Imagine your warehouse grinding to a halt as a conveyor belt snaps under heavy load, causing hours of downtime, soaring repair costs, and mounting frustration across the team. This scenario is all too common in fast-paced industrial environments. Understanding the rubber conveyor belt manufacturing process changes everything—showing how precise steps such as mixing, calendering, laminating, and vulcanization build belts with exceptional strength and longevity. With over 20 years of expertise, we use the rubber conveyor belt manufacturing process to craft reliable, customized solutions that keep B2B operations running smoothly and without interruption.

1. Evolution in Rubber Conveyor Belt Manufacturing Process

The rubber conveyor belt manufacturing process evolved from 19th-century leather belts to today’s automated precision systems.

Early Innovations

But wait, how did it start? You shifted from manual leather stitching to vulcanized rubber for industrial durability. Leather slipped and tore easily. Vulcanization boosted strength and flex. Steam-powered factories handled basic assembly.

Modern Advancements

Ready to see the tech upgrade? You now use AI-monitored lines for error-free layering and curing. Robots reinforce fabrics. Sensors ensure real-time thickness. Sustainable materials slash waste by 20%.

Impact on Industry

What does this mean for you? Evolution yields belts for extreme conditions, enhancing efficiency and safety. Maintenance drops. Standards comply globally. Lifespans reach five years.

| Aspect | Early Method | Modern Method | |

|---|---|---|---|

| Material | Leather | Synthetic Rubber | |

| Durability | Low | High | |

| Production Speed | Manual, Slow | Automated, Fast |

Analysis: This progression cuts costs and risks, optimizing B2B throughput. Key Takeaway: Evolution equips you with reliable belts for modern demands.

2. Raw Materials in Rubber Conveyor Belt Manufacturing Process

Raw materials anchor the rubber conveyor belt manufacturing process, blending rubber compounds with reinforcements for core strength.

Rubber Compounds

Here’s the deal: You blend natural and synthetic rubbers with additives for heat or abrasion resistance. This forms tough covers. Antioxidants curb cracking. Carbon black amps strength. Oils add bend flexibility.

Reinforcement Fabrics

Ever question why belts endure? You embed polyester or steel cords for tension support. EP suits light loads. Steel tackles mining heavies. Nylon resists impacts.

Additives Role

What’s next? You leverage chemicals for bonding and longevity against oils or UV. Plasticizers ensure pliability. Bonding agents secure layers. Flame retardants boost safety.

| Material Type | Key Benefit | Common Use | |

|---|---|---|---|

| Rubber Compound | Flexibility | Covers | |

| Fabric | Strength | Core | |

| Additives | Durability | Enhancement |

Analysis: Quality inputs directly correlate to belt lifespan, reducing B2B failures by 30%. Key Takeaway: Premium materials guarantee robust performance in your setups.

