IW/SW Steel Mesh Conveyor Belt

Engineered for Extreme Conditions - Maximum Protection Against Impact, Tears & High Temperatures

Steel Mesh Reinforced Conveyor Solutions

Discover the power of woven steel cord technology - engineered to outperform traditional fabric belts in the toughest industrial applications

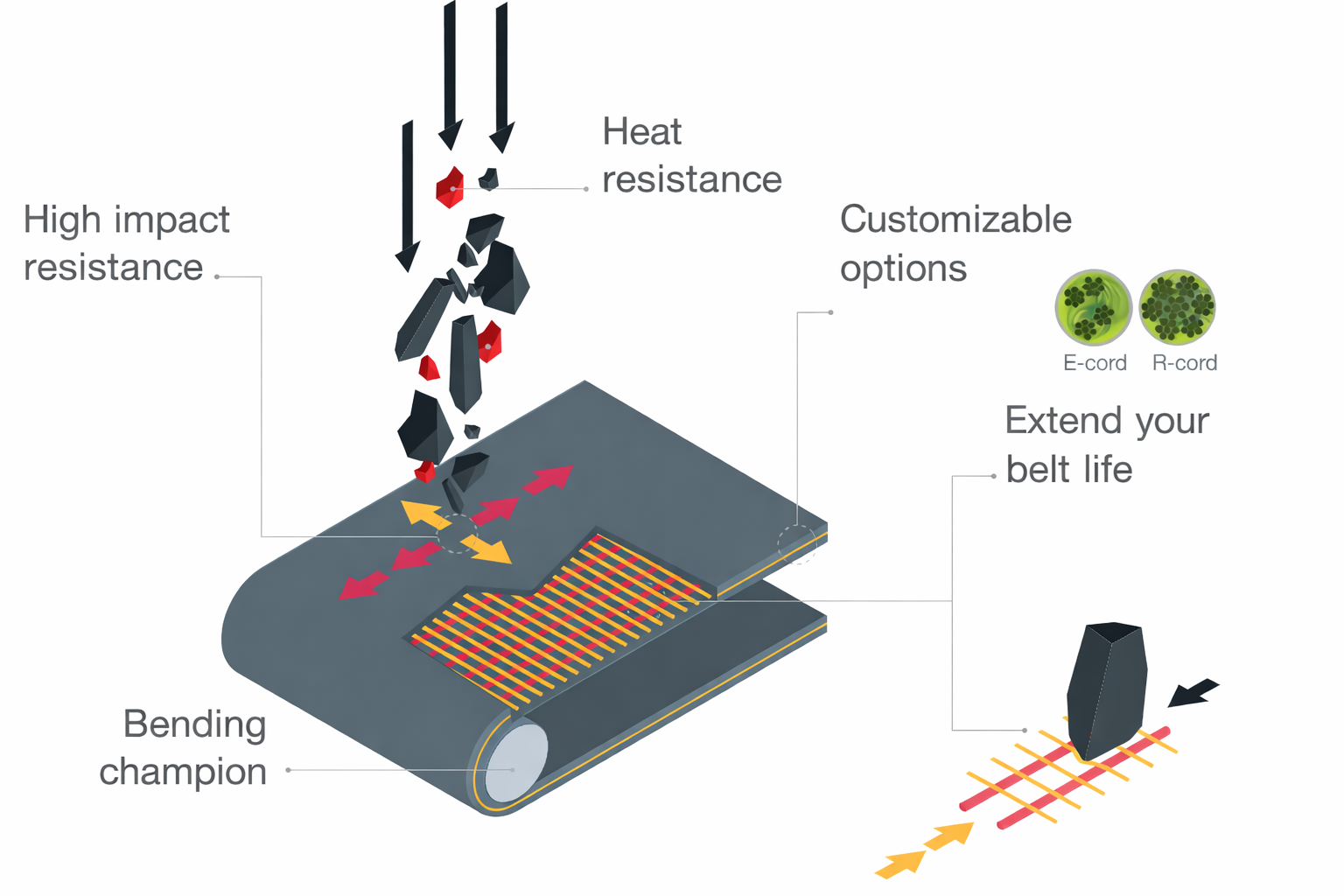

IW (Impact Weft) Conveyor Belt

Application

Specially designed for heavy-duty operations where brutal impacts, severe cuts, and tearing are daily challenges. The integrated woven steel cord fabric provides exceptional durability in quarrying, steel works, waste recycling, and mining environments where conventional belts fail repeatedly.

