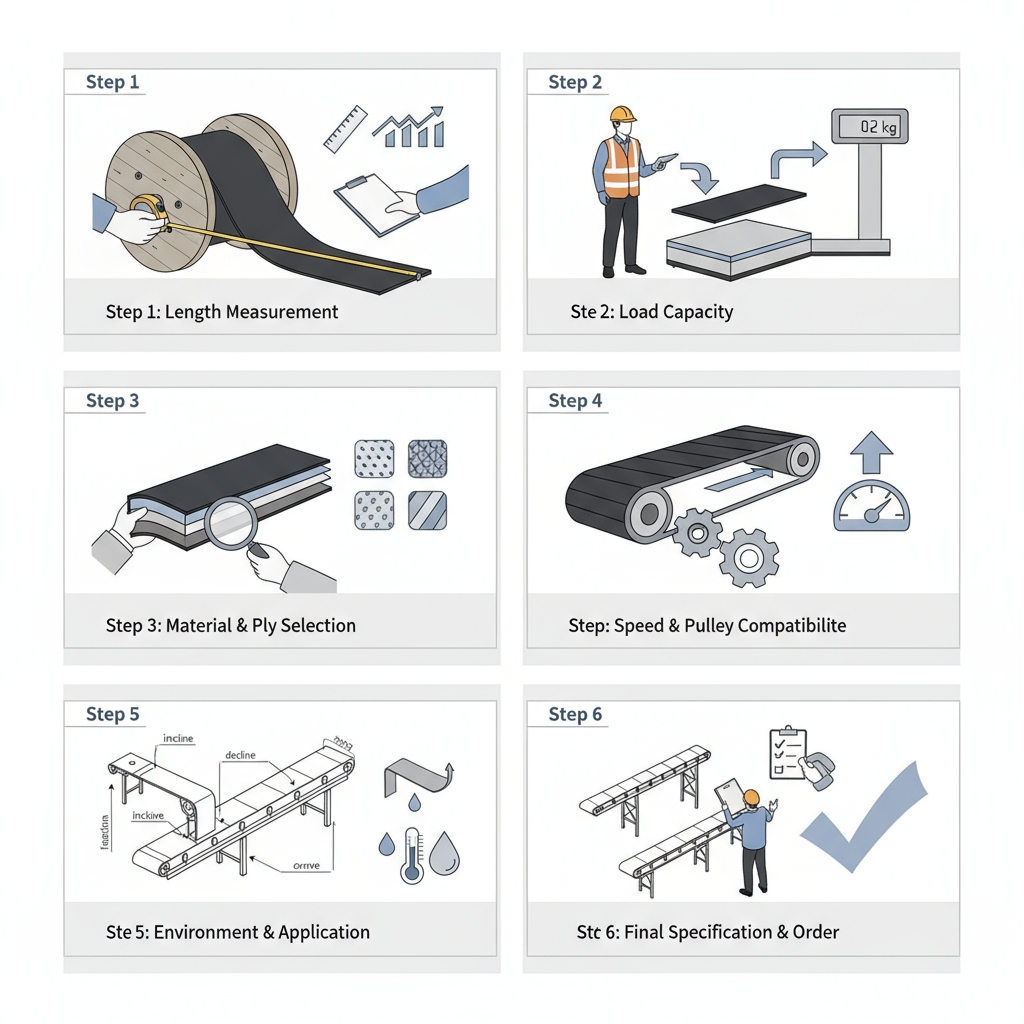

Choosing the right rubber conveyor belt for sale can feel overwhelming, with countless options that make it easy to select the wrong one. When a belt doesn’t match your application, failures, downtime, and expensive repairs follow—directly hurting productivity. With expert guidance, you can confidently identify durable, customized rubber conveyor belts for sale that fit your operation perfectly. Our experience ensures you get a belt engineered to your needs, improving efficiency while eliminating unnecessary headaches.

1. Why Choose Rubber Conveyor Belt for Sale?

What Makes Rubber Ideal for Transport?

Rubber excels in flexibility and grip for smooth material flow.

- Handles inclines up to 20° without slippage.

- Resists wear in dusty environments. But here’s the kicker—you gain reliability for daily hauls.

