Imagine your production line coming to a standstill because an unsuitable conveyor belt wears out prematurely under abrasive loads, causing costly and unexpected downtime. These failures can escalate repair expenses—sometimes thousands per hour—while delaying shipments, frustrating teams, and eroding your competitiveness in fast-paced manufacturing environments. Gaining a clear understanding of rubber conveyor belt specification helps you select the right belt grade for durability, abrasion resistance, fire safety, and overall efficiency. By knowing which specifications match your operating conditions, you can ensure smoother performance, fewer disruptions, and long-term operational stability.

Basics of Rubber Conveyor Belt Specification

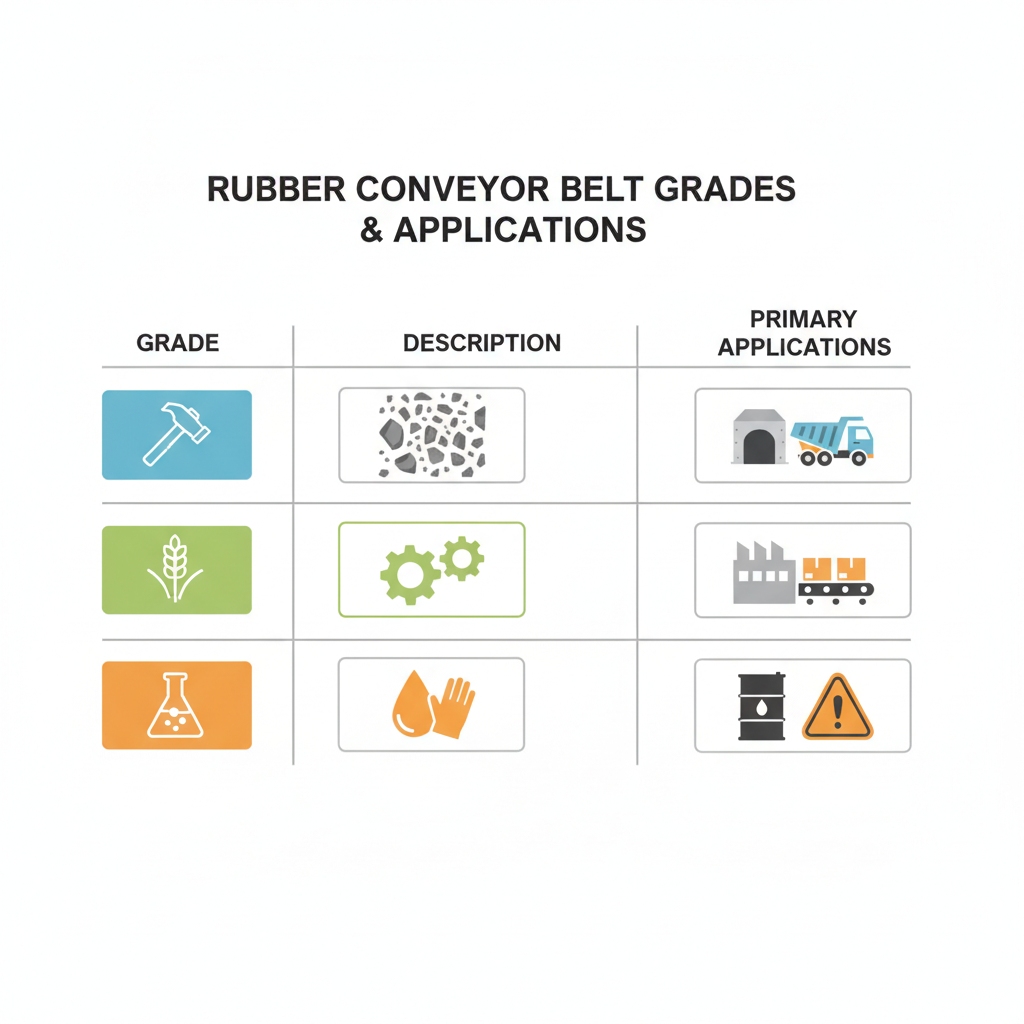

What Defines Rubber Conveyor Belt Grades?

