Your operation comes to a standstill when one of your critical Rubber Conveyor Belts fails—halting production, threatening deadlines, and causing immediate financial losses. Every minute of downtime costs revenue and productivity, while uncertainty over repair time adds to the pressure. This article takes you behind the scenes of the professional repair process for Rubber Conveyor Belts, revealing how expert technicians assess, prepare, and restore your system—turning unexpected breakdowns into fast, reliable recoveries that get your production moving again.

What starts a rubber conveyor belt repair call?

A rubber conveyor belt repair call typically starts when a client reports a critical failure, such as a tear or splice failure, that has halted their operations. This initial contact is crucial for understanding the urgency and scope of the problem. From there, our team can immediately begin mobilizing a response to get your system back online.

Urgent requests vs. planned maintenance

Emergency calls prioritize immediate fixes to minimize costly downtime, often requiring rapid on-site problem-solving. But what’s the real difference? Planned service, on the other hand, is proactive and focuses on inspections and component replacements to prevent these very failures from happening in the first place.

What initial information is needed?

To ensure the technician arrives prepared, you should provide specific details about the failure. This information allows for a faster and more effective on-site diagnosis and repair. The more details you can give, the better prepared we can be.

- Belt dimensions (length, width, thickness)

- Type of material conveyed

- Description of the damage

- Location and site access conditions

Key Takeaway: A successful repair begins with a clear and detailed initial report.

| Information Type | Importance | Example | |

|---|---|---|---|

| Belt Specifications | Critical | 1200mm wide, 10mm thick | |

| Damage Details | Critical | 2-meter rip, center of belt | |

| Site Logistics | High | Indoor facility, 3rd floor access | |

| This initial data exchange is fundamental to a rapid and effective service response. |

How is a rubber conveyor belt repair prepared?

Preparing for a rubber conveyor belt repair involves selecting the appropriate tools, materials, and safety equipment based on the initial damage report and belt specifications. This meticulous planning ensures the technician arrives on-site fully equipped for the specific job at hand. It eliminates guesswork and reduces time spent on the job site.

Assembling the right tool kit

A professional service vehicle is stocked with a wide array of specialized tools ready for any scenario. This includes everything from heavy-duty vulcanizing presses to precision grinders and belt cutters. Having the right tool for the job is not just about efficiency; it’s about the quality of the final repair.

Matching repair materials to the belt

Here’s the deal: using the wrong materials will lead to a failed repair. Technicians must precisely match repair compounds and fabrics to your belt’s specific construction and application. This ensures compatibility and creates a bond as strong as the original belt.

- Correct vulcanizing solution

- Appropriate fabric or steel cord patch material

- Cover rubber compounds that match the original

- Mechanical fasteners of the right size

Key Takeaway: Arriving on-site with the correct tools and perfectly matched materials is the foundation of a durable repair.

| Preparation Step | Objective | Key Items | |

|---|---|---|---|

| Tool Selection | Efficiency & Quality | Vulcanizing press, belt cutters, grinders | |

| Material Matching | Durability & Compatibility | Patch kits, cements, fasteners | |

| Safety Planning | Accident Prevention | Lockout/tagout kits, PPE, fire extinguisher | |

| This preparation phase directly impacts the success and longevity of the on-site work. |

What is the on-site rubber conveyor belt check?

The on-site rubber conveyor belt check is a thorough inspection to confirm the reported damage and identify any underlying issues that could compromise the repair. A technician will walk the line to assess the full extent of the problem beyond the initial report. This step prevents fixing a symptom while ignoring the root cause.

Confirming the initial report

The first step on-site is to visually verify the reported damage. Often, the initial description may not capture the full complexity of the failure. The technician assesses the tear, gouge, or splice issue firsthand to develop a precise plan of action.

