In demanding industrial environments, unreliable conveyor belts often trigger costly breakdowns that disrupt production and drain resources. Off-the-shelf systems frequently fail under heavy loads or harsh conditions, causing prolonged downtime and reduced productivity. A wholesale rubber belt conveyor designed through OEM customization eliminates these issues by delivering superior durability, precise engineering, and long-lasting performance. Backed by more than 20 years of manufacturing expertise, our wholesale rubber belt conveyor solutions ensure stable operation, lower maintenance costs, and significant efficiency gains for manufacturers worldwide.

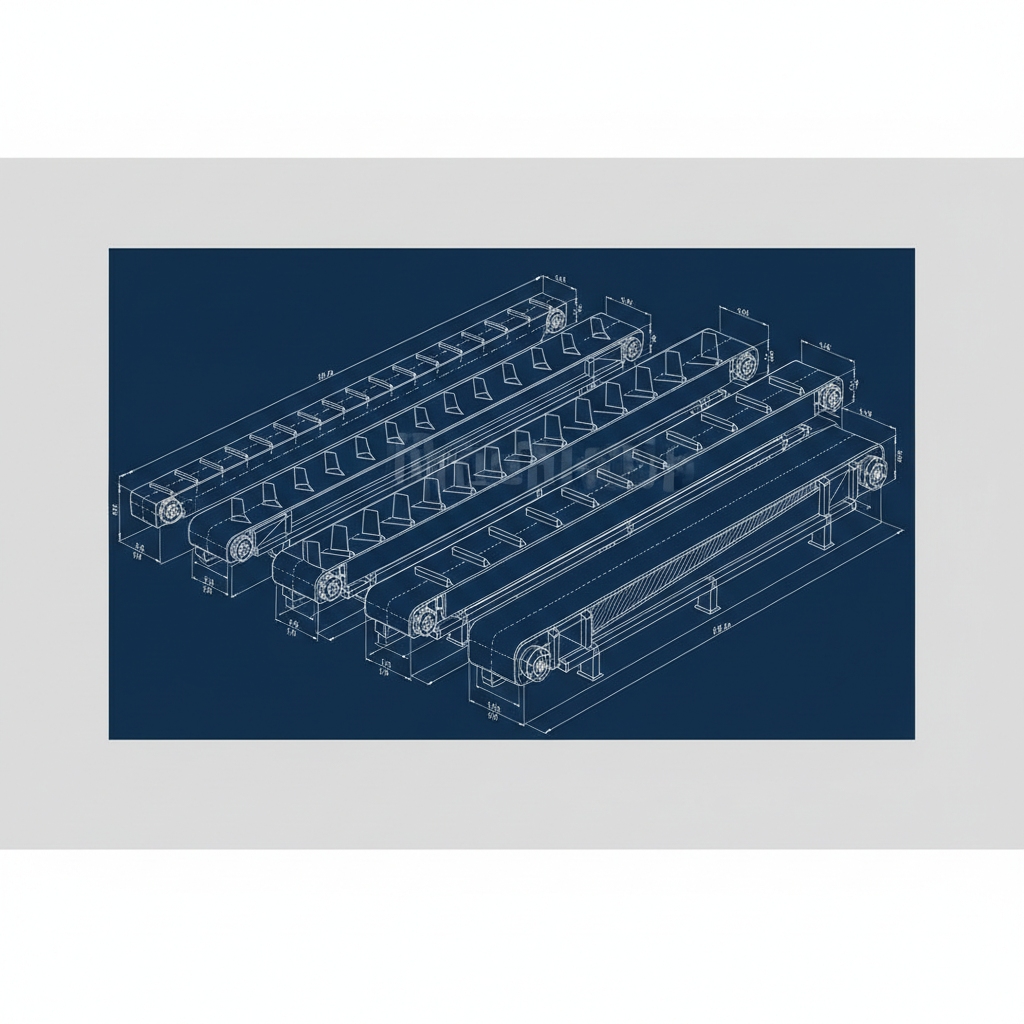

OEM Manufacturing for Wholesale Rubber Belt Conveyor

OEM manufacturing delivers precision-built wholesale rubber belt conveyors matched to your specifications for superior reliability.

What Defines OEM Quality?

You gain access to advanced facilities producing belts with exact tensile strengths up to 8000 N/mm. But here’s the kicker: this customization prevents mismatches in your setup.