Features

- Woven steel cords in both longitudinal and transversal directions create an integrated fabric that prevents cable separation during operation

- Integrated transversal cords distribute impact forces smoothly, offering superior embedded protection against rips and cuts

- E-cord (elongation cord) construction delivers rubberized flexibility far exceeding conventional steel cord belts, reducing pulley wear

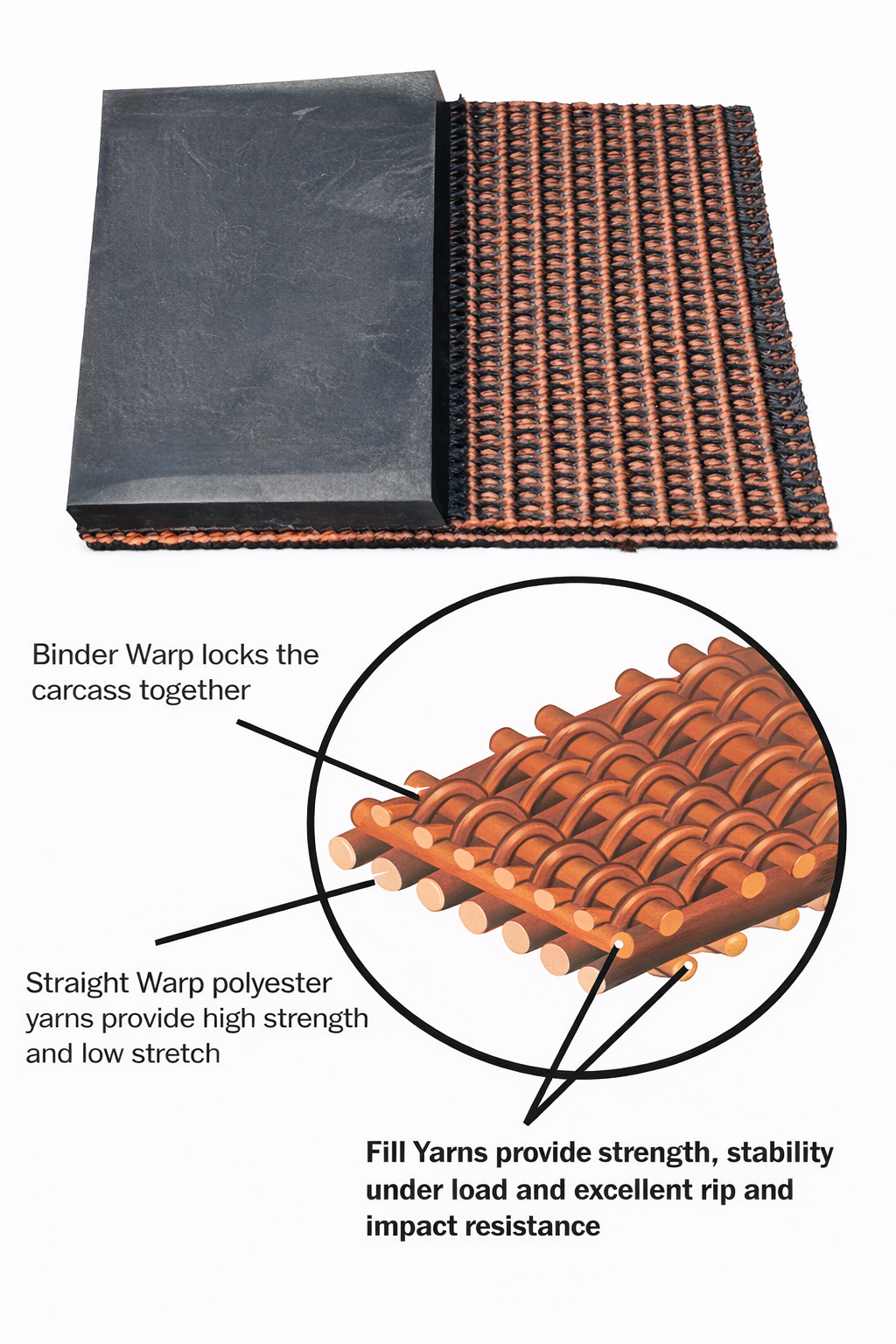

SW (Straight Warp) Conveyor Belt

Application

Engineered for heavy-duty conveyors requiring impact and tear resistance while working with smaller pulley diameters than standard textile or steel cord belts. Ideal for quarrying, open-cast mining, steel industries, and applications demanding narrow yet robust belting solutions such as tunneling operations.