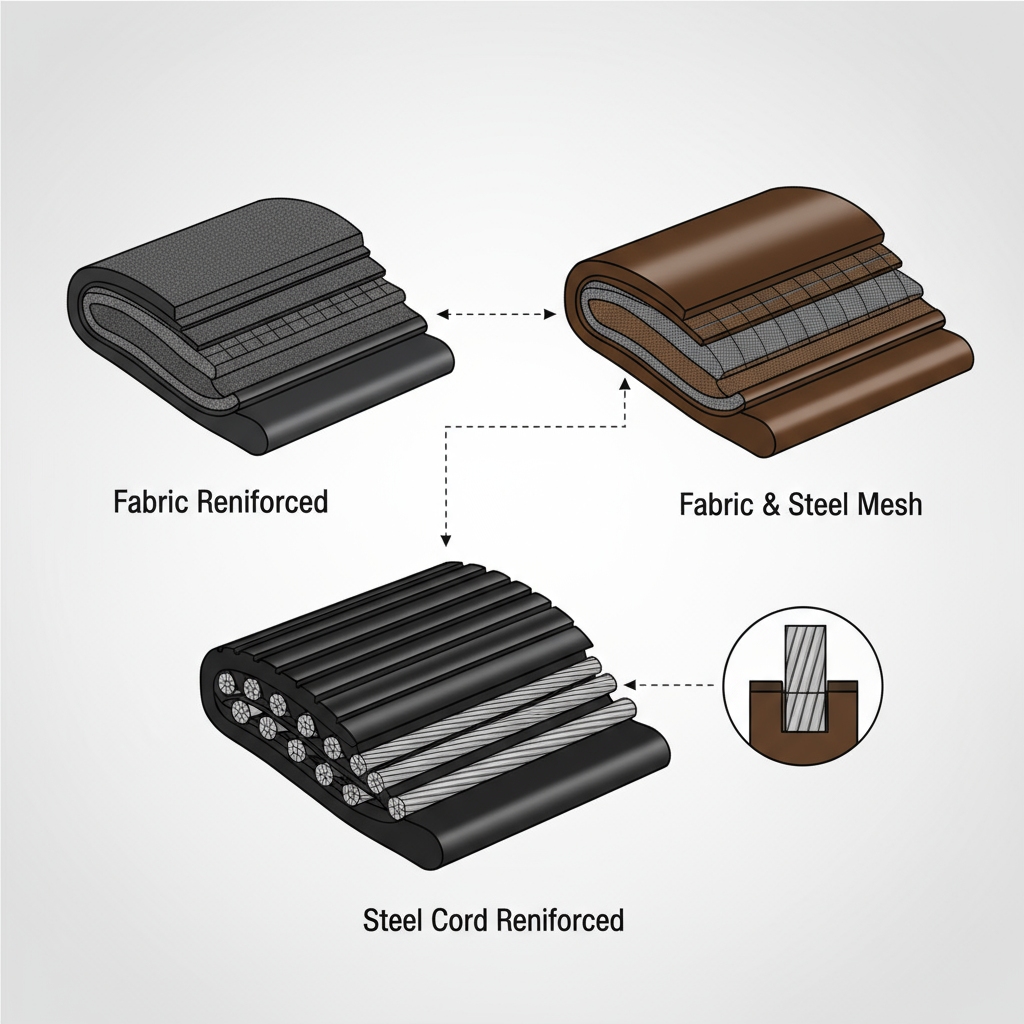

How Does Reinforcement Affect Choices?

Fabric or steel cords provide strength based on length.

- Fabric suits short runs under 100m.

- Steel handles long-distance tension. You avoid elongation issues this way.

Key Takeaway on Basics

Rubber conveyor belt for sale basics ensure longevity.

| Feature | Benefit | Example Use | |

|---|---|---|---|

| Fabric | Lightweight | Warehouses | |

| Steel | High tensile | Mines |

Analysis: Opting for reinforced types minimizes failures, saving you 30% on replacements.