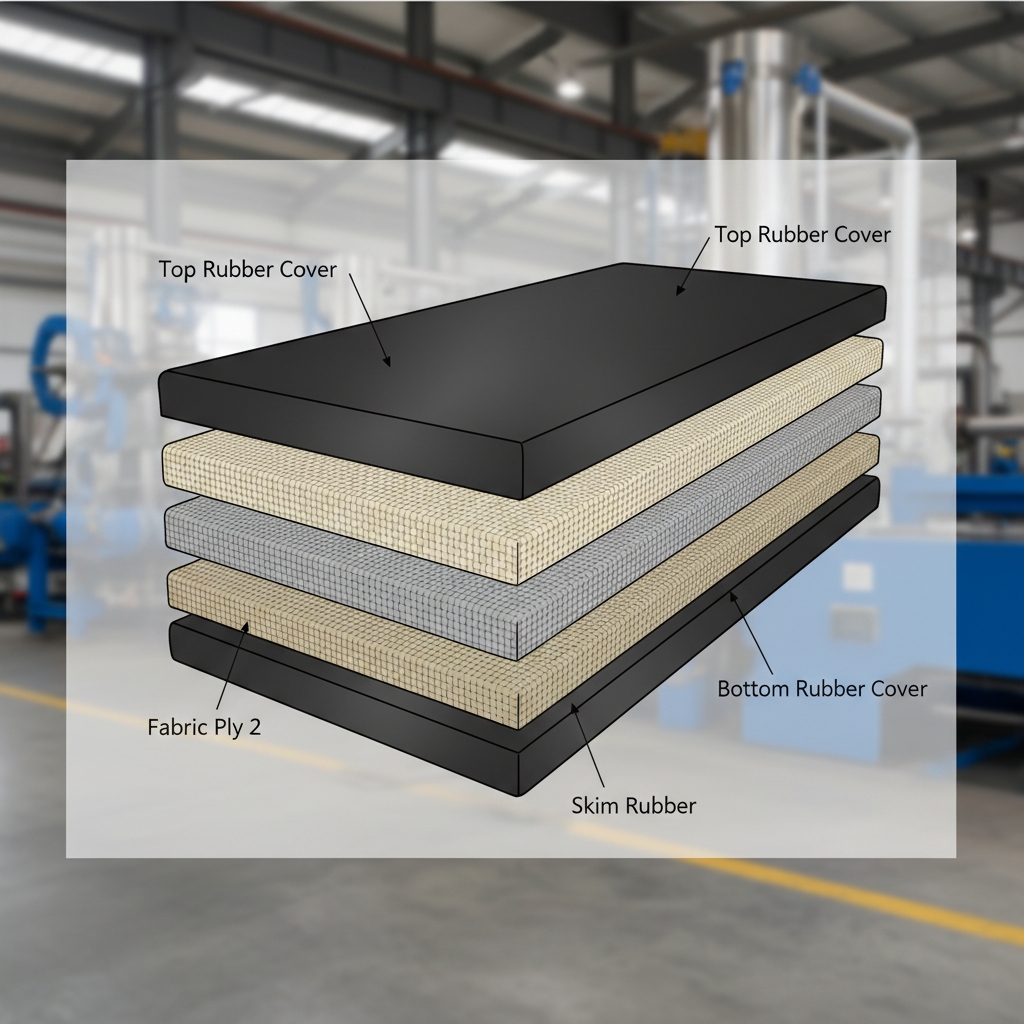

You rely on conveyor belts daily, so grasping grades starts with their core makeup. Here’s the deal: Grades classify rubber based on resistance to wear, heat, or static.

- Natural rubber offers flexibility for light loads.

- Synthetic blends boost toughness in harsh spots.

- Ply count determines load capacity you handle.

You might be wondering how this ties to your setup—grades ensure belts last longer without surprises.

Why Follow ISO 433 Standards?

Standards keep your operations safe and consistent. You avoid fines by meeting ISO 433, which sets benchmarks for rubber conveyor belt specification.

- Tests verify abrasion and tensile strength.

- Compliance cuts replacement frequency.

- Global alignment simplifies sourcing.

But wait, there’s more: Adhering prevents failures that halt production.

