Your production line’s performance depends heavily on the reliability of its Rubber Conveyor Belts. Frequent belt failures can cause costly downtime, material slippage, and unplanned replacements that disrupt efficiency. Selecting the wrong belt type accelerates wear and reduces productivity. This comprehensive guide explores ten essential insights about Rubber Conveyor Belts, helping you identify the ideal belt type for your operation—one that ensures superior reliability, long-lasting performance, and minimal maintenance interruptions.

1. What defines quality rubber-conveyor-belts?

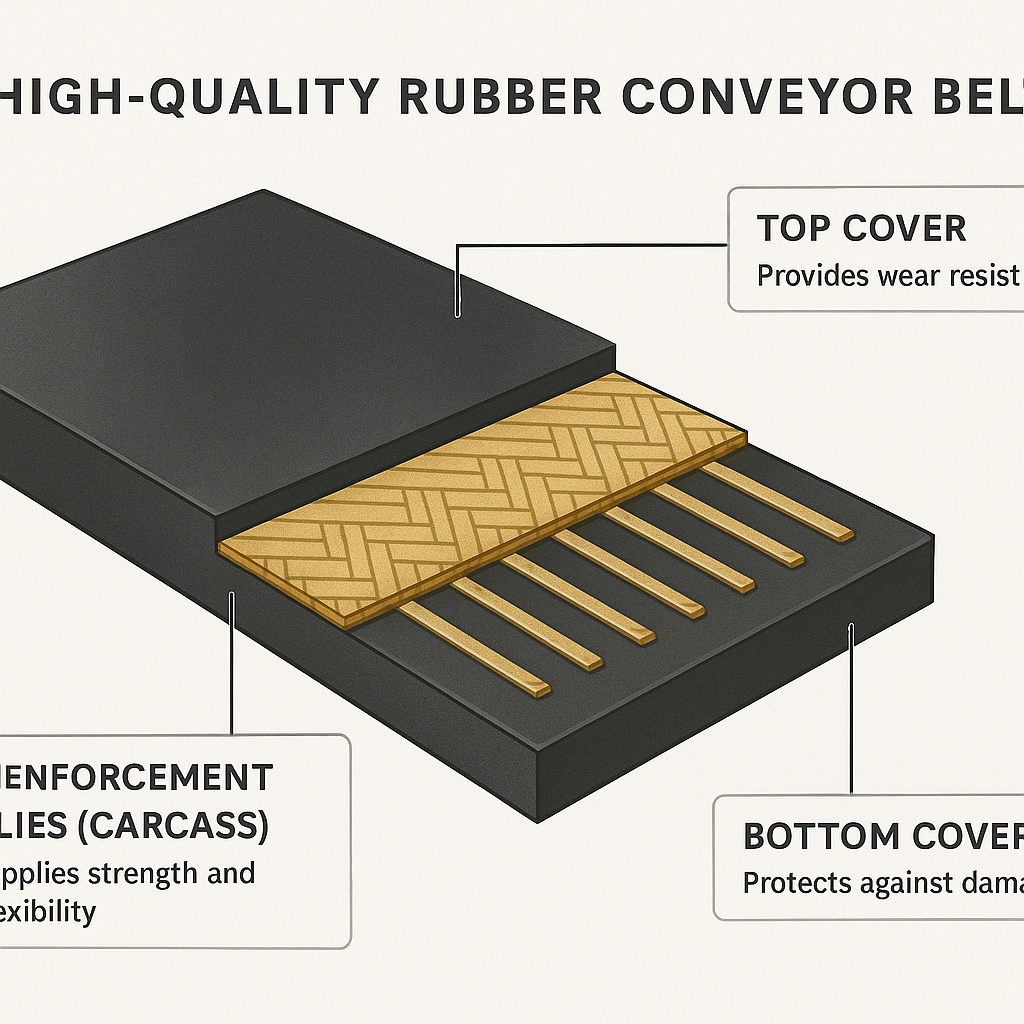

The quality of rubber-conveyor-belts is defined by the synergy between their internal strength (carcass) and their protective outer layers (covers).

Understanding Carcass Reinforcement

The belt’s carcass provides its core tensile strength and structure, acting as the skeleton.

- It is usually made of multiple layers of synthetic fabric, such as polyester or nylon.

- This reinforcement resists stretching and carries the load of the material being transported.

You might be wondering… how do you choose the right reinforcement? It depends on the conveyor’s length and tension.

Fabric vs. Steel Cord Belts

Fabric reinforcement is the standard for most small to medium-length conveyors due to its flexibility and cost-effectiveness.

- Steel cords are used for very long-distance or high-tension installations.

- They offer superior tensile strength and minimal elongation over great distances.

Key Quality Indicators

A quality belt features durable rubber covers that resist abrasion, cuts, and environmental factors.

- Strong adhesion between all layers is crucial to prevent delamination under stress.

- The rubber compound itself must match the application, from general-purpose to heat or oil-resistant.

Key Takeaway: The quality of rubber-conveyor-belts depends on both the internal carcass for strength and the external rubber covers for protection.

| Feature | Fabric-Reinforced Belts | Steel Cord-Reinforced Belts | |

|---|---|---|---|

| Ideal Use Case | Small to medium-length conveyors | Long-distance, high-tension systems | |

| Tensile Strength | Good | Excellent | |

| Flexibility | High | Lower | |

| Elongation | Higher | Very Low |

The combination of a robust carcass and appropriate covers ensures a long and reliable service life.