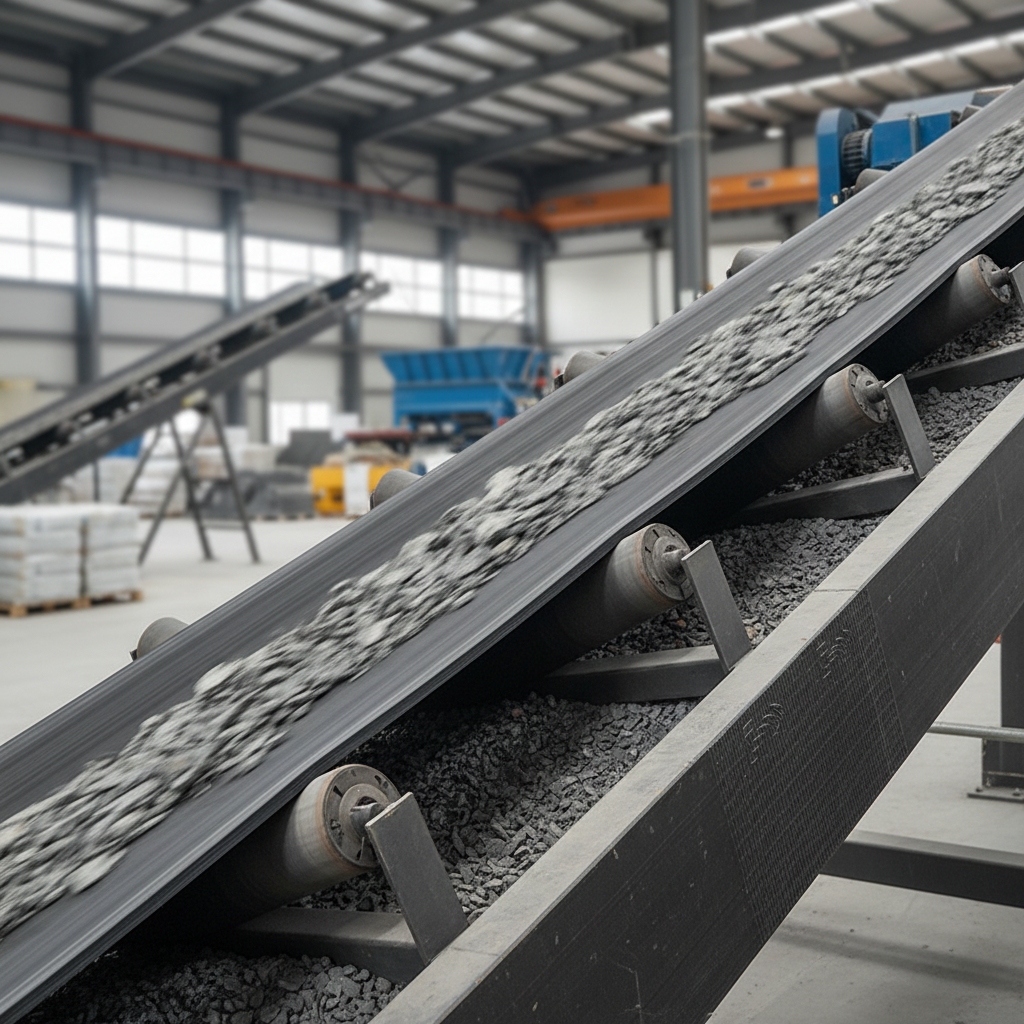

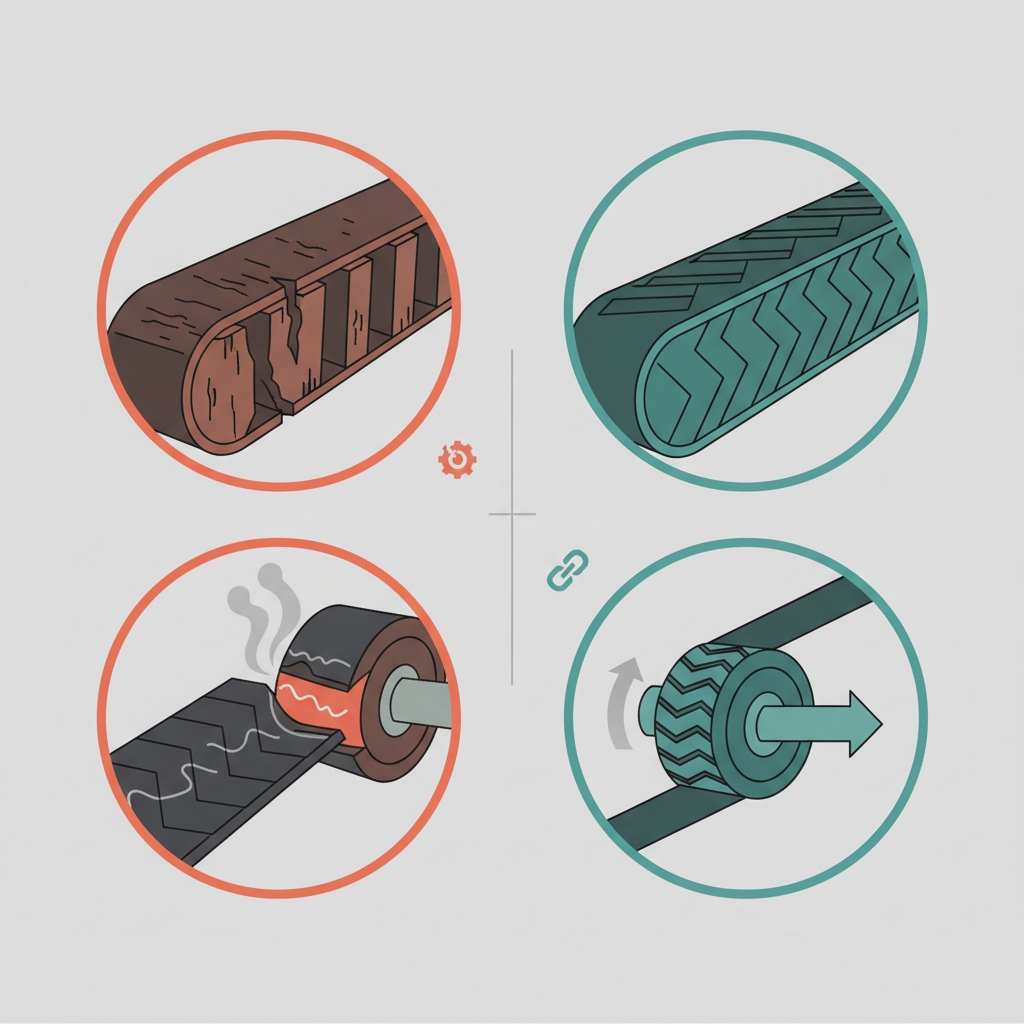

2. What Types Fit Steep Angles in Rubber Conveyor Belt for Sale?

Smooth vs. Profiled Options?

Smooth belts work for flat paths; profiled add grip for slopes.

- Chevron patterns prevent rollback at 35°.

- Sidewalls secure loads up to 87°. You might wonder—which suits your incline?

When to Use Elevator Styles?

Bucket-attached belts lift vertically without spills.

- Ideal for 45°+ rises.

- Custom cleats match cargo size. You streamline vertical moves easily.

Key Takeaway on Angles

Profiled rubber conveyor belt for sale conquers tough terrains.

| Type | Max Angle | Load Type | |

|---|---|---|---|

| Smooth | 20° | Flat goods | |

| Chevron | 45° | Bulk |

Analysis: Selecting angle-specific belts reduces slippage risks by half.

3. How to Pick Reinforcement for Rubber Conveyor Belt for Sale?

Fabric Layers Explained?

Multi-ply fabrics support medium loads affordably.

- Elongates less than 2% over time.

- Suits widths 500-2000mm. Ready to dive deeper? Consider your span.

Steel Cord Advantages?

Steel prevents stretch in long belts over 500m.

- Boosts tensile strength to 3000N/mm.

- Pairs with breakers for cover protection. You handle heavy hauls confidently.

Key Takeaway on Strength

Reinforced rubber conveyor belt for sale ensures durability.

| Material | Length Fit | Strength | |

|---|---|---|---|

| Fabric | Short | Medium | |

| Steel | Long | High |

Analysis: Steel cords extend belt life in demanding setups.

4. Which Qualities Suit Challenges in Rubber Conveyor Belt for Sale?

Normal Quality Basics?

NQ handles -35°C to +80°C without chemicals.

- Versatile for general transport.

- Short peaks to +100°C tolerated. Here’s the deal—start simple for most jobs.

Oil-Resistant Variants?

Oil compounds protect against fats and minerals.

- Covers and carcass resist penetration.

- Ideal for greasy workshops. You cut contamination worries.