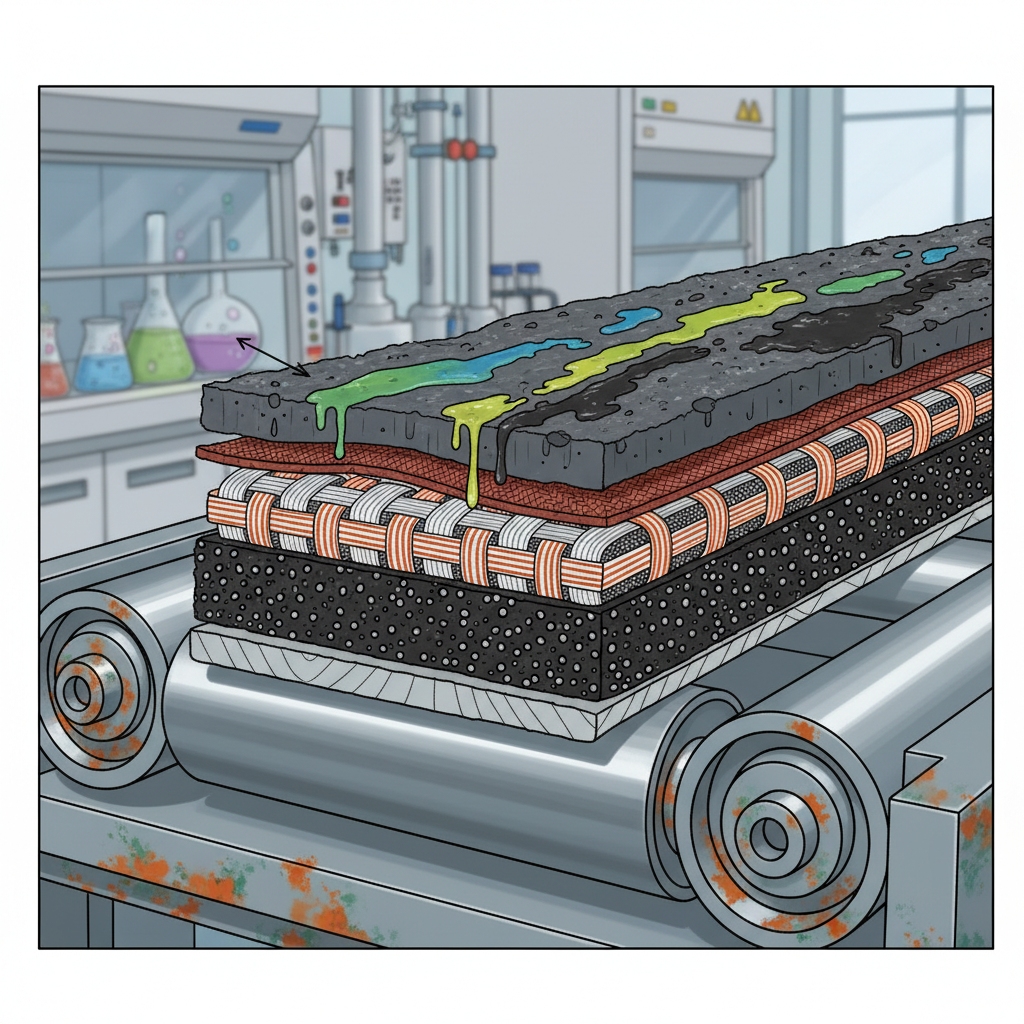

How Do Compounds Affect Performance?

Compounds shape how belts perform under stress. You select them to match your materials’ demands in rubber conveyor belt specification.

- Styrene-butadiene resists cracking from flexing.

- Neoprene handles oils without swelling.

- Carbon black additives enhance durability.

What’s the catch? Wrong compounds lead to early breakdowns, but right ones optimize flow.

Key Takeaway

Mastering basics in rubber conveyor belt specification builds reliable systems.

| Aspect | Benefit | Example | |

|---|---|---|---|

| Grades | Durability | Abrasion for ore | |

| Standards | Safety | ISO 433 compliance | |

| Compounds | Efficiency | Synthetic for heat |

This foundation reveals why precise specs prevent costly errors in your facility.

General Purpose in Rubber Conveyor Belt Specification

When to Choose Grade M or N?

You need versatile belts for routine tasks. Grade M suits moderate abrasion in rubber conveyor belt specification, while N fits lighter duties.

- M for gravel transport without excess wear.

- N for packaging lines with minimal stress.

- Both cut costs over specialized options.

Ready for the good part? Picking M extends uptime in busy warehouses.

How Does Quality Impact Daily Use?

Higher quality means fewer interruptions for you. In rubber conveyor belt specification, M’s superior strength reduces stretching.

- Less elongation keeps alignment sharp.

- Better tear resistance handles impacts.

- Smoother runs lower energy use.

This is where it gets interesting: Quality directly boosts your output rates.

What Are Cost-Effective Applications?

Balance budget with performance in your choices. Rubber conveyor belt specification guides affordable uses like bulk handling.

- Grain elevators favor N for low abrasion.

- Recycling sorts use M economically.

- Warehousing benefits from both’s longevity.

You might be wondering about ROI— these grades pay off through reduced swaps.

Key Takeaway

General purpose grades streamline everyday operations affordably.

| Grade | Strength | Application | |

|---|---|---|---|

| M | High | Bulk materials | |

| N | Medium | Light loads | |

| Both | Versatile | Cost savings |

Selecting wisely in rubber conveyor belt specification minimizes expenses while maximizing reliability.

