Conveyor Belts: Types, Production and Uses

Manually handling materials is slow, labor-intensive, and prone to costly mistakes. It exhausts your workforce, increases safety hazards, and disrupts production flow. The solution lies in understanding the right types of conveyor belts — from flat and cleated designs to steel cord and sidewall systems — each engineered to automate transport, minimize human strain, and achieve higher productivity with consistent reliability.

The Fundamentals of Conveyor Belts

A conveyor belt system is a mechanical apparatus that uses a continuous moving belt to transport materials from one location to another. It forms the backbone of automated material handling in countless industries. These systems streamline your workflows and reduce manual labor.

What is a conveyor belt system?

At its heart, a conveyor system automates the movement of goods, saving you time and money. It replaces manual carrying with a consistent, reliable flow. This automation is key to scaling your operations efficiently.

- The best part is its versatility. You can use it for:

- Moving small parts

- Transporting heavy boxes

- Handling bulk materials

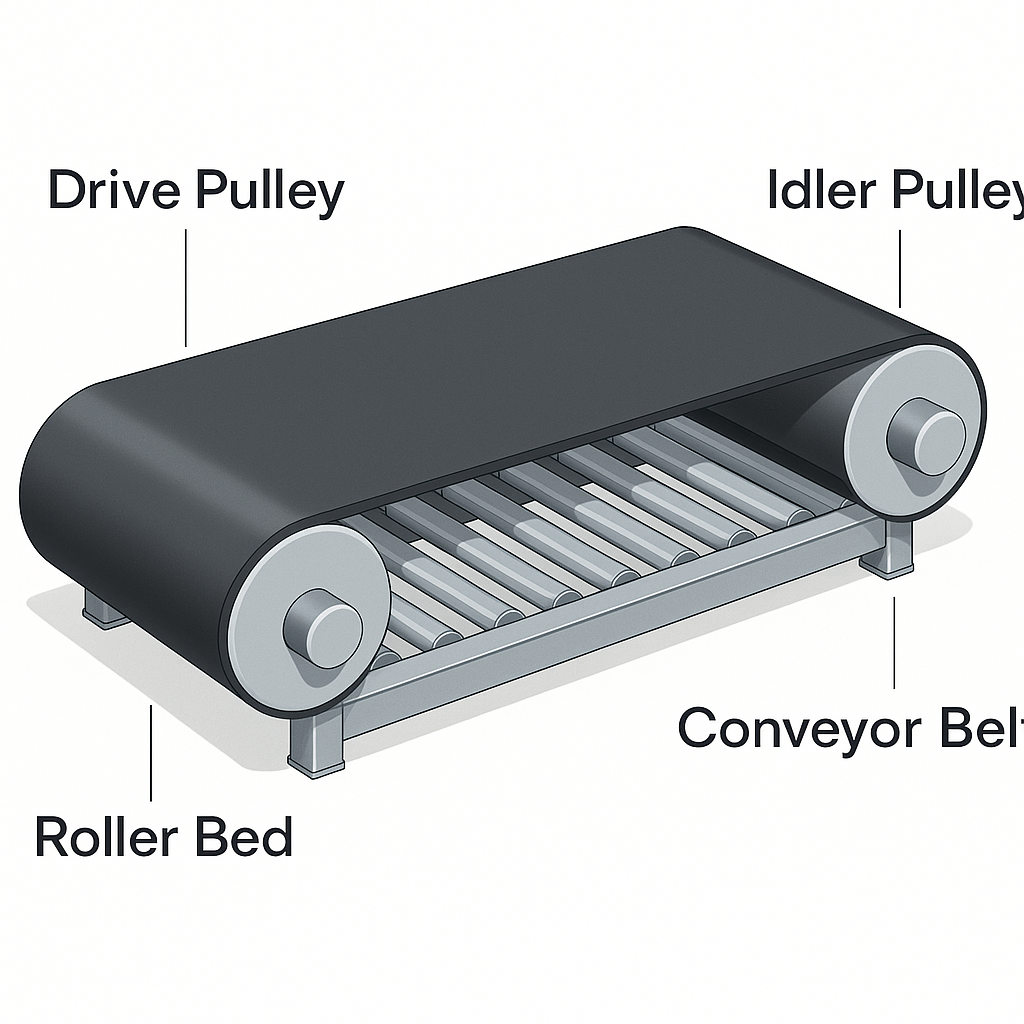

The Core Components Explained

The main components work in harmony to create motion, including the belt, motor, pulleys, and support structure. Understanding these parts helps you diagnose issues quickly. This knowledge ensures you can keep your system running smoothly.

