start the rubber conveyor belt manufacturing process by blending raw materials in a Banbury mixer for uniform compounds. You might be wondering how this initial step ensures your belts perform reliably under heavy loads.

What Materials Go In?

You’ll need a synthetic rubber base for flexibility, sulfur for vulcanization strength, and carbon black to enhance wear resistance. Antioxidants protect against heat degradation, while oils improve processability. These ingredients form the compound that withstands industrial stresses.

Why Mix Precisely?

Think about it: Ensures consistent belt properties and prevents weak spots in the final product. Uniform mixing avoids inconsistencies that could lead to early failures during operation.

Key Takeaway: Precise mixing sets the foundation for durable belts.

| Step Aspect | Key Benefit | Common Pitfall | |

|---|---|---|---|

| Material Blend | Uniform strength | Overheating |

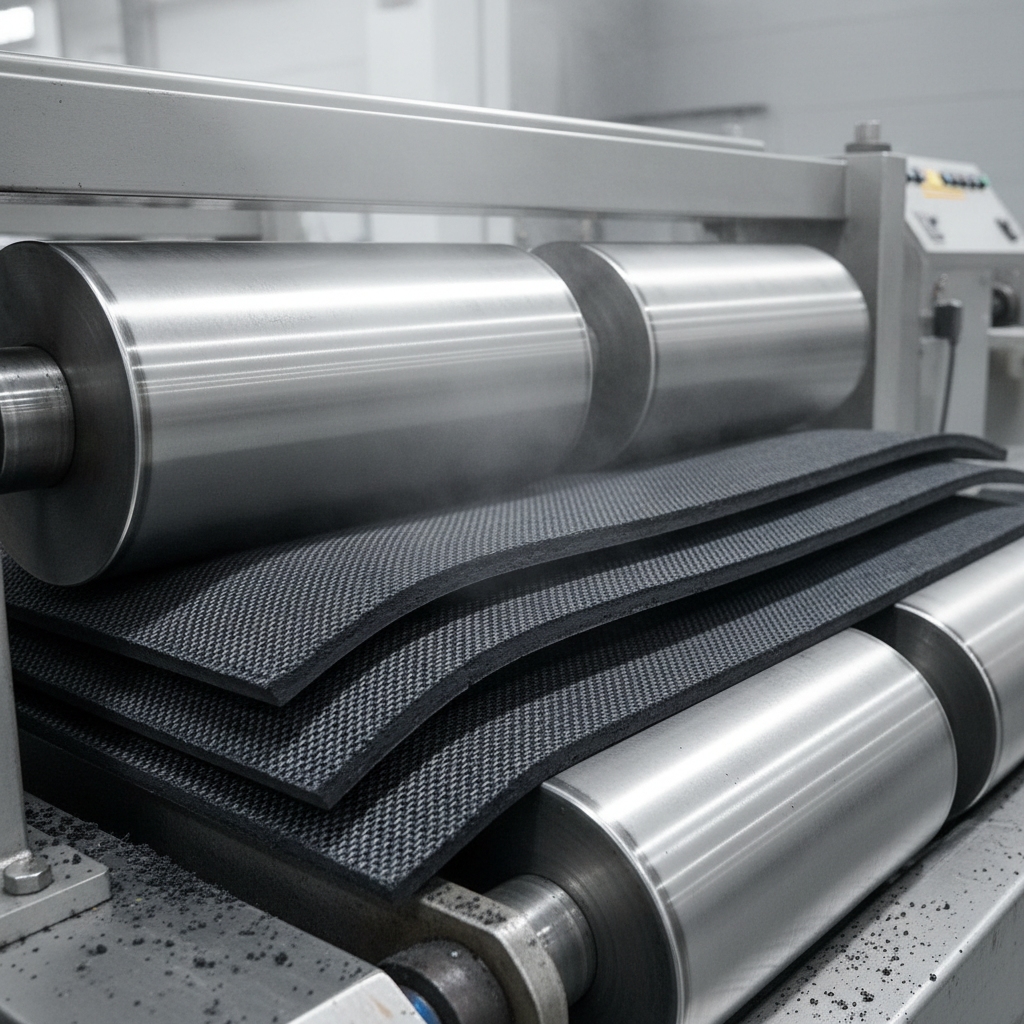

Calendaring for Sheet Formation

In the rubber conveyor belt manufacturing process, calendaring presses mixed rubber into thin, even sheets via heavy rollers. This creates the foundational layers essential for belt integrity.

How Rollers Shape Rubber?

Apply pressure and heat for uniformity, stretch material to desired thickness, and integrate fabric like nylon for support. You’ll feed the compound slowly to avoid tears, ensuring smooth sheets ready for layering.

Fabric Layer Options?

Polyester offers high tensile strength for heavy-duty use, while cotton provides cost-effective flexibility for lighter applications.