Abrasion Resistance in Rubber Conveyor Belt Specification

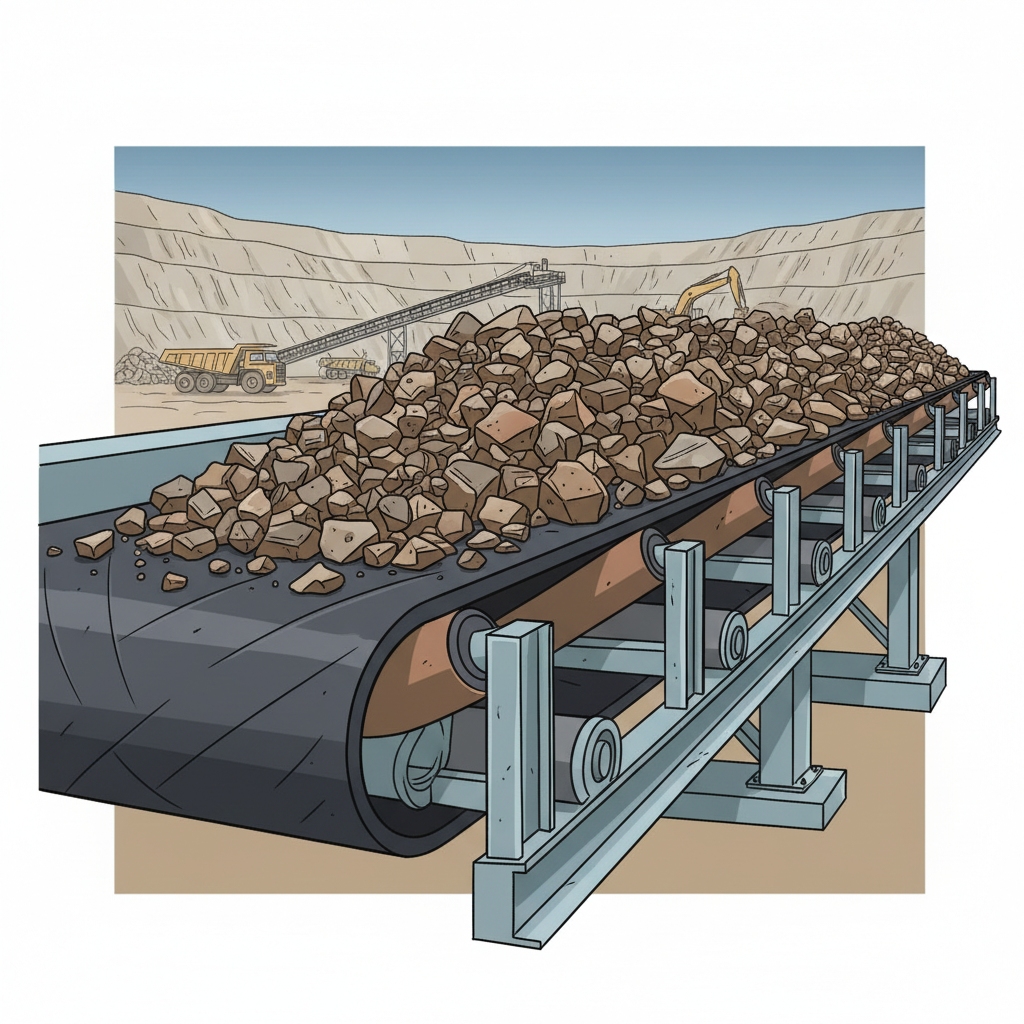

Why Pick Grade A for Tough Materials?

