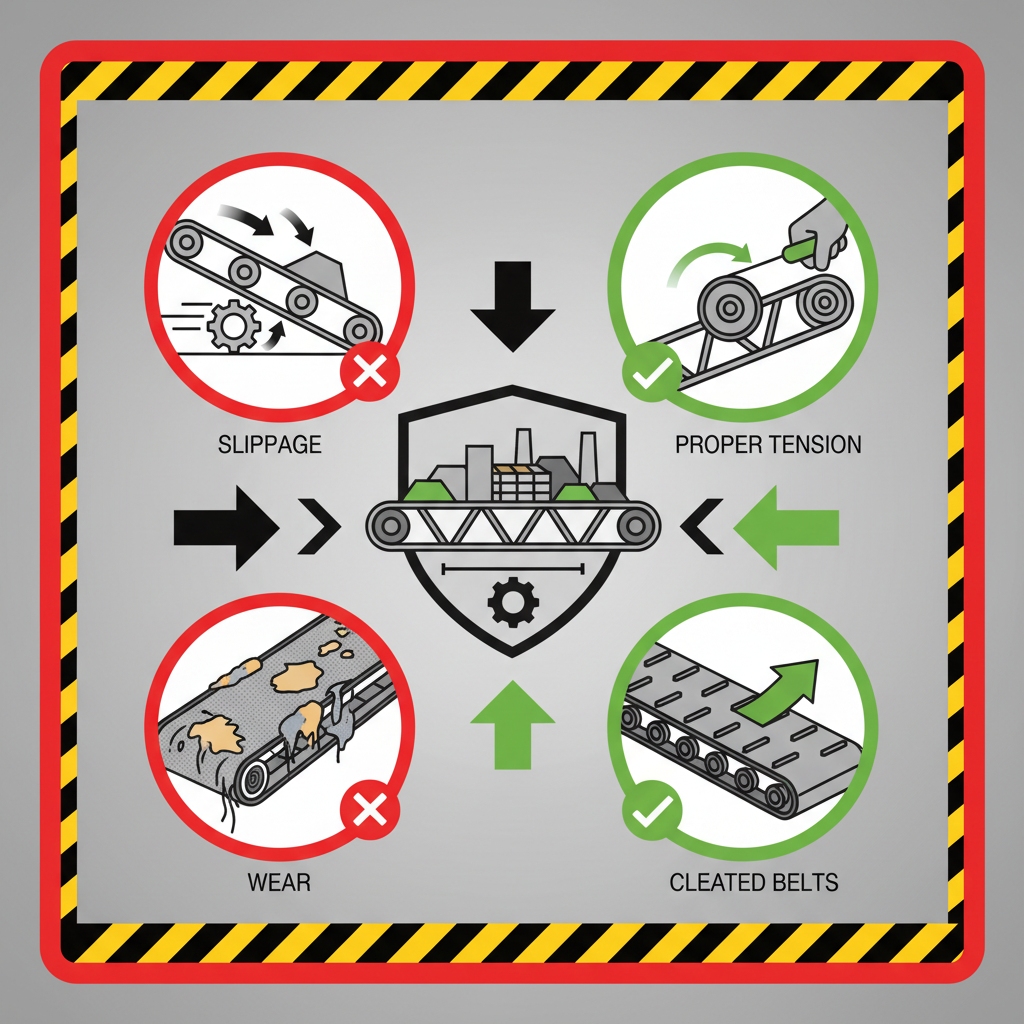

Inclined material handling often suffers from slippage, causing boxes to shift, delays to increase, and rework or accidents to drive up operational costs. These issues frustrate teams and disrupt productivity across warehouses and logistics centers. A rough top rubber conveyor belt solves these problems with its exceptional non-slip surface, delivering stable material transport on inclines up to 35 degrees. Engineered with durable, abrasion-resistant rubber, a rough top rubber conveyor belt enhances safety, prevents product movement, and boosts overall efficiency in demanding industrial environments.