Features

- Polyester straight-warp construction with protective weft lines in polyamide delivers superior cut, impact, and wear resistance

- Thin carcass design enables use with smaller pulley diameters, reducing installation footprint and costs

- Reinforced fabric plies resist puncturing and maintain structural integrity under continuous stress

- Excellent troughability ensures smooth material flow on small to medium-sized pulleys

- Carcass frame adheres to RFL coating and features various rubber cover options: anti-abrasive, oil-resistant, heat-resistant (T150°-T200°), providing versatility for diverse operating conditions

- Extended lifespan outlasts multi-ply belts, delivering cost savings through reduced downtime and replacement frequency

Technical Parameters & Specifications

Comprehensive technical data to help you select the perfect belt grade for your operational requirements

IW Steel Mesh Technical Parameters

| Type | Tensile Strength KN/m |

Carcass Thickness mm |

Carcass Weight Kg/m² |

|---|---|---|---|

| IW500 | 500 | 3.2 | 2.45 |

| IW630 | 630 | 3.2 | 2.95 |

| IW800 | 800 | 4.5 | 4.15 |

| IW1000 | 1000 | 4.5 | 5.00 |

| Cord Diameter Warp mm |

Cord Pitch Warp mm |

Cord Diameter Weft mm |

Cord Pitch Weft mm |

|---|---|---|---|

| 2.00 | 5.81 | 1.52 | 17.5 |

| 2.00 | 4.63 | 1.52 | 17.5 |

| 2.85 | 6.67 | 2.10 | 20.0 |

| 2.85 | 5.38 | 2.10 | 20.0 |

| Type | Tensile Strength KN/m |

Carcass Thickness mm |

Carcass Weight Kg/m² |

|---|---|---|---|

| IW1250 | 1250 | 6.0 | 6.35 |

| IW1400 | 1400 | 6.0 | 7.05 |

| IW1600 | 1600 | 6.0 | 7.90 |

| IW2000 | 2000 | 6.0 | 8.50 |

| Cord Diameter Warp mm |

Cord Pitch Warp mm |

Cord Diameter Weft mm |

Cord Pitch Weft mm |

|---|---|---|---|

| 3.90 | 7.04 | 2.40 | 20.0 |

| 3.90 | 6.25 | 2.40 | 20.0 |

| 3.90 | 5.50 | 2.40 | 20.0 |

| 3.90 | 4.65 | 2.40 | 20.0 |

SW Steel Mesh Technical Parameters

| Type | Tensile Strength KN/m |

Carcass Thickness mm |

Carcass Weight Kg/m² |

|---|---|---|---|

| SW500 | 500 | 4.6 | 3.10 |

| SW630 | 630 | 4.6 | 3.60 |

| SW800 | 800 | 5.4 | 4.55 |

| SW1000 | 1000 | 5.4 | 5.40 |

| Cord Diameter Warp mm |

Cord Pitch Warp mm |

Cord Diameter Weft mm |

Cord Pitch Weft mm |

|---|---|---|---|

| 2.00 | 5.81 | 1.29 | 6.67 |

| 2.00 | 4.63 | 1.29 | 6.67 |

| 2.85 | 6.67 | 1.29 | 6.67 |

| 2.85 | 5.38 | 1.29 | 6.67 |

| Type | Tensile Strength KN/m |

Carcass Thickness mm |

Carcass Weight Kg/m² |

|---|---|---|---|

| SW1250 | 1250 | 6.3 | 6.50 |

| SW1400 | 1400 | 6.3 | 7.25 |

| SW1600 | 1600 | 6.3 | 8.10 |

| SW2000 | 2000 | 6.3 | 9.30 |

| Cord Diameter Warp mm |

Cord Pitch Warp mm |

Cord Diameter Weft mm |

Cord Pitch Weft mm |

|---|---|---|---|

| 3.90 | 7.04 | 1.29 | 6.67 |

| 3.90 | 6.25 | 1.29 | 6.67 |

| 3.90 | 5.50 | 1.29 | 6.67 |

| 3.90 | 4.65 | 1.29 | 6.67 |

Need help selecting the right specification for your application?