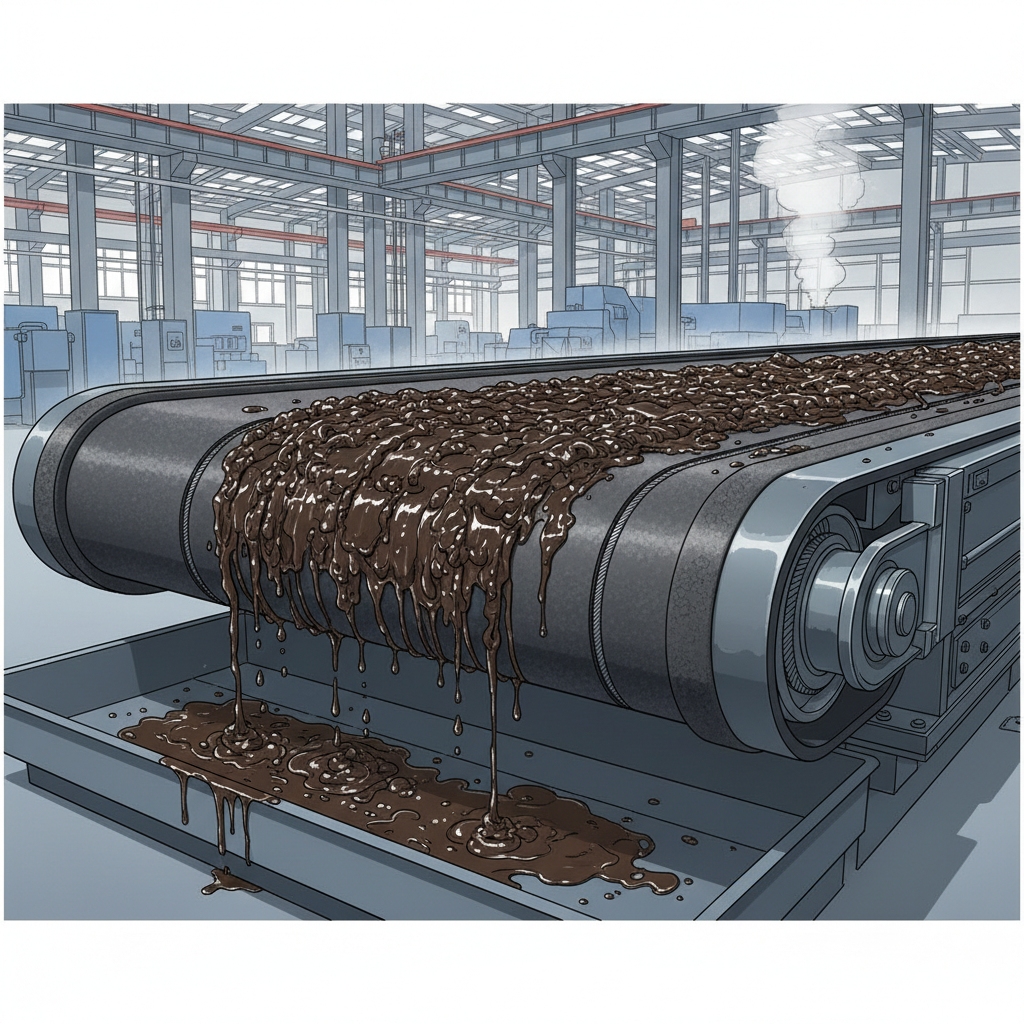

You face rough cargos that shred standard belts. Grade A in rubber conveyor belt specification withstands sharp edges.

- DIN abrasion under 120 mm³ for longevity.

- Ideal for rocks or minerals.

- Prevents frequent halts in your line.

Here’s the deal: It shields against daily grind.

How Does It Extend Belt Life?

Resistance slows degradation over time. You gain months from Grade A’s tough cover in rubber conveyor belt specification.

- Thicker compounds absorb impacts.

- Reduced friction lowers heat buildup.

- Cleaner surfaces from less embedment.

But wait, there’s more: Extended life slashes your maintenance budget.

What Industries Benefit Most?

Mining and aggregates thrive with this spec. Rubber conveyor belt specification targets high-wear sectors for you.

- Quarries move stone without issues.

- Cement plants handle clinker efficiently.

- Construction sites process debris.

What’s the catch? Without it, downtime soars in abrasive environments.

Key Takeaway

Grade A fortifies against wear for demanding roles.

| Feature | Advantage | Industry | |

|---|---|---|---|

| Low Abrasion | Longevity | Mining | |

| Impact Absorption | Reliability | Aggregates | |

| Cost Offset | Efficiency | Cement |

Abrasion-focused rubber conveyor belt specification transforms vulnerability into strength.

Static Conducting via Rubber Conveyor Belt Specification

What Makes Grade E Essential?

Static buildup risks explosions in your ops. Grade E dissipates charges in rubber conveyor belt specification.

- Conductivity below 3×10^8 ohms.

- Embedded wires ground safely.

- Suits dusty or fibrous loads.

Ready for the good part? It safeguards volatile areas.

How Does It Prevent Sparks?

Charges flow away before igniting. You stay compliant with Grade E’s design in rubber conveyor belt specification.

- Uniform dissipation across surface.

- No accumulation in dry conditions.

- Pairs with earthing systems.

This is where it gets interesting: Sparks vanish, risks plummet.

Why Use It in Explosive Settings?

Hazardous sites demand this protection. Rubber conveyor belt specification mandates E for powders or gases you process.

- Grain handling avoids dust blasts.

- Chemical plants manage volatiles.

- Wood mills control fibers.

You might be wondering about alternatives—none match its safety.

Key Takeaway

Grade E neutralizes static threats effectively.

| Property | Function | Use Case | |

|---|---|---|---|

| Conductivity | Discharge | Grain | |

| Grounding | Prevention | Chemicals | |

| Compliance | Safety | Wood |

Static-conducting rubber conveyor belt specification ensures secure handling in peril-prone zones.