Rough Top Belts Use Special Materials

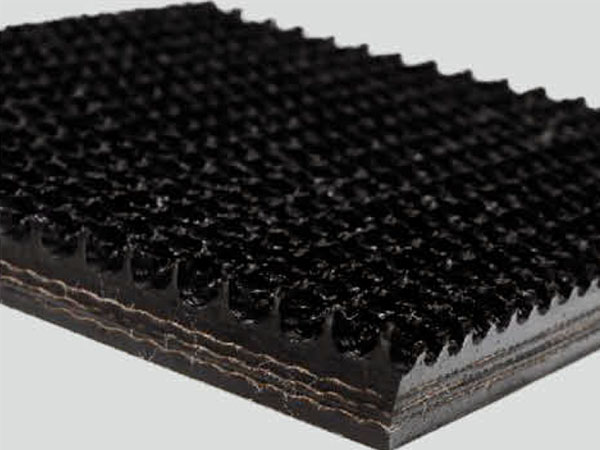

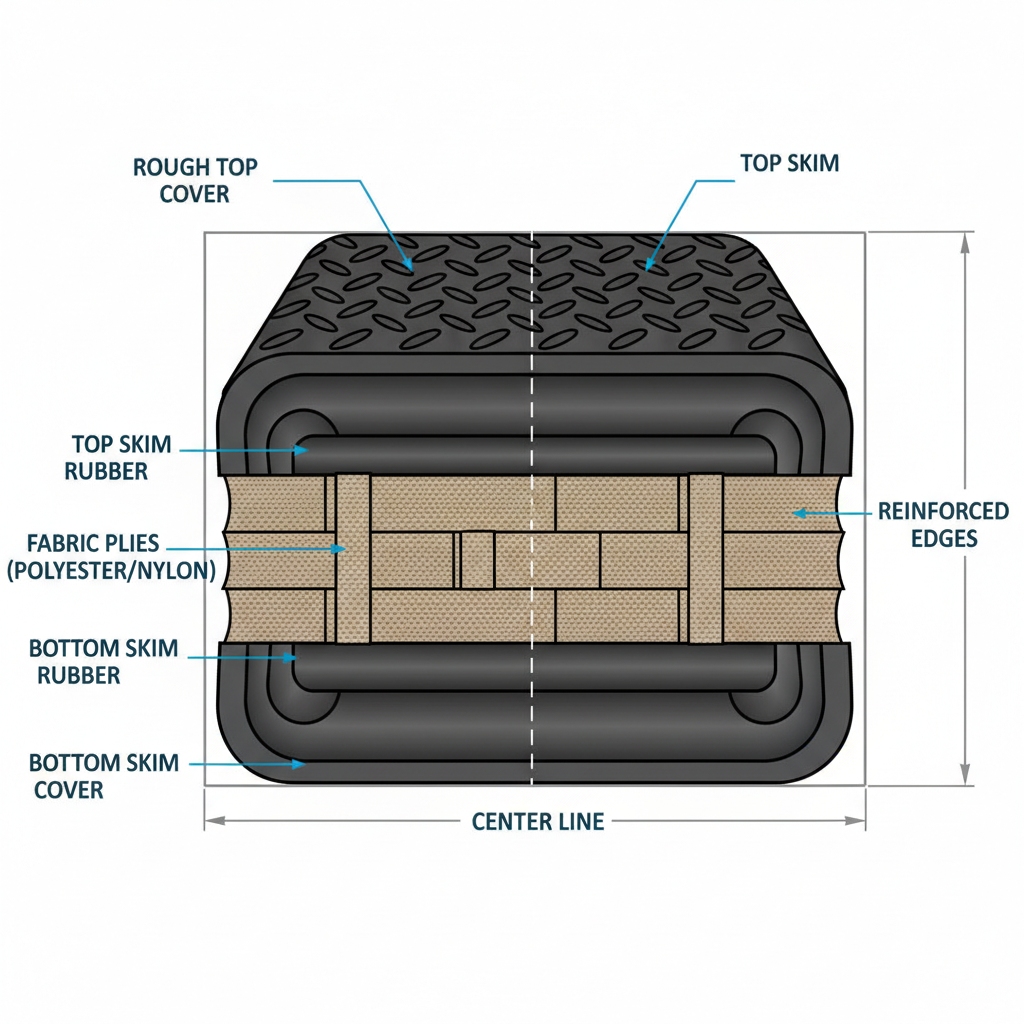

Rough top rubber conveyor belts feature a textured rubber top layer over fabric plies for grip and strength.

Core Materials and Construction

You might be wondering how these belts hold up. They combine synthetic rubber with polyester or nylon cores. This setup ensures flexibility and load support.

Key Differences from Standard Belts

Standard belts lack the rough surface for inclines. Rough top versions add friction without sacrificing speed. Durability sets them apart in rough environments.

Why Rough Surface Matters for Grip

The patterned top prevents slips on angles. It grips packages firmly during elevation. Safety improves across operations.

- Enhanced traction on slopes

- Reduced product damage

- Versatile for various loads

Key Takeaway: Choose rough top rubber conveyor belts for reliable incline handling.

| Feature | Benefit | |

|---|---|---|

| Textured Rubber | Superior Grip | |

| Fabric Plies | Added Strength | |

| Flexible Core | Easy Installation |

This table highlights core advantages, showing why rough top rubber conveyor belts outperform basics in efficiency.