- Here’s the breakdown of what you need to know:

- Belt: The moving surface that carries your items.

- Pulleys: The wheels that the belt loops around.

- Motor: The power source that drives the system.

Head Drives vs. Tail Drives

The drive location affects performance, particularly with tension and load capacity. A head drive pulls the belt, while a tail drive pushes it. Your choice depends on the specific application and system layout.

- Think of it this way for your setup:

- Head Drive (Pull): Better for most applications, creates more tension.

- Tail Drive (Push): Useful for reversing belts or special layouts.

Key Takeaway: Understanding the core components and drive types is the first step to selecting and maintaining an efficient conveyor system for your needs.

| Drive Type | Pros | Cons | |

|---|---|---|---|

| Head Drive | Better tension control, pulls the load | Can increase stress on the belt splice | |

| Tail Drive | Good for reversing, simpler design | Can cause belt slippage with heavy loads |

How Do Conveyor Systems Operate?

Conveyor systems operate through a motor that powers a drive pulley, which in turn grips and moves the continuous loop of the belt. The belt is supported by rollers or a flat bed to ensure smooth transit of items. This simple principle allows for continuous, automated movement.

The Role of the Motor

The motor is the powerhouse of your conveyor system, converting electrical energy into mechanical force. Its horsepower determines the system’s speed and load capacity. Choosing the right motor is critical for optimal performance.

- So, what does it really do for you?

- Provides the torque to start the belt.

- Maintains a consistent speed under load.

- Enables stopping and starting on demand.

How do pulleys ensure movement?

Pulleys create the tension and traction needed to move the belt. The drive pulley is powered by the motor to pull the belt, while the idler pulley guides it back. Proper alignment is key to preventing belt wear and tear.

- The bottom line is this simple relationship:

- The drive pulley actively moves the belt.

- Idler pulleys support and guide the belt’s return path.

- Together, they form a stable, continuous loop.

The Function of Support Rollers

Support rollers, or a slider bed, sit underneath the belt to prevent it from sagging under the weight of the items you’re moving. They reduce friction and ensure goods travel smoothly. Without them, the belt would droop and fail.

- Here’s the deal on choosing the right support:

- Rollers are best for heavier items.

- Slider beds are ideal for smaller or delicate items.

- They both minimize friction and wear on the belt.

Key Takeaway: The synergy between the motor’s power, the pulleys’ grip, and the rollers’ support is what makes a conveyor system a reliable workhorse.

| Component | Primary Function | Key Benefit for You | |

|---|---|---|---|

| Motor | Provides power and rotational force | Ensures consistent speed and load capacity | |

| Pulleys | Grip and guide the belt | Creates a stable, continuous moving loop | |

| Rollers | Support the belt and reduce friction | Allows for smooth transport of heavy goods |

Common Types of Conveyor Belts

The most common types of conveyor belts include roller bed, flat belt, and modular belt conveyors, each designed for specific loads and environments. You choose one based on the weight, shape, and fragility of the items being transported. They are the foundation of modern logistics.

The Workhorse: Roller Bed Belts

A roller bed conveyor uses rollers as the support surface, making it ideal for moving heavy, flat-bottomed items like boxes and totes. The rollers reduce friction, requiring less power. This makes them highly efficient for your warehouse.

- Look at it this way, they’re perfect for:

- Distribution centers

- Manufacturing assembly

- Packing stations

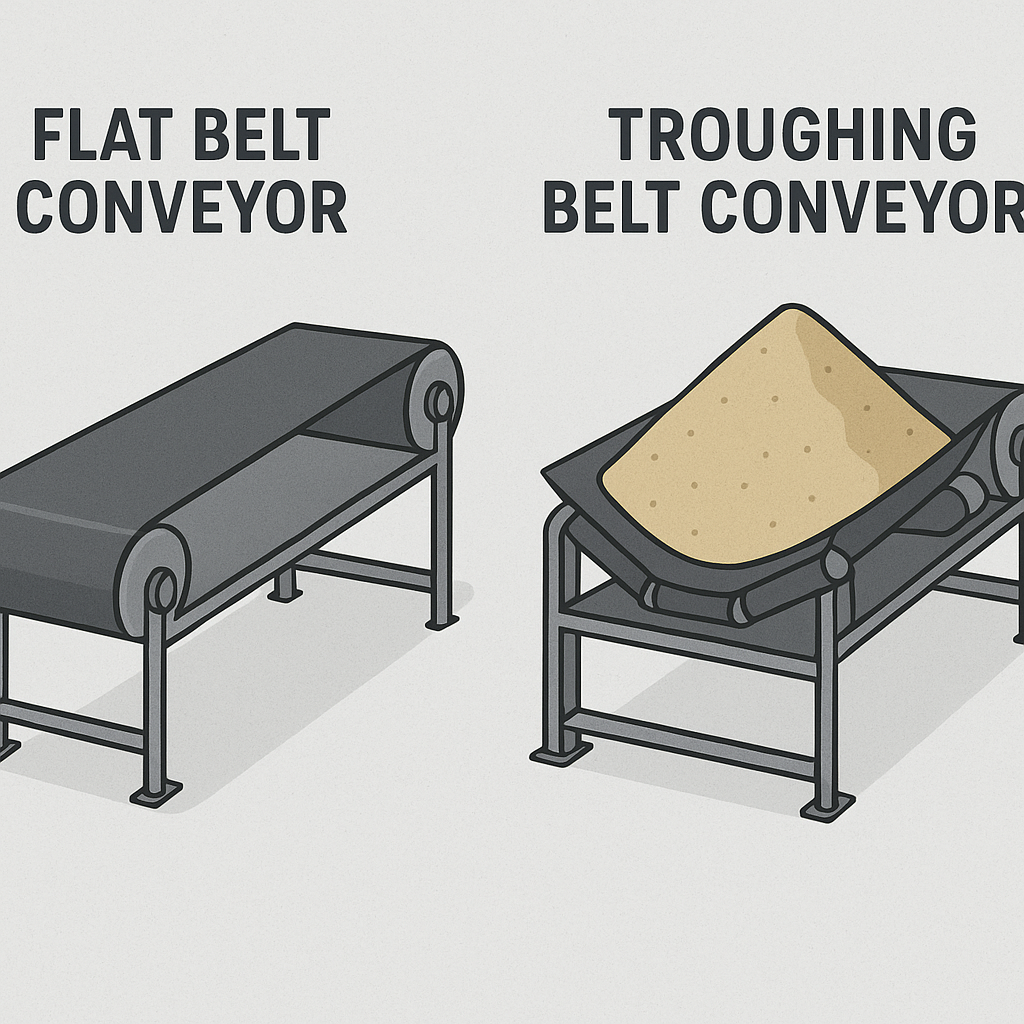

Why choose a flat belt conveyor?

You should choose a flat belt conveyor for its smooth, continuous surface, which is perfect for moving small, delicate, or irregularly shaped items. It provides excellent support and stability. This is your go-to for parts handling and assembly.

- Here’s the thing you need to remember:

- Ideal for small components and bagged items.

- Often used in food processing and electronics.

- Provides a stable surface for tasks like scanning.

The Versatile Modular Belt

Modular belts are made from interlocked plastic segments, making them incredibly durable and easy to repair. You can simply replace a damaged section instead of the entire belt. Their open-grid design is great for drainage.

- The reality is, they excel in these areas:

- Food and beverage industries (wash-downs).

- Handling both straight runs and curves.

- Applications requiring high durability.

Key Takeaway: Selecting between roller, flat, or modular belts depends entirely on what you need to move, setting the stage for operational efficiency.

| Belt Type | Best For | Common Industries | |

|---|---|---|---|

| Roller Bed | Heavy, flat-bottomed items (boxes, totes) | Logistics, Warehousing | |

| Flat Belt | Small, delicate, or irregular items | Electronics, Assembly | |

| Modular Belt | Applications needing curves or drainage | Food, Beverage |

Specialized Types of Conveyor Belts

Specialized conveyor belts, like incline, curved, and sandwich belts, are designed to solve specific layout challenges such as changing elevation or navigating corners. They allow you to build complex material handling routes in tight spaces. These systems optimize your facility’s footprint.

Moving Items on an Incline or Decline

Incline and decline belts move products between different floor levels. To prevent items from slipping, they often feature a high-friction surface or cleats. This ensures your products move safely up or down.

- The key is choosing the right surface:

- Rough top belts offer extra grip.

- Cleated belts provide physical barriers.

- This choice depends on the angle and product type.

How do curved conveyors save space?