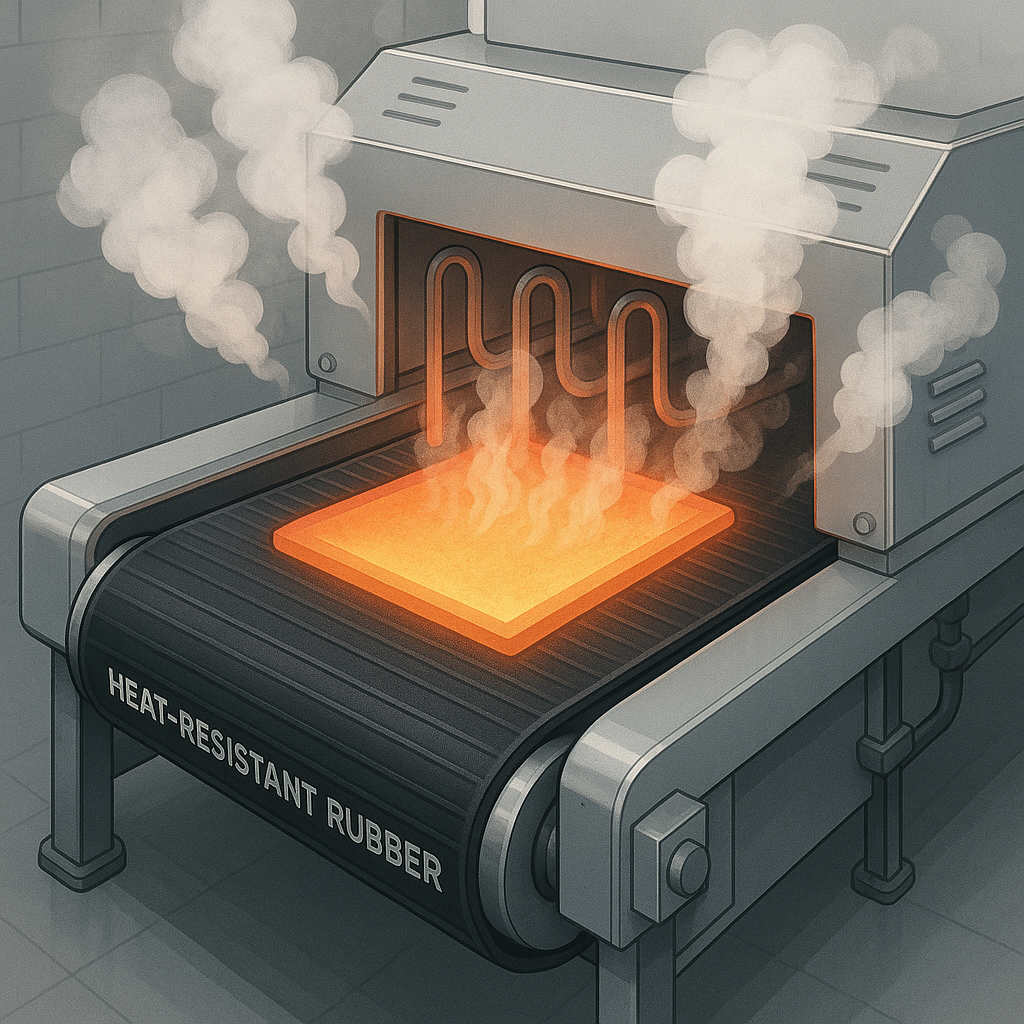

Fire Resistance in Rubber Conveyor Belt Specification

When Is Grade F a Must-Have?

Heat or flames threaten belts in hot zones. Grade F resists ignition in rubber conveyor belt specification.

- Self-extinguishing per ISO tests.

- For coal or heated aggregates.

- Limits flame spread.

Here’s the deal: It buys time in emergencies.

How Does It Handle Heat?

Compounds withstand temperatures up to 65°C. You operate steadily with Grade F in rubber conveyor belt specification.

- Low propagation rate.

- Maintains integrity post-exposure.

- Reduces smoke emission.

But wait, there’s more: Heat no longer derails your schedule.

What Safety Gains Follow?

Lives and assets stay protected. Rubber conveyor belt specification with F cuts fire risks for your team.

- Underground mining evacuations ease.

- Power plants avoid outages.

- Compliance meets regs.

What’s the catch? Standard belts fail fast in fire-prone spots.

Key Takeaway

Grade F delivers vital fire protection.

| Trait | Benefit | Setting | |

|---|---|---|---|

| Ignition Resistance | Containment | Mining | |

| Heat Tolerance | Stability | Power | |

| Low Smoke | Visibility | General |

Fire-resistant rubber conveyor belt specification prioritizes safety without compromise.

Combined Properties in Rubber Conveyor Belt Specification

Why Opt for Grade S Dual Features?

Dual needs arise in risky ops. Grade S merges static and fire in rubber conveyor belt specification.

- Conducts while resisting flames.

- For explosive, heated dusts.

- Streamlines single-belt use.

Ready for the good part? One grade covers multiple threats.

How Do E and F Grades Merge?

Blends create versatile covers. You get balanced performance in rubber conveyor belt specification.

- Antistatic additives with flame retardants.

- Uniform properties throughout.

- Tested for both hazards.

This is where it gets interesting: Merging simplifies your inventory.

What High-Risk Uses Demand It?

Environments with combo dangers require S. Rubber conveyor belt specification fits mines or refineries you run.