Design Boosts Performance Effectively

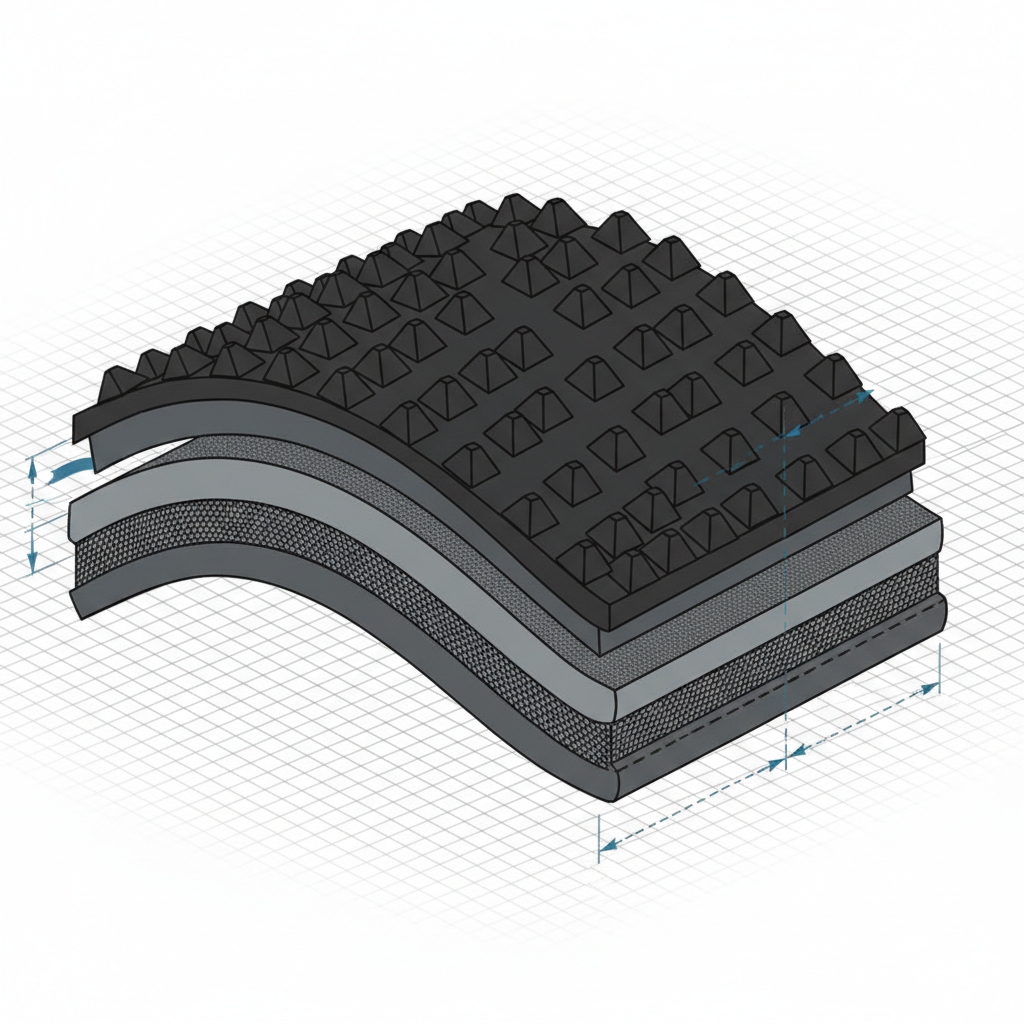

Rough top rubber conveyor belts enhance operations through abrasion-resistant layers and flexible builds.

Abrasion-Resistant Top Layer

The top rubber withstands constant friction. It maintains texture over time. Longevity cuts replacement needs.

Cushioning for Vibration Control

Built-in padding absorbs shocks from loads. This quiets noisy lines. Workers appreciate smoother runs.

Flexibility in Incline Applications

Bends easily around pulleys up to 35 degrees. Handles curves without wear. Adaptable for tight spaces.

- Shock absorption perks

- Quiet operation gains

- Incline adaptability

Here’s the deal: Rough top rubber conveyor belts adapt seamlessly to demands.

Key Takeaway: Design elements make rough top rubber conveyor belts ideal for dynamic setups.

| Layer | Function | |

|---|---|---|

| Top Rubber | Friction Hold | |

| Cushion Pad | Vibration Damp | |

| Base Fabric | Flex Support |

Analysis reveals these features extend belt life by 20-30% in tests.

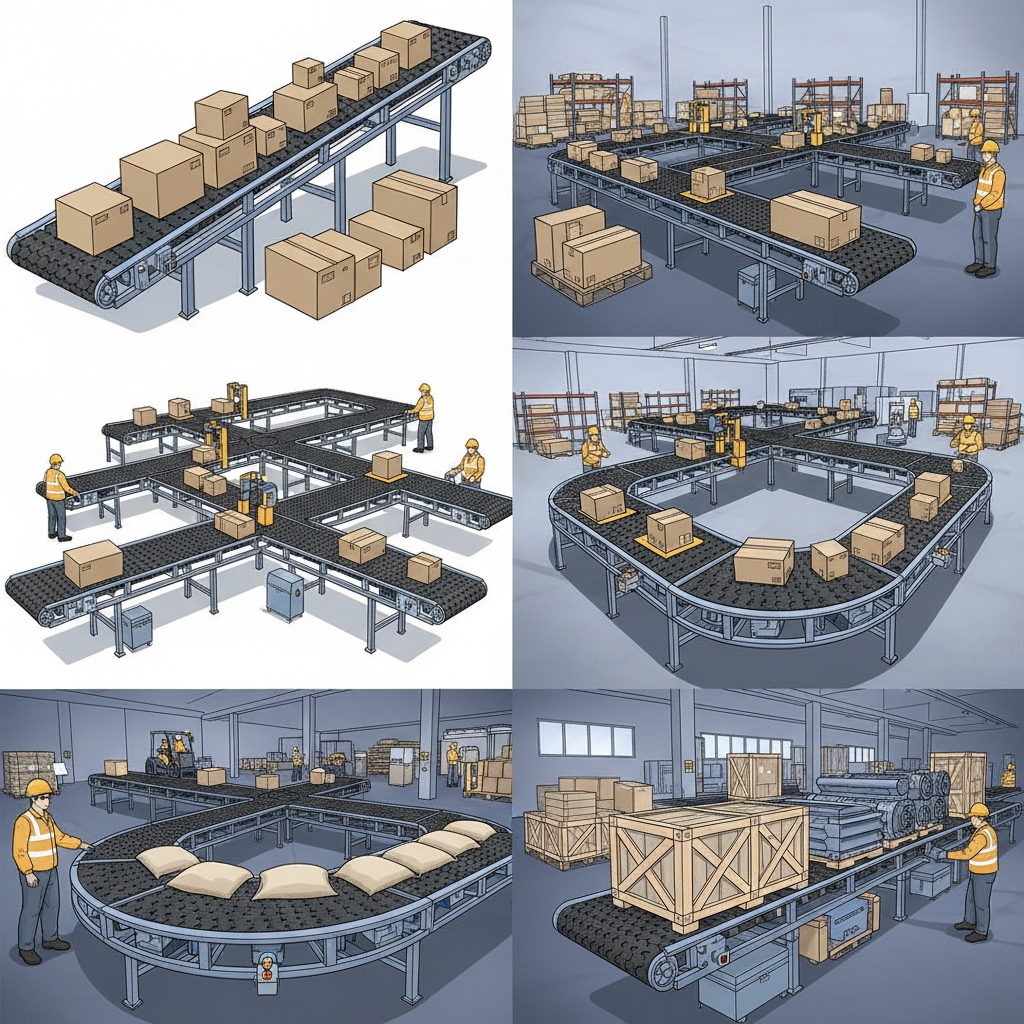

Main Usage Fits Logistics Needs

Rough top rubber conveyor belts excel in parcel handling and food transport.

