Manual material handling slows down production, increases labor costs, and raises the risk of workplace injuries. These inefficiencies create bottlenecks that directly affect your bottom line. A Conveyor Belt provides an automated, reliable solution to move goods smoothly through your process. By reducing manual effort and ensuring consistent material flow, a Conveyor Belt significantly boosts productivity, minimizes downtime, and enhances safety across industrial operations.

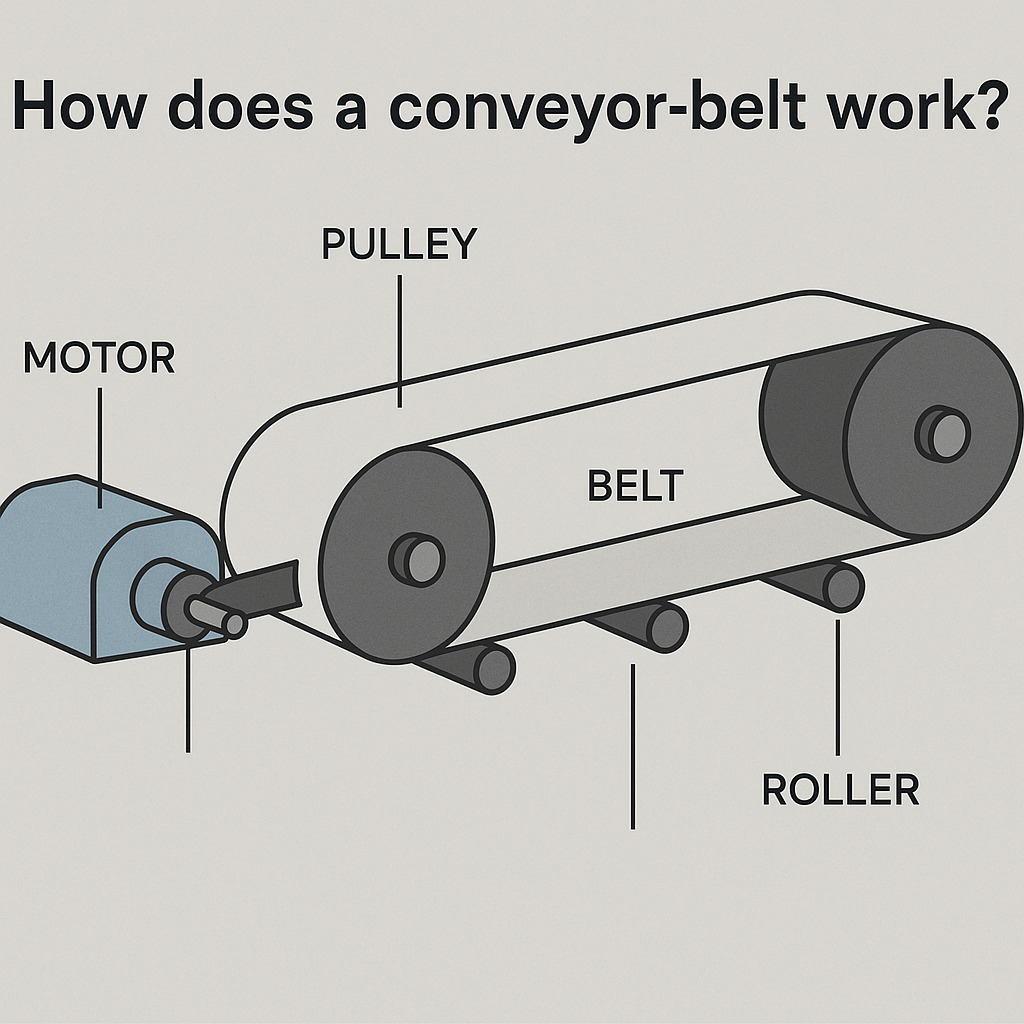

How does a conveyor-belt work?

What are the basic mechanics of movement?

A conveyor belt operates on a simple, continuous loop principle. The system uses two or more pulleys, with the belt tensioned between them. When a motor powers one of the pulleys (the drive pulley), it rotates, pulling the belt and everything on it forward.

What parts drive the belt system?

The primary driver is an electric motor connected to a drive pulley. This pulley grips the belt and initiates movement. Idler pulleys and rollers support the belt along its length, reducing friction and maintaining tension to prevent slippage.

How does it transport different materials?

The belt’s surface moves at a controlled speed, carrying items from one point to another. But here’s the kicker: accessories like cleats can help move materials up an incline, while specialized belt materials can handle everything from hot components to food-grade products.