Key Takeaway on Qualities

Tailored rubber conveyor belt for sale matches hazards.

| Quality | Resistance | Temp Range | |

|---|---|---|---|

| NQ | General | -35 to 80°C | |

| Oil | Fats | Similar |

Analysis: Right quality slashes wear by 40%.

5. What Heat Options Exist for Rubber Conveyor Belt for Sale?

High-Temp Material Needs?

Heat belts endure ageing from hot loads.

- Prevents cracks in clinker handling.

- Suits cement and steel plants. What’s the catch? Standard rubber fails fast here.

Durability Features?

Layers maintain flexibility under heat.

- Custom thickness for exposure.

- Reduces delamination risks. You operate safely longer.

Key Takeaway on Heat

Heat-resistant rubber conveyor belt for sale protects investments.

| Feature | Temp Limit | Application | |

|---|---|---|---|

| Standard | 80°C | Mild | |

| Heat | 200°C+ | Slag |

Analysis: These belts lower downtime in thermal ops.

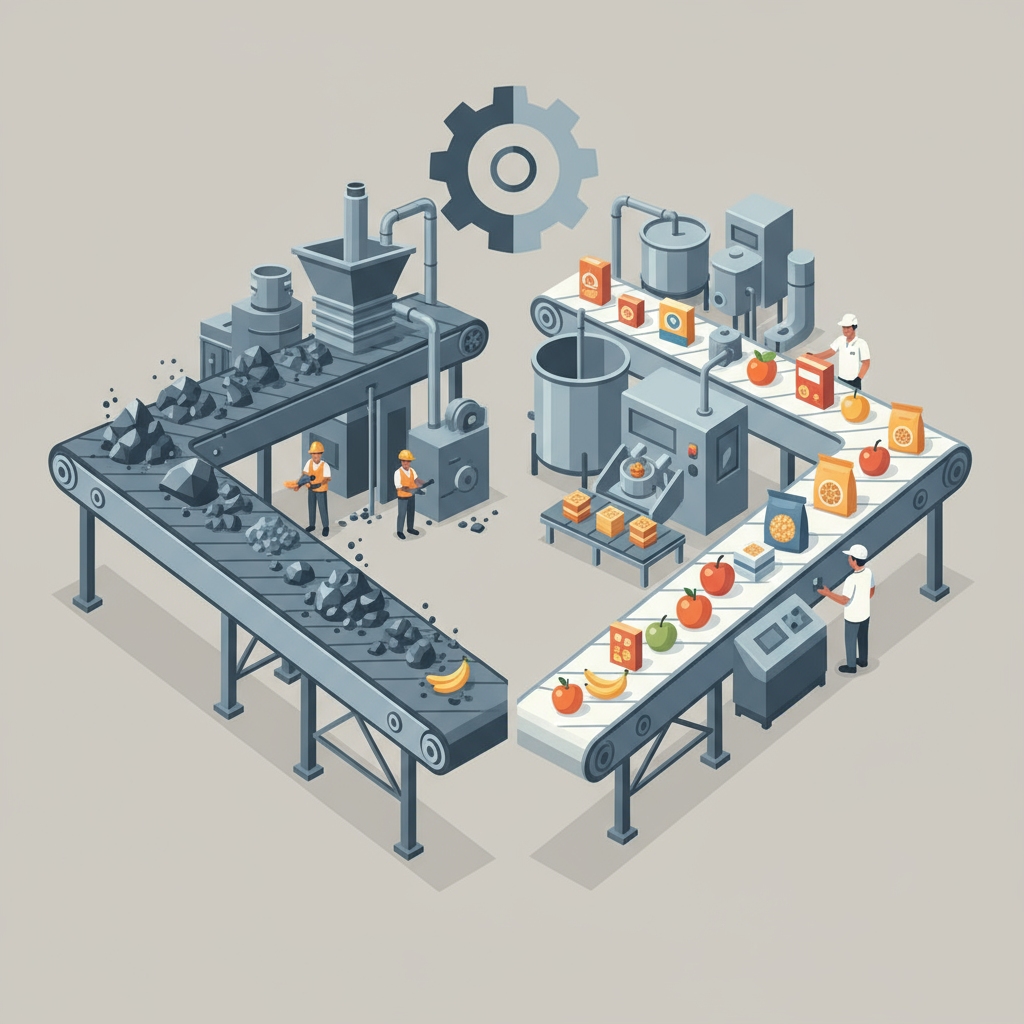

6. How Do Food-Grade Belts Work in Rubber Conveyor Belt for Sale?

Approval Standards?