2. How do you match rubber-conveyor-belts to materials?

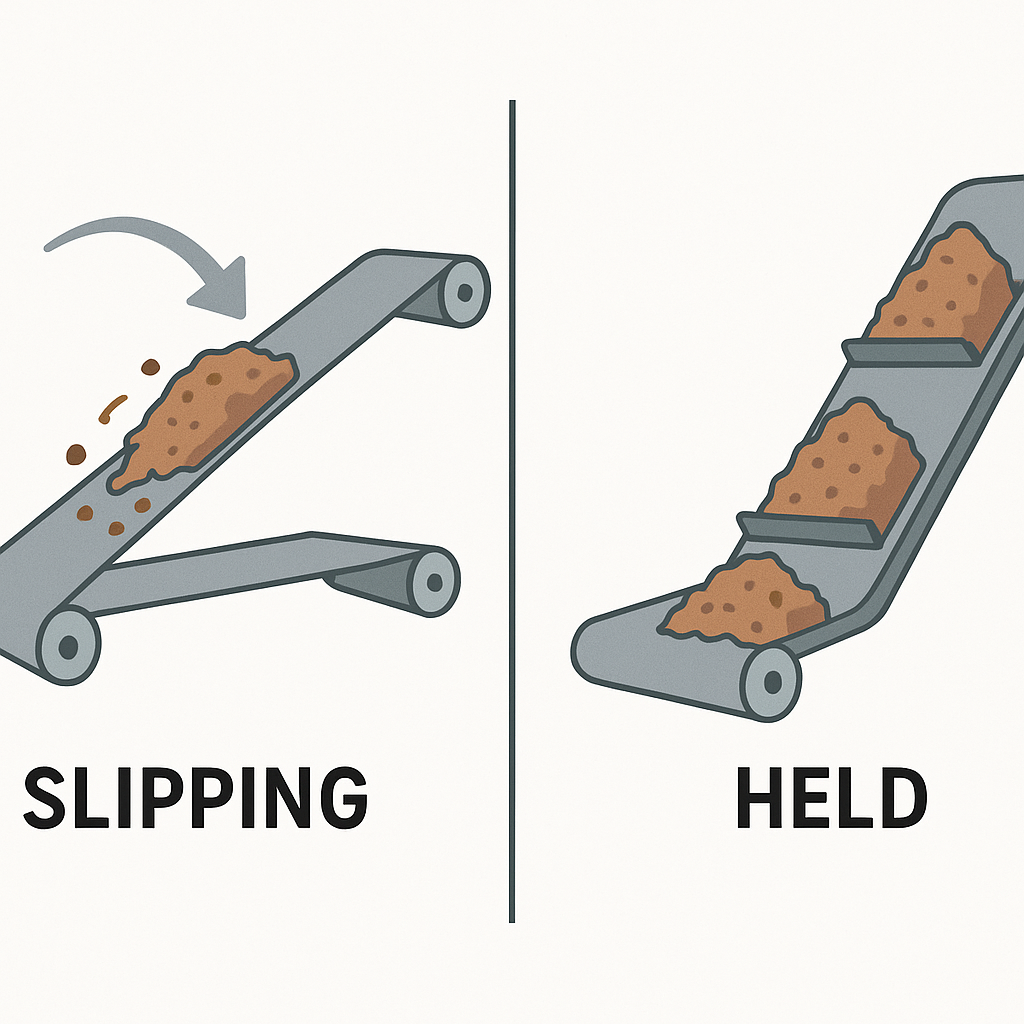

You match rubber-conveyor-belts to materials by selecting a surface texture—smooth or profiled—that prevents the specific cargo from slipping or rolling back.

When to Use Smooth Surface Belts

Smooth belts are the default choice for horizontal transport or on inclines up to approximately 20°.

- They are ideal for packaged goods like boxes and uniform bulk items.

- Materials that don’t have a tendency to roll back are conveyed efficiently on smooth surfaces.

Here’s the deal. For many standard applications, a smooth belt is the simplest and most effective solution.

The Role of Profiled Surfaces

Profiled or textured surfaces provide the extra grip needed when materials start to slide or roll back on smooth belts.

- These textures can range from a simple rough top to intricate patterns.

- They are essential for maintaining control over loose or rounded items on an incline.

Matching Belt Texture to Your Cargo

The choice between smooth and profiled surfaces depends entirely on the material’s properties and the angle of conveyance.

- Loose, fine materials may require one type of profile, while larger, lumpy items need another.

- Analyzing your specific cargo and incline is the first step to making the right choice.

Key Takeaway: Selecting the right surface texture for your rubber-conveyor-belts is fundamental to preventing material loss and ensuring system efficiency.

| Surface Type | Best For | Incline Angle | |

|---|---|---|---|

| Smooth | Packaged goods, uniform items | 0-20° | |

| Profiled | Loose items, parcels, bags | 20-35° |

This fundamental choice dictates whether your material stays on the belt or causes blockages and spills.

3. When do rubber-conveyor-belts need steep inclines?

Rubber-conveyor-belts need specialized features like cleats and sidewalls for steep inclines where gravity would otherwise cause material to fall back.

Using Chevron Belts for Angles up to 45°

For inclines between 35° and 45°, chevron belts are the solution.

- Vulcanized cleats in “V” shapes or other patterns are integrated into the belt surface.

- These cleats act as physical barriers, holding bulk materials like gravel in place.

The Function of Sidewall Belts

But what about steeper angles? For those, sidewall belts create contained pockets for the material.

- These belts feature corrugated walls along the edges and transverse cleats.

- This design allows for conveying at very steep angles, even up to 87°.

Vertical Transport with Elevator Belts

For true 90° vertical transport, elevator belts are the optimal choice.

