Choosing the wrong rubber conveyor belt can lead to premature wear, costly repairs, and serious safety risks. A sudden belt failure can bring production to a standstill—or worse, cause hazards in high-temperature or flammable environments. This guide breaks down the key grades and performance factors of rubber conveyor belts, helping you make an informed choice that ensures safety, longevity, and optimal operational efficiency.

Why do rubber conveyor belt grades matter?

Rubber conveyor belt grades matter because they classify a belt’s physical properties, ensuring you select one that can withstand the specific demands of your application. Choosing the right grade is critical for safety, efficiency, and cost-effectiveness.

What are the costs of a mismatch?

Using an incorrect belt can lead to rapid deterioration and operational failure. But what happens if you get it wrong? You risk facing severe financial and safety consequences.

- Frequent belt replacements and repair costs

- Unplanned production downtime and lost revenue

- Damage to conveyor system components

- Potential for catastrophic accidents, fires, or explosions

Key Takeaway: The initial investment in the correct higher-grade belt is often far less than the long-term cost of using an unsuitable one.

| Consequence | Financial Impact | Operational Impact | |

|---|---|---|---|

| Premature Wear | High replacement costs | Frequent downtime | |

| Belt Failure | Catastrophic repair bills | Complete production halt | |

| Safety Hazard | Fines and legal liability | Risk to personnel |

What are Grade A rubber conveyor belt uses?

Grade A rubber conveyor belts are used for applications involving highly abrasive materials, such as sharp-edged rock, ore, and scrap metal. These belts are engineered with a superior rubber compound to resist cutting, gouging, and rapid wear.

Which industries use Grade A?

You will find Grade A belts in the most demanding industrial environments. Here’s the deal: they are the go-to solution for maximizing uptime where other belts would fail quickly.

- Mining: Conveying hard rock like iron ore and copper.

- Quarries: Moving granite, sharp stone, and aggregates.

- Recycling: Handling crushed glass and sharp scrap metal.

Key Takeaway: Grade A is a strategic investment to dramatically extend belt life and ensure operational reliability in abrasive conditions.

| Material | Grade M/N Estimated Lifespan | Grade A Estimated Lifespan | |

|---|---|---|---|

| Iron Ore | 6-9 months | 18-24 months | |

| Crushed Granite | 8-12 months | 24-30 months | |

| Scrap Metal | 4-6 months | 12-18 months |

How does Grade E ensure safety?

A Grade E rubber conveyor belt ensures safety by safely dissipating static electricity, which prevents sparks that could ignite explosive atmospheres. It is a mandatory safety feature in environments with combustible dust or flammable gases.

How does it prevent explosions?

In certain operations, the friction from a moving belt can generate a significant static charge. You might be wondering how this works. Grade E belts contain conductive elements that channel this static charge away to a grounded part of the conveyor system.

- Grain elevators and silos

- Coal processing plants

- Chemical manufacturing facilities

- Aluminum refineries

Key Takeaway: In any environment with explosive dust or gas, using a Grade E belt is a non-negotiable safety requirement to protect your facility and personnel.

| Feature | Standard Belt | Grade E Belt | |

|---|---|---|---|

| Static Buildup | High | Negligible | |

| Spark Risk | Significant | Eliminated | |

| Safety | Unsafe in volatile areas | Essential for volatile areas |

What is a Grade F rubber conveyor belt for?

A Grade F rubber conveyor belt is for fire safety, designed with self-extinguishing properties to prevent the spread of flames. It is engineered to resist ignition and will not continue to burn once the external heat source is removed.

Where is Grade F essential?

This grade is crucial in applications where a fire could have devastating consequences. What’s the real story behind fire resistance? It provides precious time for evacuation and fire suppression efforts.