White belts meet FDA for safe processing.

- Handles grains, nuts without taint.

- From harvest to packaging. This gets interesting—hygiene first.

Flame-Resistant Add-Ons?

Special K combines food safety with fire resistance.

- For sugar or flour transport.

- ATEX compliant zones. You meet regs effortlessly.

Key Takeaway on Food

Compliant rubber conveyor belt for sale ensures purity.

| Type | Cert | Use | |

|---|---|---|---|

| White | FDA | Processing | |

| Special K | ATEX | Flammable |

Analysis: They boost compliance and speed.

7. Why Abrasion-Resistant for Rubber Conveyor Belt for Sale?

Handling Sharp Loads?

W-quality rubber withstands gravel impacts.

- For quarries and ports.

- Resists acceleration wear. But wait—ordinary belts shred quickly.

Grip for Inclines?

Structured tops secure parcels at 20-35°.

- Prevents sliding in logistics.

- Molded patterns available. You transport uphill smoothly.

Key Takeaway on Abrasion

Tough rubber conveyor belt for sale endures abuse.

| Resistance | Material | Industry | |

|---|---|---|---|

| High | W | Mining | |

| Grip | Structured | Logistics |

Analysis: Cuts replacement frequency significantly.

8. What Custom Features Boost Rubber Conveyor Belt for Sale?

Tailored Confectioning?

Workshops adapt belts to exact specs.

- Endless or open lengths.

- Edges molded for fit. The real secret? Personalization pays off.

Special Combos?

Oil-flame hybrids suit chemicals.

- For fertilizers safely.

- ISO-tested resistance. You solve unique pains.

Key Takeaway on Custom

Bespoke rubber conveyor belt for sale fits perfectly.

| Feature | Benefit | Example | |

|---|---|---|---|

| Endless | Seamless | Loops | |

| Hybrid | Multi-resist | Chem |

Analysis: Customs reduce install time by 25%.

9. How Maintain Rubber Conveyor Belt for Sale Long-Term?

Daily Checks?

Inspect alignment to spot issues early.

- Clean debris promptly.

- Monitor tension weekly. You might wonder—prevention saves big.

Repair Tips?

Splicing extends life without full swaps.

- Use vulcanized joins.

- Track wear patterns. You keep ops running.

Key Takeaway on Maintenance

Proper care maximizes rubber conveyor belt for sale value.

| Task | Frequency | Tool | |

|---|---|---|---|

| Inspect | Daily | Visual | |

| Splice | As needed | Kit |

Analysis: Routine upkeep doubles lifespan.

10. Which Industries Need Rubber Conveyor Belt for Sale?

Aggregates and Mining?

Durable types handle rocks and ore.

- Abrasion-proof for quarries.

- High-capacity for dumps.

Food and Logistics?

Hygienic or grippy belts speed flows.

- FDA for processing.

- Inclined for warehouses. Here’s why it matters—versatility wins.

Key Takeaway on Industries

Versatile rubber conveyor belt for sale serves all.

| Industry | Belt Type | Challenge | |

|---|---|---|---|

| Mining | Abrasion | Wear | |

| Food | White | Hygiene |

Analysis: Industry-specific picks optimize performance across sectors.

Conclusion

Unique applications demand tailored rubber conveyor belt for sale to avoid pitfalls. Downtime from poor fits drains resources. Contact experts for quotes on custom solutions. Reliable belts transform your operations into efficient powerhouses—reach out today for seamless transport.

FAQs

Q1: What factors influence rubber conveyor belt for sale pricing? Prices vary by material, length, and reinforcements—expect $10-50 per meter based on quality.

Q2: How long does a rubber conveyor belt for sale last? With proper maintenance, 2-5 years in moderate use; heat or abrasion shortens to 1-2 years.

Q3: Can I get custom rubber conveyor belt for sale? Yes, tailor widths, profiles, and resistances to your setup for optimal fit.

Q4: What maintenance tips for rubber conveyor belt for sale? Check tension daily, clean regularly, and splice promptly to extend life.