- These systems use buckets that are bolted directly onto a base belt.

- They are designed to scoop and lift materials vertically, common in grain silos and processing plants.

Key Takeaway: For steep inclines, specialized rubber-conveyor-belts with physical barriers like cleats, sidewalls, or buckets are necessary to control the cargo.

| Belt Type | Max Incline Angle | Best For | |

|---|---|---|---|

| Chevron | 35-45° | Bulk materials like gravel or coal | |

| Sidewall | 45-87° | High-volume bulk on steep inclines | |

| Elevator | 90° | Vertical transport of grain, pellets |

Choosing the correct incline-specific belt prevents spillage and maximizes throughput in space-constrained layouts.

4. Which rubber-conveyor-belts resist abrasion?

Rubber-conveyor-belts with specially formulated, wear-resistant rubber compounds are required to resist abrasion.

Defining High-Abrasion Environments

High-abrasion environments are common in industries handling sharp, rough materials.

- Examples include quarries, cement plants, and steel mills.

- Abrasion is caused by the scraping and cutting action of materials like crushed rock or recycled glass.

Rubber Compounds for Sharp Materials

What’s the catch? Standard rubber will be torn apart quickly in these conditions.

- Special rubber compounds are formulated to offer superior resistance to cutting and gouging.

- These heavy-duty covers protect the belt’s inner carcass from damage.

Industries That Require Abrasive Resistance

Using the correct abrasive-resistant belt is crucial for operational longevity in harsh sectors.

- This choice dramatically increases the belt’s service life.

- It significantly reduces costly downtime associated with frequent belt replacements.

Key Takeaway: In environments with sharp or rough materials, choosing rubber-conveyor-belts with a specialized wear-resistant compound is non-negotiable for longevity.

| Environment | Common Materials | Required Belt Feature | |

|---|---|---|---|

| Mining/Quarry | Crushed rock, ore, gravel | High abrasion resistance | |

| Recycling | Glass, sharp metal scrap | High cut & gouge resistance | |

| Cement Plant | Clinker, limestone | Abrasion & heat resistance |

Investing in the correct cover compound directly translates to lower maintenance costs and higher productivity.