- Underground mining operations (especially coal mines)

- Power generation plants

- High-temperature industrial processing

- Facilities where welding or sparks are common

Key Takeaway: Grade F is a critical safety measure that mitigates the risk of a small fire escalating into a catastrophic event, particularly in enclosed spaces.

| Property | Standard Belt | Grade F Belt | |

|---|---|---|---|

| Ignition | Ignites easily | Resists ignition | |

| Burning | Continues to burn | Self-extinguishes | |

| Application | General use | High fire-risk areas |

What are M & N rubber conveyor belts?

Grades M and N are the most common general-purpose rubber conveyor belts, but Grade M offers superior quality and durability compared to the more economical Grade N. Your choice depends on the intensity and demands of your application.

What is the quality difference?

While both are for general use, their performance capabilities are distinct. So, what’s the difference? Grade M provides better overall value for moderately demanding tasks.

- Hardness: Grade M has a higher rubber hardness for better durability.

- Strength: Grade M features higher tensile strength.

- Abrasion Resistance: Grade M offers better resistance to wear and tear.

Key Takeaway: Although both are “general purpose,” Grade M provides a longer service life and better performance for all but the lightest-duty applications.

| Feature | Grade N | Grade M | |

|---|---|---|---|

| Quality | Standard | Superior | |

| Abrasion Resistance | Good | Excellent | |

| Best For | Light-duty, low-impact applications | Moderate-duty, general applications |

What are Grade S rubber conveyor belt properties?

A Grade S rubber conveyor belt combines the properties of both static-conducting (Grade E) and fire-resistant (Grade F) belts for dual protection. It is the ultimate safety choice for the highest-risk industrial environments.

When should you choose Grade S?

You should select a Grade S belt when your operation faces both explosion and fire hazards simultaneously. This is where it gets interesting. This dual-property belt addresses multiple safety risks with a single solution.

- Underground coal mines with methane gas and coal dust

- Facilities handling combustible powders

- High-risk chemical plants

Key Takeaway: Grade S offers comprehensive protection for the most hazardous environments, addressing both ignition and explosion risks in one product.

| Risk Factor | Grade E | Grade F | Grade S | |

|---|---|---|---|---|

| Explosion (Static) | ✅ | ❌ | ✅ | |

| Fire | ❌ | ✅ | ✅ | |

| Best For | Single Hazard (Static) | Single Hazard (Fire) | Dual Hazard (Both) |