Curved conveyors allow your production line to turn corners, making the most of your available floor space. They eliminate the need for multiple straight conveyors and transfers. This creates a more fluid and compact workflow.

- The secret is their design flexibility:

- They can create 90-degree or 180-degree turns.

- Modular plastic belts are often used for curves.

- They connect different stages of your process seamlessly.

The Power of Sandwich Belts

Sandwich belts use two belts that press together to securely grip items. This allows you to move materials at extremely steep angles, even vertically. They are perfect for elevating bulk materials in a small footprint.

- But how do they work? It’s simple:

- One belt runs on top of the other.

- Gentle pressure “sandwiches” the material.

- This allows for vertical or near-vertical movement.

Key Takeaway: Specialized conveyors give you the power to design a material handling system that fits your facility’s unique layout, not the other way around.

| Specialized Type | Primary Function | Benefit for Your Facility | |

|---|---|---|---|

| Incline/Decline | Move items between elevations | Utilizes vertical space effectively | |

| Curved | Navigate corners and change direction | Optimizes floor plan and saves space | |

| Sandwich | Move materials at very steep angles | Enables vertical transport in a small footprint |

A Deep Dive into Cleated Conveyor Belts

Cleated conveyor belts use vertical barriers or “cleats” to securely move loose materials or small parts up steep inclines and declines. The cleats act like pockets, preventing items from rolling back. This ensures a consistent flow against gravity.

Preventing Rollback with Cleats

Cleats are the projecting partitions on a belt that create compartments for your products. They provide positive traction for loose, granular, or small items. This prevents slippage and maintains spacing.

- Here’s the scoop on why cleats are essential:

- They contain and stabilize materials on an incline.

- They ensure consistent spacing between items.

- They allow for steeper angles than a standard belt.

Common Cleat Shapes and Their Uses

Cleats come in various shapes, and the one you choose depends on the product. Common shapes include the Inverted V, T-cleat, and L-cleat. Each is engineered for a specific task.

- The trick is to match the cleat to the product:

- Inverted V: Best for granular materials like sand or grain.

- T-Cleat: Ideal for light-duty parts or packaged goods.

- L-Cleat: Used for small boxes or items needing support.

What are sidewall conveyors?

Sidewall conveyors add corrugated walls to the edges of a cleated belt. This creates a fully contained pocket, allowing you to move bulk materials at very steep angles without spillage. They are like a flexible, moving bucket elevator.

- The bottom line is containment:

- Sidewalls prevent material from falling off the sides.

- Combined with cleats, they form complete pockets.

- This enables incline angles of up to 90 degrees.

Key Takeaway: Cleated belts are your solution for defying gravity, ensuring that loose or small products move reliably up steep inclines without rollback.

| Cleat/Wall Type | Best Use Case | Primary Benefit | |

|---|---|---|---|

| Inverted V | Granular or powder materials | Centers material and allows for drainage | |

| T-Shape | Packaged goods, small parts | Provides support and maintains spacing | |

| Sidewalls | Bulk materials at steep inclines | Prevents spillage and enables vertical lift |

Advanced Types of Conveyor Belts

Advanced conveyor belts like filter, timing, and anti-static belts are engineered for highly specialized tasks that standard belts cannot handle. These belts manage liquids, ensure precise positioning, or protect sensitive electronics. They are critical for your high-tech manufacturing.

Handling Liquids with Filter Belts

Filter belts are made of a porous mesh that allows liquids to drain through while retaining solid materials. You use them in food processing to dewater vegetables or in industrial settings to separate solids from slurry. They are essential for separation tasks.

- The main advantage is simple but powerful:

- They separate solids from liquids efficiently.

- Ideal for washing, cooling, or dewatering processes.

- Materials range from metal mesh to synthetic fabrics.