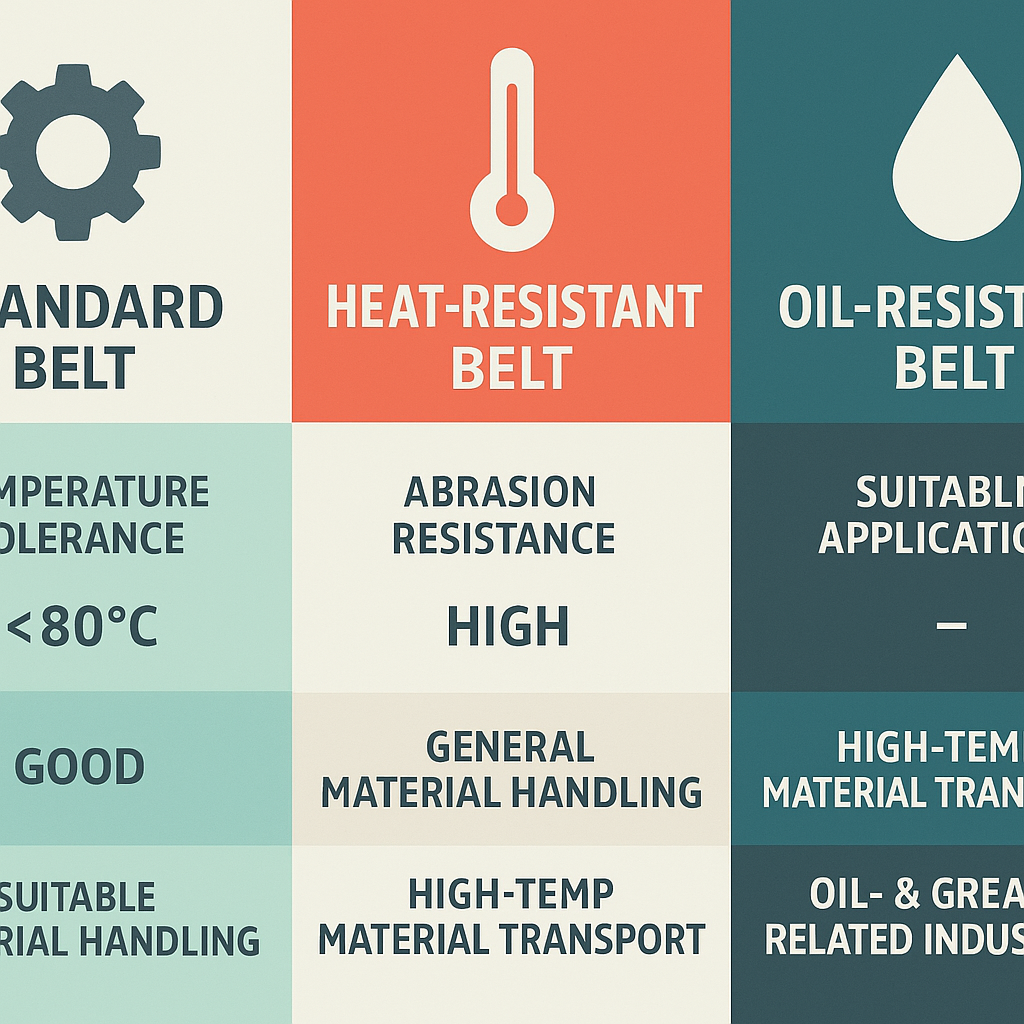

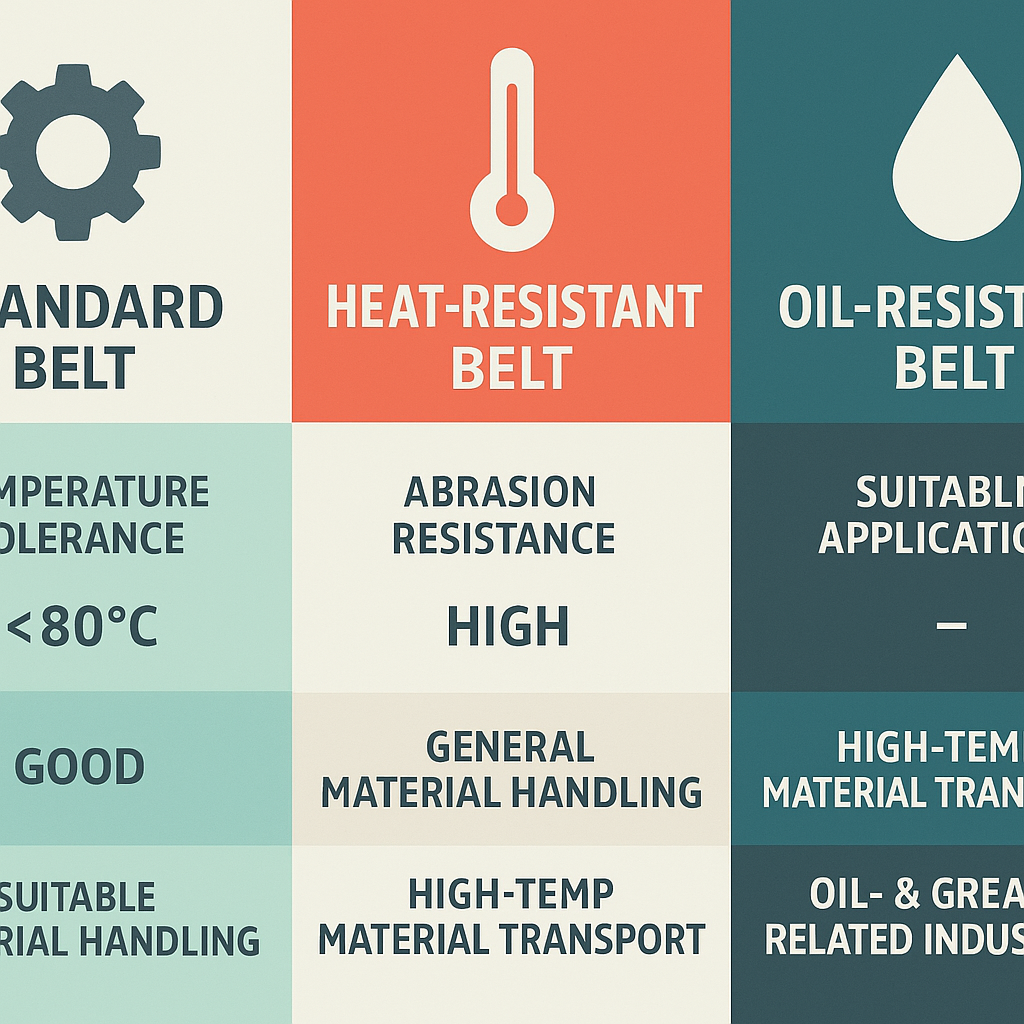

5. Do your rubber-conveyor-belts handle high heat?

Yes, specially designed rubber-conveyor-belts can handle high heat using compounds that resist accelerated aging and degradation.

Challenges of High-Temperature Conveying

High temperatures cause standard rubber to harden, crack, and delaminate from its reinforcement layers.

- This process, known as accelerated aging, drastically shortens a belt’s life.

- A standard belt can fail in minutes when exposed to materials like hot clinker or slag.

Here’s a little secret. The damage is often irreversible once it starts.

Properties of Heat-Resistant Rubber

Heat-resistant belts are engineered to withstand continuous high temperatures without losing their integrity.

- They resist premature wear from hot materials.

- Their reinforced layers are designed to maintain tensile strength even when hot.

Applications in Steel and Cement Plants

These belts are essential in many heavy industrial processes.

- They are used to handle hot clinker in cement plants.

- Other applications include transporting slag in the steel industry or moving hot asphalt.

Key Takeaway: For any application involving high-temperature materials, you must use specially designed heat-resistant rubber-conveyor-belts to ensure safety and operational uptime.

| Key Feature | Benefit for High-Heat Applications | |

|---|---|---|

| Heat Resistance | Endures high material temperatures without rapid degradation. | |

| Durability | Resists cracking, hardening, and premature wear. | |

| Increased Service Life | Reduces maintenance costs and operational downtime. |

Using the right heat-resistant belt is a critical decision for both safety and financial performance.

6. What rubber-conveyor-belts are oil-resistant?

Rubber-conveyor-belts designed with nitrile-based compounds are oil-resistant, preventing the swelling and softening caused by exposure to oils and fats.

The Damaging Effects of Oils and Fats

Mineral oils, greases, and animal fats can cause standard rubber compounds to swell, soften, and lose structural integrity.

- This damage leads to belt tracking problems as the belt deforms.

- Ultimately, it can result in catastrophic belt failure and production halts.

Think about this for a moment. A swollen belt is an accident waiting to happen.

Selecting Oil-Resistant Rubber Covers

For applications with moderate or incidental oil exposure, a belt with oil-resistant rubber covers is often sufficient.

- The resistant outer layer protects the standard inner carcass from damage.