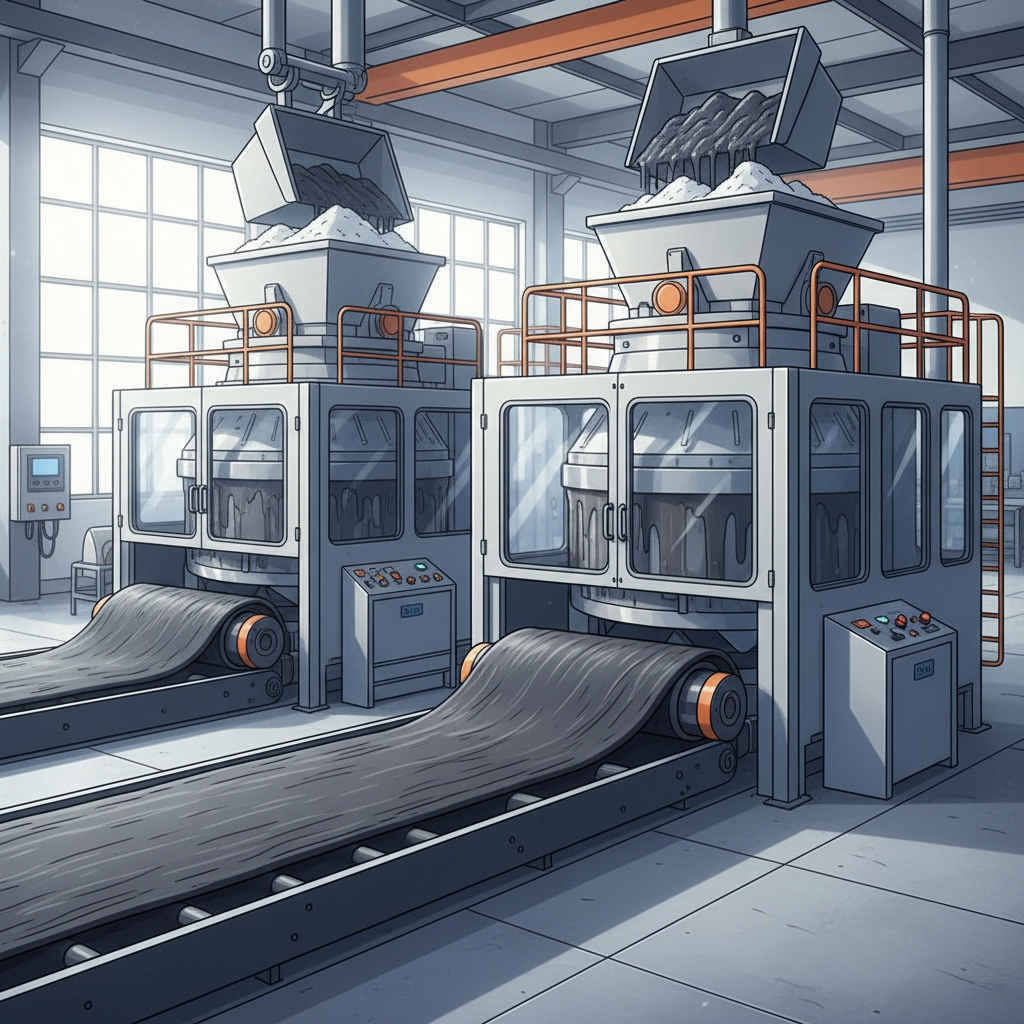

3. Mixing Step in Rubber Conveyor Belt Manufacturing Process

The mixing step in the rubber conveyor belt manufacturing process precisely blends compounds for optimal properties.

Dry Ingredients First

Why start dry? You distribute fillers evenly before liquids. Carbon black builds abrasion resistance. Calcium carbonate tunes rigidity. Accurate weighing avoids clumps.

Adding Liquids

But here’s the kicker: You adjust viscosity with oils for smooth flow. Balance prevents brittleness. Measure to specs. Test uniformity.

Final Blending

How do you unify? You employ high-shear mixers with heat. Rubbers integrate with sulfur and accelerators. Stable sheets cool for storage.

| Mixing Phase | Components | Purpose | |

|---|---|---|---|

| Dry | Fillers | Base Structure | |

| Liquid | Oils | Flow Control | |

| Blend | Rubbers | Uniformity |

Analysis: Uniform mixing minimizes defects, boosting yield rates in production. Key Takeaway: This foundation averts breakdowns in tough environments.