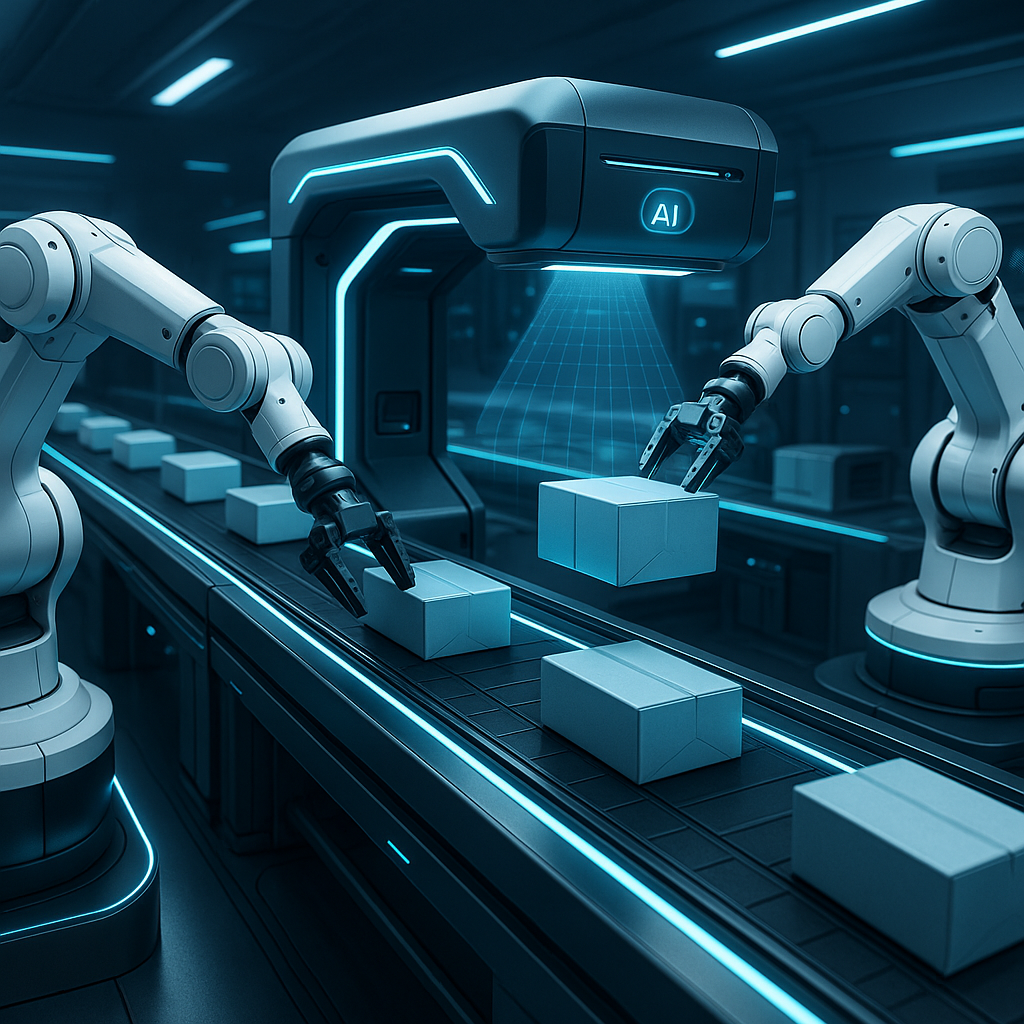

What are timing belts for?

Timing belts have teeth that engage with matching toothed pulleys, ensuring no slippage. This allows for precise, repeatable movement, which is critical for automated and robotic processes. You use them when exact positioning is non-negotiable.

- You’ll see them in applications that need precision:

- Robotic pick-and-place systems.

- Indexing and positioning tasks.

- Automated assembly lines.

Preventing Shocks with Anti-Static Belts

But what about static electricity? Anti-static belts are made with conductive materials that safely dissipate static charges, protecting sensitive electronic components from damage. If you handle circuit boards or microchips, these are a must.

- Here’s why you need them for electronics:

- They prevent electrostatic discharge (ESD).

- ESD can destroy delicate electronic components.

- They are mandatory in electronics manufacturing.

Key Takeaway: Advanced belts solve complex challenges, enabling processes that require precision, filtration, or electrostatic protection for your most sensitive products.

| Advanced Type | Key Feature | Why You Need It | |

|---|---|---|---|

| Filter Belt | Porous, mesh construction | To separate liquids from solids during transport | |

| Timing Belt | Toothed profile for precise movement | For robotic and automated positioning tasks | |

| Anti-Static | Conductive material | To protect sensitive electronics from ESD |

How Are Conveyor Belts Manufactured?

Conveyor belts are manufactured by layering and bonding materials like rubber, plastic, fabric, or metal to achieve specific properties for strength, flexibility, and resistance. The process involves carcass weaving, material compounding, and vulcanization. This creates a belt tailored to your needs.

Durable Metal and Rubber Belts

Rubber and metal belts are built for toughness. Rubber belts offer excellent grip and impact resistance, while metal belts are ideal for high-temperature or cut-prone applications. Your choice depends on durability requirements.