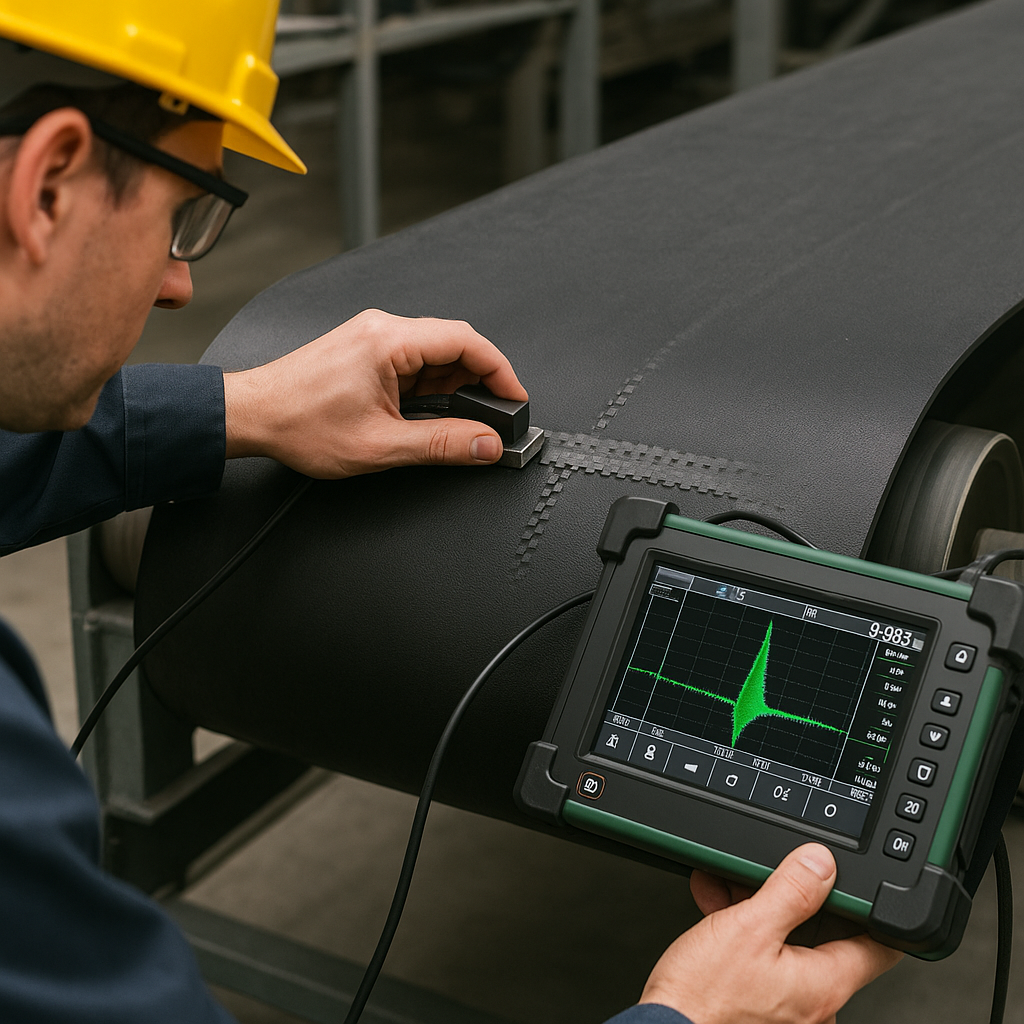

How is structural integrity assessed?

This is where it gets interesting: a technician looks beyond the surface damage. They check for hidden issues that could cause future failures, ensuring the repair will last. This deep dive is what separates a quick patch from a professional solution.

- Checking for moisture ingress in the belt carcass

- Inspecting pulleys and idlers for wear

- Verifying belt alignment and tension

- Looking for signs of material spillage or build-up

Key Takeaway: A comprehensive on-site assessment ensures the root cause of the failure is addressed, not just the symptom.

| Inspection Area | What to Look For | Implication of Failure | |

|---|---|---|---|

| Belt Surface | Rips, gouges, tears | Immediate material loss | |

| Belt Carcass | Ply separation, moisture | Structural integrity is compromised | |

| System Components | Worn idlers, misaligned pulleys | Root cause of belt damage | |

| This diagnostic step is critical for ensuring a repair is a permanent solution, not a temporary fix. |

How is the rubber conveyor belt itself repaired?