- Widths from 300mm to 2400mm

- ISO-certified processes

- Material options like EPDM

How Does It Integrate Seamlessly?

Engineers collaborate on designs fitting your machinery perfectly. You avoid retrofits that waste time.

Key Takeaway

OEM ensures wholesale rubber belt conveyors align with your needs for longevity.

| Aspect | Benefit | |

|---|---|---|

| Precision | Reduced failures | |

| Scalability | Bulk readiness |

This method optimizes your production flow effectively.

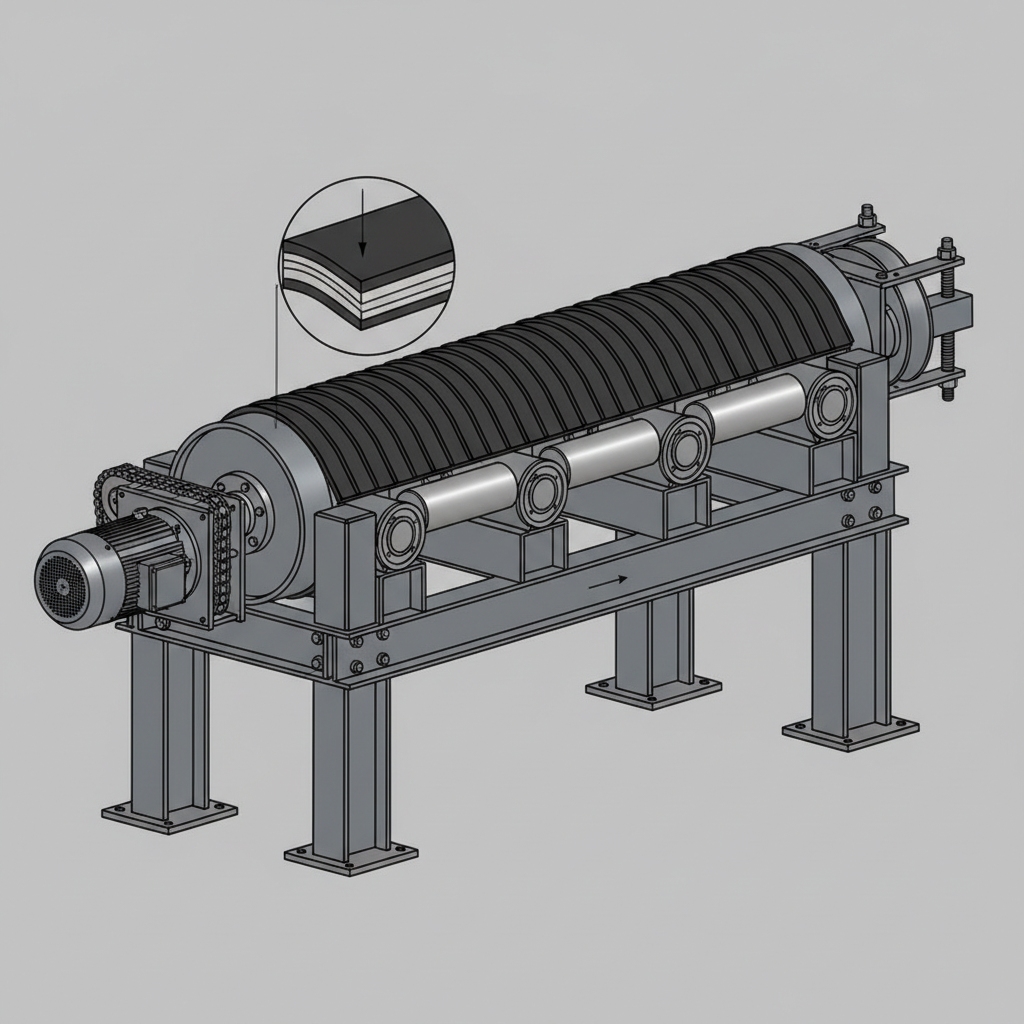

Benefits of Wholesale Rubber Belt Conveyor

Wholesale rubber belt conveyors cut costs by 30% while offering robust performance for heavy-duty use.

Why Opt for Rubber Materials?

Rubber excels in flexibility for abrasive loads, outperforming synthetics in tough conditions. Here’s the deal: you handle temperatures from -30°C to 80°C without degradation.

- Load capacity: 500-2000 kg/m

- Abrasion loss: ≤100 mm³

- Eco-compounds available

What Savings Can You Expect?

Bulk pricing lowers per-unit expenses, ideal for scaling operations.