Key Takeaway: Calendaring builds the belt’s core structure for reliability.

| Factor | Impact on Belt | Adjustment Tip | |

|---|---|---|---|

| Temperature | Smooth flow | 80-100°C ideal | |

| Speed | Even thickness | Slow for precision |

Laminating Layers Together

Laminating in the rubber conveyor belt manufacturing process stacks rubber and fabric layers with adhesives for added strength. What’s the real story? This bonding prevents separation under tension.

What Bonds the Layers?

Specialized adhesives ensure strong adhesion, while high-pressure machines stack layers firmly. But don’t stop there—curing follows to lock everything in place.

Alignment Challenges?

Misalignment causes weak points, so proper setup prevents delamination. Inspect visually during the process to catch issues early.

Key Takeaway: Strong lamination creates resilient, multi-layer belts.

| Layer Type | Strength Gain | Risk if Poor | |

|---|---|---|---|

| Rubber-Fabric | Tensile boost | Peeling under load | |

| Multiple Stacks | Durability | Uneven flex |

Vulcanizing for Durability

Vulcanization transforms the rubber conveyor belt manufacturing process by applying heat and pressure to cure layers into a tough material. This step is crucial for long-term performance.

How Heat Changes Rubber?

Heat alters the molecular structure for elasticity and builds resistance to chemicals and wear. You’ll see the belt harden without cracking, gaining the toughness needed for harsh environments.

Pressure’s Role?

Pressure ensures even curing and prevents air pockets, resulting in a seamless, solid product.

Key Takeaway: Vulcanizing makes belts ready for industrial demands.

| Parameter | Optimal Setting | Outcome | |

|---|---|---|---|

| Heat | 150-180°C | Flexible strength | |

| Pressure | High psi | Seamless bond |

Quality Checks Post-Process

Final checks in the rubber conveyor belt manufacturing process inspect vulcanized belts for defects like cracks or thickness issues. Ready for the good part? These ensure only top-quality products ship.

What Tests Are Done?

Conduct visual scans for bubbles, strength pulls for tensile testing, and flexibility bends under load to simulate real use.

When to Reject?

Reject if uneven thickness exceeds 5% or visible cracks appear, safeguarding against failures.

Key Takeaway: Rigorous checks guarantee performance and safety.

| Test Type | Pass Criteria | Failure Rate Impact | |

|---|---|---|---|

| Thickness | ±2mm variance | Reduces by 15% | |

| Strength | 300N/mm min | Ensures longevity |

Cutting and Packaging Steps

After checks, the rubber conveyor belt manufacturing process cuts belts to length and packages them for shipment. Precision here maintains product integrity.

How to Cut Precisely?

Use automated shears for accuracy and measure per customer specs to meet exact requirements.

Packaging Best Practices?

Roll to prevent creases and protect with wraps from damage during transit.

Key Takeaway: Proper finishing ensures belts arrive ready to install.

| Aspect | Method | Benefit | |

|---|---|---|---|

| Cutting | Laser-guided | Zero waste | |

| Packaging | Moisture-proof | Extends shelf life |

Materials Selection Impact

Choosing materials shapes the entire rubber conveyor belt manufacturing process for specific industry needs. This is where it gets interesting: Tailoring boosts efficiency.

Rubber Types for Durability?

Natural rubber provides flexibility for general use, while synthetic offers heat resistance for extreme conditions.

Key Takeaway: Tailored materials match your operational challenges.