A rubber conveyor belt is repaired by meticulously cleaning and preparing the damaged area, applying a compatible patch or new splice, and using pressure or heat to create a permanent bond. The method chosen depends on the belt type, the damage, and the operational requirements of your system. Each repair is a precise, multi-step process tailored to the situation.

Preparing the damaged section

You might be wondering if cleaning is really that important. The answer is yes; proper surface preparation is the most critical part of the process. The technician uses grinders and solvents to remove contaminants and expose fresh rubber, ensuring the strongest possible adhesion.

Hot vulcanization vs. cold bonding

The choice of repair method depends on factors like required cure time and belt tension. Each has its place, and a skilled technician will recommend the best one for your situation.

- Hot Vulcanization: Uses heat and pressure for the strongest, most seamless bond.

- Cold Bonding: Uses a chemical adhesive system for faster repairs in less demanding applications.

- Mechanical Fasteners: The quickest method, best for temporary or emergency repairs.

Key Takeaway: The choice of repair method is critical and depends on the application, tension, and required uptime.

| Repair Method | Speed | Durability | Best Use Case | |

|---|---|---|---|---|

| Hot Vulcanization | Slow | Excellent | High-tension, permanent repairs | |

| Cold Bonding | Moderate | Good | General use, moderate tension | |

| Mechanical Fasteners | Fast | Fair | Emergency, temporary fixes | |

| While mechanical fasteners offer speed, a vulcanized repair provides superior long-term reliability. |

What tools fix a rubber conveyor belt?

Fixing a rubber conveyor belt requires specialized tools including a vulcanizing press, belt cutters, ply separators, and grinders designed for precision and safety. General-purpose tools are not sufficient for achieving a durable, safe repair that meets industry standards. These professional tools are essential for quality workmanship.

The role of the vulcanizing press

The vulcanizing press is the heart of a hot splice repair. It applies uniform heat and pressure across the entire repair area. This process cures the rubber and fuses the splice materials, creating a seamless and durable bond that is as strong as the original belt.

Essential hand and power tools

But here’s the kicker: even with a large press, the details matter. A variety of hand and power tools are needed to prepare the belt with the necessary precision for a successful bond.

- Belt Grinder: To create a rough, clean surface for bonding.

- Ply Knife/Separator: For stepping down the belt layers accurately for a splice.

- Belt Cutter/Skiver: To ensure straight, clean cuts without damaging the belt.

- Tensioning Clamps: To hold the belt securely in place during the repair.

Key Takeaway: Professional-grade tools are a necessity, ensuring precision, safety, and a repair that meets original specifications.

| Tool | Function | Why It’s Essential | |

|---|---|---|---|

| Vulcanizing Press | Cures rubber with heat/pressure | Creates the strongest possible bond | |

| Belt Grinder | Prepares the belt surface | Ensures optimal adhesion of cement | |

| Ply Knife | Separates belt layers | Allows for a proper stepped splice | |

| Using the correct equipment is non-negotiable for a repair that is both safe and built to last. |

Why is safety vital for conveyor belt work?

Safety is vital during rubber conveyor belt work due to the extreme tension, heavy machinery, and potential energy stored in the system. A conveyor can cause severe injury if it starts unexpectedly, making safety protocols the top priority. No repair is successful if someone gets hurt in the process.

Lockout/Tagout (LOTO) procedures

What’s the real story behind this? Before any work begins, the technician must completely de-energize and lock the conveyor’s power source. This Lockout/Tagout (LOTO) procedure ensures the machine cannot be turned on accidentally while someone is working on it.

Personal Protective Equipment (PPE)

Proper PPE is your first line of defense against workplace hazards. Technicians must wear the right gear to protect themselves from cuts, impacts, and other potential injuries. This is a fundamental requirement for any on-site service.