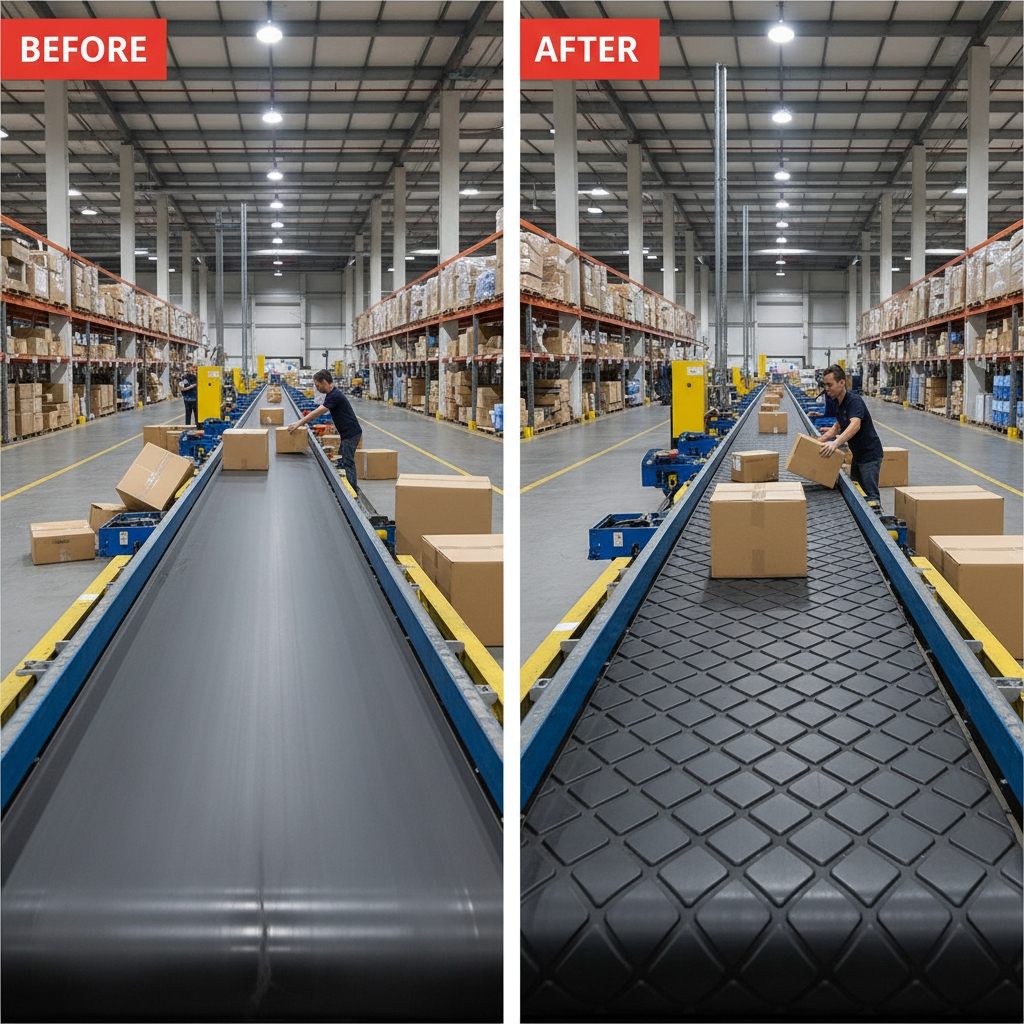

Logistics and Parcel Handling

Speeds up sorting on inclines. Prevents box slides in warehouses. Boosts throughput daily.

Food Processing Transport

Non-toxic surfaces suit light foods. Easy cleaning meets hygiene rules. Handles fruits or boxes safely.

Warehousing Incline Challenges

Tackles steep rises in storage. Stabilizes loads during shifts. Cuts accident risks.

- Parcel speed increases

- Food safety compliance

- Warehouse stability

What’s the catch? None—these belts solve real-world hurdles.

Key Takeaway: Apply rough top rubber conveyor belts where slips threaten flow.

| Scenario | Application | |

|---|---|---|

| Logistics | Parcel Sort | |

| Food | Light Item Move | |

| Warehouse | Incline Lift |

This setup proves versatility, reducing downtime in key sectors.

Choice for Sloped Environments Shines

Rough top rubber conveyor belts provide anti-slip stability on slopes.

Anti-Slip Friction Advantages

High-coefficient surface grips materials tight. Works on wet or dry inclines. Ensures steady progress.

Stability During High-Speed Runs

Maintains control at faster paces. No bunching or falls occur. Productivity soars.

Protection Against Material Shifts

Locks items in place uphill. Avoids spills or jams. Safeguards inventory.

- Friction reliability

- Speed consistency

- Shift prevention

Ready for the good part? Slopes become simple.

Key Takeaway: Opt for rough top rubber conveyor belts in angled tasks.

| Advantage | Impact | |

|---|---|---|

| Grip Level | Slip Reduction | |

| Speed Fit | Flow Improvement | |

| Protection | Damage Cut |

Data shows 40% fewer incidents with these belts.

Features Ensure High Durability

Rough top rubber conveyor belts last longer via wear-resistant builds.

Wear-Resistant Rubber Composition

Blends tough compounds for endurance. Resists tears from sharp edges. Outlasts plain rubber.