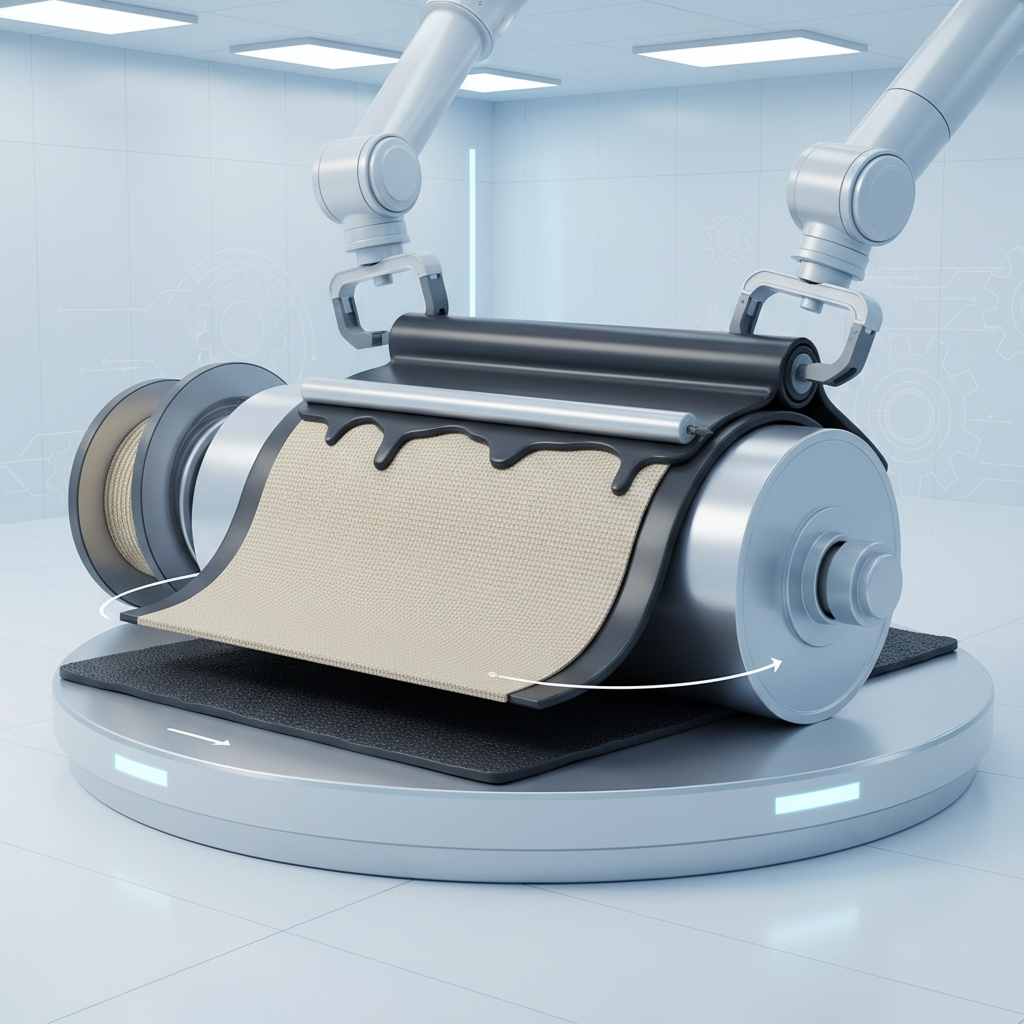

4. Calendering Step in Rubber Conveyor Belt Manufacturing Process

Calendering in the rubber conveyor belt manufacturing process creates uniform sheets via heated rollers.

Extrusion Prep

What prepares the mix? You reheat via extruders for consistent strips. This cuts defects. Controls width. Ensures even heat.

Roller Forming

Ready for the good part? You hit precise thickness with multi-rolls. Sensors tweak pressure. Builds smooth layers to 0.1mm.

Post-Calender Storage

How prevent sticking? You use liners on rolls in controlled spots. Maintains quality for lamination.

| Calendering Element | Function | Control Method | |

|---|---|---|---|

| Extrusion | Prep Flow | Screw Mechanism | |

| Rollers | Form Sheets | Pressure Sensors | |

| Storage | Protect | Liners |

Analysis: Precision here enhances load-bearing, vital for high-speed lines. Key Takeaway: Calendering secures consistent belt integrity.

5. Laminating Step in Rubber Conveyor Belt Manufacturing Process

Laminating in the rubber conveyor belt manufacturing process assembles layers into a solid build pre-curing.

Layer Selection

Why specific plies? You tailor covers and fabrics to loads. Top fights abrasion. Fabrics handle tension.

Assembly Process

This is where it gets interesting: You stack on beds with guides. Rollers banish air. Tack bonds naturally. Lasers align under 2mm.