- Hard hats

- Steel-toed boots

- Safety glasses

- Cut-resistant gloves

- High-visibility clothing

Key Takeaway: A repair is only successful if it is completed without incident.

| Safety Measure | Purpose | Consequence of Neglect | |

|---|---|---|---|

| Lockout/Tagout | Prevent accidental startup | Severe injury or fatality | |

| Proper PPE | Protect technician from hazards | Cuts, burns, impact injuries | |

| Site Awareness | Identify environmental risks | Slips, falls, exposure | |

| Rigorous adherence to safety protocols is the most important step in any conveyor service. |

How do you test a repaired rubber conveyor belt?

A repaired rubber conveyor belt is tested by running the system under no-load conditions first, then gradually introducing material while monitoring the repair area. This commissioning phase is essential to validate the quality of the repair. It ensures the belt tracks correctly and the splice holds up under operational stress.

The initial no-load run

The first step is to run the conveyor empty for several rotations. The technician carefully watches the repaired section as it passes through all pulleys and idlers. This initial run checks for proper alignment, smoothness, and any obvious issues with the splice before putting it under strain.

What are you monitoring under load?

Ready for the good part? Once the no-load test is successful, material is gradually introduced onto the belt. The technician closely monitors the system’s performance to ensure the repair is sound.

- Belt tracking: Is it staying centered on the idlers?

- Splice integrity: Are there any signs of lifting or separation?

- Noise levels: Do you hear any unusual sounds indicating a problem?

- Material flow: Is material transitioning smoothly over the repair?

Key Takeaway: The job isn’t finished until the repair is proven to work under real-world conditions.

| Test Phase | Objective | Success Indicator | |

|---|---|---|---|

| No-Load Run | Check alignment and splice integrity | Belt runs true and smooth | |

| Loaded Run | Verify performance under stress | No slippage, separation, or mistracking | |

| Final Handover | Confirm client satisfaction | System operates at full capacity | |

| A careful testing phase validates the quality of the work and ensures a smooth handover. |

What maintenance does a rubber conveyor belt need?

A rubber conveyor belt requires regular maintenance, including routine inspections for wear, cleaning to prevent material build-up, and checks on tracking and tension. Proactive maintenance is the most effective way to maximize the belt’s lifespan and prevent unplanned downtime. It shifts your focus from reactive repairs to proactive prevention.

Creating a preventive inspection schedule

The bottom line is this: a simple checklist can save you thousands in repair costs. Operators should perform daily visual checks, while more detailed inspections of splices, idlers, and pulleys should occur weekly or monthly. A consistent schedule is key to catching problems early.

Key areas for regular checks

Regular walk-throughs of your conveyor system can spot trouble before it starts. Focus your attention on high-stress areas and components that are critical to the belt’s function. This simple habit can significantly extend the life of your belt.

- Splices: Look for any signs of lifting or damage.

- Belt Edges: Check for fraying, which often indicates a tracking problem.

- Top Cover: Inspect for gouges, rips, or excessive wear patterns.

- Cleanliness: Ensure belt scrapers are working and there is no build-up on pulleys.

Key Takeaway: Proactive maintenance is far less expensive than reactive repair.

| Frequency | Inspection Task | Goal | |

|---|---|---|---|

| Daily | Visual check for obvious damage | Catch major issues early | |

| Weekly | Check belt tracking and scrapers | Prevent long-term wear patterns | |

| Monthly | Inspect splices and idlers | Ensure structural integrity | |

| A simple but consistent inspection routine can prevent catastrophic failures. |

When to replace a rubber conveyor belt?

You should replace a rubber conveyor belt when it has extensive carcass damage, has been repaired multiple times, or when the cost of repairs outweighs the cost of a new belt. Knowing when to stop repairing and start replacing is a key strategic decision for any operation. This choice balances short-term expenses with long-term reliability.

Signs of terminal belt fatigue

So, what should you look for? Certain types of damage are clear indicators that a belt is at the end of its life. Widespread carcass damage, deep cracks, and loss of elasticity mean a repair is no longer a reliable option.