Shock Absorption Mechanisms

Layers buffer impacts effectively. Lowers stress on structure. Prolongs overall use.

Long-Term Service Life Factors

Quality plies fight fatigue. Proper tension extends years. Maintenance plays key role.

- Compound toughness

- Impact buffering

- Fatigue resistance

This is where it gets interesting: Durability pays off quickly.

Key Takeaway: Build quality in rough top rubber conveyor belts saves costs.

| Factor | Lifespan Boost | |

|---|---|---|

| Rubber Blend | Tear Resistance | |

| Absorption | Stress Relief | |

| Plies | Fatigue Delay |

Studies confirm 3-5 year spans under load.

Select Specs for Optimal Fit

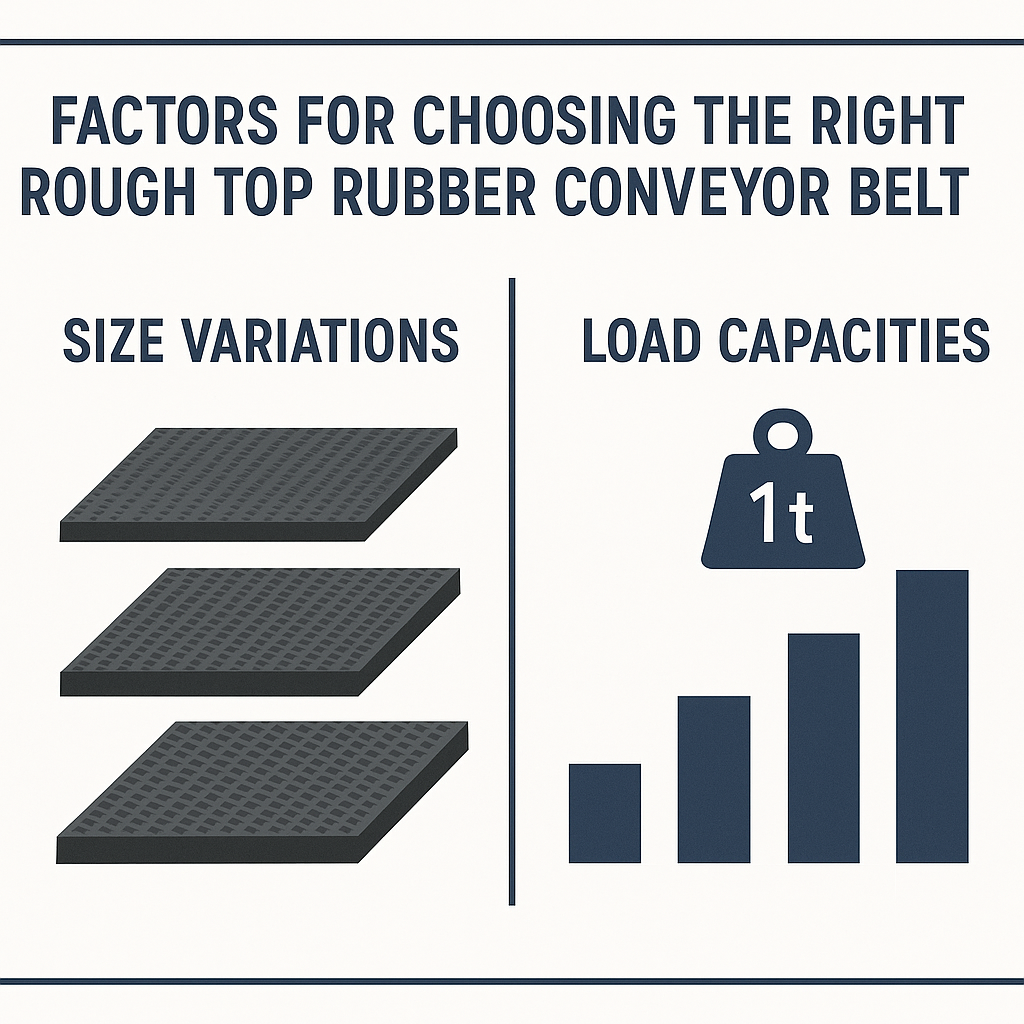

Rough top rubber conveyor belts require matching thickness to loads.

Thickness and Width Options

Ranges from 5-10mm thick. Widths up to 2 meters suit needs. Customize for exact paths.

Load Capacity Guidelines

Supports 100-200 kg/m² max. Check incline for limits. Avoid overloads.

Temperature and Speed Limits

Handles -20°C to 80°C. Speeds to 3 m/s safe. Monitor extremes.

- Thickness choices

- Capacity rules

- Temp/speed bounds

But here’s the kicker: Right specs prevent failures.

Key Takeaway: Tailor rough top rubber conveyor belts to operations.

| Spec | Range | |

|---|---|---|

| Thickness | 5-10mm | |

| Width | Up to 2m | |

| Load | 100-200 kg/m² |

Selection analysis minimizes mismatches effectively.

Best Applications Include Sorting

Rough top rubber conveyor belts fit express and elevation tasks.

Express Delivery Sorting Systems

Grips parcels in high-volume sorts. Handles 35-degree rises. Speeds deliveries.

Light Material Elevation Tasks

Lifts boxes or bags uphill. Prevents rolls back down. Efficient for light ops.

Custom Incline Setups

Adapts to unique angles. Integrates with existing lines. Versatile installs.

- Sorting efficiency

- Elevation security

- Custom flexibility

You might be wondering: Where else? Many places.

Key Takeaway: Target rough top rubber conveyor belts for targeted uses.

| Application | Benefit | |

|---|---|---|

| Delivery Sort | Volume Handle | |

| Material Lift | Secure Rise | |

| Incline Custom | Adapt Fit |

These shine in dynamic B2B flows.