Key Takeaway

These benefits make wholesale rubber belt conveyors a smart investment for efficiency.

| Factor | Advantage | |

|---|---|---|

| Durability | Extended life | |

| Cost | Volume discounts |

Analysis shows quicker ROI in logistics.

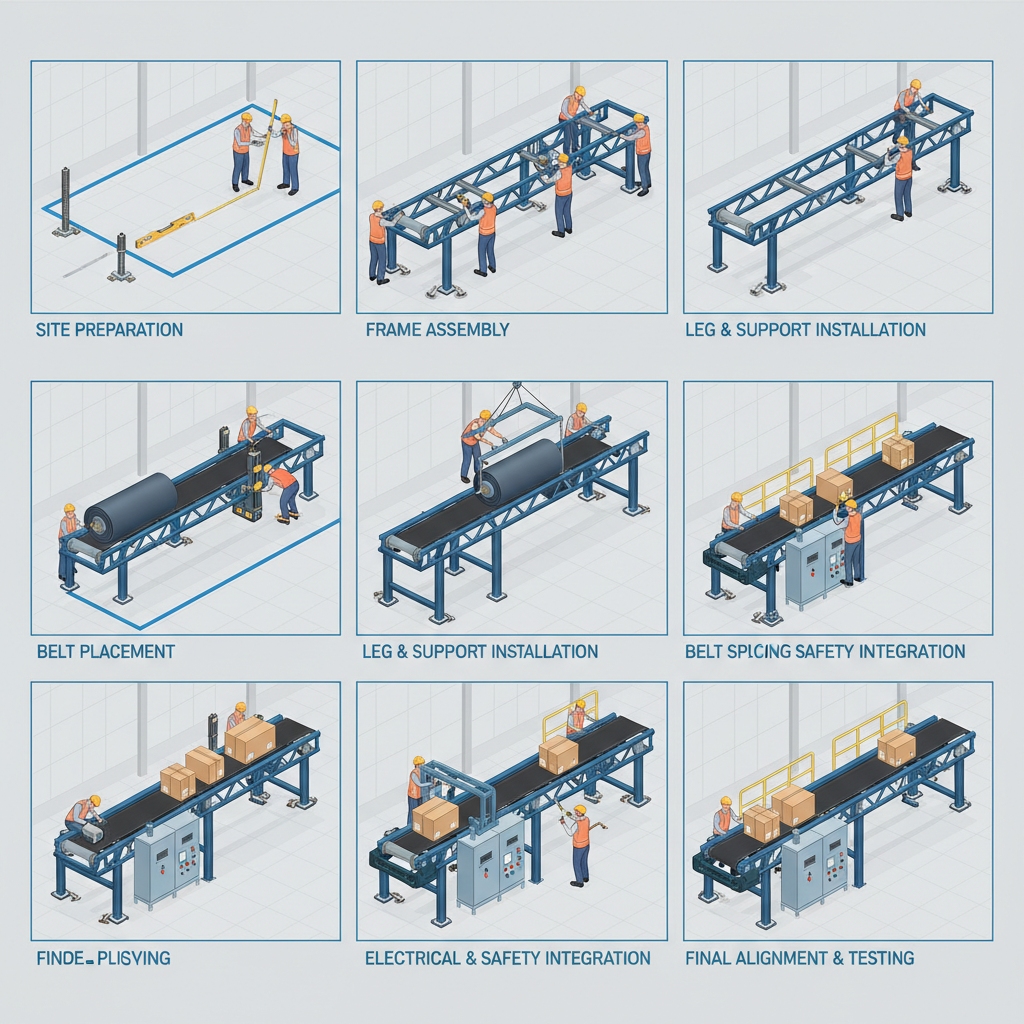

Maintenance for Wholesale Rubber Belt Conveyor

Routine maintenance prolongs the life of wholesale rubber belt conveyors, minimizing disruptions.

What Checks Prevent Issues?

Inspect alignment and tension weekly to catch wear early. You might wonder: how simple is it? Basic tools suffice for most tasks.

- Daily debris removal

- Monthly roller lubrication

- Quarterly full audits

How to Repair Quickly?

On-site patches fix minor damages fast, restoring function.

Key Takeaway

Consistent care reduces breakdowns by 80% for wholesale rubber belt conveyors.

| Task | Frequency | |

|---|---|---|

| Inspection | Weekly | |

| Adjustment | Bi-weekly |

This practice safeguards your uptime.