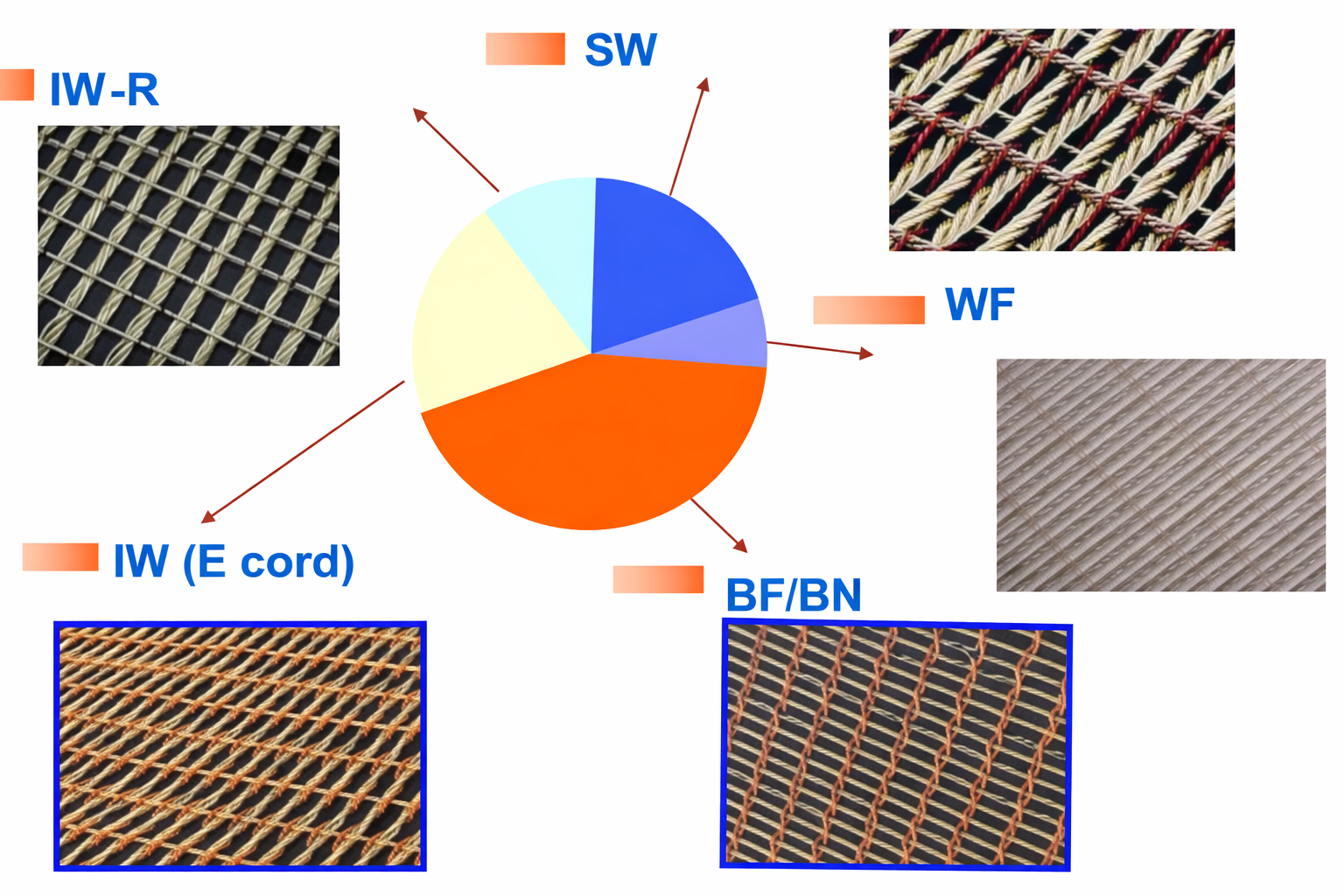

Steel Mesh Belt Type Comparison

Choose the optimal steel mesh construction for your specific operational challenges

Unsure which type suits your needs best? Let our experts guide you.