Trimming Prep

What after stacking? You trim edges, add tapers. Tags spec for curing.

| Lamination Stage | Action | Benefit | |

|---|---|---|---|

| Selection | Choose Plies | Tailored Strength | |

| Assembly | Stack Layers | Bond Integrity | |

| Trimming | Edge Finish | Installation Ease |

Analysis: Strong lamination cuts splice failures by 25%. Key Takeaway: It forges unified belts for dependable runs.

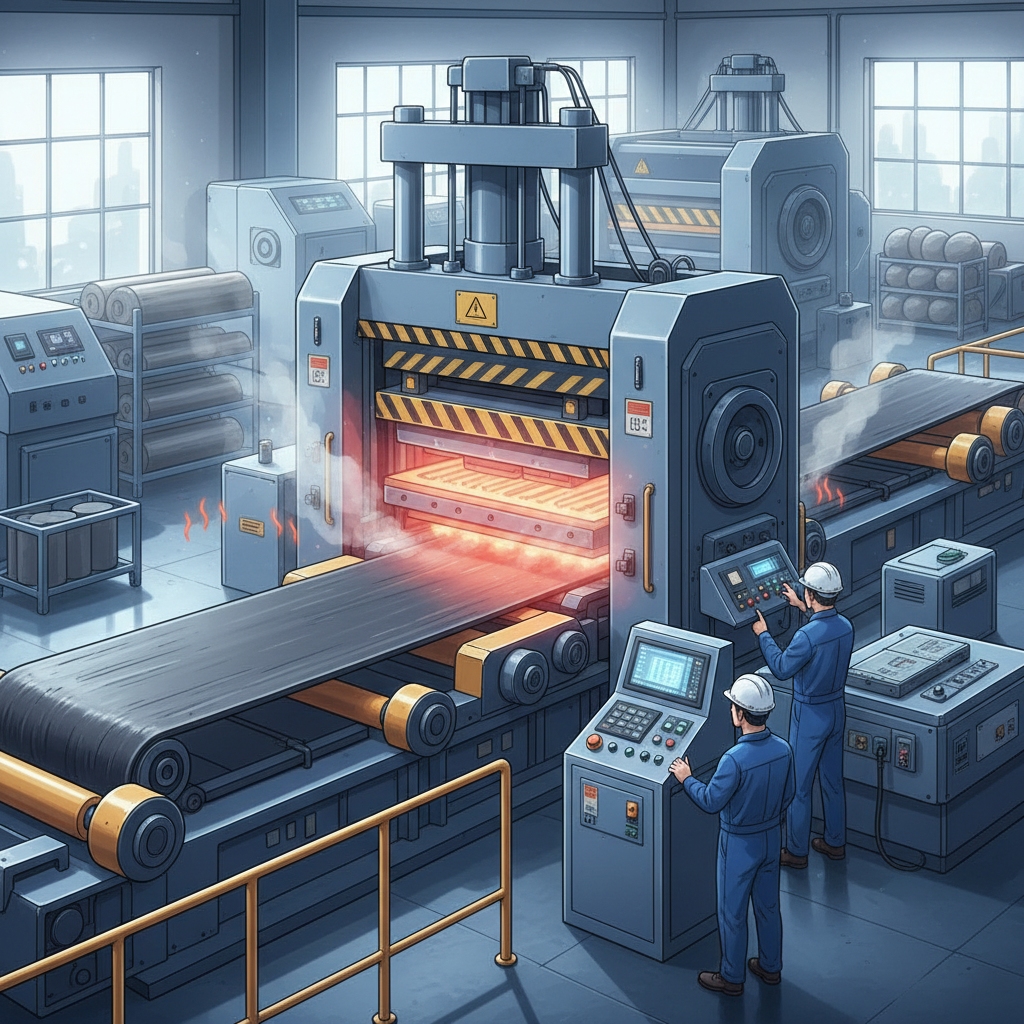

6. Vulcanization Step in Rubber Conveyor Belt Manufacturing Process

Vulcanization cures layers in the rubber conveyor belt manufacturing process under heat and pressure for lasting bonds.