- Remember this for heavy-duty jobs:

- Rubber: Used for bulk materials like rock and coal.

- Metal (Steel): Used in ovens, forges, or for sharp parts.

- Both offer superior strength and longevity.

Lightweight Plastic and Fabric Belts

Plastic and fabric belts are versatile and lightweight. Fabric belts (like canvas or polyester) form the core strength layer in many rubber belts. Modular plastic belts are strong, easy to clean, and chemical-resistant.

- Here’s the deal for general-purpose use:

- Fabric: Provides tensile strength without the weight.

- Plastic: Excellent for food, beverage, and pharma.

- They are cost-effective and easy to maintain.

The Classic Leather Belt

Though less common now, leather belts were once the standard. They offer a good grip and are naturally pliable. Today, you might find them in specialized, light-duty applications or power transmission.

- Why would you still consider leather?

- It has a naturally high coefficient of friction.

- It is flexible and easy to splice.

- Best suited for specific, non-abrasive applications.

Key Takeaway: The material a belt is made from directly defines its performance, so matching the material to your application is crucial for longevity and reliability.

| Material | Key Property | Ideal Environment | |

|---|---|---|---|

| Metal | High Temp/Cut Resistance | Ovens, foundries, sharp parts handling | |

| Rubber | High Durability & Grip | Mining, bulk material handling | |

| Plastic/Fabric | Lightweight & Cleanable | Food processing, general logistics |

Key Industrial Uses for Conveyor Belts

The key industrial uses for conveyor belts range from moving thousands of tons of bulk materials in mining to precisely positioning components on manufacturing assembly lines. They are the essential arteries of modern production and logistics. These systems enable mass-scale operations.

Bulk Material Handling

In industries like mining, agriculture, and shipping, troughing belt conveyors move massive quantities of materials like coal, grain, or ore. These systems can be miles long. They are the most efficient way to transport bulk goods.

- The numbers speak for themselves:

- Capable of moving thousands of tons per hour.

- Drastically reduces labor costs and time.

- Essential for large-scale resource extraction.

How are they used in assembly lines?

On an assembly line, conveyors move products from one workstation to the next at a controlled pace. This allows your workers to perform specific tasks sequentially. It is the core principle of modern mass production.

- It’s a game-changer for manufacturing:

- It sets the pace of production.

- It brings the work directly to the worker.

- It ensures a consistent and orderly workflow.

Efficient Ship Loading and Unloading

At ports, large-scale conveyors are used to load and unload ships with incredible speed. These systems can move everything from bulk cargo like grain to individual containers. They are vital to the global supply chain.

- The impact on logistics is massive:

- Reduces ship turnaround time from days to hours.

- Minimizes manual labor and associated risks.

- Connects land-based transport to sea freight.

Key Takeaway: From raw materials to finished goods, conveyor belts are the driving force behind industrial efficiency on a global scale.

| Industry | Primary Use | Core Benefit | |

|---|---|---|---|

| Mining | Transporting ore, coal, rock | Massive throughput, reduced labor | |

| Manufacturing | Moving parts on assembly lines | Paced production, improved workflow | |

| Logistics | Loading/unloading ships, trucks | Faster turnaround, supply chain speed |

Conveyors in Specialized Environments

In specialized environments like airports, manufacturing plants, and excavation sites, conveyors are custom-designed to meet unique challenges. They handle everything from passenger luggage with care to moving tons of rock from below ground. This adaptability makes them indispensable.

Luggage Transport in Airports

At an airport, a complex web of conveyors transports your bag from check-in, through security screening, to the correct gate for loading. This automated system handles thousands of bags per hour. It ensures your luggage makes the flight.

- Follow the journey of your bag:

- It gets a tag and is placed on a belt.

- Scanners route it through a maze of conveyors.

- It arrives at the sorting bay for your flight.

Moving Parts in Manufacturing

In cleanrooms or high-tech manufacturing, conveyors must be pristine and precise. They move delicate components like microchips or pharmaceuticals without contamination. These systems are often made of stainless steel or specialized plastics.

- Here’s what you need for these environments:

- Non-shedding and easy-to-clean materials.

- Smooth, vibration-free movement.

- Often integrated with robotic systems.

What are excavation conveyors?