- Coal transport with dust.

- Grain drying processes.

- Petrochemical handling.

You might be wondering if it’s overkill—it’s essential for peaks.

Key Takeaway

Grade S handles layered risks seamlessly.

| Combo | Protection | Application | |

|---|---|---|---|

| Static + Fire | Dual | Coal | |

| Balanced | Versatility | Grain | |

| Tested | Reliability | Petro |

Combined rubber conveyor belt specification adapts to complex scenarios.

Special Grades in Rubber Conveyor Belt Specification

What Sets Grade Z Apart?

Unique demands call for custom tweaks. Grade Z tailors rubber conveyor belt specification to odd conditions.

- Oil or chemical resistance added.

- For non-standard loads.

- Bespoke compounding.

Here’s the deal: It fits where others falter.

How to Customize for Unique Needs?

Assess your specifics first. You engineer Grade Z in rubber conveyor belt specification via additives.

- Test for pH or temperature.

- Adjust hardness levels.

- Validate in trials.

But wait, there’s more: Customization yields precise fits.

Why Tailor for Niche Applications?

Off-the-shelf fails in specialties. Rubber conveyor belt specification via Z serves your rare cases.

- Food processing hygiene.

- High-acid environments.

- Extreme flexing.

What’s the catch? Tailoring invests in longevity.

Key Takeaway

Grade Z solves bespoke challenges.

| Element | Customization | Niche | |

|---|---|---|---|

| Additives | Resistance | Food | |

| Testing | Fit | Acid | |

| Trials | Proof | Flex |

Special rubber conveyor belt specification innovates for your edges.

Combined Grades within Rubber Conveyor Belt Specification

How Do MA Grades Work?

Layer general with abrasion for balance. MA in rubber conveyor belt specification enhances everyday toughness.

- M base plus A cover.

- For mixed loads.

- Cost-effective hybrid.

Ready for the good part? It broadens usability.

What Blends Boost Versatility?

Mix specs for broader coverage. You gain flexibility in rubber conveyor belt specification.

- Abrasion + oil resistance.

- Fire with general purpose.

- Static in abrasion layers.

This is where it gets interesting: Blends adapt on the fly.

When to Layer Multiple Specs?

Overlapping risks need this approach. Rubber conveyor belt specification layers for your multi-hazard sites.

- Surface abrasion, core static.

- Top fire, base strength.

- In variable processing.

You might be wondering about complexity—layers simplify overall.

Key Takeaway

Combined grades offer adaptable solutions.

| Blend | Versatility | When | |

|---|---|---|---|

| MA | Tough Daily | Mixed | |

| Abrasion + Oil | Broad | Variable | |

| Layered | Multi-Risk | Sites |

Hybrid rubber conveyor belt specification maximizes efficiency across uses.

