An unexpected rubber conveyor belt failure can halt your entire operation, causing costly downtime and production delays. The frustration of watching a critical belt fail prematurely can take a toll on both efficiency and profitability. The key is understanding what distinguishes a durable, high-performance rubber conveyor belt from one that can’t withstand demanding conditions. This guide reveals the essential factors behind belt design and manufacturing, helping you make smarter, more reliable investment decisions for your business.

Raw materials for a rubber conveyor belt

What are the core components?

The quality of a conveyor belt begins with its raw materials. You can’t build a strong product on a weak foundation. Here’s the deal: there are three primary components:

- Rubber Compounds: Natural or synthetic rubbers (like Neoprene or Nitrile) form the body and covers.

- Reinforcements: Fabric plies or steel cords provide tensile strength and structural integrity.

- Chemical Additives: Curing agents, fillers, and antioxidants enhance specific properties like durability and resistance.

How are reinforcement materials chosen?

The choice between fabric and steel reinforcement depends entirely on your application’s demands. Fabric is ideal for general-purpose conveying due to its flexibility, while steel is necessary for heavy-duty work requiring extreme strength and low stretch.

Key Takeaway: Selecting the right reinforcement is critical for ensuring the belt’s load-carrying capacity and operational lifespan.

| Reinforcement | Primary Benefit | Ideal Use Case | |

|---|---|---|---|

| Fabric (Polyester, Nylon) | Flexibility & Impact Resistance | General material handling, mining | |

| Steel Cord | High Tensile Strength & Low Elongation | Long-distance, heavy-duty conveying |

This choice directly impacts your belt’s performance and longevity.

Compounding a rubber conveyor belt mix

Why is rubber compounding necessary?

Raw rubber alone doesn’t have the properties needed to withstand industrial environments. Compounding is the meticulous process of mixing rubber with various additives in a machine like a Banbury mixer to create a homogenous material with specific performance characteristics.

What additives are mixed in?

You might be wondering what goes into this mix. Specific additives are chosen to achieve desired qualities, from hardness to heat resistance.

- Fillers: Carbon black enhances strength and abrasion resistance.

- Curing Agents: Sulphur creates the cross-links during vulcanization.

- Antioxidants: These protect the belt from degradation due to oxygen and ozone exposure.

Key Takeaway: Compounding transforms basic rubber into a highly engineered material tailored for your specific operational challenges.

| Additive | Function | Benefit for Your Operation | |

|---|---|---|---|

| Carbon Black | Reinforcement | Improved wear and tear resistance | |

| Sulphur | Curing Agent | Provides strength and elasticity | |

| Antioxidants | Protection | Extends the service life of the belt |

This engineered compound is the heart of a durable belt.