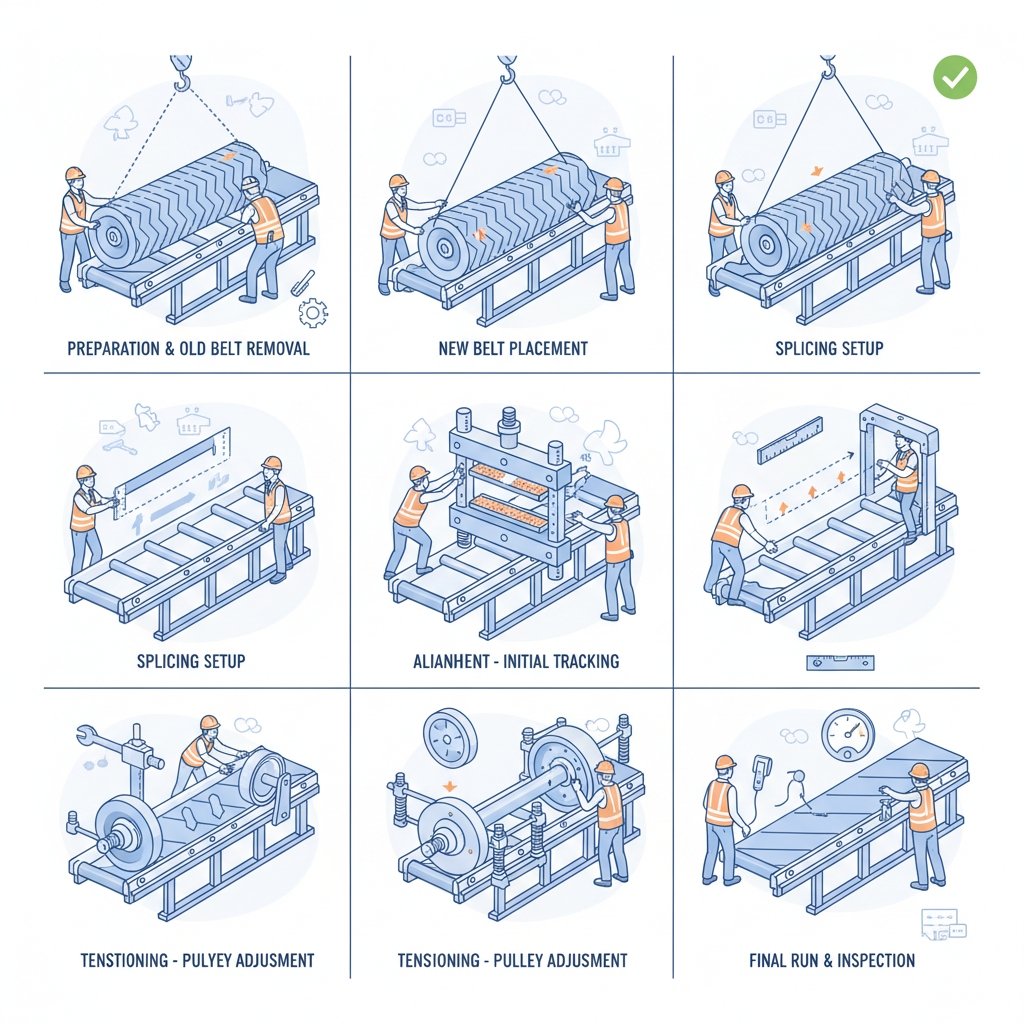

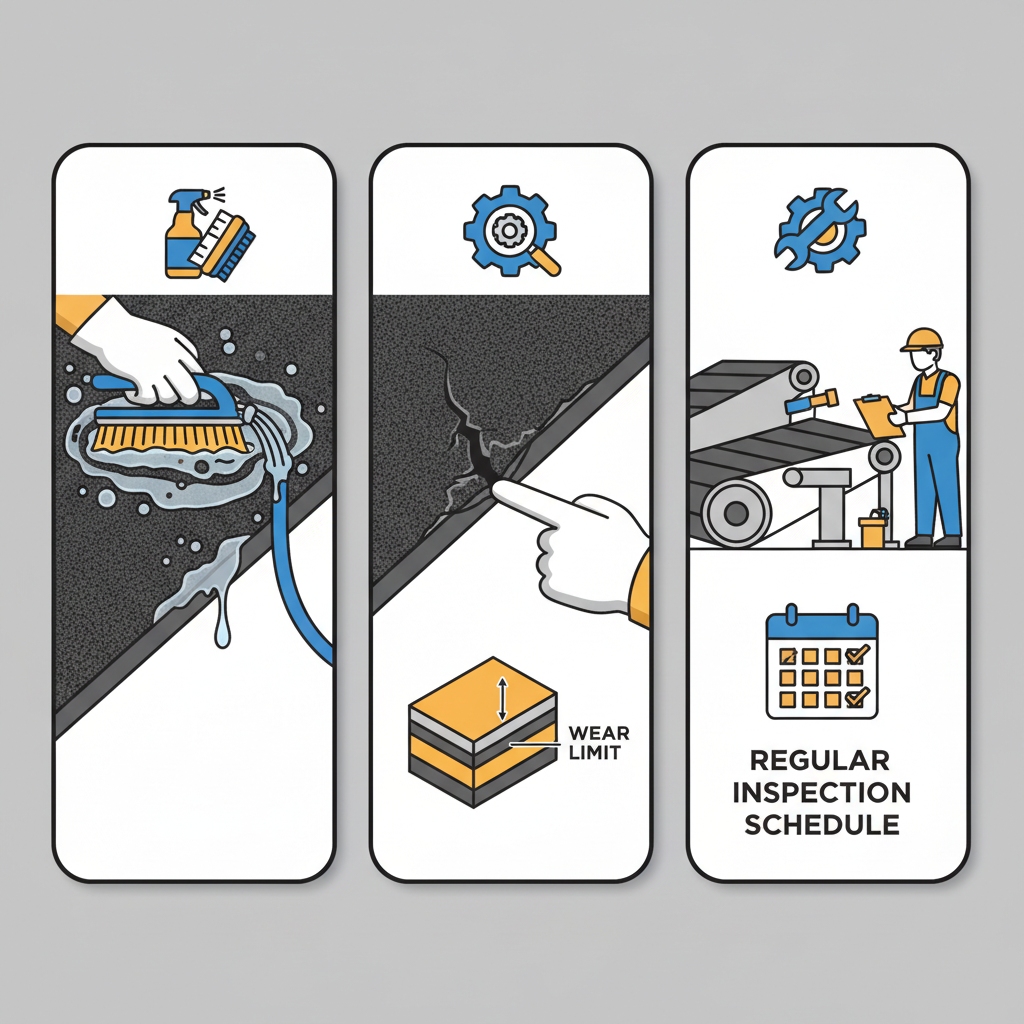

Maintenance Practices Extend Life

Rough top rubber conveyor belts benefit from regular checks.

Routine Inspection Tips

Scan for cracks weekly. Test tension monthly. Spot wear early.

Cleaning for Longevity

Wipe with mild soap. Avoid harsh chemicals. Keeps grip intact.

Repair Methods to Extend Use

Patch small tears promptly. Splice ends if needed. Prolongs service.

- Inspection routines

- Cleaning steps

- Repair techniques

Here’s the deal: Simple care yields big returns.

Key Takeaway: Maintain rough top rubber conveyor belts diligently.

| Practice | Frequency | |

|---|---|---|

| Inspection | Weekly | |

| Cleaning | As Needed | |

| Repair | Prompt |

Practices cut costs by 25% per reports.

Efficiency Gains from Reduced Downtime