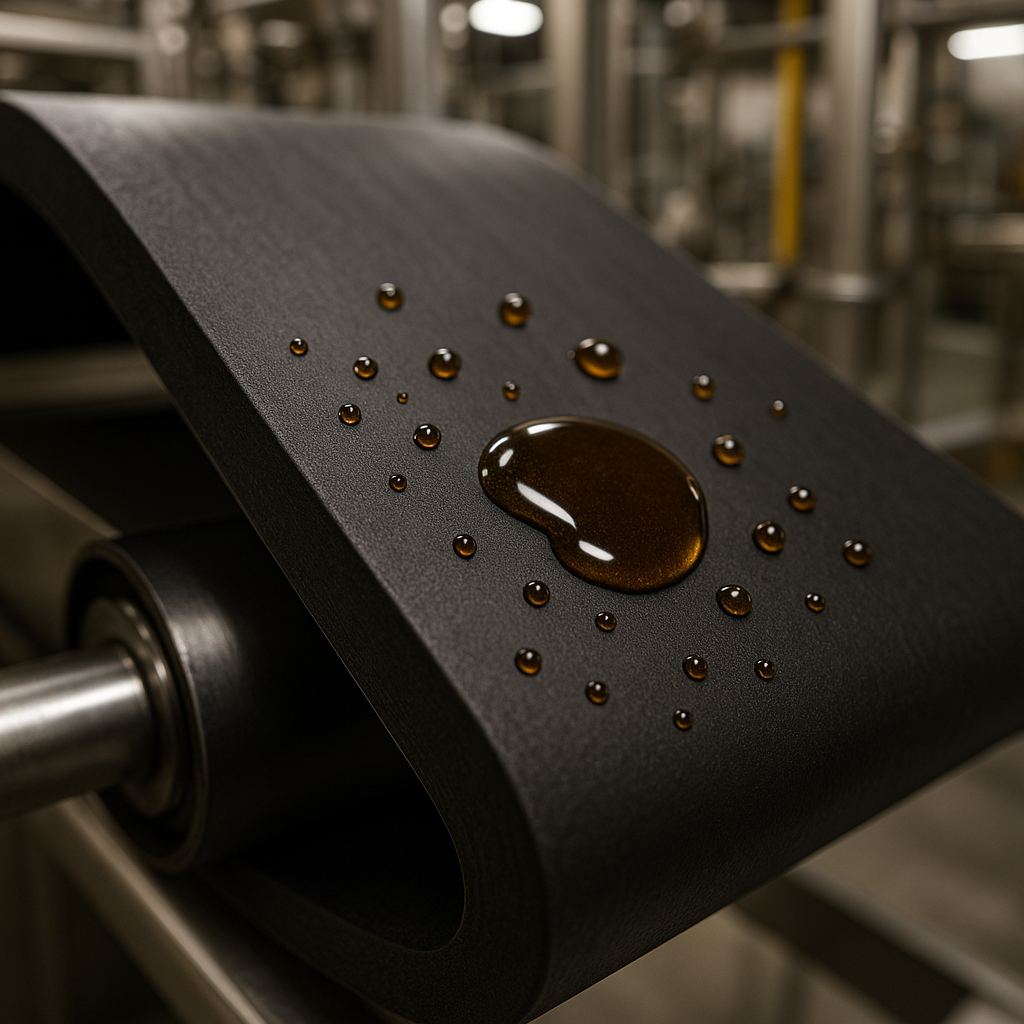

What are Grade Z rubber conveyor belt specs?

Grade Z rubber conveyor belts are custom-engineered solutions with special properties tailored for unique applications that standard grades cannot address. This category allows for a belt designed specifically to overcome your operational challenges.

What are some “special properties”?

“Special” refers to any property not covered by the standard A, E, F, M, N, or S grades. But what does “special” really mean? It means a solution can be created for almost any problem.

- Oil and Fat Resistance: For food processing or recycling oily materials.

- Extreme Temperature Resistance: For applications in freezers or near furnaces.

- Chemical Resistance: For use in chemical processing plants.

- High Impact Resistance: For handling large, heavy falling objects.

Key Takeaway: Grade Z demonstrates that if a standard belt doesn’t exist for your unique challenge, a custom solution can be engineered to meet your needs.

| Custom Property | Industry Example | Solves Problem Of… | |

|---|---|---|---|

| Oil Resistant (OR) | Food Processing | Belt degradation from fats and oils | |

| High Temp (HR) | Foundries | Belt melting or cracking from heat | |

| Chemical Resistant | Fertilizer Plants | Corrosion from chemical exposure |

How do you choose your rubber conveyor belt?

Choosing your rubber conveyor belt requires a careful assessment of your operational environment and the materials you handle. Matching the belt’s grade to these factors is the key to a successful, long-lasting installation.

What key factors should you consider?

A systematic approach ensures you cover all critical variables. Ready for the good part? Analyze these factors to narrow down your selection.

- Material Handled: Abrasiveness, size, weight, and temperature.

- Environmental Risks: Presence of explosive dust/gas or fire hazards.

- Operational Demands: Belt speed, incline, and expected tonnage.

- Budget: Balancing initial cost with long-term value and safety.

Key Takeaway: A thorough analysis of your application is the most important step in selecting a belt that delivers both performance and value.

| Grade | Primary Use | Key Benefit | |

|---|---|---|---|

| A | Abrasive Materials (Ore, Granite) | Extreme Wear Life | |

| E | Explosive Atmospheres (Dust, Gas) | Prevents Static Discharge | |

| F | High-Heat/Fire-Risk Areas | Resists Ignition, Self-Extinguishing | |

| M | General Purpose (Moderate Duty) | Good Durability & Value | |

| N | General Purpose (Light Duty) | Economical Choice | |

| S | High-Risk Environments | Dual Fire & Static Protection | |

| Z | Unique Applications | Custom-Engineered Solution |

Why decode rubber conveyor belt standards?