- This is a cost-effective solution when deep contamination is not a risk.

When to Choose a Fully Resistant Carcass

In heavily contaminated environments, such as recycling oily metal parts, a fully resistant belt is necessary.

- In this design, both the covers and the internal fabric carcass are made of an oil-and-fat-resistant compound.

- This provides maximum protection against degradation from all sides.

Key Takeaway: The level of oil resistance needed for your rubber-conveyor-belts depends on the intensity of contamination; you can choose between resistant covers or a fully resistant construction.

| Oil Exposure | Recommended Belt | Rationale | |

|---|---|---|---|

| Moderate | Oil-Resistant Covers Only | Protects from surface contact. | |

| Heavy | Fully Oil-Resistant Construction | Prevents saturation and internal damage. |

Matching the level of oil resistance to the application prevents belt degradation and extends service life.

7. Are there food-safe rubber-conveyor-belts?

Yes, there are food-safe rubber-conveyor-belts made from compounds that comply with strict regulatory standards like FDA and EC 1935/2004.

Meeting Food-Grade Compliance Standards

For any material intended for human consumption, you must use belts that meet government safety regulations.

- These standards ensure no harmful substances can leach from the belt into the food.

- Compliance is mandatory for consumer safety and legal operation.

You’re probably asking yourself… why are they often white?

Benefits of White Rubber Compounds

Food-grade belts are often white or light blue, making it easy to spot dirt, mold, or other contaminants.

- This visual check is a simple but effective part of any sanitation protocol.

- The compounds are non-toxic and resistant to fats and oils commonly found in food.

Applications from Harvest to Packaging

These belts are used across the entire food production chain.

- Their uses range from harvesting and washing raw ingredients to sorting and packaging finished goods.

- You’ll find them processing nuts, cereals, salt, grains, and more.

Key Takeaway: For any application involving direct contact with food, you must use certified food-grade rubber-conveyor-belts to comply with safety regulations and protect consumers.

| Compliance Standard | Region/Authority | Purpose | |

|---|---|---|---|

| FDA 21 CFR | USA | Regulates materials for repeated use in contact with food. | |

| EG 1935/2004 | European Union | Framework regulation for food contact materials. |

These standards are non-negotiable for maintaining hygiene and ensuring the safety of the food supply chain.

8. Can rubber-conveyor-belts be flame-resistant?

Yes, rubber-conveyor-belts can be made flame-resistant to ensure safety in environments with a risk of fire or dust explosions.

Understanding Flame Resistance Standards

Flame-resistant belts are self-extinguishing, meaning they will not propagate a flame.

- They must meet strict safety standards like ISO 340.

- Many are also designed to be anti-static to prevent sparks in explosive atmospheres (ATEX-rated zones).

Applications in High-Risk Environments

But here’s the kicker… even seemingly harmless materials can create explosive dust.

- Industries like sugar processing, grain elevators, and flour mills are at high risk.

- Flame-resistant belts are critical to preventing ignition from friction, static, or external sources.

Combining Flame and Oil Resistance

Some applications require belts that are resistant to both flames and oil.

- These belts are engineered for challenging industries like fertilizer and chemical production.

- This dual resistance provides a comprehensive safety solution in complex environments.

Key Takeaway: In any environment with a risk of fire or dust explosion, using certified flame-resistant rubber-conveyor-belts is a critical safety measure.

| Feature | Purpose | Common Industries | |

|---|---|---|---|

| Flame Resistance (ISO 340) | Prevents fire propagation. | Coal Mining, Tunnels | |

| Anti-Static Properties (ATEX) | Prevents sparks from static buildup. | Grain Elevators, Sugar Mills |

Proper belt selection in these zones is a fundamental part of your facility’s fire prevention strategy.