Key Takeaway: A conveyor belt is a mechanically simple system driven by a motor and pulleys, designed for efficient and continuous material transport.

| Component | Function | |

|---|---|---|

| Motor | Powers the entire system. | |

| Drive Pulley | Rotates to move the belt. | |

| Idler Rollers | Support the belt and reduce friction. | |

| Belt | The moving surface that carries materials. |

Top uses for a conveyor-belt

Which industries rely on them most?

You can find conveyor belts in almost every industry. Key sectors include:

- Manufacturing and Assembly

- Warehousing and Logistics

- Mining and Agriculture

- Airports and Postal Services

What are some everyday examples?

The most common example is the checkout counter at a grocery store. Others include airport baggage carousels and the moving walkways in large public venues.

How does a conveyor-belt improve efficiency?

By automating the movement of goods, a conveyor-belt reduces the need for manual labor. What does this mean for you? It means faster processing times, lower operational costs, and a significant reduction in workplace injuries associated with lifting and carrying.

Key Takeaway: Conveyor belts are fundamental to efficiency across countless industries, from logistics to retail.

| Industry | Common Application | |

|---|---|---|

| Logistics | Sorting and moving packages. | |

| Food & Beverage | Transporting products through processing lines. | |

| Airports | Handling passenger luggage. | |

| Mining | Moving bulk materials like coal or ore. |

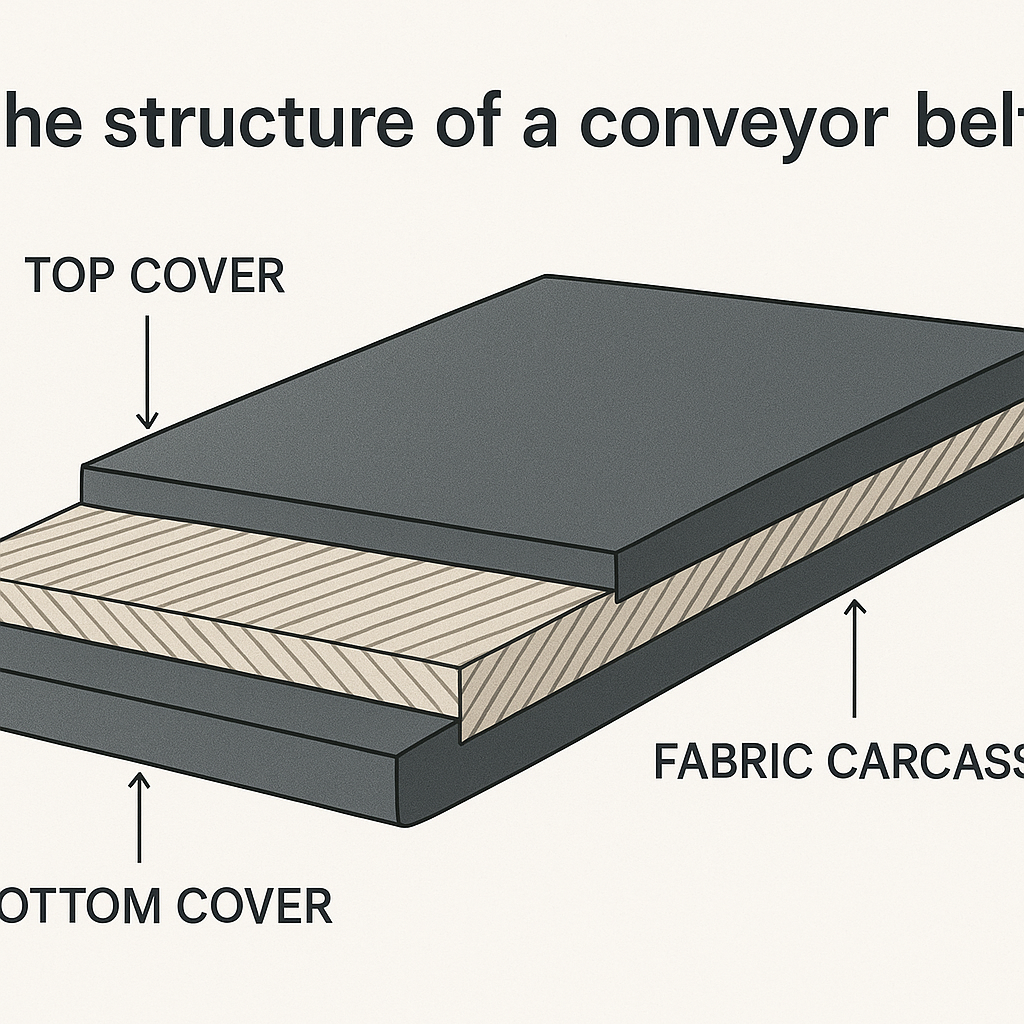

The structure of a conveyor-belt

What are the main layers of a belt?

