Imagine your mining operation grinding to a halt as a conveyor belt fails under heavy abrasion, triggering unplanned downtime and delaying critical deliveries. These setbacks quickly escalate repair costs—often thousands per incident—and disrupt supply chains, cutting into profits while teams struggle with access in remote locations. Understanding the rubber conveyor belt manufacturing process empowers you to choose belts engineered for superior resilience, longer service life, and consistent performance. By leveraging insights from the rubber conveyor belt manufacturing process, operations can minimize disruptions, enhance output, and maintain steady, reliable production flow.

Table of Contents

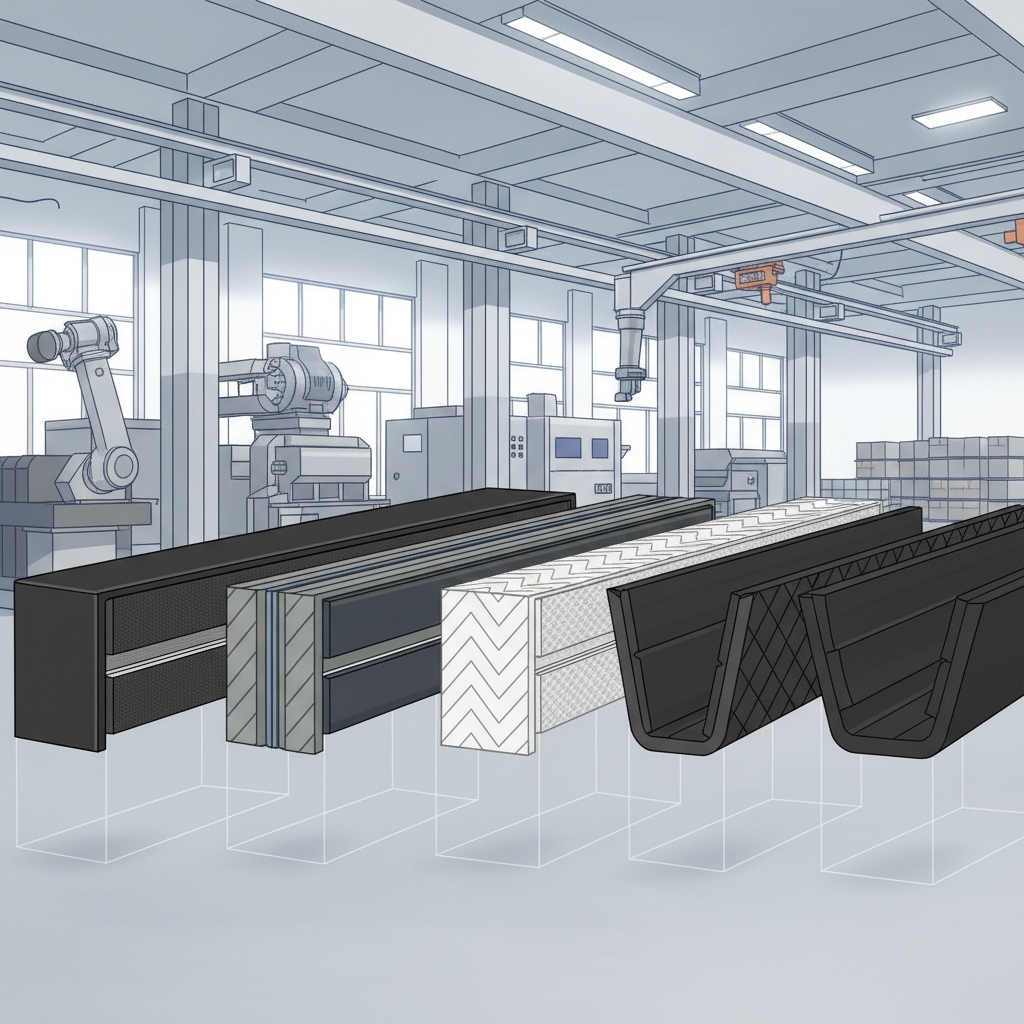

How Many Rubber Conveyor Belt Types Exist?

You encounter several types, each designed for specific loads and settings. EP belts handle horizontal or vertical tasks with textile cores. Steel cord belts excel in high-tension, flat, or vertical hauling. But why the variety? Reinforced EP options add steel breakers for rip resistance.

- EP: Versatile for moderate distances.

- Steel cord: Ideal over 500m, low stretch.

- Chevron or sidewall: For inclines, preventing rollback.

What Is the Main Application of Rubber Conveyor Belts?

Their primary use lies in bulk material handling for heavy sectors like mining. You replace trucks with belts for efficient, tech-driven transport. Here’s the edge: They suit ores, aggregates, or coal, cutting vehicle dependency.