Decoding rubber conveyor belt standards like ISO 433 is important because they provide a universal language for quality, safety, and performance. Compliance with these standards guarantees that the belt you purchase will perform as expected.

Why does compliance matter to you?

These aren’t just arbitrary rules; they are your assurance of reliability. Why should you care about this? Following these standards ensures you get a product with predictable characteristics.

- Safety Assurance: Guarantees the belt meets critical safety criteria (e.g., fire or static resistance).

- Quality Control: Ensures the rubber compound and construction meet durability benchmarks.

- Global Interoperability: Allows for consistent specifications across different manufacturers.

Key Takeaway: Adherence to international standards is a mark of a quality product and your guarantee of predictable, reliable performance.

| Benefit of Standards | For Safety | For Operations | |

|---|---|---|---|

| Predictability | Confirmed fire/static properties | Consistent wear life | |

| Quality | Reduced risk of catastrophic failure | Fewer unexpected replacements | |

| Compliance | Meets regulatory requirements | Ensures operational reliability |

What are combined grade rubber conveyor belts?

Combined grade rubber conveyor belts are hybrid solutions that merge properties from different grades to solve complex, multi-faceted challenges. These belts are engineered for applications where a single standard grade is insufficient.

What is a common combined grade?

Beyond the standard Grade S, other combinations are possible to fine-tune performance. Let’s break it down. One common example is a Grade MA belt, which is useful in many bulk material handling applications.

- Grade MA: Combines General Purpose (M) quality with enhanced Abrasion Resistance (A) for handling moderately abrasive materials like sand and gravel.

- Grade SA: A Static/Fire Resistant (S) belt with added Abrasion Resistance (A) for moving abrasive materials in a coal mine.

- Grade MOR: A General Purpose (M) belt with added Oil Resistance (OR) for recycling plants handling oily components.

Key Takeaway: Combined grades offer a pathway to a perfectly optimized belt, ensuring you don’t overpay for features you don’t need or compromise on essential properties.

| Combination | Properties | Typical Application | |

|---|---|---|---|

| MA | General Purpose + Abrasion Resistant | Sand and gravel conveying | |

| SA | Static/Fire Resistant + Abrasion | Abrasive material in a coal mine | |

| MOR | General Purpose + Oil Resistant | Recycling plants with oily parts |

You’ve seen that selecting the right rubber conveyor belt grade—from abrasion-resistant Grade A to dual-protection Grade S—is fundamental to operational safety and efficiency. This choice is not just about buying a product; it’s about engineering a reliable, resilient, and safe operation from the ground up. To ensure you have the perfect belt for your unique needs, contact an engineering expert today for a personalized application analysis.

Frequently Asked Questions (FAQ)

1. Can I use a general-purpose belt for abrasive materials?No, it is not recommended. While a Grade M or N belt might work temporarily, it will wear out extremely quickly, leading to higher long-term costs from frequent replacements and unplanned downtime.

2. How do I know if I need a fire-resistant belt?You need one if your application involves high heat or is in an environment where fire spread is a major risk, such as underground mines, power plants, or near furnaces.

3. What’s the main difference between Grade M and Grade N?The main difference is quality and durability. Grade M uses a higher-quality rubber with greater hardness and abrasion resistance than Grade N, making it suitable for moderate use while Grade N is for light-duty tasks.

4. Can a rubber conveyor belt have more than two properties?Yes. Belts can be custom-engineered as Grade Z to combine multiple properties, such as being abrasion-resistant, fire-resistant, and oil-resistant for a highly specific industrial process.

5. Is a more expensive belt grade always better?Not necessarily. “Better” means “best-suited” for the application. Using a top-tier Grade A belt to move lightweight boxes is inefficient and wasteful; the goal is to match the belt to the job for the best overall value.