Why IW/SW Steel Mesh Belts?

Understanding your operational challenges and how steel mesh technology delivers superior solutions

Common Conveyor Belt Challenges You Face

Puncture & Tear Damage

Regular textile belts easily get punctured by sharp rocks, metal scraps, and irregular materials, leading to frequent costly replacements and unplanned downtime that disrupts your production schedule.

Impact Zone Failures

Heavy falling materials in loading areas cause rapid belt deterioration. Standard belts cannot absorb repeated high-impact loads, resulting in premature carcass damage and expensive emergency repairs.

Heat Degradation Issues

In high-temperature environments like sintering plants and焦化 facilities, conventional rubber belts age rapidly, losing strength and flexibility, forcing you to replace belts more frequently than planned.

Belt Slippage Problems

Vertical or steep-incline conveyors struggle with material slippage using standard belts, reducing efficiency and creating safety hazards as loads shift unpredictably during transport.

How IW/SW Steel Mesh Solves These Problems

Unmatched Tear & Puncture Resistance

The integrated woven steel cord fabric creates a protective barrier that sharp objects cannot easily penetrate. Unlike fabric belts where individual plies separate, our steel mesh construction distributes stress across the entire carcass, preventing rip propagation and extending belt life by 3-5x in harsh conditions.

Superior Impact Absorption

Transversal steel cords embedded throughout the belt smoothly distribute impact forces from falling materials, protecting the carcass integrity. The E-cord (elongation cord) design adds rubberized flexibility that cushions shocks far better than rigid steel cord belts, dramatically reducing damage at loading points.

Excellent Heat Tolerance

Steel cords maintain structural strength at elevated temperatures where textile fibers would fail. Brass-coated steel construction resists thermal degradation, while specialized heat-resistant rubber covers (T150°-T200°) protect against direct heat exposure, ensuring reliable performance in sintering, casting, and other high-temperature applications.

Enhanced Grip & Stability

SW straight warp construction delivers excellent troughability and material retention on inclines. The open cord structure allows deep rubber penetration, creating a bonded matrix that prevents slippage and maintains positive material control even on steep gradients or in vertical conveying systems.

IW/SW steel mesh construction provides better anti-tear capability and anti-puncture performance than EP, NN, or conventional steel cord belts. The integrated woven structure prevents cable separation and delivers superior embedded protection that keeps your operations running with minimal interruption.

Real-World Applications & Global Delivery

See our steel mesh conveyor belts in action across diverse industries and our commitment to reliable worldwide shipping

Application Scenarios

Proven performance in mining, quarrying, steel works, cement plants, and heavy industry environments where extreme durability is essential

Professional Packaging & Shipping

Secure packaging and logistics management ensuring your belts arrive in perfect condition, ready for installation worldwide

Why Work With Our Factory?

Partner with China's leading steel mesh conveyor belt manufacturer - where advanced engineering meets proven reliability

Our Competitive Advantages

Leading Manufacturer

Advanced production facilities with automated quality control

Full Customization

Tailor structure, strength, and width to your exact needs

ISO Certified

ISO 9001:2015 certified with rigorous testing protocols

Fast Delivery

15-20 day standard delivery, 25-35 for custom orders

Inside Our Manufacturing Facility

International Certifications & Standards

Let's Build Reliable Conveyor Solutions Together

Send us your specifications or project details — our engineers will analyze your requirements in 24h

Why Choose ZHENXING?

Contact Information

zhenxinglisa@hotmail.com

+86 18661664598

1. EP NN CC ST,SIDEWALL FR MOR HR EPDM -DONGYING

2. Solid Woven PVC PVG Conveyor Belt -JINING, Shandong

3. Sidewall Conveyor Belt -Weifang, Shandong

Get Your Custom Solution in 24 Hours

Share your requirements and receive expert guidance with a tailored quote