Calculating the cost of repair vs. replacement

Making a purely financial decision requires looking at more than just the cost of one more repair. Consider the total impact of the failing belt on your operation. A new belt might be a better investment if you are experiencing frequent downtime.

- Cumulative cost of recent repairs

- Total downtime caused by belt failures

- Risk of catastrophic failure to the system

- Efficiency losses from a worn belt

Key Takeaway: Knowing when to move from repair to replacement is a strategic decision that balances cost with long-term reliability.

| Condition | Recommended Action | Rationale | |

|---|---|---|---|

| Localized Rip | Repair | Cost-effective and fast solution | |

| Multiple Old Repairs | Consider Replacement | Repair integrity is compromised | |

| Extensive Carcass Damage | Replace | Unsafe and unreliable to repair | |

| This evaluation prevents you from investing in a belt that is no longer viable. |

How to choose the right rubber conveyor belt?

Choosing the right rubber conveyor belt involves matching the belt’s construction, compound, and strength to your specific material and system requirements. The wrong belt will wear out prematurely and perform poorly, leading to more downtime. Getting the selection right from the start is an investment in productivity.

Matching the belt to the material

The material you are conveying is the most important factor in belt selection. A belt designed for abrasive rock will fail quickly if used in an oily environment. You must choose a cover compound that is engineered to resist the specific challenges of your application.

Understanding tension ratings and specs

Here’s what most people don’t know: the belt’s technical specifications are just as important as its cover compound. Understanding these ratings ensures the belt can handle the mechanical stresses of your conveyor system.

- PIW Rating: Pounds per Inch of Width indicates the belt’s maximum operating tension.

- Number of Plies: Contributes to the belt’s overall strength and puncture resistance.

- Cover Compound: Determines resistance to abrasion, heat, oil, or flame.

Key Takeaway: The right belt is an investment in uptime and ensures maximum performance and a longer service life.

| Consideration | Factor to Analyze | Impact of Wrong Choice | |

|---|---|---|---|

| Material Conveyed | Abrasiveness, temperature, oil | Premature belt wear and failure | |

| System Design | Tension, incline, pulley diameter | Splice failure, tracking issues | |

| Environment | Indoor/outdoor, chemical exposure | Cover cracking, degradation | |

| Consulting with an expert to select the perfect belt for your application prevents costly future problems. |

Conclusion

We’ve walked through the entire repair process, from the initial emergency call to the final performance test. You’ve seen how expert preparation, meticulous execution, and a focus on safety turn a costly breakdown into a reliable, long-term solution. Our goal is to be more than just a service provider; we aim to be your partner in productivity, ensuring your operations run smoothly and efficiently.

Don’t let a belt failure disrupt your business. If you need expert repair or advice on selecting the right belt, contact our technical team today.

Frequently Asked Questions (FAQ)

- Q1: Can I repair a major rip in my rubber conveyor belt myself?

- It is not recommended. Professional repair requires specialized tools, materials, and safety procedures (like LOTO) to ensure the repair is safe and durable. A failed DIY repair can cause even greater damage.

- Q2: What’s the best repair method for a high-tension rubber conveyor belt?

- Hot vulcanization is undoubtedly the best method. It creates a seamless, homogenous splice with the highest possible strength, making it ideal for demanding, high-tension applications where reliability is paramount.

- Q3: How do I know if my rubber conveyor belt is mistracking?

- You’ll know it’s mistracking if the belt consistently drifts to one side of the conveyor frame, causing the belt edge to rub against the structure. This often results in visible edge wear, fraying, and potential structural damage.

- Q4: Can I use mechanical fasteners on any rubber conveyor belt?

- No, you cannot. Mechanical fasteners are not suitable for all belts, especially those with thin covers or those used on small-diameter pulleys. They also create a non-seamless point that can interfere with belt scrapers and cause spillage.

- Q5: What’s the best way to extend the life of my rubber conveyor belt?

- The single best way is through consistent, proactive maintenance. Regularly cleaning the belt, ensuring scrapers are functional, and conducting routine inspections for tracking issues and wear will prevent small problems from becoming major failures.