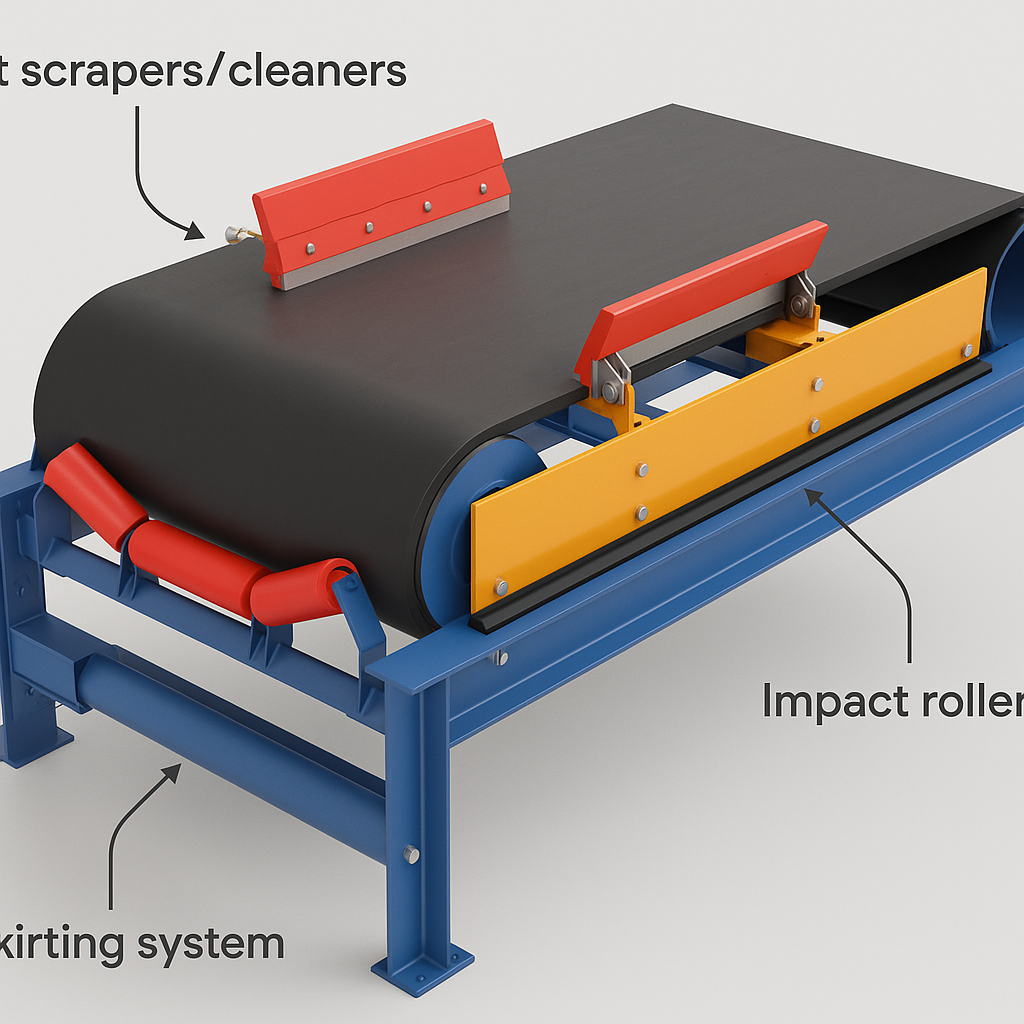

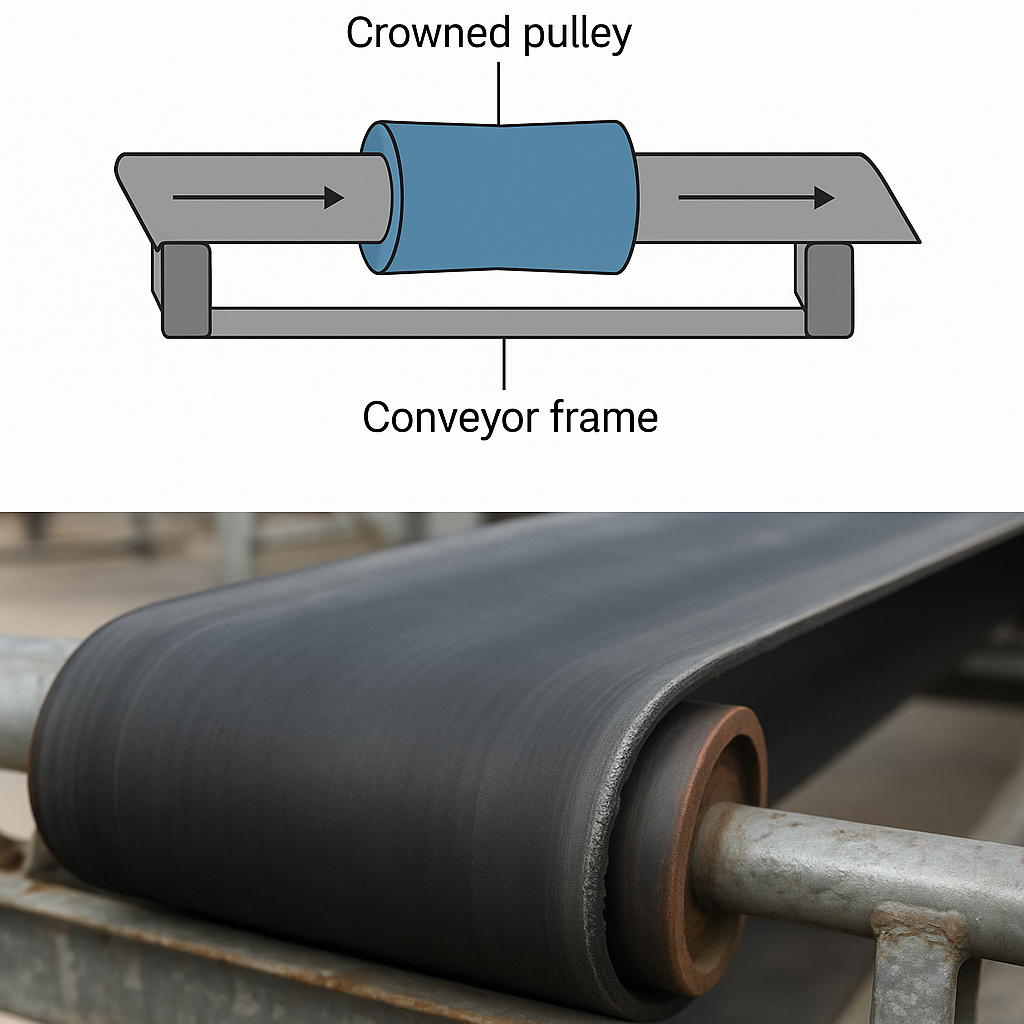

9. How are rubber-conveyor-belts customized?

Rubber-conveyor-belts are customized through a confectioning process that modifies standard belting to fit unique applications, such as adding cleats or creating endless loops.

Tailoring Belts to Your Application

Standard, off-the-shelf belts are a starting point, but they don’t fit every need.

- Customization ensures a belt is perfectly adapted to your machinery and material.

- A tailored belt improves efficiency and reduces wear and tear.

Exploring Tubular or Pipe Conveyors

Now, let’s get down to business. Some designs are highly specialized.

- Tubular conveyors are formed into a pipe shape after the loading point, fully enclosing the material.