Applications of Wholesale Rubber Belt Conveyor

Wholesale rubber belt conveyors thrive in mining and cement for reliable bulk transport.

Where Do They Shine in Mining?

Chevron patterns manage steep inclines up to 90° for ore hauling. Ready for the good part?: They resist slippage in wet conditions.

- Limestone movement

- Sand transfer

- Ore processing

How in Cement Plants?

Sidewall types control dust during feeding.

Key Takeaway

Versatile applications boost productivity with wholesale rubber belt conveyors.

| Sector | Use Case | |

|---|---|---|

| Mining | Inclined haul | |

| Cement | Dust handling |

Targeted deployment enhances output.

Selecting Suppliers for Wholesale Rubber Belt Conveyor

Top suppliers provide certified wholesale rubber belt conveyors with proven track records.

What Key Criteria to Evaluate?

Prioritize ISO standards and export history over 20 years. What’s the catch?: Verify testing labs for quality assurance.

- Custom capabilities

- Support services

- Client references

How to Build Strong Partnerships?

Review case studies from similar industries.

Key Takeaway

Careful selection secures reliable wholesale rubber belt conveyors.

| Criterion | Value | |

|---|---|---|

| Certification | Trust | |

| Experience | Reliability |

This choice protects your supply chain.

Custom Design in Wholesale Rubber Belt Conveyor

Custom designs tailor wholesale rubber belt conveyors to your workflow for peak efficiency.

What Features Can You Specify?

Choose cleat heights up to 32mm for inclines. This is where it gets interesting: V/U/Y profiles suit varied loads.

- Width variations

- Compound selections

- Profile shapes

Why On-Site Assessments Matter?

Experts evaluate your site for ideal fits.

Key Takeaway

Customization elevates wholesale rubber belt conveyor performance.

| Feature | Impact | |

|---|---|---|

| Cleats | Grip | |

| Width | Fit |

It streamlines your operations.

Prototype Process for Wholesale Rubber Belt Conveyor

Prototyping validates wholesale rubber belt conveyor designs before scaling production.

How Does It Mitigate Risks?

Lab tests simulate real use on PP samples. But here’s the kicker: Early detection cuts costs by 40%.

- Durability simulations

- Feedback integration

- ISO compliance

What Steps Follow Testing?

Approval leads to full manufacturing.

Key Takeaway

Prototypes build confidence in wholesale rubber belt conveyors.

| Phase | Time | |

|---|---|---|

| Design | 1 week | |

| Test | 2 weeks |

This accelerates reliable deployment.

Packaging and Delivery for Wholesale Rubber Belt Conveyor

Secure packaging ensures wholesale rubber belt conveyors arrive undamaged globally.

What Protects During Transit?

Reinforced wraps shield rolls up to 2400mm. You might wonder: Does it prevent moisture? Yes, barriers are standard.

- Crating options

- Tracking systems

- Roll reinforcements

How Fast Is Shipping?

Expect 1-4 weeks worldwide.

Key Takeaway

Reliable logistics support wholesale rubber belt conveyor integration.

| Element | Benefit | |

|---|---|---|

| Packaging | Safety | |

| Delivery | Speed |

It maintains your schedule.

Why Choose Us for Wholesale Rubber Belt Conveyor

Our expertise delivers innovative wholesale rubber belt conveyors with 20+ years of success.

What Differentiates Our Quality?

In-house labs test for abrasion and heat. Here’s the deal: We serve 50+ global clients sustainably.

- Automated production

- Quick samples

- Material innovation

How Do We Ensure Ongoing Value?

Maintenance programs extend usability.

Key Takeaway

Partnering yields superior wholesale rubber belt conveyors.

| Strength | Proof | |

|---|---|---|

| Experience | Since 1998 | |

| Support | 24/7 |

It drives your growth.