Rough top rubber conveyor belts streamline B2B operations.

Cost Savings from Reduced Downtime

Fewer stops mean steady output. Lowers labor fixes. Profits rise.

Easy Installation Benefits

Quick pulley mounts. Minimal tools required. Operational fast.

Scalability for Growing Operations

Expands with business. Modular lengths fit. Future-proof.

- Downtime cuts

- Install ease

- Scale options

What’s the real story? Efficiency transforms workflows.

Key Takeaway: Deploy rough top rubber conveyor belts for gains.

| Gain | Outcome | |

|---|---|---|

| Downtime | Cost Save | |

| Install | Quick Start | |

| Scale | Growth Fit |

Analysis shows 15-20% productivity uplift.

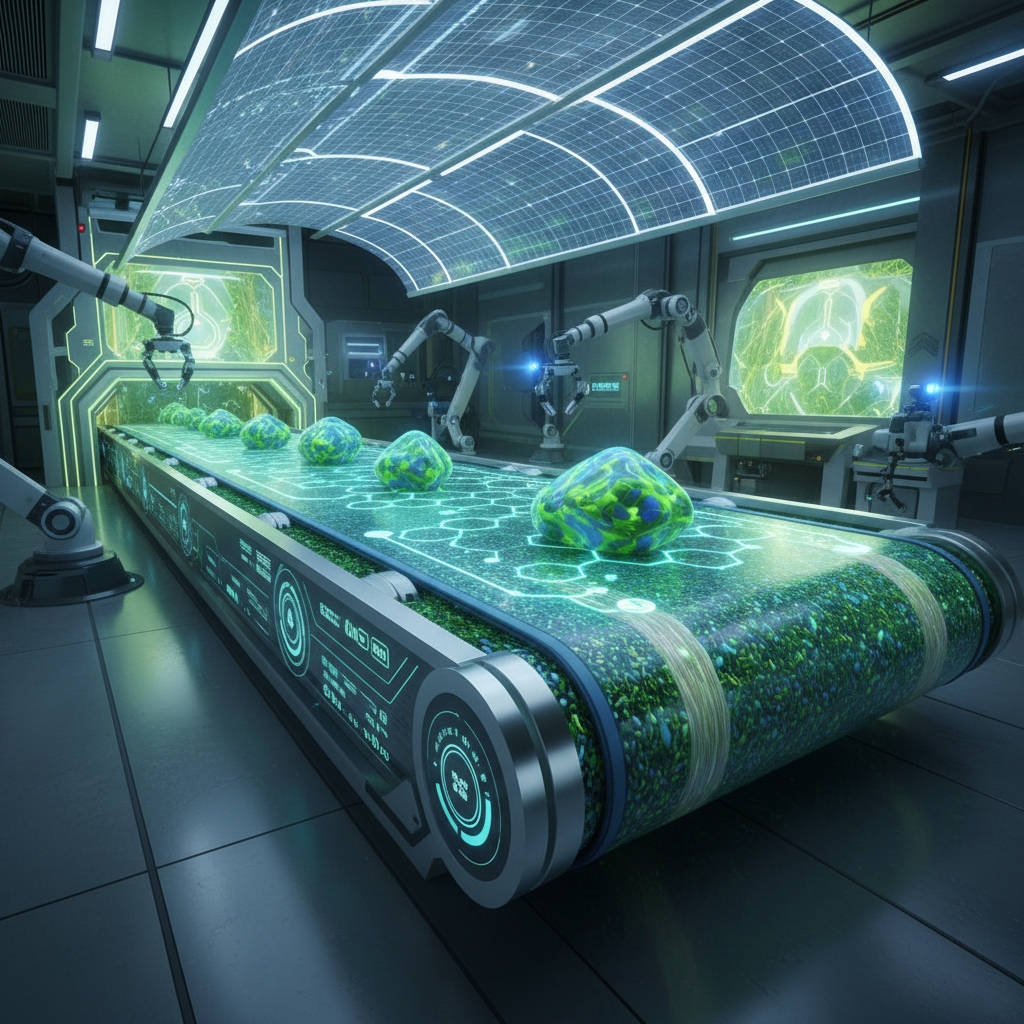

Innovations Drive Future Models

Rough top rubber conveyor belts evolve with eco-materials.