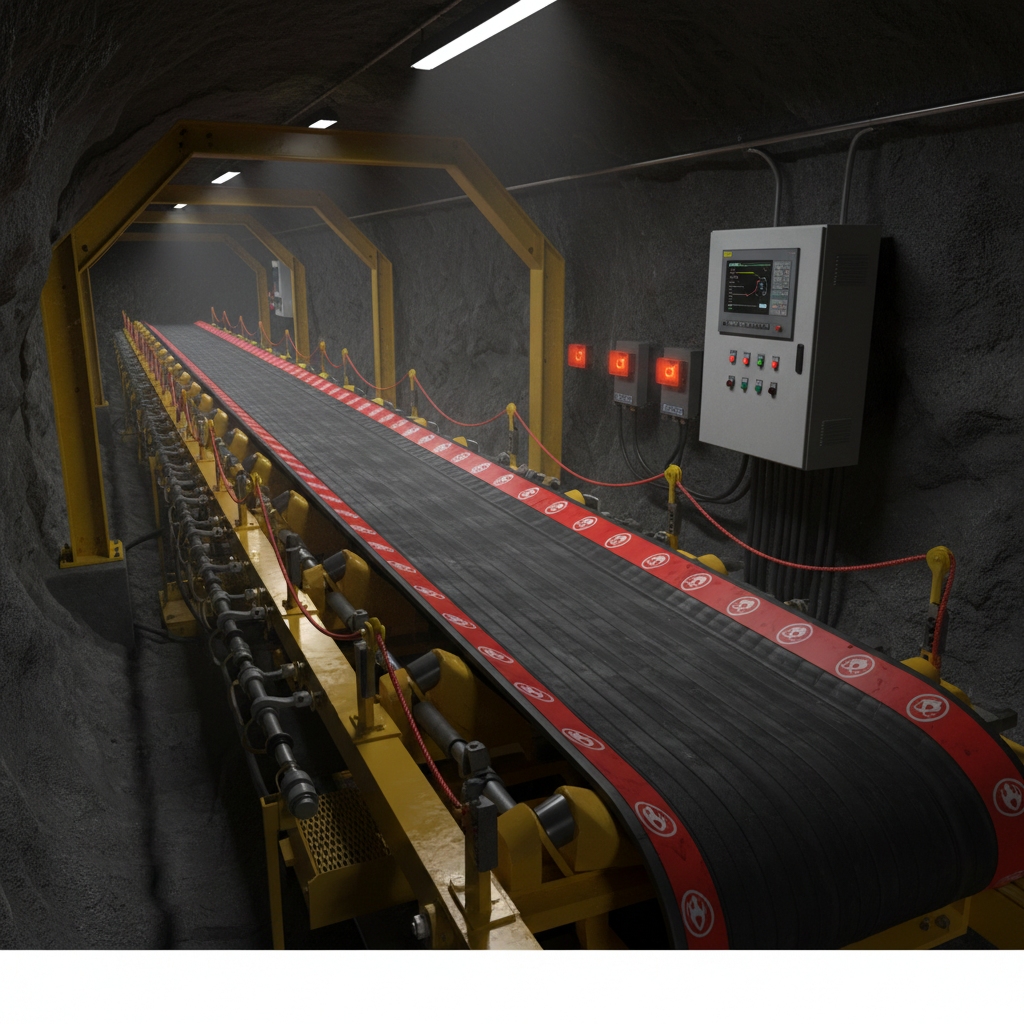

Selecting Rubber Conveyor Belt Specification by Industry

How Do Mining Needs Differ?

Ruggedness rules here for you. Rubber conveyor belt specification favors A and F grades.

- Ore abrasion demands high wear.

- Dust requires static control.

- Depths need fire safety.

Here’s the deal: Mining specs endure extremes.

What Specs Fit Power Plants?

Heat and bulk shape choices. You pick F with general in rubber conveyor belt specification.

- Coal handling resists ignition.

- Ash transport uses abrasion.

- Efficiency via M blends.

But wait, there’s more: Power specs ensure steady energy flow.

Why Adapt for Refineries?

Chemicals demand resistance layers. Rubber conveyor belt specification customizes for corrosives you manage.

- Oil blends prevent swelling.

- Static for vapors.

- Fire for hot processes.

What’s the catch? Adaptation averts leaks and blasts.

Key Takeaway

Industry-tailored specs align with unique pressures.

| Industry | Key Spec | Reason | |

|---|---|---|---|

| Mining | A/F | Ruggedness | |

| Power | F/M | Heat/Bulk | |

| Refinery | Oil/F | Chemicals |

Targeted rubber conveyor belt specification drives sector success.

Maintenance Tips for Rubber Conveyor Belt Specification

How to Avoid Premature Wear?

Proactive checks preserve your investment. Align with rubber conveyor belt specification by monitoring loads.

- Balance tensions evenly.

- Clear debris promptly.

- Rotate for even use.

Ready for the good part? Avoidance extends specs’ value.

What Cleaning Extends Life?

Routine care fights buildup. You maintain rubber conveyor belt specification integrity via methods.

- Mild solvents for covers.

- Brushes without abrasion.

- Dry runs post-wash.

This is where it gets interesting: Clean belts run cooler, last longer.

When to Inspect Key Features?

Schedule based on hours. Rubber conveyor belt specification demands checks for cracks or thinning.

- Weekly for high-use.

- Monthly splices and edges.

- Annually full audits.

You might be wondering about signs—fraying signals swaps.

Key Takeaway

Smart maintenance upholds spec performance.

| Tip | Frequency | Outcome | |

|---|---|---|---|

| Alignment | Daily | No Wear | |

| Cleaning | Weekly | Longevity | |

| Inspection | Monthly | Detection |

Consistent upkeep in rubber conveyor belt specification prevents failures.

Recap how mastering rubber conveyor belt specifications—from general purpose to specialized grades—solves downtime, safety risks, and cost overruns, empowering your operations with reliable performance. Ready to optimize? Contact a supplier for a custom audit and elevate your conveyor efficiency today. Vision: Seamless, durable systems that keep industries moving without interruption.

FAQs

- What Is the Most Common Rubber Conveyor Belt Specification? Grade M/N as versatile defaults for non-harsh uses, with pros like affordability and strength comparisons.

- How Do You Choose Abrasion Resistance in Specs? Detail Grade A for rough materials like ore, including wear rate factors and life extension benefits.

- Why Add Fire Resistance to Belt Specifications? Cover Grade F for heated or underground environments, emphasizing ignition prevention and safety standards.

- Can You Combine Multiple Grades in One Spec? Yes, like Grade S or MA; discuss common blends, applications, and how they enhance multi-risk handling.

- What Maintenance Supports Belt Specifications? Recommend regular checks for cleaning systems and wear, tying back to spec longevity for cost savings.