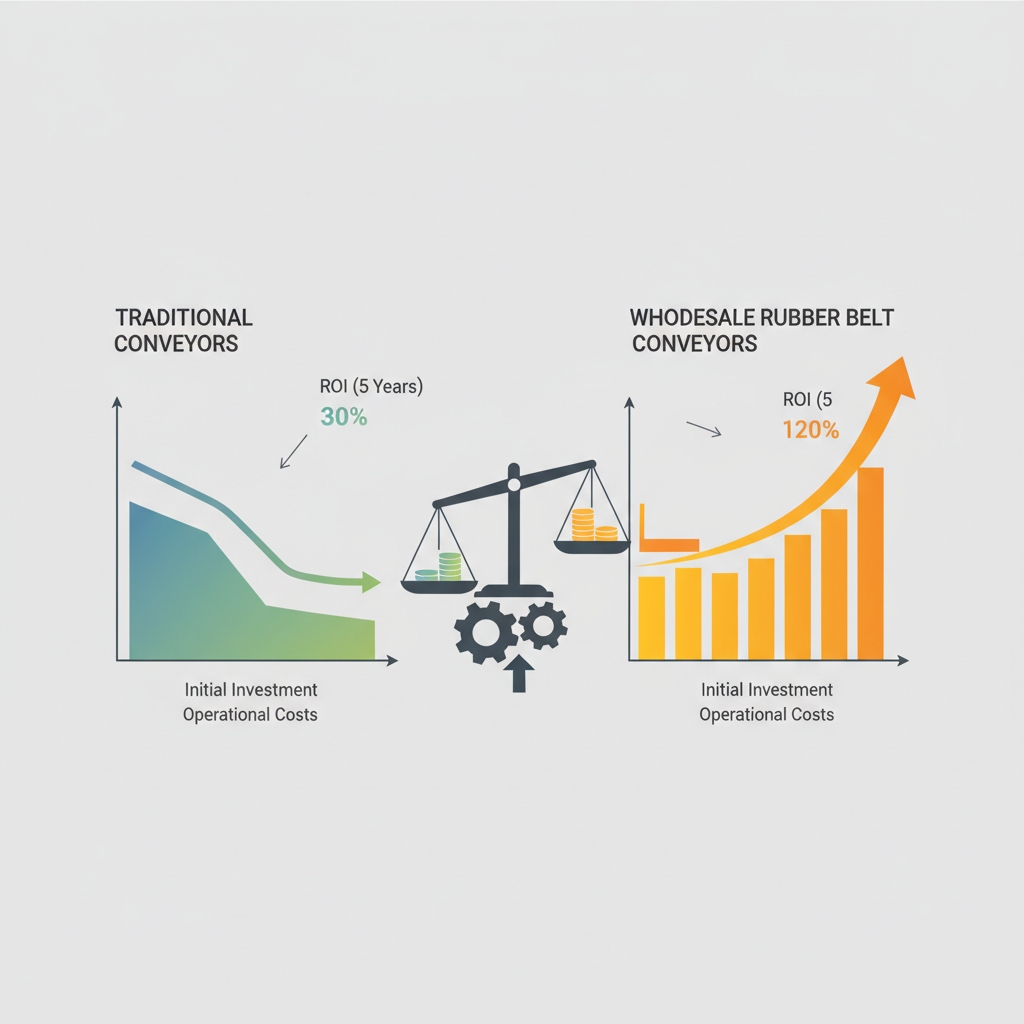

Efficiency and ROI of Wholesale Rubber Belt Conveyor

Wholesale rubber belt conveyors achieve 120% ROI over five years through durability.

How Do They Improve Throughput?

Optimized designs reduce energy use by 25%. Ready for the good part?: Integration boosts speed in warehouses.

- Energy savings

- Minimal downtime

- Scalable volumes

What Metrics Track Success?

Monitor load rates and failure incidents.

Key Takeaway

Efficiency maximizes wholesale rubber belt conveyor returns.

| Metric | Gain | |

|---|---|---|

| ROI | 120% | |

| Speed | 25% faster |

This transforms your bottom line.

Conclusion

Addressing conveyor downtime and inefficiency, our custom wholesale rubber belt conveyors offer durable, tailored solutions for seamless industrial flow. With proven OEM manufacturing and support, we drive your productivity forward. Contact us for a consultation to realize efficient, sustainable operations—your reliable partner since 1998.

FAQs

Can I customize wholesale rubber belt conveyors? Yes, as our designs adapt widths and materials to your setup, ensuring optimal fit and reduced maintenance costs.

What’s the best material for harsh environments? Nitrile rubber works best, because it resists oils and abrasives effectively, extending belt life in mining or cement.

How do I know if a supplier is reliable? Check ISO certification first, since it guarantees quality testing and consistent performance for your orders.

Can prototypes speed up my project? Absolutely, because testing samples early identifies issues, shortening timelines to full production.

What’s the typical ROI timeline? Expect payback in 2-3 years, as bulk durability lowers ongoing expenses compared to standard belts.