Excavation conveyors are rugged, portable systems used on construction and tunneling sites. They move earth, rock, and debris out of the way continuously. This is far more efficient than using trucks or loaders in confined spaces.

- The big advantage on a job site is efficiency:

- Continuous removal of excavated material.

- Reduces vehicle traffic and improves safety.

- Can be extended as the excavation progresses.

Key Takeaway: Conveyors can be adapted to almost any environment, from the pristine cleanroom to the rugged construction site, solving unique material handling puzzles.

| Environment | Conveyor’s Role | Key Feature | |

|---|---|---|---|

| Airports | Baggage handling and sorting | Speed, accuracy, and high volume | |

| Cleanrooms | Transporting sensitive components | Hygienic design, precision movement | |

| Excavation | Removing earth and debris | Portability and extreme durability |

Safety Standards and Regulations

Safety standards from bodies like OSHA, FDA, and MSHA are mandatory regulations that govern the design, installation, and operation of conveyor systems. These rules are in place to protect your workers from injury and ensure product safety. Compliance is non-negotiable.

OSHA and Worker Safety Rules

OSHA provides strict guidelines for conveyor safety to protect your workers. This includes requirements for emergency stops, guarding for moving parts, and proper training. Following these rules prevents accidents.

- Your essential safety checklist should include:

- Guarding: All pinch points and moving parts must be guarded.

- E-Stops: Emergency stop pull-cords or buttons must be accessible.

- Training: Workers must be trained on safe operating procedures.

FDA Rules for Food-Contact Belts

For food and pharmaceutical applications, the FDA mandates that conveyors be sanitary and easy to clean. Belts must be made from non-toxic, non-absorbent materials. This prevents contamination and protects consumer health.

- What makes a belt food-safe?

- Made from FDA-approved materials.

- Designed to be easily disassembled for cleaning.

- Resistant to bacteria growth and cleaning chemicals.

MSHA Mining-Specific Standards

The Mine Safety and Health Administration (MSHA) has its own strict set of rules for conveyors used in mining. These focus on fire resistance for belts and robust guarding. This is due to the harsh and hazardous nature of the mining environment.

- The focus in mining is on extreme hazards:

- Fire-Retardant Belts: Mandatory to prevent fires underground.

- Robust Guards: Must withstand a highly abrasive environment.

- Lockout/Tagout: Strict procedures for maintenance are enforced.

Key Takeaway: Adhering to safety standards isn’t just about compliance; it’s a fundamental commitment to protecting your people and your products.

| Agency | Focus Area | Key Requirement for You | |

|---|---|---|---|

| OSHA | General Worker Safety | Proper guarding and emergency stops | |

| FDA | Food & Pharma Safety | Sanitary, non-toxic materials | |

| MSHA | Mining Safety | Fire-retardant belts, robust guards |

Conclusion

By choosing the right conveyor system, you directly solve the crippling problems of inefficiency, high operational costs, and persistent safety hazards. A modern conveyor is not just a piece of equipment; it’s a strategic investment in industrial productivity, reliability, and growth that pays dividends year after year. Our commitment is to empower industries with innovative and reliable automation solutions that drive progress and operational excellence.

Ready to transform your material handling? Contact our experts today for a personalized consultation and find the perfect conveyor solution for your business.

Frequently Asked Questions (FAQ)

1. Can a single conveyor system handle curves and inclines?Yes, absolutely. Modular belt conveyors are exceptionally good at this, as they can be configured to create complex routes that include straight sections, curves, and inclines within a single, continuous system.

2. What is the best belt for hot or oily parts?For these conditions, metal belts, particularly woven wire or steel belts, are often the best choice. They are impervious to heat damage and are not degraded by oils, making them far more durable than rubber or plastic options.

3. How do I determine the right motor horsepower?Determining the right horsepower is a critical calculation based on belt speed, belt weight, load weight, incline angle, and friction. It’s highly recommended to consult with a conveyor engineer to perform these calculations to ensure the motor is not under- or overpowered.

4. Are there quiet conveyor options for noise-sensitive places?Yes, quiet options are available. Systems that use high-quality precision bearings, low-friction materials, and brushless DC motors are significantly quieter than traditional industrial conveyors and are ideal for laboratories, offices, or quiet assembly areas.

5. How often should conveyor rollers be inspected?Regular inspections are crucial. For high-use systems, rollers should be checked weekly for signs of seizure, debris buildup, or unusual noise. A more thorough inspection should be part of a monthly or quarterly preventative maintenance schedule.