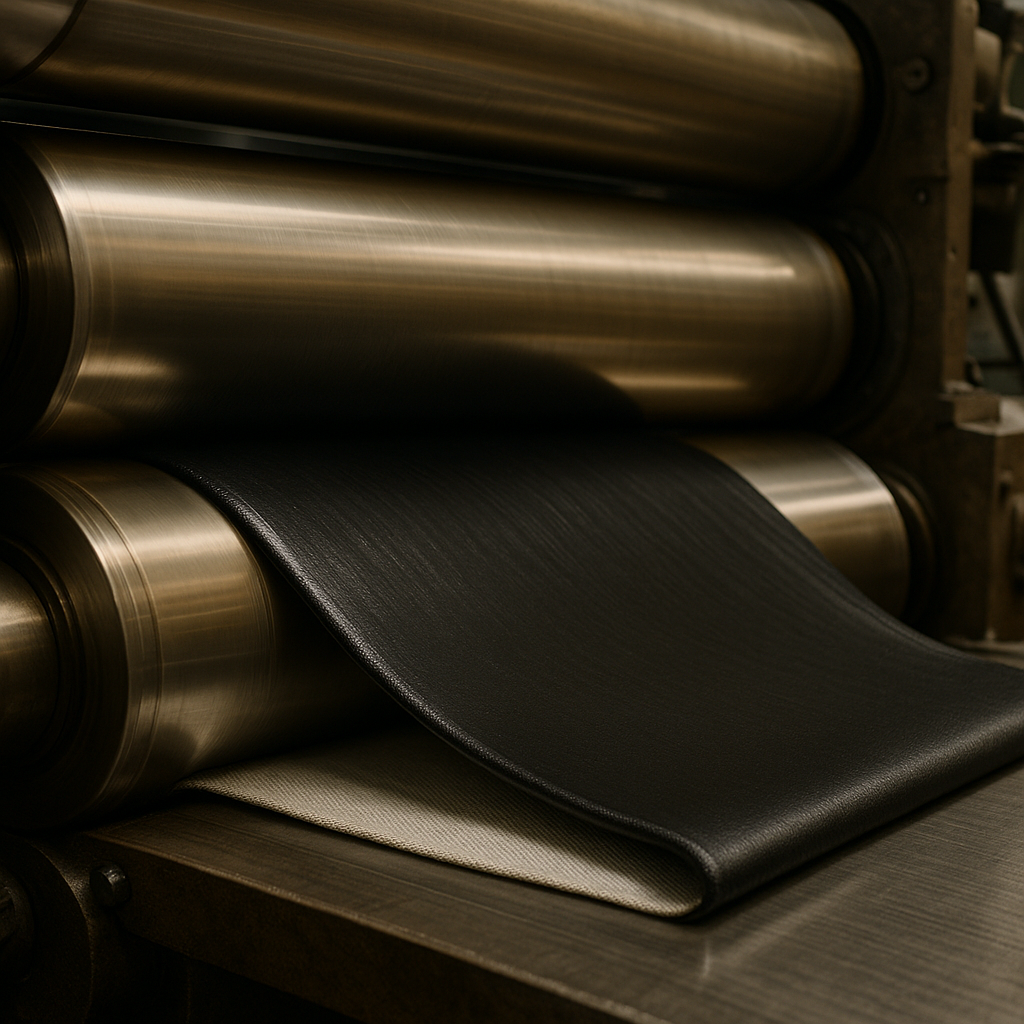

Calendaring a rubber conveyor belt

What happens during calendaring?

During calendaring, the rubber compound is passed through a series of large, heated rollers. This process flattens the rubber into smooth, continuous sheets of a precise and uniform thickness.

How is thickness consistency achieved?

The gap between the calendar rollers is precisely controlled by automated systems. This ensures that every inch of the rubber sheet meets exact specifications, which is critical for balanced belt performance.

How are reinforcement layers embedded?

This is where it gets interesting. The fabric or steel cord reinforcements are fed through the calendar rollers along with the rubber sheets. The pressure from the rollers forces the rubber to permeate and bond with the reinforcement, creating a single, integrated ply.

Key Takeaway: Calendaring is a precision process that creates the foundational layers of the belt, ensuring uniform thickness and strong adhesion.

| Step | Action | Purpose | |

|---|---|---|---|

| 1. Feeding | Rubber compound is fed into rollers. | Prepare material for shaping. | |

| 2. Pressing | Rollers flatten rubber to a set thickness. | Ensure uniformity. | |

| 3. Embedding | Reinforcement is pressed into the rubber. | Create a strong, bonded ply. |

This process builds the core structure of your belt.

Vulcanizing your rubber conveyor belt

What is the goal of vulcanization?

Vulcanization is a chemical process that transforms soft, pliable rubber into a strong, durable, and elastic material. The un-cured belt is placed in a large press where it’s subjected to intense heat and pressure.

What are the process parameters?

What’s the real story here? This isn’t just simple heating. The process is carefully controlled to activate the curing agents added during compounding. This creates cross-links between the rubber molecules, giving the belt its final strength and resilience.

Key Takeaway: Vulcanization is the crucial final step that locks in the belt’s physical properties, turning a layered sheet into a tough, unified product.

| Parameter | Typical Range | Impact on Belt | |

|---|---|---|---|

| Temperature | 140-160°C (284-320°F) | Activates curing agents | |

| Pressure | High and uniform | Ensures density and removes air | |

| Time | Varies by belt thickness | Allows complete chemical cross-linking |

Proper vulcanization determines the belt’s ultimate durability.

Finishing a rubber conveyor belt

How is the belt cooled and cut?

After vulcanization, the large rolls of belting are allowed to cool gradually to stabilize their structure. Once cooled, automated cutting machines trim the belts to their final, specified width and length with high precision.

What surface textures can be added?

But wait, there’s more. Depending on your needs, a surface finish may be applied. For applications requiring extra grip, especially on inclines, textured surfaces can be added.

- Grooved Patterns: Help channel away water and fine materials.

- Diamond Patterns: Provide multi-directional grip for packages and bags.

Key Takeaway: The finishing stage tailors the belt’s physical dimensions and surface characteristics to meet the precise requirements of your conveyor system.

| Texture | Primary Benefit | Common Application | |

|---|---|---|---|

| Smooth | General purpose, easy to clean | Bulk material transport | |

| Grooved | Enhanced grip and drainage | Inclined conveyors, wet conditions | |

| Diamond | Multi-directional traction | Package and luggage handling |

This final touch ensures the belt is ready for its specific job.

QA for a new rubber conveyor belt

What defects are inspectors looking for?

Before a belt ever leaves the factory, it undergoes rigorous quality assurance. Inspectors visually check for any surface imperfections, such as blisters, cracks, or inconsistencies in thickness that could compromise performance.

What performance tests are conducted?

Here’s the bottom line: a visual check isn’t enough. Samples are taken from the belt and subjected to a battery of physical tests to ensure they meet standards.

- Tensile Strength Test: Measures the force required to break the belt.

- Abrasion Resistance Test: Determines how well the belt withstands wear.

- Adhesion Test: Checks the bond strength between the rubber layers and reinforcement.

Key Takeaway: A thorough QA process is the final gatekeeper that guarantees your conveyor belt meets the specifications required for reliable, long-term performance.

| Test | What It Measures | Why It Matters for You | |

|---|---|---|---|

| Tensile Strength | The belt’s breaking point under tension. | Ensures it can handle your load. | |

| Abrasion Resistance | Durability against friction and wear. | Predicts lifespan with abrasive materials. | |

| Adhesion Strength | Bond between plies. | Prevents delamination and premature failure. |

Only belts that pass these tests are cleared for shipment.