Chemical Process

How it works? You crosslink with sulfur at 140-160°C. Builds elasticity. Matches thickness.

Curing Methods

What’s the catch? You opt batch for customs or continuous for speed. Ensures even heat.

Post-Cure Checks

Why inspect? You test adhesion and dims post-cool. Reworks flaws.

| Vulcanization Type | Speed | Best For | |

|---|---|---|---|

| Batch | Slow | Custom | |

| Continuous | Fast | Standard |

Analysis: Proper curing doubles tensile strength for harsh uses. Key Takeaway: It embeds resilience against stresses.

7. Quality Control in Rubber Conveyor Belt Manufacturing Process

Quality control spans the rubber conveyor belt manufacturing process to snag defects and uphold standards.

Material Testing

What kicks off? You audit rubbers for purity. Labs check flow, moisture.

In-Process Monitoring

But here’s the kicker: You deploy sensors in mixing, calendering. Flags variances real-time.

Final Inspections

How confirm? You run mechanical tests post-cure. Spots cracks. Logs trends.

| QC Phase | Test Type | Outcome | |

|---|---|---|---|

| Material | Lab Audits | Purity | |

| In-Process | Sensors | Consistency | |

| Final | Mechanical | Reliability |

Analysis: Thorough QC slashes recalls, saving B2B downtime. Key Takeaway: It assures surprise-free reliability.

8. Cutting and Packaging in Rubber Conveyor Belt Manufacturing Process

Cutting and packaging wrap the rubber conveyor belt manufacturing process for safe, install-ready delivery.

Precision Cutting

Why accurate? You machine widths, lengths to specs. Aids splicing.

Edge Finishing

Ready for the good part? You bevel, groove as needed. Clears debris.

Secure Packaging

What shields transit? You coil, wrap in films on pallets. Labels ID.

| Packaging Step | Method | Protection | |

|---|---|---|---|

| Cutting | Machine | Accuracy | |

| Finishing | Bevel/Groove | Functionality | |

| Wrapping | Film/Pallets | Transit Safety |

Analysis: Clean finishes ease installs, cutting setup time 15%. Key Takeaway: It ensures belts arrive primed to excel.

9. Customization Options in Rubber Conveyor Belt Manufacturing Process

Customization adapts the rubber conveyor belt manufacturing process to tackle industry-specific hurdles like heat or chemicals.

Compound Tailoring

How adapt? You mix for resistance. Nitrile fights chemicals. SBR saves costs.

Structure Variations

What’s next? You layer plies, cords for loads. Steel for mining.

Feature Additions

Why extras? You add cleats for grip. Sidewalls for inclines.

| Customization Area | Option | Application | |

|---|---|---|---|

| Compound | Resistant Blends | Harsh Environments | |

| Structure | Cords/Plys | Load Bearing | |

| Features | Cleats/Edges | Site Specific |

Analysis: Tailored designs lift efficiency 20% in niche ops. Key Takeaway: It matches belts to your precise needs.