| Material | Use Case | Pro/Con | |

|---|---|---|---|

| Carbon Black | Wear-prone areas | Strong / Adds weight |

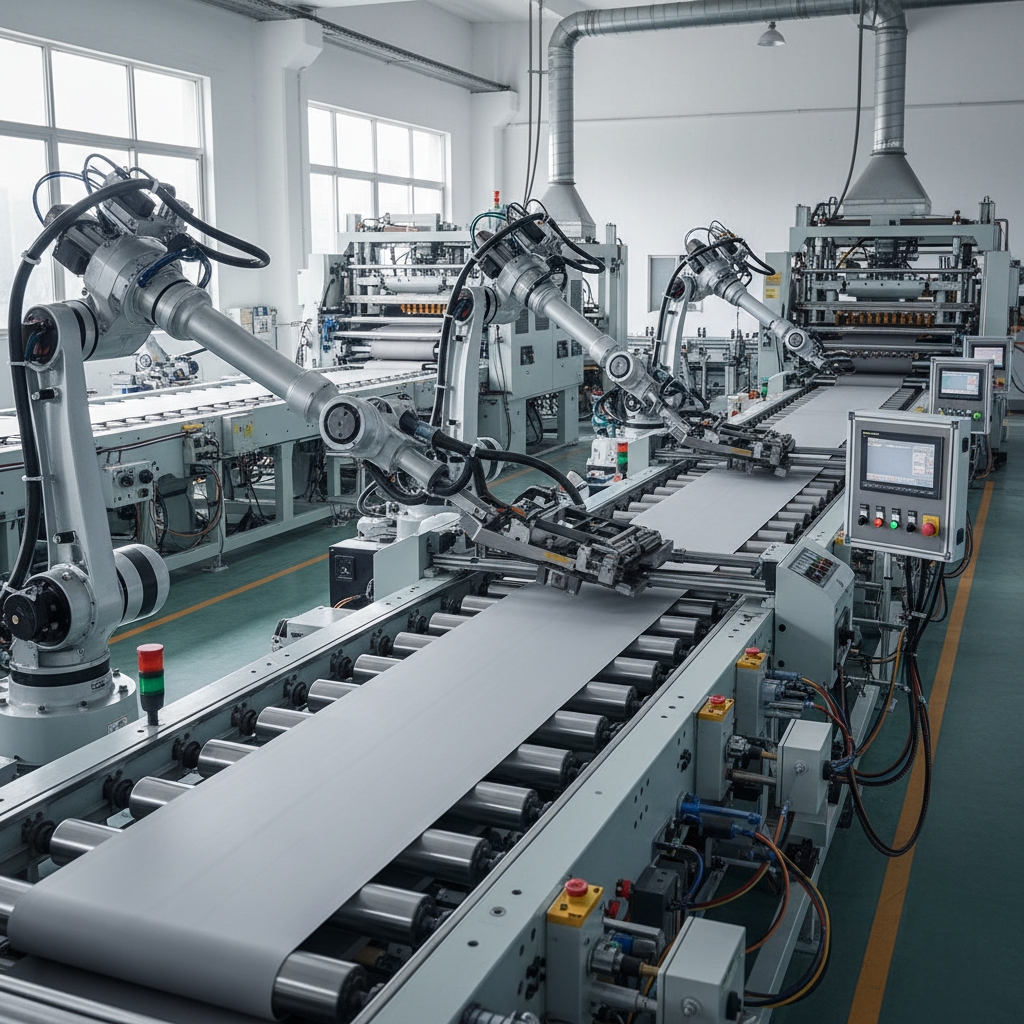

Machinery in Production

Specialized machines drive efficiency in the rubber conveyor belt manufacturing process from mixing to curing. Now, picture this setup in action for seamless output.

Key Machines Explained?

Banbury mixers blend compounds, calenders form sheets, and presses handle vulcanizing for complete production.

Maintenance Needs?

Perform regular lubrication and daily inspections to keep operations running smoothly.

Key Takeaway: Reliable machinery ensures consistent output.

| Machine | Function | Maintenance Tip | |

|---|---|---|---|

| Mixer | Compound prep | Clean weekly | |

| Press | Curing | Calibrate heat |

Safety in Manufacturing

Safety protocols protect workers throughout the rubber conveyor belt manufacturing process involving heat and heavy equipment. Prioritizing this avoids costly incidents.

Common Hazards?

Watch for hot surfaces causing burns and pinch points on rollers that pose injury risks.

Prevention Steps?

Wear PPE always, train on emergency stops, and ensure ventilation for fumes. You’ll avoid accidents by following these protocols diligently.

Key Takeaway: Prioritizing safety sustains smooth operations.

| Hazard | Control Measure | Effectiveness | |

|---|---|---|---|

| Heat | Guards/shields | 95% reduction | |

| Fumes | Exhaust systems | Improves air quality |

Benefits of Quality Process

A refined rubber conveyor belt manufacturing process yields belts that enhance productivity and reduce downtime. But here’s the kicker: It delivers real ROI.

Longevity Gains?

Belts withstand 10,000+ hours of use and resist abrasion effectively in tough settings.

Key Takeaway: Invest in quality for lasting efficiency.

| Benefit | Metric | Industry Edge | |

|---|---|---|---|

| Durability | 5x longer life | Cuts replacement costs |

Conclusion

Echoing your struggles with unreliable belts causing delays, this guide outlines proven manufacturing steps for robust solutions that drive efficiency and reliability in your operations. Ready to upgrade? Contact experts today to customize belts for your vision of seamless production—reach out for a quote and transform your workflow.

FAQ

Q1: Can I customize belt thickness in manufacturing? Yes, but stick to standard ranges (5-30mm) for optimal performance—thicker suits heavy loads, as thinner risks tearing under stress.

Q2: What’s the best rubber type for mining? Synthetic blends excel here, offering superior abrasion resistance over natural rubber, which wears faster in dusty environments.

Q3: How do I know if a belt is well-vulcanized? Test for elasticity without cracking; poor vulcanization leads to brittleness, confirmed by lab pulls showing under 200N/mm strength.

Q4: Can the process handle eco-friendly materials? Absolutely, incorporate recycled rubbers if specs allow—they maintain 90% durability while reducing environmental impact through sustainable sourcing.

Q5: What’s the best way to store manufactured belts? Keep in cool, dry areas rolled flat; improper storage causes warping, shortening lifespan by up to 30% per industry tests.