Eco-Friendly Material Trends

Uses recycled rubbers now. Reduces waste impact. Green certs available.

Enhanced Tensile Strength

New fibers boost pull resistance. Handles heavier pulls. Stronger builds.

Integration with Automation

Sensors embed for monitoring. Syncs with robots. Smart factories.

- Eco shifts

- Strength upgrades

- Automation ties

Ready for the good part? Future looks bright.

Key Takeaway: Embrace innovations in rough top rubber conveyor belts.

| Innovation | Advance | |

|---|---|---|

| Eco Materials | Waste Cut | |

| Tensile Boost | Load More | |

| Automation | Smart Sync |

Trends point to sustainable, integrated futures.

Rough top rubber conveyor belts solve incline transport woes by providing unmatched grip, durability, and efficiency for B2B operations. We help select and implement the right fit—contact experts for custom advice. Upgrade today to streamline workflows, cut costs, and envision safer, faster production lines.

FAQ

Can it handle heavy loads? Yes, up to 200 kg/m² on inclines under 35 degrees, as the reinforced plies distribute weight evenly without slippage.

How long does it last? Typically 3-5 years with proper care in standard conditions, thanks to abrasion-resistant layers that withstand daily wear.

Is it suitable for food industries? Absolutely, with non-toxic, easy-clean surfaces for light items, ensuring compliance with hygiene standards.

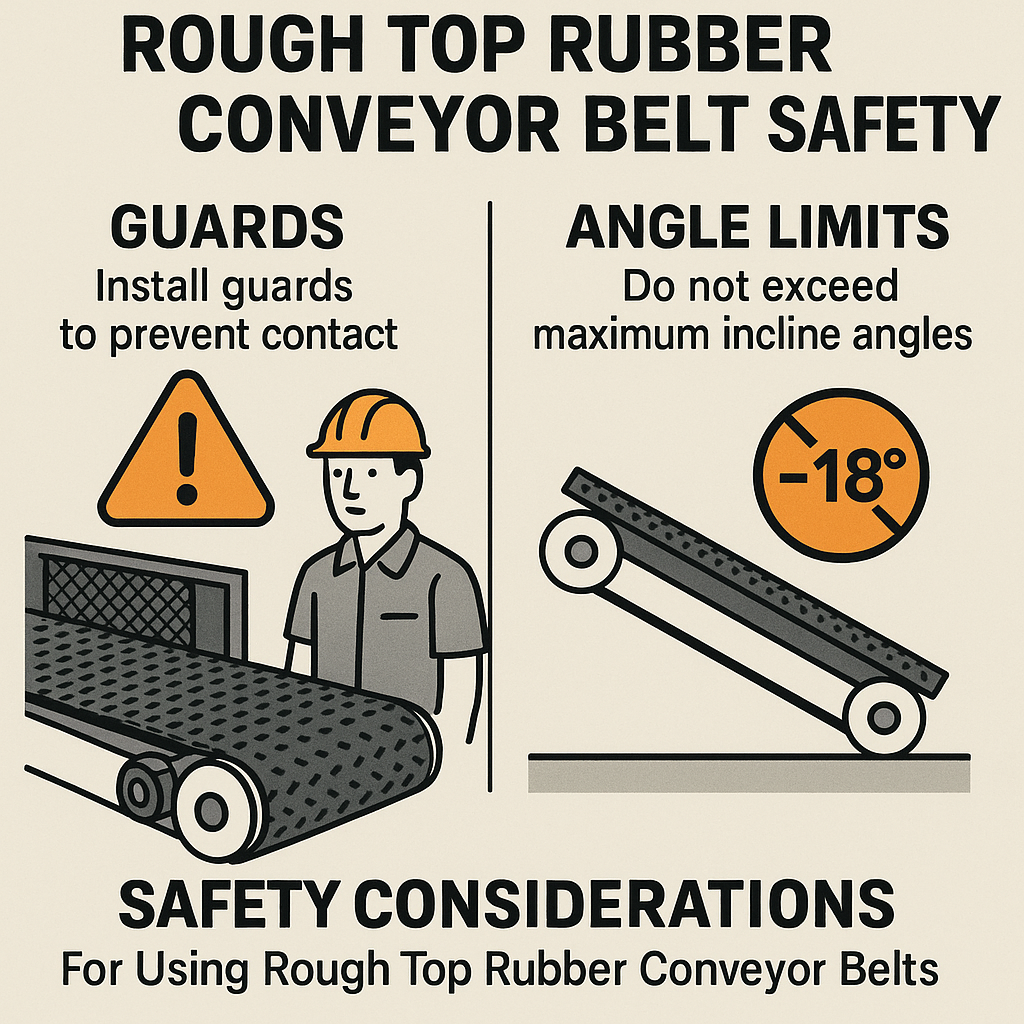

What if slippage occurs? Check angle limits and surface wear; replacements ensure safety, preventing accidents from exceeded capacities.