- This protects the cargo from the elements and prevents dust emissions, making it ideal for wood chips or biomass.

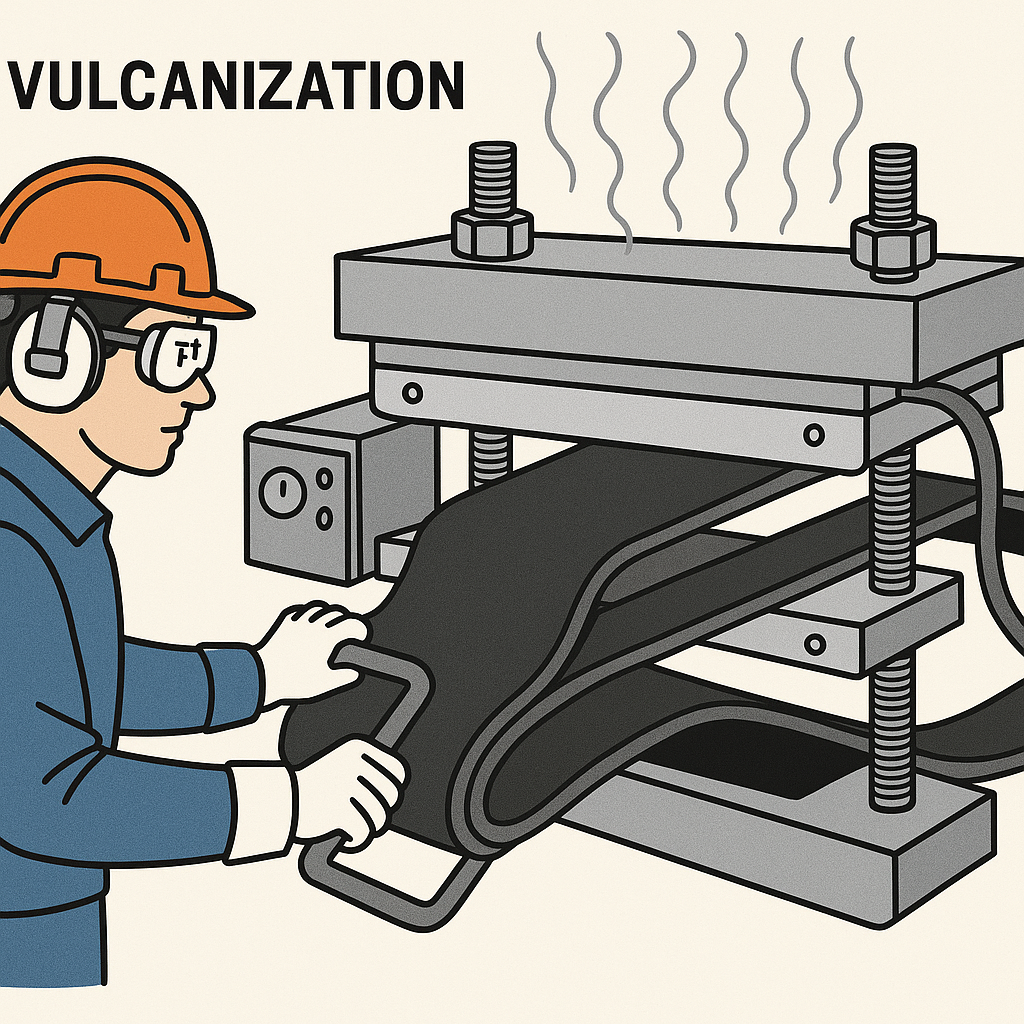

The Process of Custom Confectioning

Custom confectioning involves several workshop processes to create a finished belt.

- Cutting belts to precise widths and lengths.

- Hot vulcanizing (bonding) cleats, sidewalls, or guides onto the belt surface.

- Splicing the belt to create a strong, endless loop ready for installation.

Key Takeaway: Custom-made rubber-conveyor-belts provide a tailored solution for unique applications, from specialized profiles to completely enclosed tubular systems.

| Customization Type | Description | Common Use | |

|---|---|---|---|

| Adding Cleats | Vulcanizing profiles onto the belt surface. | Steep incline conveying. | |

| Adding Sidewalls | Attaching corrugated walls to the belt edges. | Containing loose material. | |

| Tubular/Pipe Design | Forming the belt into a tube shape. | Dust-free transport of bulk goods. |

This tailoring process transforms a simple component into a high-performance, application-specific solution.