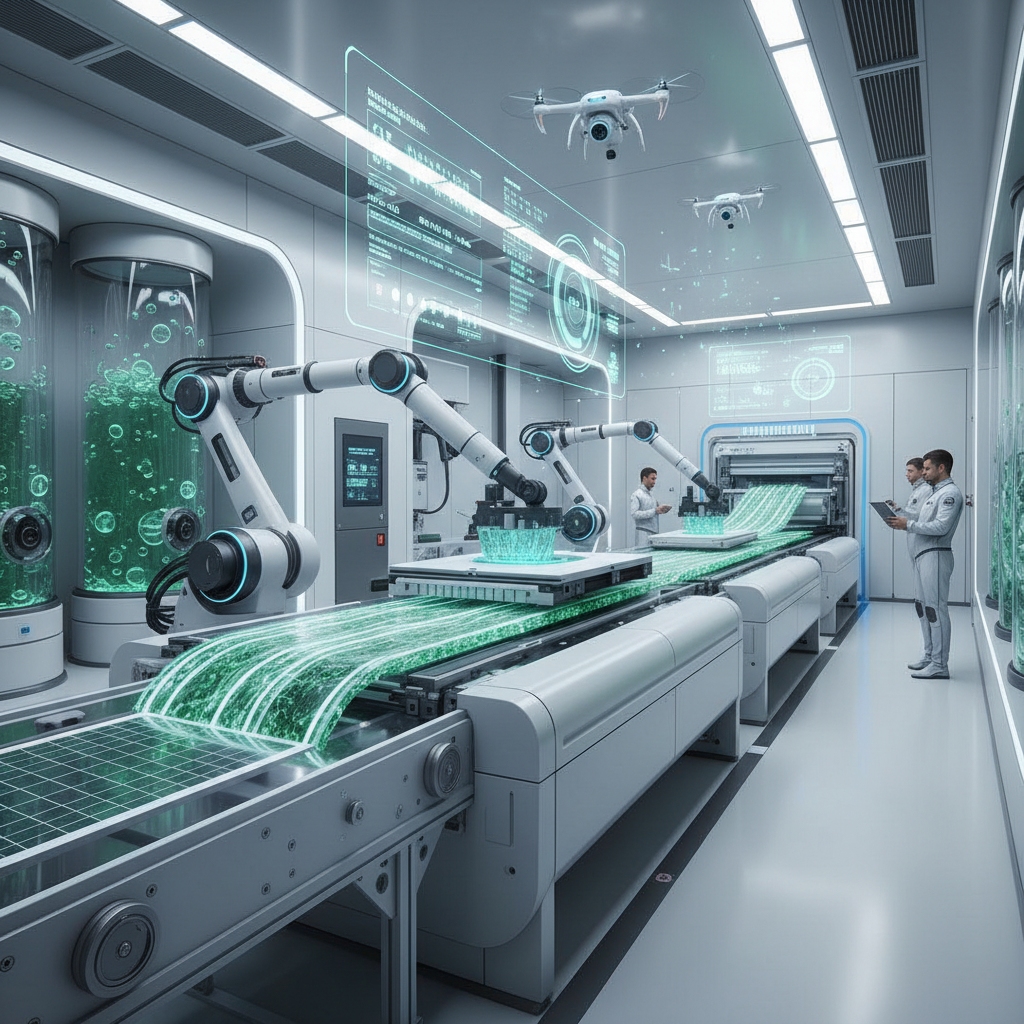

10. Future Trends in Rubber Conveyor Belt Manufacturing Process

Future trends in the rubber conveyor belt manufacturing process emphasize sustainability and smart tech for eco-smart production.

Eco Materials

What greens it? You reuse rubber, low-VOC additives. Cuts emissions sans quality hit.

Smart Tech

This is where it gets interesting: You add MES, AI for tracking. Predicts upkeep.

Innovation Drives

How evolve? You probe bio-rubbers, IoT. Meets regs.

| Trend | Benefit | Implementation | |

|---|---|---|---|

| Eco Materials | Waste Reduction | Reclaimed Use | |

| Smart Tech | Efficiency | MES Integration | |

| Innovation | Adaptability | IoT Sensors |

Analysis: These shifts lower costs 15% while greening supply chains. Key Takeaway: Trends future-proof your operations sustainably.

Conclusion: Call to Action

Unlock downtime-free ops by diving into the rubber conveyor belt manufacturing process—from raw blends to smart cures. These insights arm you with durable picks for peak productivity. Partner with us for bespoke belts that propel your business forward. Ready to upgrade? Reach out today for a consult.

FAQs

Q1: Why choose in-house mixing? It tailors compounds to needs, ensuring top performance without delays.

Q2: How does calendering affect belt life? Uniform layers cut wear spots, stretching durability in stresses.

Q3: What if I need custom features? We tweak plies and edges in lamination for perfect site matches.

Q4: Is quality testing thorough? Yes, from materials to finals, it guarantees full compliance.

Q5: Can trends make belts greener? Yes, reclaimed inputs and monitoring slash impact while holding strength.