A standard conveyor belt consists of three main layers. The top cover is the contact surface, the fabric carcass is the core, and the bottom cover runs along the rollers.

Why is the fabric carcass so important?

The fabric carcass provides the belt’s tensile strength and structural integrity. It’s typically made from multiple layers of woven material (like polyester or nylon) that resist stretching and tearing under heavy loads.

How does the top layer affect performance?

The top cover is critical. This is where it gets interesting… Its material and texture determine durability, grip, and resistance to abrasion, heat, or chemicals. A smooth surface works for boxes, while a textured one might be needed for inclines.

Key Takeaway: The layered structure of a conveyor belt, especially the carcass and top cover, dictates its strength and application suitability.

| Layer | Purpose | |

|---|---|---|

| Top Cover | Protects the carcass and provides grip. | |

| Fabric Carcass | Provides tensile strength and structure. | |

| Bottom Cover | Protects the carcass from rollers and friction. |

Types of conveyor-belt material

When is a rubber conveyor-belt the best choice?

Rubber belts are the workhorses for heavy-duty applications. They are ideal for moving abrasive materials like gravel, coal, and ore in mining and construction due to their high durability and impact resistance.

What are synthetic conveyor-belts used for?

Synthetic materials like PVC and Polyurethane (PU) are used where hygiene is a priority. You’ll find them in the food processing and pharmaceutical industries because they are easy to clean and resist oils and fats.

How does material affect durability?

The material directly correlates to the belt’s lifespan. Think about it this way: using a PVC belt for sharp rocks will cause it to fail quickly, while an expensive, heat-resistant rubber belt is overkill for moving cardboard boxes. Matching the material to the job is essential for durability.

Key Takeaway: Choosing the right belt material—from heavy-duty rubber to hygienic synthetics—is critical for performance and longevity.

| Material | Primary Use Case | |

|---|---|---|

| Rubber | Heavy-duty, abrasive materials (mining, construction). | |

| PVC | General purpose, logistics, food handling. | |

| Polyurethane (PU) | Food-grade applications, oil resistance. | |

| Fabric | Lightweight transport, check-out counters. |

Core components of a conveyor-belt

What are drive drums and rollers?

The drive drum, or pulley, is the powered component that moves the belt. Rollers are the non-powered wheels that support the belt’s weight along the conveyor frame, ensuring it runs smoothly and with minimal friction.

Why are scrapers and cleats needed?

Scrapers are installed to clean the belt surface, removing residual material that could cause buildup and tracking issues. Cleats are raised partitions on the belt surface used to secure items when the conveyor is on an incline.

How do sidewalls prevent spillage?

Corrugated sidewalls are flexible walls on the edges of the belt. Here’s a simple breakdown: they form a trough-like shape that contains bulk materials like grain, sand, or powders, preventing them from spilling over the sides.

Key Takeaway: Beyond the belt itself, components like drums, scrapers, and sidewalls are vital for a system’s functionality and cleanliness.

| Component | Purpose | |

|---|---|---|

| Drive Drum | Moves the belt. | |

| Scrapers | Clean the belt surface. | |

| Cleats | Hold items on an incline. | |

| Sidewalls | Contain bulk materials and prevent spillage. |

Safety rules for a conveyor-belt

What are the primary safety risks?

The main risks are entanglement and pinch points. Loose clothing, hair, or jewelry can get caught in moving parts like rollers and pulleys, leading to serious injury.

How can entanglement be prevented?

Proper machine guarding is the first line of defense. All moving parts should be covered. Additionally, operators must never wear loose items and should be trained to keep their hands and tools clear of the belt.

What are key emergency stop procedures?

Every conveyor should have clearly marked emergency stop buttons or pull-cords located at regular intervals. This is critical: all personnel working near the conveyor must know their locations and how to use them instantly.