Core layers of a rubber conveyor belt

What purpose does the top cover serve?

The top cover is the belt’s first line of defense. It’s the layer that comes into direct contact with the material you’re conveying. Its primary job is to protect the inner carcass from abrasion, impact, and any environmental factors.

What is the function of the carcass?

Think of it this way: the carcass is the belt’s skeleton. Comprised of the fabric or steel reinforcement layers embedded in rubber, it provides the belt’s tensile strength and structural integrity. It’s what allows the belt to carry heavy loads over long distances without stretching or breaking.

Key Takeaway: Each layer of a conveyor belt has a distinct and vital function, working together to provide strength, protection, and durability.

| Layer | Function | Your Benefit | |

|---|---|---|---|

| Top Cover | Protects from material impact and wear. | Extends the belt’s operational life. | |

| Carcass | Provides tensile strength and structure. | Enables load-carrying capacity. | |

| Bottom Cover | Protects the carcass from the conveyor frame. | Ensures smooth operation and prevents friction wear. |

Understanding these layers helps you diagnose wear patterns.

Specialty rubber conveyor belt types

What makes a belt heat resistant?

Heat-resistant belts use special rubber compounds, like EPDM, that are formulated to withstand high temperatures without cracking or hardening. They are essential for applications like foundries and cement plants.

How are belts made fire resistant?

Fire resistance is achieved by using self-extinguishing rubber compounds like chloroprene. These belts are designed to not propagate a flame, a critical safety feature in underground mining and grain handling.

What about oil and chemical resistance?

Now for a key detail. For environments with exposure to oils, greases, or chemicals, you need a belt made from Nitrile or PVC compounds. These materials prevent the rubber from swelling, weakening, and degrading, which would otherwise lead to rapid failure.

Key Takeaway: Specialty belts are not a luxury; they are a necessity for safe and efficient operation in harsh or demanding environments.

| Belt Type | Key Property | Typical Industry | |

|---|---|---|---|

| Heat Resistant | Withstands high temperatures. | Steel, Cement, Foundries | |

| Fire Resistant | Self-extinguishing. | Mining, Grain Elevators | |

| Oil Resistant | Does not degrade from oil exposure. | Recycling, Food Processing |

Choosing the right specialty belt prevents catastrophic failures.

Maintaining your rubber conveyor belt

How can you inspect your belt?

Regular inspection is the key to maximizing your belt’s lifespan. You should routinely check for:

- Proper belt tracking and alignment.

- Signs of damage or wear on the top and bottom covers.

- Integrity of the splice points.

- Functionality of belt cleaners and scrapers.

What are common signs of wear?

You need to know this. Catching wear early can prevent a major failure. Look for:

- Cracks, gouges, or exposed fabric on the covers.

- Fraying or damage along the belt edges.

- Hardening or softening of the rubber surface.

- Grooving or uneven wear patterns across the belt’s width.

Key Takeaway: Proactive maintenance and regular inspections are the most effective ways to extend your conveyor belt’s service life and prevent unscheduled downtime.

| Sign of Wear | Potential Cause | Recommended Action | |

|---|---|---|---|

| Edge Fraying | Belt misalignment or rubbing on structure. | Realign the belt and check clearances. | |

| Surface Cracking | Exposure to UV, heat, or chemicals. | Verify belt-type is correct for the environment. | |

| Grooving | Material build-up on rollers or pulleys. | Inspect and clean rollers and idlers. |

A few minutes of inspection can save you hours of downtime.

Conclusion

The journey from a pile of raw materials to a finished, high-performance rubber conveyor belt is a complex and precise manufacturing process. Each step—from compounding and calendaring to vulcanization and quality testing—is critical in building a product that can withstand the rigors of your operation. By understanding this process, you are better equipped to evaluate the quality of your conveyor belts, select the right product for your needs, and implement maintenance practices that boost efficiency and prevent costly downtime.

FAQ

Q1: Can I request a custom rubber conveyor belt?Absolutely. Most manufacturers can produce belts with custom widths, lengths, cover thicknesses, and special compounds to meet the unique demands of your specific application.

Q2: Can I repair a damaged rubber conveyor belt?Yes, for minor damages like small punctures or gouges, repairs can often be made using cold bonding kits or hot vulcanization patches to extend the belt’s service life.

Q3: Can I use one belt for different materials?It is not recommended. A belt designed for abrasive rock will perform poorly with oily materials, and vice versa. Using the correct belt type for the material being conveyed is crucial for both safety and longevity.

Q4: Can I increase my belt’s lifespan?Definitely. Proper installation, regular inspections, maintaining correct belt tension and alignment, and ensuring belt cleaners are functional are all key practices that will significantly prolong the life of your belt.

Q5: Can I install a rubber conveyor belt myself?While possible, it is highly advised to have experienced technicians handle installation, especially the splicing. An improper splice is a common point of failure and can lead to significant operational and safety risks.