Frequently Asked Questions

Common questions about sidewall conveyor belts

Q1: Are these sidewall belts manufactured in your own factory?

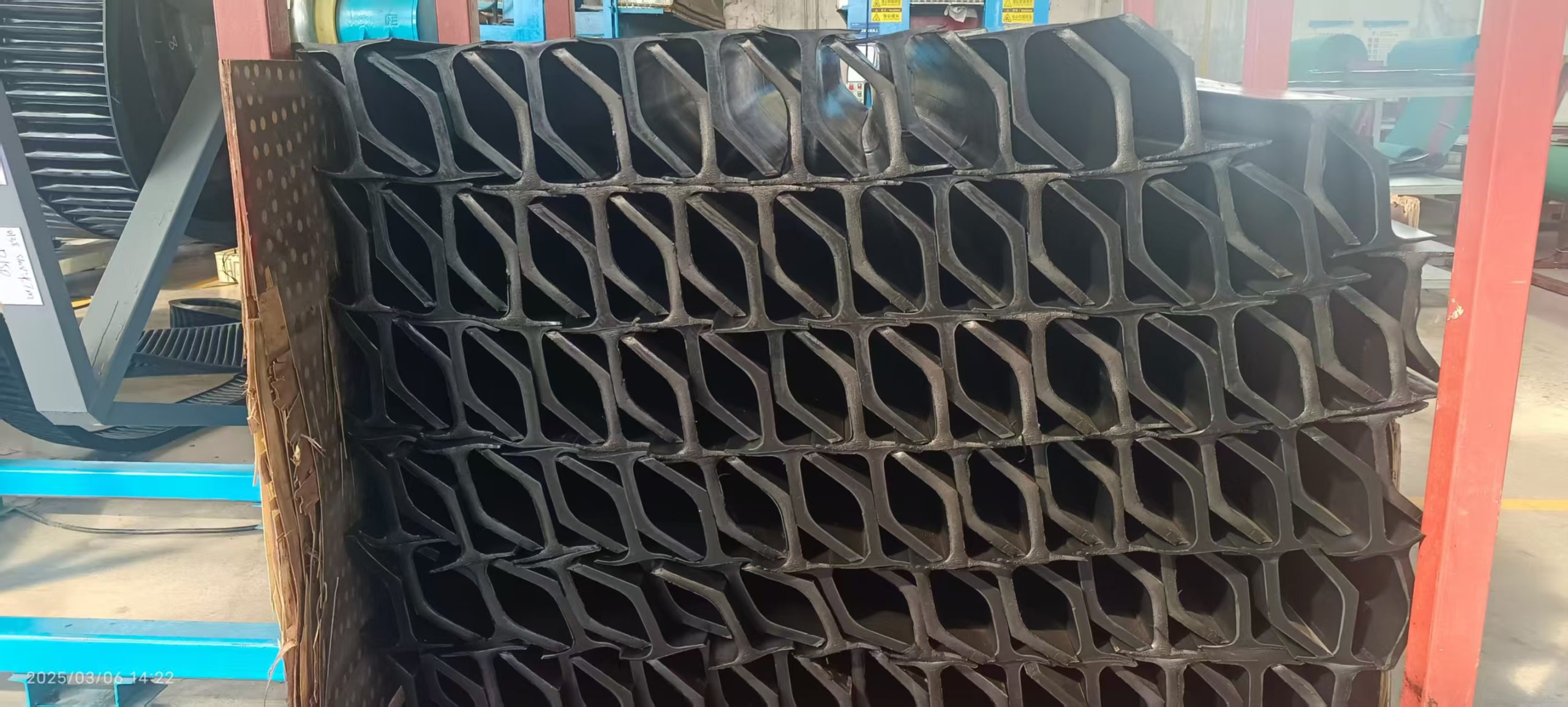

Yes, all our sidewall conveyor belts are manufactured in our own facility with 40 years of production experience. We control every stage from rubber compounding to final vulcanization, ensuring consistent quality and the ability to customize specifications to your exact requirements. Our factory is equipped with European-standard production lines and automated quality control systems.

Q2: What is the typical delivery time for sidewall conveyor belts?

Standard specifications typically ship within 15-20 working days. Custom-designed belts require 25-35 working days depending on complexity and quantity. We maintain inventory of common sizes and materials to expedite delivery. Express production is available for urgent orders. All timelines include complete quality testing and inspection before shipment.

Q3: How are sidewall conveyor belts packaged for shipping?

Belts are carefully rolled onto sturdy wooden or steel cores to prevent deformation during transport. The entire roll is wrapped in waterproof plastic film, then protected with heavy-duty fabric covering. For export shipments, we provide fumigation-certified wooden packaging or use steel frames with strapping. Each package includes detailed specification labels and handling instructions. Special packaging is available for extreme climate conditions.

Q4: What quality testing is performed before delivery?

Every belt undergoes comprehensive testing including tensile strength verification, adhesion testing between components, dimensional accuracy measurement, and visual inspection. We perform dynamic fatigue testing on sidewalls and cleats, abrasion resistance testing on covers, and verify all specifications against international standards (DIN, ISO, EN). Complete test reports and certificates are provided with each shipment.