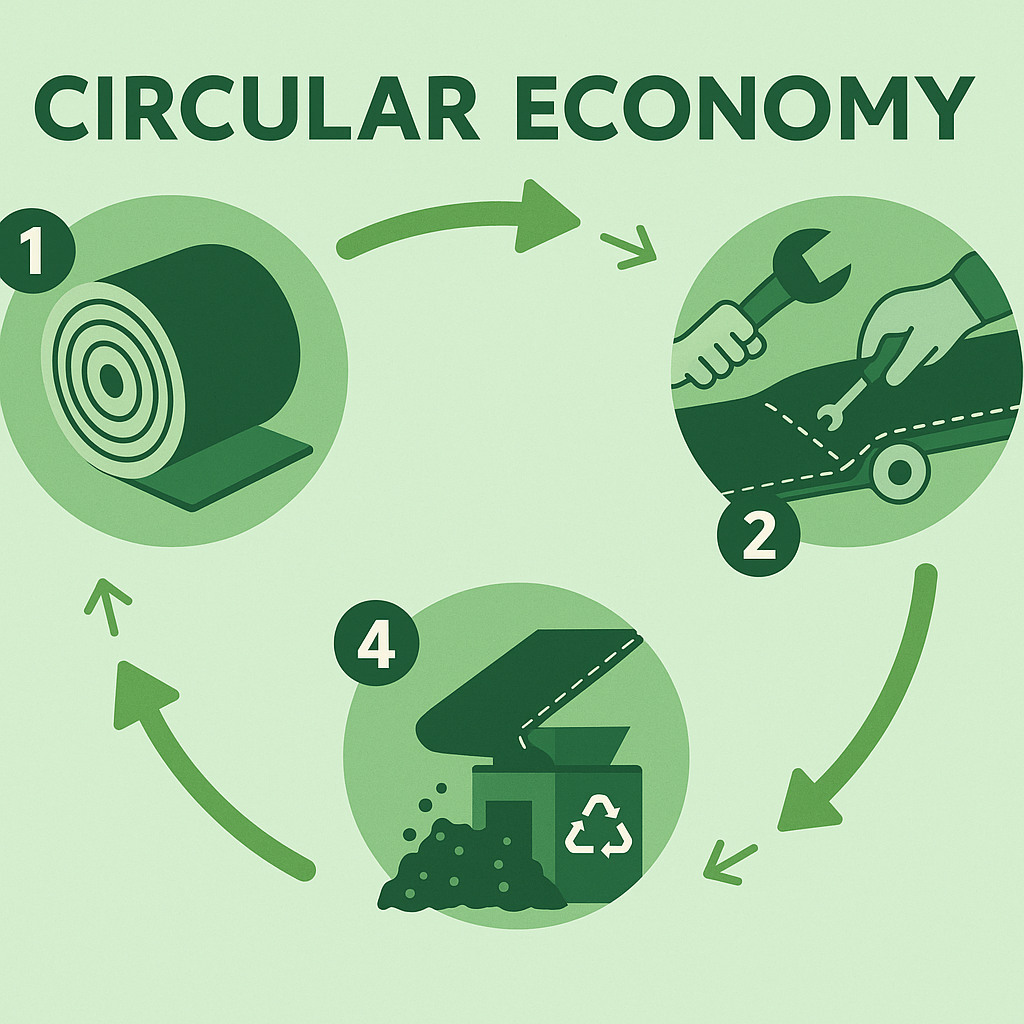

10. What industries use rubber-conveyor-belts most?

Nearly every industry relies on rubber-conveyor-belts, but they are most prevalent in heavy industries, production and processing, and logistics.

Heavy Industries: Mining and Aggregates

Heavy-duty, abrasion-resistant belts are the workhorses of the mining, quarry, and aggregate industries.

- They move massive quantities of rock, coal, sand, and ore over long distances.

- These sectors depend on the extreme durability of reinforced rubber belts.

Let’s put this into perspective. Without these belts, many large-scale extraction operations would not be feasible.

Production and Processing: Food and Chemicals

The food and chemical industries require highly specialized belts to meet safety and material compatibility needs.

- Food production uses certified food-grade belts for hygiene.

- Chemical plants need belts that can resist corrosion and potentially flammable materials.

Logistics and Specialized Applications

The boom in e-commerce and logistics has increased the demand for conveyor belts.

- Grip-top and standard belts are used in distribution centers to move parcels efficiently.

- Other key sectors include agriculture, demolition/recycling, and power plants, demonstrating their versatility.

Key Takeaway: From the heaviest mining operations to the cleanest food production lines, nearly every industry relies on a specific type of rubber conveyor belt to maintain its workflow.

| Industry | Primary Belt Requirement | Example Belt Type | |

|---|---|---|---|

| Heavy Industry | Abrasion Resistance | Heavy-duty, wear-resistant | |

| Food Processing | Hygiene & Safety | White, FDA-compliant | |

| Logistics | Grip & Speed | Grip-top, smooth |

The sheer diversity of applications highlights the conveyor belt’s role as a cornerstone of modern industry.

Conclusion

Selecting the right rubber-conveyor-belts involves matching reinforcement, surface profile, and rubber quality to your specific application, whether you need heat resistance, food-grade safety, or custom features. A well-chosen belt is not an expense, but an investment in uptime and efficiency.

Ready to improve your operational efficiency? Contact our experts today to find the perfect conveyor solution for your facility.

Frequently Asked Questions (FAQ)

- Q1: Can I use a standard belt for slightly oily materials?

- A: For very light or occasional oil contamination, a standard belt might suffice for a short time. However, for consistent exposure, a belt with at least an oil-resistant cover is strongly recommended to prevent premature failure.

- Q2: What is the maximum incline for a smooth rubber conveyor belt?

- A: A smooth belt is generally effective for horizontal transport and inclines up to about 20 degrees. Beyond that, materials may begin to slip or roll back, requiring a profiled or cleated belt.

- Q3: How do I know if I need a steel cord or fabric belt?

- A: The choice depends on your conveyor’s length and tension. Fabric belts are great for most small-to-medium systems. If you have a very long conveyor (e.g., several hundred meters or more) or require extremely high tensile strength, a steel cord belt is the better option.

- Q4: Are food-grade belts harder to maintain?

- A: Not necessarily. Their white or light color makes spotting dirt and contamination easier, which can actually simplify cleaning protocols. Maintenance routines are similar to standard belts but with a stronger focus on sanitation.

- Q5: Can you add cleats to any type of rubber conveyor belt?

- A: In theory, yes. Cleats are typically vulcanized (hot-bonded) onto a smooth base belt. The process is most effective when done in a workshop to ensure a strong, permanent bond. Cleats can be added to standard, oil-resistant, or heat-resistant belts as needed.