Key Takeaway: Conveyor safety hinges on proper guarding, operator awareness, and accessible emergency stop controls.

| Safety Measure | Description | |

|---|---|---|

| Machine Guarding | Physical barriers preventing contact with moving parts. | |

| Lockout/Tagout | Procedures to de-energize equipment during maintenance. | |

| Emergency Stops | Easily accessible buttons or pull-cords to halt the system. | |

| Operator Training | Education on risks and safe operating practices. |

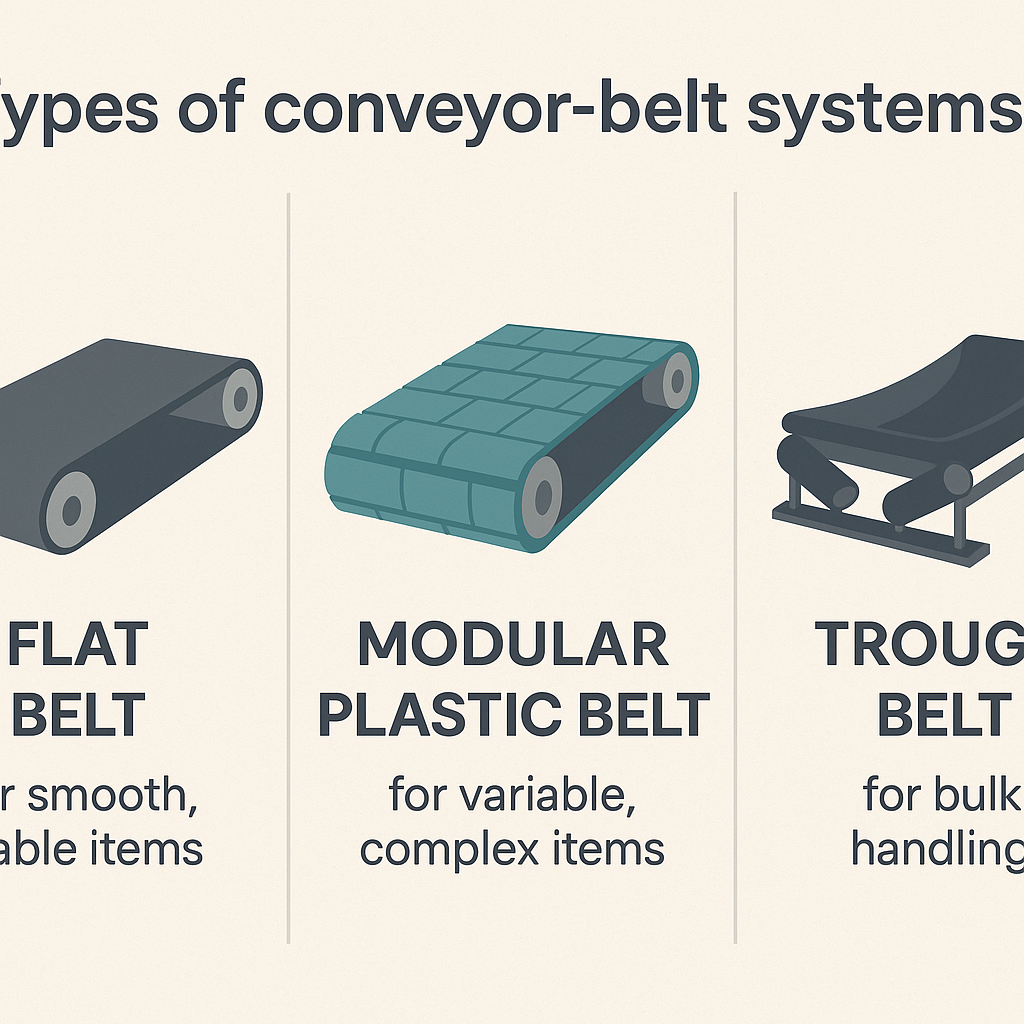

Choosing your conveyor-belt

What factors should guide my choice?

Your decision should be based on several factors:

- The type and weight of the material being transported.

- The required speed and throughput.

- The operating environment (e.g., temperature, moisture).

- The conveyor path (e.g., inclines, curves).

How do I match the belt to the material?

For light boxes, a simple PVC belt is sufficient. For bulk, abrasive materials, you need a heavy-duty rubber belt. For food items, a food-grade PU belt is non-negotiable.

When should I seek expert advice?

Here’s the bottom line: if you are unsure about any of the technical specifications or if your application involves complex factors like high temperatures, sharp materials, or strict hygiene standards, consult an expert to avoid a costly mistake.

Key Takeaway: Selecting the right conveyor belt requires a careful analysis of the material, environment, and performance needs.

| Factor | Consideration | |

|---|---|---|

| Load | The weight and size of the product. | |

| Speed | How fast the material needs to move. | |

| Environment | Temperature, chemicals, or moisture exposure. | |

| Material | Abrasiveness, texture, and hygiene requirements. |

Key Factors in a conveyor-belt Installation

What are the site preparation needs?