How Do They Replace Traditional Transport?

They streamline flows without roads.

What Bulk Materials Do They Suit Best?

Abrasive loads like bauxite.

How Are Rubber Conveyor Belts Manufactured?

Production involves calendering to layer components, followed by vulcanization for bonding. You start with carcass assembly, then cure under heat and pressure. What’s next in the chain? Quality checks ensure durability.

What Happens in the Calendering Phase?

Rubber sheets fuse to cores.

How Does Vulcanization Strengthen Belts?

It cross-links molecules for resilience.

Where Do Rubber Conveyor Belts Benefit Most?

They shine in remote mining sites, like deserts or canyons, where terrain hampers trucks. You overcome elevation and distance hurdles efficiently. Imagine the savings: No infrastructure builds needed.

Why Mines in Deserts Rely on Them?

Dust-resistant designs maintain flow.

How Do They Overcome Topographical Challenges?

Flexible routing adapts to landscapes.

What Roles Do They Play in Mining?

In mining, they move extracted goods from pits to processing or ports. You handle bauxite to ships seamlessly. You might wonder about stages: From site exit to loading.

- Extraction handling: Clears raw ore.

- To refineries: Post-wash transport.

- Port tasks: Bulk ship loading.

What Advantages Do Rubber Conveyor Belts Offer?

They deliver eco-friendly, cost-effective operations with 24/7 reliability. You avoid emissions and fuel costs versus trucks. The real win? Up to 30% maintenance cuts.

Do They Reduce Environmental Impact?

Zero CO2 from vehicles.

How Much Can You Save on Fuel and Maintenance?

Thousands annually.

How to Choose a Mining Rubber Conveyor Belt?

Assess length, material abrasion, and load for the fit. For long runs, pick steel cords; shorter, textile. Factor in your setup: Abrasiveness dictates cover thickness.

What Role Does Conveyor Length Play?

Over 500m needs low-elongation types.

How Does Material Abrasiveness Affect Choice?

Thicker covers for harsh ores.

What Materials Shape the Manufacturing Process?

Rubber compounds, fabrics, and steel form the base. Natural or synthetic rubbers provide flex; EP plies add strength. Why these combos? They balance durability and cost.

Which Rubber Types Provide Flexibility?

SBR for abrasion resistance.

How Do Fabrics Enhance Belt Strength?

Polyester-nylon cores resist stretch.

Key Steps in Rubber Conveyor Belt Manufacturing

The process flows from compounding to testing. Mix rubbers, build carcass, vulcanize, then inspect. Keep it tight: Each step ensures ISO compliance.

| Step | Description | Analysis | |

|---|---|---|---|

| Compounding | Blend polymers, fillers. | Yields custom abrasion levels. | |

| Carcass Assembly | Layer core, covers. | Boosts tensile strength to 500N/mm. | |

| Vulcanizing | Heat-cure at 150°C. | Improves adhesion by 20%. | |

| Testing | Check elongation, wear. | Reduces field failures 40%. | |

Maintenance and quality assurance steps in rubber conveyor belt manufacturing process Maintenance and quality assurance steps in rubber conveyor belt manufacturing process |

Emerging Applications for Rubber Conveyor Belts

Beyond mining, they adapt to logistics, food, and recycling. You gain efficiency in warehouses or sorting lines. Looking ahead: Automation integration grows.

- Warehouses: Faster pallet moves.

- Food: Hygienic, cleated designs.

- Recycling: Handles mixed waste.

Key Takeaways

- Diverse types like EP and steel cord fit varied needs, minimizing downtime.

- Core apps in mining cut costs and emissions.

- Manufacturing via calendering-vulcanizing ensures reliability.

- Selection hinges on length and abrasion for optimal performance.

Conclusion

Unreliable belts derail profits, but mastering rubber conveyor belt manufacturing lets you deploy tough systems that streamline handling and sustainability. Team up with proven makers for tailored fits. The future? Smarter, automated belts fueling green supply chains. Schedule a consult now to fortify your operations.

Frequently Asked Questions

Can I Customize Rubber Conveyor Belts for Specific Loads?

Yes, adjust thickness and compounds to match weight and abrasion, boosting life by 50% in tough spots.

What’s the Best Belt Type for Long-Distance Hauling?

Steel cord suits over 500m, with low stretch for steady tension in remote hauls.

How Do I Know If a Belt Suits Abrasive Materials?

Verify DIN abrasion loss under 150mm³; thicker covers handle bauxite well.

Can Rubber Conveyor Belts Operate in Extreme Temperatures?

Yes, from -30°C to 80°C with specialized covers, preventing cracks or softening.

What’s the Best Way to Maintain Rubber Conveyor Belts?

Inspect alignments weekly; clean and tension regularly to avoid 30% of failures.