Before installation, ensure you have adequate floor space, a level surface, and access to a suitable power source. The structure must be able to support the weight of the conveyor and its maximum load.

How complex is the setup process?

Complexity varies. A small, straight conveyor may be a simple bolt-together assembly. However, a large, integrated system with curves, inclines, and multiple drives can be a major engineering project.

Who should handle conveyor-belt installation?

Let’s be direct: unless it’s a very simple, standalone unit, professional installers are recommended. They have the tools and expertise to ensure proper alignment, tensioning, and tracking, which are critical for performance and safety.

Key Takeaway: Proper installation, from site prep to final alignment, is crucial for the long-term, trouble-free operation of a conveyor system.

| Installation Phase | Key Task | |

|---|---|---|

| Preparation | Ensure space, power, and structural support. | |

| Assembly | Construct the frame and install components. | |

| Alignment | Align pulleys and rollers to ensure the belt tracks straight. | |

| Tensioning | Set the correct belt tension to prevent slippage. |

Maintaining a conveyor-belt

How often should a belt be inspected?

A daily visual check for obvious issues is good practice. A more thorough inspection of tracking, tension, and components should be performed weekly or monthly, depending on usage intensity.

What are the common signs of wear?

Look for fraying edges, surface cracks, and any signs of mistracking (the belt drifting to one side). Also listen for unusual noises from rollers or motors, which can indicate bearing failure.

Can a damaged conveyor-belt be repaired?

Minor damage like small punctures or tears can often be repaired with patching kits. But there’s a catch: extensive damage, such as a long rip or widespread surface wear, usually means the belt must be replaced to prevent catastrophic failure.

Key Takeaway: Regular inspection and proactive maintenance are the best ways to maximize a conveyor belt’s lifespan and prevent costly downtime.

| Check | Frequency | What to Look For | |

|---|---|---|---|

| Visual Check | Daily | Debris, obvious damage, mistracking. | |

| Tension | Weekly | Slippage or excessive strain. | |

| Components | Monthly | Wear on rollers, scrapers, and pulleys. | |

| Structure | Monthly | Loose bolts or frame damage. |

The future of the conveyor-belt

What innovations are emerging now?

Smart conveyors with IIoT (Industrial Internet of Things) sensors are becoming more common. These sensors monitor tension, speed, and motor health in real-time, enabling predictive maintenance.

Will automation change belt systems?

Absolutely. Conveyor belts are integrating more closely with robotics. Robots can now pick, place, and sort items directly on a moving belt, creating a fully automated production or fulfillment line.

How is sustainability impacting design?

This is a big one. Manufacturers are developing belts from more sustainable materials and designing energy-efficient drive systems to reduce the overall carbon footprint of material handling operations.

Key Takeaway: The future of the conveyor belt is smart, automated, and sustainable, with technology driving greater efficiency and integration.

| Innovation | Impact | |

|---|---|---|

| IIoT Sensors | Enables predictive maintenance and reduces downtime. | |

| Robotic Integration | Allows for fully automated sorting and handling. | |

| Energy-Efficient Drives | Lowers operational costs and environmental impact. | |

| Sustainable Materials | Reduces the carbon footprint of manufacturing. |

Frequently Asked Questions

Q1: How do I know if my business needs a conveyor-belt?If your operation involves repetitive manual moving of items from one station to another, a conveyor belt can likely improve your efficiency, reduce labor costs, and enhance worker safety.

Q2: What’s the best conveyor-belt for handling food products?You should use a food-grade belt, typically made from Polyurethane (PU) or another non-toxic, non-absorbent synthetic material that is easy to clean and sanitize.

Q3: Can I upgrade my existing conveyor-belt system?Yes. You can often upgrade components like the belt itself (to a more durable material), the motor (for higher speed), or add accessories like scanners and diverters.

Q4: How do I calculate the load capacity for a conveyor-belt?Load capacity is determined by the weight of the product per foot or meter. You must calculate the maximum load you will have on the conveyor at any one time to ensure the belt, motor, and frame can support it.

Q5: What’s the most common reason a conveyor-belt fails?The most common cause of failure is belt mistracking—when the belt drifts to one side—which leads to frayed edges and eventual tearing. This is often caused by improper loading, incorrect tensioning, or component misalignment.

A properly chosen and maintained conveyor belt is a foundational asset for industrial efficiency, safety, and growth. Analyze your material handling process today to identify where automation can deliver the greatest return on investment and operational improvement.